Академический Документы

Профессиональный Документы

Культура Документы

23

Загружено:

dipali22290 оценок0% нашли этот документ полезным (0 голосов)

11 просмотров16 страницResults are given for a range of water / fuel ratios and for three methods of water injection for a direct injection diesel engine. NO is reduced by up to 70% by using water injection in the air inlet or with the fuel. A previously developed computer model of the diesel combustion process is used to predict the effect of water injection on NO, smoke and fuel economy.

Исходное описание:

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документResults are given for a range of water / fuel ratios and for three methods of water injection for a direct injection diesel engine. NO is reduced by up to 70% by using water injection in the air inlet or with the fuel. A previously developed computer model of the diesel combustion process is used to predict the effect of water injection on NO, smoke and fuel economy.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

11 просмотров16 страниц23

Загружено:

dipali2229Results are given for a range of water / fuel ratios and for three methods of water injection for a direct injection diesel engine. NO is reduced by up to 70% by using water injection in the air inlet or with the fuel. A previously developed computer model of the diesel combustion process is used to predict the effect of water injection on NO, smoke and fuel economy.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 16

EFFECTS OF WATER I NTRODUCTI ON ON DI ESEL ENGI NE

COMBUSTI ON AND EMI SSI ONS

G. GREEVES, I. M. KHAN, AND G. ONION

Research Department, CA V Limited, Acton, London, England

Experimental results are presented for the effect of water injection on fuel economy and

ignition delay and on exhaust emissions of smoke, CO, NO and HC for a direct injection

diesel engine. Results are given for a range of water/fuel ratios and for three methods

of water injection. Compared with fuel injection only, NO is reduced by up to 70% by

using water injection in the air inlet or with the fuel. But while the former method increases

smoke and CO, the latter method reduces CO and smoke by up to 50% together with small

improvements in specific fuel consumption. However due to an increase of HC beyond

a water/fuel ratio of 0.6 the NO reduction would be limited to 50% when injecting water

with the fuel, though this situation could be improved by increasing the engine compression

ratio. The results obtained by the authors are compared with those available in the literature.

Experimental data are presented on droplet size distributions for water, fuel and all spray

droplets and there is a change in the state of the water/fuel spray for water/fuel ratios

greater than 0.2..Also a previously developed computer model of the diesel combustion

process is used to predict the effect of water injection on NO, smoke and fuel economy.

The calculations over-estinaate some of the trends but show that, in addition to the thermal

effect of water injection, water injection affects the rates of air entrainment and fuel/air

mixing. In particular, water injected with the fuel is an additional source of injected momentum

for fuel/air mixing.

1. I n t r o d u c t i o n

The i nt roduct i on of water i nt o heteroge-

neous l i qui d hydr ocar bon/ ai r combust i on

systems offers a number of possi bl e benefits.

These i ncl ude reduced system temperatures,

i mproved at omi sat i on and a reduct i on i n the

emissions of soot and ni t rogen oxides. In oil

fired furnaces the i nt r oduct i on of wat er / f uel

emul si on can be very effective i n reduci ng

smoke emi ssi ons wi t h resi dual fuels I t hough

not necessarily with lighter fuel oils 2 where

atomisation is a less domi nant factor. The

reduced smoke emi ssi ons have been at t ri but ed

to the oecurence of ' mi cro-expl osi ons' caused

by the di srupt i ve effect of water vapori si ng

wi t hi n the fuel droplets dur i ng the droplet

heat i ng period. The mi cro-expl osi on phenom-

enon has been observed under laboratory

condi t i ons and a review of the literature to-

gether wi t h details of some recent work are

given i n reference 3.

I n the aut omot i ve appl i cat i on of the di esel

engi ne there is renewed interest i n water injec-

t i on wi t h the prospect of more severe emissions

l egi sl at i on together wi t h the need to conserve

or i mprove fuel economy. Previous experi-

ment al studies on the effect of water i nj ect i on

i n diesel engi nes have been reported i n refer-

ences 4-10 and t he results show that NO

reduct i ons of at least 50% can be achieved.

However there is little comprehensi ve in-

format i on on the relative advantages of the

vari ous methods by whi ch water can be inject-

ed i nt o the diesel combust i on system.

Work has been carried out at the authors'

laboratory to det ermi ne t he effect of water

i nj ect i on i n aut omot i ve type diesel engines.

The experimental work was ai med at provi di ng

comprehensi ve data on the effects of water

i nj ect i on on engi ne performance, i gni t i on

delay and on emi ssi ons of smoke, NO, CO

and unbur nt hydrocarbons. I n particular

various methods of i nt r oduci ng the water were

explored. I n addi t i on to engi ne performance

and emi ssi ons experiments, the state of the

321

322 POWER SYSTEMS

wa t e r / f u e l s pr a y us e d i n t he e ngi ne exper i -

ment s was d e t e r mi n e d e xpe r i me nt a l l y. Al s o a

pr e vi ous l y d e v e l o p e d mode l of t he di e s e l com-

bus t i on pr oces s has be e n us ed t o i nt e r pr e t t he

e ngi ne p e r f o r ma n c e a nd emi s s i ons r es ul t s .

2. De t a i l s of the En g i n e Ex p e r i me n t s

The e ngi ne us e d for t he i nve s t i ga t i on is a

na t ur a l l y a s p i r a t e d a ut omot i ve t ype f our -

c yl i nde r f our - s t r oke di r ect i nj ect i on engi ne.

Cy l i n d e r s we pt v o l u me is 0. 97 l i t r es pe r cyl -

i nder , c o mp r e s s i o n r at i o 16:1, a nd an i nj e c t i on

nozzl e wi t h a c onf i gur a t i on of 4 x 0. 28 (4

hol es of 0. 28 mm di amet er ) a nd wi t h a noz z l e

o p e n i n g pr e s s ur e of 175 at m is n o r ma l l y us ed.

The wat er i nj e c t i on t est s wer e c o n f i n e d t o a

s i ngl e c y l i n d e r of t he f our c yl i nde r e n g i n e t o

al l ow t he t est c y l i n d e r t o be mot or e d a n d t o

gi ve gr eat est f l e xi bi l i t y i n t he use of t he i nj ec-

t i on e q u i p me n t f or t he var i ous t e c hni que s of

wat er i nj ect i on. Two of t he r e ma i n i n g c yl i n-

der s wer e s u p p l i e d b y a s epar at e f u e l i n g sys-

t em at f i xed f u e l i n g a nd t i mi ng a nd t he c yl i n-

der adj acent t o t he t est c yl i nde r was mot or e d.

The i n d i c a t e d p o we r out put a nd cor r e-

s p o n d i n g s pe c i f i c f uel c o n s u mp t i o n of t he t est

c yl i nde r wer e c a l c ul a t e d di r e c t l y f r om t he

di f f e r e nc e of t he e ngi ne out put t or ques mea-

s ur e d for f i r i ng a nd mot or i ng c ondi t i ons of

t he t est c yl i nde r .

Recor ds wer e t a ke n of t he c y l i n d e r pr e s s ur e

a nd of t he l i f t of t he nozzl e needl e val ve. Th e

t i mi ng of i nj e c t i on is d e f i n e d as t he c r a nk a ngl e

at whi c h t he n e e d l e st ar t s t o l i f t a nd t he i g n i t i o n

de l a y was me a s u r e d f r om t he st art of t he n e e d l e

l i f t t o t he st ar t of c o mb u s t i o n pr e s s ur e r i se.

Conc e nt r a t i ons of CO a nd NO i n t he e ngi ne

exhaus t wer e me a s u r e d wi t h n o n - d i s p e r s i v e

i nf r a- r ed gas a na l ys e r s a nd HC c onc e nt r a t i on

was me a s ur e d wi t h a he a t e d f l ame i oni s a t i on

det ect or a nd h e a t e d s a mpl e l i ne. The e mi s s i o n

anal ys i s e q u i p me n t a nd pr oc e dur e s f ol l ow

t hos e r e c o mme n d e d i n SAE J177 a n d J215

a nd i n t he case of t he NDI R anal ys er s t he

s a mpl e is d r i e d i n a t hr ee st age pr oc e s s so

t hat a ny r e ma i n i n g H 2 0 has ne gl i gi bl e ef f ect

(I)

(2)

i n j e c t o r /

Inlet

manifold

Fuel ~

/ i n j m o r I I

rnjection

Inlet val ve

\

Exhaust valve

pumps

Cc_ of bore

_ ~ Fuel nozzle

~ . ~ \ \ \ ~ /T- piece w i t h

(3bl ~ ~-~0,-woy vo,ws

Injection p u m p s

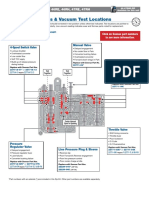

FIG. 1. Water injection system; (1) air inlet mani fol d water injection system, (2) two pump two i nj ect or.

system, (3b) two pump one injector system.

EFFECTS OF WATER INTRODUCTION 323

on t he me a s ur e me nt s . Th e me a s ur e me nt s of

exhaus t s moke wer e c o n v e r t e d t o mas s con-

cent r at i ons b y us i ng a p r e v i o u s l y e s t a bl i s he d

cor r el at i on 15 whi c h is a p p l i c a b l e t o a ut omot i ve

di es el engi nes f ue l e d wi t h gas oi l . Th e va l i di t y

of t he s moke n u mb e r / ma s s cor r el at i on for

wat er i nj ect i on e xpe r i me nt s is pe r ha ps s ubj ect

t o s ome doubt s i nce i t was de r i ve d f r om f uel

onl y engi ne dat a. Howe ve r , as di s c us s e d l at er ,

t her e ar e good r eas ons t o be l i e ve t hat soot

f or ma t i on is a gas pha s e pr oces s i n t he au-

t omot i ve di es el e ngi ne so t hat a ddi t i ona l H 2 0

va pour s houl d not d r a ma t i c a l l y af f ect t he ba s i c

soot par t i cl e si ze ( di a me t e r --- 250A) nor t he

pr oces s of a g g l o me r a t i o n i nt o l ar ger par t i cl es

( di amet er = 1- 2t xm) J 6 Co n s e q u e n t l y t he

s moke n u mb e r / ma s s c or r e l a t i on s houl d not

be s er i ous l y i n error.

Th e f uel us ed was an a ut omot i ve gas oi l

wi t h I. B. P. = 180~ 50% B. P. = 260~ F. B. P.

-- 360~ a nd eet ane n u mb e r = 56. Thr e e

t e c hni que s of wat er a d d i t i o n wer e i nve s t i ga t e d

a nd ar e i l l us t r at ed i n Fi g. 1.

1. Wat er i nj ect i on i nt o t he ai r i nl et ma ni f ol d.

The wat er i nj ect i on noz z l e ha d a s i ngl e hol e

of 0. 58 mm di a me t e r a n d was set t o a nozzl e

o p e n i n g pr e s s ur e of 175 at m. Wa t e r i nj ec-

t i on was p h a s e d t o oc c ur at t op de a d cent r e

of t he non- f i r i ng s t r oke a nd t est s wer e

car r i ed out for a r a nge of wa t e r / f u e l r at i os

up t o t he mi s f i r e l i mi t .

2. Wa t e r i nj ect i on d i r e c t l y i nt o t he c y l i n d e r

t hr ough a s epar at e i nj e c t i on p u mp a nd i n-

j ect i on nozzl e. The wa t e r i nj ect i on nozzl e

was set t o a nozzl e o p e n i n g pr e s s ur e of 165

at m a nd ha d 3 hol es of 0. 32 mm di a me t e r

or i e nt a t e d as s hown i n Fi g. 1. Wi t h t hi s

me t h o d t he p h a s i n g of t he t i mi n g of wat er

i nj ect i on wi t h r e s pe c t t o t he t i mi n g of f uel

i nj ect i on was va r i e d i n a d d i t i o n t o t he

va r i a t i on of wa t e r / f u e l r at i o.

3. Wat er i nj ect i on di r e c t l y i nt o t he c y l i n d e r

wi t h t he f uel a n d t h r o u g h t he f uel i nj ect i on

nozzl e. Set s of e xpe r i me nt s wer e p e r f o r me d

us i ng:

a) A me c h a n i c a l l y p r e p a r e d wa t e r / f u e l

di s pe r s i on f ed t o t he f uel i nj ect i on pump.

The wat er / f uel d i s p e r s i o n was p r o d u c e d

i n a s u p p l y t a nk b y us i ng an e l e c t r i c a l l y

dr i ve n gear p u mp t o p r o v i d e c ont i nuous

r eci r cul at i on of t he wa t e r / f u e l mi xt ur e

i mme d i a t e l y u p s t r e a m of t he i nj ect i on

pump.

b) A s epar at e i nj e c t i on p u mp t o i nt r oduc e

t he wat er i nt o t he h i g h pr e s s ur e f uel l i ne

b e t we e n t he f uel i nj e c t i on p u mp a nd t he

nozzl e.

I n or der t o s i mp l i f y t he pr e s e nt a t i on, onl y

r e pr e s e nt a t i ve r es ul t s ar e pr e s e nt e d here. A

f u e l i n g l evel of 60- 65 mm3 / s t r o k e a nd an

e ngi ne s pe e d of 2000 r e v / mi n wer e chos en

as a r ef er ence c ondi t i on. Th i s c ondi t i on corre-

s p o n d e d t o f ul l l oa d f u e l i n g at 70% of t he

r a t e d e ngi ne s peed. A f uel i nj ect i on t i mi ng

of 20 cr ank degr ees be f or e t op de a d cent r e

(~ woul d n o r ma l l y be us e d t o gi ve

be s t f uel e c o n o my but mor e r e t a r de d t i mi ngs

of i 5 ~ a nd 10 ~ B. T. D. C. wer e al so expl or ed

s i nc e t hes e are r e l e va nt i n t he cont ext of

r e d u c i n g NO emi s s i ons .

3. Co mp a r i s o n of t he Va r i ous Me t h o d s of

Wa t e r I n j e c t i o n

Fi gur e s 2 a nd 3 s how a c ompa r i s on of

r e pr e s e nt a t i ve r es ul t s o b t a i n e d for t he t hr ee

t e c hni que s of wat er i nj ect i on. The r es ul t s ar e

e xpr e s s e d as t he f act or i al change, t hat is t he

r es ul t s obs e r ve d wi t h wat er i nj ect i on d i v i d e d

b y t he r es ul t obs e r ve d wi t h no wat er i nj ect i on,

a n d ar e pl ot t e d as a f u n c t i o n of t he vol ume t r i c

wa t e r / f u e l r at i o (fuel d e n s i t y = 0. 83 g / c c ) .

Technique (1)

The r es ul t s for wat er i nj ect i on i n t he ai r

i nl et ma n i f o l d s how t hat NO decr eas es pr o-

gr e s s i ve l y wi t h i ncr eas e of wa t e r / f u e l r at i o.

At W/ F = 0. 5 t he NO r e d u c t i o n is 30% wh i c h

is i n good a gr e e me nt wi t h t he r esul t s of ot her s

s uch as 6 a nd 8. Smoke, CO a nd i gni t i on de l a y

i ncr eas e t oget her wi t h s mal l i ncr eas es i n spe-

c i f i c f uel c ons umpt i on.

Technique (2)

Th e dat a for wat er i nj e c t i on vi a a s epar at e

i nj ect or i nt o t he c y l i n d e r ar e for a t i mi n g of

20 ~ B. T. D. C. for i nj e c t i on of bot h wat er a n d

f uel , t hat is wi t h 0 ~ p h a s i n g b e t we e n wat er

a n d f uel . Thi s s ys t em gi ves ver y s i mi l ar r educ-

t i ons of NO t o t hos e o b t a i n e d wi t h wat er

i nj e c t i on i n t he i nl et ma n i f o l d but t her e is

a gr eat er i ncr eas e of s moke wi t h i ncr eas e of

wa t e r / f u e l r at i o. Ot he r r es ul t s , obt a i ne d f or

t he ef f ect of p h a s i n g wi t h t hi s syst em, s h o we d

t hat ear l y t i mi ngs of wa t e r i nj ect i on gave t he

l eas t i ncr eas e i n s moke a n d s i mi l ar r esul t s t o

t hos e s hown for i nj e c t i on of wat er i n t he i nl et

ma n i f o l d wer e t he n obt a i ne d.

Technique (3b)

Th e r es ul t s s hown f or wat er i nj ect i on wi t h

t he f uel wer e o b t a i n e d wi t h a s ys t em us i ng

s e pa r a t e i nj ect i on p u mp s c onne c t e d t o t he f uel

324 POWER SYSTEMS

I I I I

1 . 8

/ \ co . . . .

" / \ "-~

tA I \ . . / . . . . ~ "

1 . 0

O~ ~ o . _ _ . . o

U 3

t . 9

NO

U

Q6 ~ ~ 1 7 6 ~ - "~

3.0 ~I ~'

2..5 SMOKE - " "

p

2 D I " A _ . . ~ -- -- -- A-- # 1 1

~ o__.__o_ _

ID U"C --0 " ~ T "-- " 0--' -"0--' --0

0.5 ~ o ~ ~

I I I t

0 O . S 1.0 1.5

WATER/ FUEL . ( by vol ume)

FIG. 2. Compari son of three techniques of water injection, square = water injection in air inlet (system

1), triangle = water injection with separate injector (system 2), circle = water injection with the fuel

(system 3b). Fuel i ng = 60-65 mma/ st roke, fuel nozzle had 4 holes x 0.28 mm diameter, nozzle openi ng

pressure = 175 atm, fuel timing = 20-15~

i nj ect or b y a T- p i e c e a n d p h a s e d so t hat f uel

a nd wat er p u mp i n g c o mme n c e d at t he s a me

t i me. For a gi ve n W/ F r at i o, i nj ect i on of wa t e r

wi t h t he f uel gi ves a gr eat er r e duc t i on of NO

t han for t he ot he r t e c hni que s of wat er i nj e c t i on.

I n a d d i t i o n r e d u c t i o n s of s moke a nd CO a n d

i n s ome cases s ma l l r e duc t i ons of S F C ar e

obs er ved. I g n i t i o n de l a y i ncr eas es mor e r a pi d-

l y wi t h i ncr eas e of W/ F r at i o a nd b e y o n d W/ F

= 0. 6 t he u n b u r n t hydr oc a r bons i ncr eas e.

Me a s ur e me nt s of HC wer e not t aken f or t he

ot her s ys t ems b u t i t is expect ed t hat a s i mi l a r

r el at i on b e t we e n HC a n d i gni t i on d e l a y wi l l

a ppl y. Th e r es ul t s s how t hat i gni t i on d e l a y

i s l onger for wa t e r i nj e c t i on wi t h t he f uel t ha n

for i nj ect i on i n t he ai r i nl et even wh e n W/ F

r at i o is a dj us t e d f or c o mp a r a b l e NO r e duc -

t i ons.

4. Further Results for Injecti on of Water

wi th the Fuel

Su b s e q u e n t t o t est s wi t h t he s t a nda r d i nj ec-

t i on nozzl e of 4 x 0. 28 c onf i gur a t i on, t est s

wer e car r i ed out wi t h a 4 x 0. 33 noz z l e a n d

for nozzl e o p e n i n g pr es s ur es ( NOP) of 175

a nd 300 at m. Th e r es ul t s ar e s hown i n Fi gs .

4 a n d 5 whe r e t he r es ul t s for t he 4 x 0. 28

nozzl e a n d 175 a t m NOP c or r e s pond t o t he

r esul t s for wa t e r i nj ect i on wi t h f uel s h o wn

i n Fi gs. 2 a n d 3. Ref er ence t o t he c ur ve for

i nj ect i on p e r i o d i n Fi g. 5 shows t hat i nj e c t i on

p e r i o d i ncr eas es wi t h i nc r e a s i ng wa t e r / f u e l

r at i o. No r ma l l y , wi t h f uel onl y, an i nc r e a s e

of i nj ect i on p e r i o d wi l l i ncr eas e s moke a n d

CO c onc e nt r a t i ons , n Wi t h wat er i nj e c t i on,

s moke a nd CO r e duc t i ons ar e a c hi e ve d i n s pi t e

EFFECTS OF WATER INTRODUCTION 325

IA

u.I

~D

z

"v

U

.A 1.8

n"

o

I--

u 1.4

LG

I I + r

IGNITION /

DE L A Y / ~

~ 0 ~ r l ~

o

0 0

0

S F C / o ~ - - - o - - - - - o

. . 6 ,

, . 04 / o ~ / " . . . - -

,o L - - - \ . . . . . . . . . . .

~E] - - " " ~" o 1

~o~

0 . 9 6 I i I I

0 0.5 I.O 1.5

WATER/FUEL (by volume)

FIG. 3. Comparison of three techniques of water injection, square = water injection in air inlet (system

1), triangle = water injection wi t h separate injector (system 2), circle = water injection wi t h the fuel

(system 3b). Test conditions as in Fig. 2.

of s ubs t ant i al i ncr eas es i n i nj ect i on pe r i od

us i ng t he s t a nda r d noz z l e a n d NOP. Fi g u r e

4 shows t hat s moke a n d CO can be r e d u c e d

st i l l f ur t her b y i nc r e a s i ng nozzl e hol e si ze or

by i nc r e a s i ng NOP. Ho we v e r HC i ncr eas es

wi t h t he i ncr eas e of nozzl e hol e si ze a nd t her e

i s s ome i ncr eas e of NO wi t h t he use of t he

hi ghe r i nj ect i on r at e s ys t ems .

I n a d d i t i o n t o t he gener al pa t t e r ns for t he

ef f ect of W/ I V r at i o i n Fi gs . 4 a nd 5 t her e

is an a ppa r e nt i r r e gul a r i t y wh i c h wi l l be re-

f er r ed t o l at er for t he r es ul t s wi t h W/ I V =

0.1. NO is l ow, s moke, CO a nd SFC ar e h i g h

whi l e i gni t i on de l a y i s unaf f ect ed. Fu r t h e r

e xpe r i me nt s not r e por t e d he r e wer e c a r r i e d out

for s mal l i nc r e me nt s of W/ I V r at i o i n t he r a nge

0. 0- 0. 2, t he r es ul t s of wh i c h c onf i r m t hos e

gi ven i n Fi gs. 4 a nd 5.

Al l t he r esul t s i n Fi gs . 4 a nd 5 are f or t he

me t hod 3(b) r ef er r ed t o ear l i er , t hat is us i ng

a s epar at e i nj ect i on p u mp t o i nt r oduc e t he

wat er i nt o t he hi gh pr e s s ur e f uel l i ne. Ta bl e

I s hows a c o mp a r i s o n of t he r es ul t s o b t a i n e d

wi t h t he me t hods 3(a) a n d 3( b) whe n i nj ect i ng

wa t e r wi t h t he f uel f or W/ I V = 0.8. The s e

r es ul t s s how t hat s i mi l a r r es ul t s f or NO a nd

i gni t i on de l a y are o b t a i n e d wi t h t he t wo met h-

ods a nd for a r a nge of e n g i n e f ue l i ngs a nd

i nj ect i on t i mi ngs . The r e ar e s ome di f f e r e nc e s

i n CO, s moke a n d SIVC, wh i c h can be pa r t l y

a t t r i but e d t o di f f e r e nt i nj e c t i on pe r i ods a nd

h e n c e rat es of i nj ect i on a c hi e ve d wi t h t he t wo

s ys t ems . At t he l owe r f u e l i n g l evel s of 40, 30

a nd 20 mm3 / s t r o k e t he s moke l evel s ar e i nsi g-

ni f i c a nt ( and t he va l ue s have been omi t t ed)

b u t CO i ncr eas es d r a ma t i c a l l y t oget her wi t h

i nc r e a s e d i gni t i on de l a ys at t hi s W/ I v rat i o.

5. Spr ay Cha r a c t e r i s t i c s f or t he Wa t e r / F u e l

Mi xt ur e

The st at es of t he wa t e r / f u e l mi xt ur e i n t he

h i g h pr e s s ur e f eed p i p e t o t he i nj ect or a nd

al s o i n t he wa t e r / f u e l s pr a y wer e e xa mi ne d

f or t he wat er i nj ect i on t e c h n i q u e 3(a) used i n

t he e ngi ne e xpe r i me nt s . I n t he t e c h n i q u e 3(a)

( and 3(b)) no e mu l s i f y i n g agent s wer e us ed

326 POWER SYSTEMS

1.2

1.0

. 8

s s .6

0 .4

s

. 2

0

. 6

.4

,z

0

.3

to

.2

.I

0

1400

12OO

0 800

7-

6O0

4(20

20o

0

I I I i I

NOZZLE OPENING

PRESSURE

9 {ATM}

/ ~ ' I K o 4 x .28 175

/ ! ~X ., 4 x .28 300

/ ~ g . o__ Z~4x. 33 175

I / ' ~X \ , , 4 x 33 3 0 0

~ c o

., - - - ~ , . ~ ~ ; : : . ~ . ? . _ _ . _ . . o _

,I " ~ ' 2 . 9 ~ ' ~

A

q

~ \ ~ , ~ . < Z . . N O

. . . .

.80..---0 ~ o "~'~ "\~

i i i i

.2 .4 .6 .8 1.0

WATER/FUEL, (by volume)

FIG. 4. Ef f ect of wat er i nj ect i on wi t h t he f uel

(system 3b). Engi ne speed = 2000 r ev/ mi n, fue]ing

= 60 mma/ st roke, injection timing = 15 ~ B.T.D.C.

r I t I I

!

/

25 NOZZLE OPENING I t

PRESSURE / #

(ATM) / i /

"~u o 4 x . 2 8 , 7 s / / /

o 20 9 4 x. 28 3 0 0 IV' ~

zx 4x . 33 175 .,~/1/

9 4x33 300 Z&/

~, . , , & " y

O Z 15 I G N I T I O N / ' ~ ' ~ ' -~

r- u /

_ DEL,,~ / ~" t

,OOOr A / / " / t

804 , / / , " / 4

404

2 o o L I~_" = - - - - - 0 - - o

| !

I

"~ .22 9 /

,,d o , , / - ~ . ' - ~ - , o _ _ Z , , ' i .

t o . 2 o i - , ~ 0 . . . . ~ - ~ - = 7 ~ , ~ " - -

-~ 32- ~ .

I o ,

i - o 24 --A- INJECTION

tu 20 PERIOD

I O . 2 . 4 . 6 . 8 I.O

WATER / FUEL(by volume)

FIc. 5. Ef f ect of wat er i nj ect i on wi t h t he rue]

(system 3b). Test conditions as in Fig. 4.

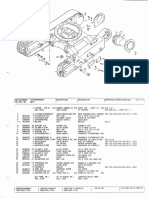

TABLE I

Results obtained with two methods of injecting water with the fuel. Factorial change is the value relative

to that with fuel only case at corresponding fueling and timing. 4 x 0.28 nozzle, 175 atm NOP, 2000

r ev/ mi n.

Technique Fuel

of water Fuel i ng timing

addition (mm 3 / str) (~

Factorial change with water

addition: W/ F = 0.8

NO Smoke CO SFC Delay Period

3(a) 70 20 0.37 0.55 0.49 0.95 1.90 1.56

60 20 0.34 0.63 0.40 0.98 1.70 1.72

50 20 0.29 0.54 1.00 0.99 2.05 1.74

40 20 0.25 2.25 0.97 2.09 1.81

30 20 0.23 10.00 1.02 2.08 1.73

20 20 0.40 19.00 1.64 2.62 1.56

3(b) 65 10 0.46 0.54 1.30 1.04 1.75 1.52

65 20 0.29 0.44 0.78 1.06 1.75 1.87

60 15 0.31 0.23 0.47 1.02 2.21 1.43

EFFECTS OF WATER INTRODUCTION 327

so that t he final spray state was det er mi ned

by mechani cal forces and by chemi cal speci es

whi ch occur nat ur al l y in t he fuel. The mi xt ure

(a)

89

(b)

2O0 ~n

Fro. 6. (a) Photomicrograph of all separate spray

droplets captured with liquid nitrogen, W/ F = 0.2,

fueling = 40 mma/stroke. (b) Photomicrograph of

water droplets containing fuel droplets, sample taken

from high pressure pipe, W/ F = 1.0.

in t he hi gh pressure feed pi pe was first exam-

i ned by r unni ng t he i nj ect i on syst em on a rig

wi t h t he injector di sconnect ed. Fi gur e 6b is

a phot omi cr ogr aph of a sampl e of t he fl ui d

del i ver ed from t he feed pi pe and shows large

wat er dropl et s cont ai ni ng fuel dropl et s. Thi s

confi rms that for W/ F = 1 the wat er / f uel

mi xt ure fed to t he i nj ect or was a fuel in water

in fuel emul si on, that is fuel dropl et s were

wi t hi n wat er dropl et s whi ch in t urn were

sur r ounded by fuel.

Wi t h t he i nj ect i on nozzl e reconnect ed to t he

feed pi pe, the spray state was exami ned by

t hree separat e met hods when i nj ect i ng into

at mospher i c pressure. I n t he first met hod one

of t he four sprays is ai med i nt o an open- t opped

fl ask cont ai ni ng boi l i ng l i qui d ni t rogen. Wi t h

t hi s t echni que t he spray ent rai ns cool N 2 gas

whi ch freezes all t he spray dropl et s. The di-

mensi on from t he nozzl e t i p to t he l i qui d N 2

surface cont rol s t he di st ance of spray travel

before freezing. Wi t h a smal l di st ance (4") fuel

fi l ament s and dropl et s wi t h tails were ob-

served so greater sampl i ng di st ances (6-8")

were used to ensure t hat at omi sat i on was

compl et e. The frozen separat e dropl et s col-

l ect ed i n t he l i qui d N 2 bel ow the nozzl e and

a sampl e of the l i qui d was t ransferred to a

speci al l y const ruct ed mi cr oscope sl i de where

t he frozen separat e dropl et s were phot o-

graphed. Fi gur e 6a shows an exampl e of t he

phot omi cr ogr aphs obt ai ned for all separat e

dropl et s in t he spray, consi st i ng of wat er drop-

lets wi t h or wi t hout encl osed fuel dropl et s and

fuel dropl et s wi t h or wi t hout encl osed wat er

dropl et s. The size di st r i but i ons obt ai ned by

t hi s met hod are in agr eement wi t h those ob-

t ai ned by other met hods for a fuel onl y spray.

In the seeond met hod t he fuel spray is agai n

di r ect ed into an open- t opped fl ask but this

t i me eont ai ni ng wat er t reat ed wi t h a det ergent

(2% Teepol ) i nst ead of t he l i qui d N' 2. Thi s

met hod capt ures all fuel dropl et s, i rrespect i ve

of whet her t hey are or i gi nal l y encl osed by

wat er or not. In t hi s ease t he spray ent rai ns

ambi ent air and t he di st ance from t he nozzl e

t i p to t he surface of t he sampl i ng l i qui d is

chosen so that t he dr opl et i mpact forces on

t he l i qui d surface are smal l compar ed to t he

forces i nvol ved in at omi sat i on and dropl et

format i on. In addi t i on t he concent rat i on of

dr opl et fl ui d col l ect ed i n t he sampl i ng l i qui d

is kept l ow (<1%) to mi ni mi se coal escence

of dropl et s and also to pr ovi de a sui t abl y di l ut e

sampl e for phot omi cr ogr aphs.

The t hi rd met hod is desi gned to capt ure all

wat er dropl et s, i r r espect i ve of whet her t hey

are ori gi nal l y encl osed by fuel dropl et s or not.

Thi s i nvol ves usi ng a si mi l ar t echni que to t he

second met hod but usi ng a sampl i ng l i qui d

328 POWER SYSTEMS

c ons i s t i ng of di e s e l f uel pr e s a t ur a t e d wi t h

di s s ol ve d wa t e r a n d c ont a i ni ng 1% of a di s pe r -

sant a ddi t i ve ( Ho n e y wi l l BR1J30).

The p h o t o mi c r o g r a p h s obt a i ne d wi t h t he

t hr ee s a mp l i n g me t hods wer e a na l ys e d t o gi ve

dr opl e t si ze di s t r i but i ons . I t is not p o s s i b l e

t o gi ve f ul l de t a i l s her e of t he dr opl e t s t udi e s ,

whi c h i n c l u d e r e s ul t s for W/ F = 0 t o W/ F

= 1, but Fi g. 7 s hows s ome r esul t s f or W/ F

= 0. 2 a nd 1.0. Th e si ze di s t r i but i ons ar e

expr es s ed i n t e r ms of t he di f f e r e nt i a l i n c r e me n t

of t he d r o p l e t v o l u me f r act i on F v ( wh i c h is

vol ume of t he dr opl e t s d i v i d e d b y v o l u me of

al l t he dr opl e t s i n t he s pr ay) pe r mi c r o n i ncr e-

ment of d r o p l e t di a me t e r d. Co n s e q u e n t l y t he

ar ea unde r a c ur ve i n Fi g. 7 b e t we e n a ny

c hos e n r ange of d r o p l e t di amt er s is e qua l t o

t he vol ume f r a c t i on of t he dr opl e t s o e c u r i n g

i n t hat si ze r ange. Thi s me t h o d of p r e s e n t a t i o n

hi ghl i ght s t he di f f e r e nt mode s of t he d i s t r i b u -

t i on cur ves o b t a i n e d wi t h t he t hr ee s a mp l i n g

me t hods . By d e f i n i t i o n t he d i s t r i b u t i o n f or al l

s epar at e d r o p l e t s mus t i n c l u d e al l wa t e r a n d

al l f uel dr opl e t s ei t her i n d i v i d u a l l y or b y

c o mb i n a t i o n of one dr opl e t wi t hi n anot her .

The dat a f or W/ F = 0. 2 wer e o b t a i n e d be f or e

t he t e c h n i q u e f or me a s u r i n g al l f uel d r o p l e t s

ha d been d e v e l o p e d . Howe ve r t he cur ves for

wat er dr opl e t s a n d al l s epar at e dr opl e t s s how

t hat t her e ar e ma n y mor e wat er dr opl e t s s ma l l e r

t ha n 5txm t ha n f or t he s epar at e dr opl e t s wi t h i n

t he s pr ay: at 31xm, for i ns t ance, t her e a r e mor e

t ha n t en t i me s as ma n y wat er d r o p l e t s as

s epar at e dr opl e t s . I t is obvi ous t he r e f or e t hat

mos t of t he s ma l l e r wat er dr opl e t s mu s t have

be e n c ont a i ne d wi t h i n f uel dr opl e t s i n t he

spr ay. I t can r e a d i l y be d e d u c e d f r om c u mu l a -

t i ve vol ume t r i c d r o p l e t si ze d i s t r i b u t i o n s ( not

s hown her e) t hat at l east 35% of t he wa t e r

vol ume mus t ha ve be e n so c ont a i ne d, a n d t her e

is no e vi de nc e t hat t her e wer e a ny s e pa r a t e

wat er dr opl e t s i n t he s pr ay. Resul t s t a ke n f or

W/ F > 0. 2 s how t hat t he s pr a y st at e changes .

For e xa mpl e at W/ F = 1 i n Fi g. 7 bot h

wat er a nd f uel d i s t r i b u t i o n s are b i - mo d a l

wh i c h is due t o t wo i n d e p e n d e n t d i s t r i b u t i o n s

I 0 i i i f

\ / " , , :

0 -.-.-"-

o ~ ~ o

x ; , / /

# , .

L)

o Z

Q2 w

2~

U.I

/ l WATER / FUEL RATIO e

0.1 / I BY VOLUME = 1,0 u._

l

0.05 _U

2 ` 0 , A..-& ~ &

2 7 2 ~ "~ 9

\o

0 >

o _

x

9 v O.! o ~

- u I . v

~ o

0.2. / WATER/ FUEL RATI O

0.1 9 BY VOL UME : 0 . 2

I I

2 5 IfO 210 5 0

DROPLET DI AMETER ( pr o)

FIG. 7. Observed dropl et size distributions at two wat er / f uel ratios. Sol i d triangles = all separate spray

droplets, solid circles = fuel droplets, open circles = water droplets. Volumetric frequency is expressed

in terms of fraction by volume (Fv) per micron increment of diameter (d). Fuel i ng = 40 mma/ st roke.

EFFECTS OF WATER INTRODUCTION 329

for e nc l os e d a nd s e pa r a t e dr opl et s . Ana l ys i s

of t hes e di s t r i but i ons t oge t he r wi t h obs er va- ~ ,31,

t i on of t he p h o t o mi c r o g r a p h s l ead t o t he f ol - 6 ~ .30

l owi ng concl us i ons . Th e v o l u me of e nc l os e d ~ ~ .29

wat er dr opl e t s is ne gl i gi bl e , t hat is t he ar ea 26oc

unde r t he wat er d r o p l e t c ur ve for di amet er s

l ess t ha n t he s ma l l e s t s e pa r a t e dr opl e t is neg- ~ 2soo

l i gi bl e. On l y 20% of t he v o l u me of t he f uel

dr opl e t s ar e e nc l os e d wi t h i n wat er dr opl e t s ~-

a nd t hes e f uel dr opl e t s ar e s ma l l e r t han 5txm 24o0

whi l e t he r e ma i n i n g 80% of t he f uel v o l u me ~o

is i n t he f or m of a l mos t pur e f uel dr opl et s . ~ .8

So t o s umma r i s e t he ma i n c onc l us i ons of ~ g 6

t he s pr a y dr opl e t s t udi e s ; f or W/ F = 0. 2- o =

1.0 t he f uel dr opl e t s c o n t a i n al mos t no wat er ~ ~ .4

whi l e for W/ F = 0. 1- 0. 2 t he l ar ger f uel .2

2o0o

dr opl e t s c ont a i n wa t e r dr opl e t s . Al so a ddi t i on-

al r es ul t s not s hown i n Fi g. 7 s how t hat for

W/ F = 0.1 t o 1.0 t he Saut er me a n di a me t e r ~.~ igoo

(S. M. D. ) of al l s e pa r a t e dr opl e t s is a bout 35%

s ma l l e r t ha n t he S. M. D. for t he dr opl e t s i n 18oo

a f uel onl y spr ay, t . o

. 8

- - . 6

0

6. Cal c ul at i ons on t he Ef f e c t of Water

I nj e c t i o n

Some c a l c ul a t i ons f or t he ef f ect of wat er

i nj ect i on have be e n c a r r i e d out us i ng t he

c omput e r mode l d e s c r i b e d i n Ap p e n d i x I. Fo r

f uel i nj ect i on onl y, t he mo d e l has be e n ext en-

s i vel y c he c ke d a ga i ns t e xpe r i me nt a l dat a f or

t he ef f ect of a r a nge of c o mb u s t i o n s ys t em

pa r a me t e r s on NO a n d s oot c onc e nt r a t i ons

e mi t t e d i n t he e ngi ne exhaus t . The qua l i t a t i ve

a gr e e me nt of t he or y a n d e xpe r i me nt is s uc h

t hat t her e is a hi gh de gr e e of c onf i de nc e t hat

t he maj or c ont r ol l i ng me c h a n i s ms f or soot a nd

NO f or ma t i on are r e p r e s e n t e d i n t he mode l

t h o u g h a mor e d e t a i l e d mo d e l is n e e d e d t o

i mpr ove qua nt i t a t i ve a c c ur a c y. For t he a ddi -

t i on of wat er , t he p h y s i c a l ef f ect s of t he a d d e d

wat er ar e mo d e l l e d a n d t he a d d e d wat er is

t r eat ed as a c h e mi c a l l y i ner t f l ui d. Th e v a l i d i t y

of t he l at t er a s s u mp t i o n i s i nve s t i ga t e d her e

b y c he c ki ng whe t he r t he mo d e l l e d phys i c a l

ef f ect s of wat er a d d i t i o n ar e s uf f i ci ent t o ex-

pl a i n t he obs e r ve d e xpe r i me nt a l t r ends. Th e

r es ul t s of p r e l i mi n a r y c a l c ul a t i ons on t he ef f ect

of wat er i nj ect i on ar e s h o wn i n Fi g. 8 for t he

t est c ondi t i ons c o r r e s p o n d i n g t o t hos e i n Fi gs .

2 a nd 3.

Th e t r ends for r e d u c t i o n of NO a nd t he

gr eat er r e duc t i on a c h i e v e d wh e n t he wat er is

i nj ect ed wi t h t he f uel ar e c or r e c t l y p r e d i c t e d

t h o u g h t he changes ar e s o me wh a t exagger at ed.

The r e duc t i on of p r o d u c t zone t e mpe r a t ur e

whi c h is c a l c ul a t e d b y t he mode l ma y be

over - es t i mat ed be c a us e of a n u mb e r of si r e-

fO- N

d " - - O ~ ~ - - - - 0

/

r - . - : =: ===~ - - ~

S FC.

a s a a ~

EM .

"~" " ~ ' ' 0 FORMATION

ZONE

"O

NO.IN

EXHAUST

%'"

MAXTEMP

o ~ . ~ ~N SOOT

FORMATION

~" -- ~ ZONE

O O.~

~' ~O

l ~ ' ~ =

"~~ ~o~ SOOT,N

D ~ o EXHAUST

N

~O~

6 o'.~ o~ 2 c ; 3 - - o - 9 4 o : s

WATERI FUELRATIO( BYVOLUME)

FIG. 8. Calculated effect of water injection. Open

circles = water injection with t he fuel, open squares

= water injection in air inlet, sol i d squares = revised

calculation for water injection in air inlet. Engine

speed = 2000 rev/ rni n, fuel i ng = 60 mm3/ st roke,

injection timing = 20~

p l i f y i n g a s s umpt i ons . I n pa r t i c ul a r t he r educ-

t i on of r a di a t i ve heat l os s es wh i c h wi l l occur

wi t h any r e duc t i on of l ocal zone t e mpe r a t ur e s

has not be e n t aken i nt o account . A r e duc t i on

of soot c onc e nt r a t i on is cor r ect l y p r e d i c t e d

wh e n i nj ect i ng wat er wi t h t he f uel t h o u g h t he

ef f ect is exagger at ed, p r o b a b l y due t o an over -

e s t i ma t e of t he r e d u c t i o n of zone t e mpe r a t ur e .

Al s o for wat er i nj e c t i on wi t h t he f uel t he

c a l c ul a t i on shows t hat f or W/ F r at i os i n t he

r a nge 0- 0. 2 t her e i s a c h a n g e i n t r e nd f or BSFC,

NO a nd s moke r el at i ve t o t he gener al pa t t e r n

c a l c ul a t e d for W/ F r at i o gr eat er t ha n 0.2. As

me n t i o n e d ear l i er t hi s c h a n g e is al so obs e r ve d

i n t he e xpe r i me nt a l r es ul t s . Th e r eas on for t he

c h a n g e i n t he c a l c ul a t e d t r e n d is t hat t he i nput

i nj e c t i on pe r i od is t hat s h o wn b y t he ope n

ci r cl es i n Fi g. 5 a nd e xhi bi t s a r e l a t i ve l y r a pi d

i nc r e a s e for W/ F r at i o of 0- 0. 1 f ol l owe d b y

a l ess r a p i d i ncr eas e wi t h f ur t her i ncr eas e of

W / F r at i o.

Fo r wat er i nj ect i on i n t he i nl et ma n i f o l d

330 POWER SYSTEMS

a smoke reduct i on is obt ai ned from t he cal-

cul at i on correspondi ng to the open squares.

I n this cal cul at i on the water is assumed to

vaporise after the i nl et valve closes and also

the effect of water vapour on the rate of air

ent rai nment is not taken into account. The

cal cul at i on correspondi ng to the solid squares

takes the latter i nt o account and i n addi t i on

it is assumed that the injected water vaporizes

to equi l i br i um saturated condi t i ons before the

inlet valve closes. These revisions to the cal-

cul at i on reduce the mass of air t rapped i n the

cyl i nder and also the rate at whi ch air is

ent rai ned i nt o the fuel spray. The cal cul at ed

smoke (solid squares) t hen increases wi t h wa-

t er / f uel ratio i n a similar way to the experi-

ment al l y observed results.

A more det ai l ed cal cul at i on to det ermi ne the

i nduct i on condi t i ons for the injected water

together wi t h a more precise t reat ment of heat

losses coul d lead to good agreement of calcu-

lated and experi ment al trends for the effect

of water injected i nt o the air inlet and for the

effect of water i nj ect ed wi t h the fuel.

The last st at ement suggests that the effects

of water i nj ect i on on bot h NO and smoke can

be expl ai ned ent i rel y by the changes of tem-

perature and rates of f uel / ai r mixing. Whi l e

the t emperat ure effect is readily appreci at ed

i n Fig. 8, the i nf l uence on rates of f uel / ai r

mi xi ng is best demonst rat ed by compari ng t he

rates of air ent r ai nment . Increased rates of air

ent rai nment have a benefi ci al effect on engi ne

performance and emi ssi ons and are especi al l y

effective i n r educi ng soot emissions. U The

ent r ai nment model of reference l i has been

further devel oped 12 to provi de a more det ai l ed

t reat ment of the f uel / ai r mi xi ng processes and

can be used to calculate the air ent rai ned by

each el ement of t he injected fuel. The ent rai n-

ment is compl et e when all fuel el ement s have

attained the overall equi val ence ratio. Fi gure

9 shows that i nj ect i on of water i n t he i nl et

mani fol d reduces the rate of air ' ent r ai nment

relative to the ' fuel onl y' case since it di l ut es

the air suppl y to the fuel spray and will reduce

the rate at whi ch oxygen reaches the fuel.

However i nj ect i on of water wi t h the fuel in-

creases the moment um of the injected fl ui d

relative to its oxygen requi rement for compl et e

combust i on. For example assumi ng a 7 x 0.28

nozzle, the nozzl e flow area is i ncreased i n

proport i on to the increase of fl ui d vol ume due

to the water and the rate of air ent r ai nment

is greatly i ncreased for the same pressure drop

across the nozzl e holes as for the ' fuel onl y'

case. The air ent r ai nment curves for water wi t h

the fuel, and t he i nj ect i on periods act ual l y

observed i n the experiments show that t he 4

x 0.33 nozzl e gives almost as good a result

as the 7 x 0.28 nozzl e since the hi gher pres-

sures compensat e for the increased i nj ect i on

hO

uJ

Z

.75

t---

Z

UJ

u_ .50

O

Z

_O

I -

L)

<

.25

0

I I I I

r / / ~ O m m 3 1 s t . 2OOOrev/min. 20~

/ / / " F U E L MEAN WATER

/ ~ NOZZLE PERIOD PRESSURE INTRODUCTION

/~'/" (~ DROP

~ / y (ATM)

4 xO.28 22 ~ 147.5 none

4 x O2 8 2 2 ~ 147.5 inlet monifold

4 x 0 2 8 3 6 ~ 194. 8 wi t h f uel

- - - - 4 x 0 . 3 3 2 6 * 193. 5 wi t h f uel

7 x 0 . 2 8 2 3 . 6 147. 5 wi t h f uel

io 20 30 40 50

~ AFTER START OF INJECTION

Fro. 9. Comparison of calculated rates of air entrainment. Values are cumulative for all injected fuel

elements relative to total air in cylinder.

EFFECTS OF WATER INTRODUCTION 331

period. But for the 4 0.28 nozzle the ent rai n-

ment is slower and is compl et e i n a similar

period to the fuel onl y case.

7. Di scussi on

7.1 Water Injection in the Inl et Mani f ol d

The injection of water i n the air inlet mani -

fold reduces cycle t emperat ures which, ac-

cordi ng to the cal cul at i on model, is the domi -

nant effect i n reduci ng the rate of format i on

of NO. Smoke increases slightly wi t h water

i nj ect i on i n the i nl et mani fol d. The smoke is

affected by bot h the lower t emperat ure whi ch

reduces it and by the poorer f uel / ai r mixing,

previ ousl y discussed, whi ch increases it. The

comput er model indicates that bot h of these

effects are significant.

A compari son of the data obt ai ned from

different sources for mani f ol d water i nj ect i on

i n diesel engines is shown i n Tabl e II. The

factorial changes are the ratio of the val ue wi t h

water i nj ect i on to that wi t h no water i nj ect i on

and i n the case of smoke the values are ex-

pressed i n terms of a mass ratio usi ng the

correlation 15 whi ch was previ ousl y ment i oned.

Data for direct i nj ect i on engi nes (DI), indirect

i nj ect i on engi nes (IDI), and t urbocharged en-

gines (TC) are i ncl uded. Whi l e the NO reduc-

t i ons wi t h water i nj ect i on are broadl y similar

this is not true of smoke and CO. For example

i n the data obt ai ned by the present authors

and also by Wi l son et al (DI engine) smoke

and CO increase whi l e the data of others show

a decrease or no change. Differences in the

at omi sat i on of the i nj ect ed water are one

possi bl e explanation. For example wi t h hi gh

pressure at omi sat i on as used i n the present

work the rates of vapori sat i on may be suffi-

ci ent l y rapid to di spl ace some of the air charge

before the inlet valve closes whi l e low pressure

at omi sat i on may delay vapori sat i on unt i l after

valve closure. As shown earlier i n the calcula-

t i on model, this can greatly affect smoke con-

centrations.

The water droplet size and vapori sat i on may

TABLE II

Comparison of selected experimental data on water injection in the inlet manifold, full load conditions,

constant fuel injection timing

Engine W/ F

Souree of Combustion speed ratio

data system (rev/min) (by vol.)

Factorial changes

NO HC Smoke CO SFC Delay

Present DI 2000 0.5 0.70 1.25 1.20 1.01 1.10

Authors 1.0 0.49 1.25 1.45 1.06 1.33

1.4 0.38 1.20 1.61 1.06 1.37

Wilson DI 2100 0.42 0.55 1.10 0.99

et al s 0.83 0.38 1.20 0.99

1.24 0.28 1.14 1.01

Valdmanis DI 2600 0.5 0.68 1.70 0.81 0.84

Wulfhorst 6 1.0 0.52 2.10 0.78 0.74

Vichnievsky DI 2000 0.5 0.77 0.41 0.60 0.96

et al lo 1.0 0.64 0.64 0.70 0.97

Marshall DI TC 2100 0.36 0.73

Hurn 5 1.08 0.32

Wilson IDI 1500 0.42 0.70 0.64 0.97

et al s 0.83 0.53 0.43 1.00

1.24 0.48 0.30 1.00

Torpey IDI 1500 0.5 0.90 1.0 1.0 1.01

et al 9 1.0 0.71 1.0 1.0 1.01

1.5 0.63 1.0 1.0 1.02

332 POWER SYSTEMS

also be important in the practical probl em of

dilution of the engine lubricating oil by water.

No data were obt ai ned on this aspect but the

severity of the probl em is indicated by Torpey

et al 9 where 10% dilution of the l ubri cat i ng

oil occurred in 50 hours of engine running.

This is one of the disadvantages of water

injection in the inlet manifold since it is

inevitable that some water droplets will contact

the cylinder surfaces which are exposed duri ng

induction and compression processes. In this

respect water injection with the fuel should

reduce the oil di l ut i on problem but practical

problems are then transferred to the fuel / water

injection equipment.

7.2 Water Inj ect i on with the Fuel

Greater reductions of NO are achieved for

a given wat er / f uel ratio when injecting the

water with the fuel and the calculations show

that this is largely the additional thermal effect

clue to the increased water concentrations in

the zones where NO forms. Unlike mani fol d

injection, water injection with the fuel reduces

soot concentration above a certain wat er / f uel

ratio. The calculations suggest that this is

partly due to the thermal effect combi ned with

the maintenance of similar or increased rates

of fuel / air mixing. The injected water provides

an additional source of injected moment um

for air entrainment and f uel / ai r mixing. Fur-

ther opt i mi sat i on of nozzle hole size and

number of holes would be required to exploit

this effect fully.

For W/ F ratios in the range 0-0.2 there is

a reversal of the trends observed at higher W/ F

ratios. The calculation model shows that this

is partly attributable to the variation of injec-

tion period wi t h W/ F ratio for the t echni que

3b. The changes in engine performance and

emissions may also be partly explained by the

observed changes in state of the wat er / f uel

spray since micro-explosions could occur for

W/ F < 0.2 but not for W/ F > 0.2. However,

as discussed later, this presupposes that

micro-explosions are sufficiently violent to

affect the rates of gas phase turbulent diffu-

sion. Another possi bl e effect is that with the

technique 3b the pumpi ng period for the water

becomes short relative to that for the fuel at

low W/ F ratio. But, because of the many

changes of section between T-piece and nozzle

and the hi ghl y turbulent flow, the water and

fuel should be well mixed before reaching the

nozzle holes. At this stage it is not clear as

to whether the reversal of trends is due solely

to the effect of injection period or part l y due

to the change of spray state.

For W/ F > 0.2 the fuel droplets contain

almost no water so that the micro-explosion

phenomena should not occur. The calculation

model shows that changes in temperature and

in the gas phase turbulent mixing rates are

quite sufficient to account for the observed

reduct i ons of NO and smoke with water injec-

tion. Also it is the author' s experience that,

at full load conditions, gas phase t urbul ent

mixing processes dominate the situation in that

appreciable changes in NO, smoke and fuel

economy are produced by factors affecting jet

mixing such as variation of fuel spray momen-

tum and air charge motion rather than by

changes which further improve atomisation

and reduce mean droplet size. We woul d

therefore doubt that the droplet micro-explo-

sion phenomena could produce dramatic im-

provements in automotive diesel engines as

suggested by Dryer 3 unless the micro-explo-

sions are sufficiently violent to affect t urbul ent

mixing on a scale comparable to the fuel spray

width. The situation could be quite different

for combustion systems using heavy fuel oils

such as furnaces, industrial boilers and low

speed diesel engines where atomisation and

droplet size may be controlling. Micro-explo-

sions within fuel droplets could well be ben-

eficial in such systems. Indeed observation

of the soot particle structure in some of these

systems confirms l i qui d phase pyrolysis while

the soot particle structure observed in the

automotive diesel exhaust confirms gas phase

soot formation reactions. 16

The possi bi l i t y that the added water modi-

fies the chemistry (for example by increasing

OH radical concentration, oxidising the soot

precursors and hence reducing soot formation)

cannot be ruled out but it is likely to be a

second order effect. Also it can be argued that

some H 20 vapour is always present from the

initial oxidation reactions and from combus-

tion products so that additional quantities

should not have dramatic effects on the chem-

istry.

A comparison of experimental data from

different sources for injection of water with

the fuel is shown in Table III. The data is

given in factorial form and the smoke is a

mass ratio as descri bed for the previous table.

In some cases a small degree of extrapolation

was required to ensure that the factorial change

with and without water injection was at a

constant injection timing.

In qualitative terms the reductions of NO,

smoke, and CO observed in the present work

are confirmed by the data for four other DI

engines though the results for the IDI engine

show some increase in CO. Quantitatively,

EFFECTS OF WATER INTRODUCTION 333

TABLE III

Comparison of selected experimental data on water injection with the fuel, constant full load or full fueling

conditions, constant fuel injection timing, (*fuel injection timing optimised for best fuel economy)

Engine W/ F

Factorial changes

Source of Combustion speed ratio

data system (rev/min) (by vol.) NO HC Smoke CO SFC Delay

Present DI (3b) 2000 0.21 0.62 1.0 1.3 1.50 1.00 1.2

Authors (3b) 0.5 0.53 1.0 0.5 0.60 0.98 1.5

(3b) 0.8 0.32 2.0 0.25 0.45 1.02 2.2

(3a) 0.8 0.34 0.63 0.40 0.98 1.7

Valdmanis

et al ~ DI 2600 0.5 0.72 2.8 0.63 0.69

Vichnievsky DI 2000 0.21 0.81

et al lo (Mono 520) 0.55 0.59

Vichnievsky DI 2000 0.21 0.67 0.25 0.77 0.96 1.04

et al 1~ (Mono 520) 0.55 0.28 0.12 0.81 0.94 1.56

Vichnievsky DI 1500 0.21 0.68 0.64 0.60 0.98 1.13

et allo (Poyaud

6L85)

Vichnievsky DI 2500 0.21 0.76 0.35

et a110 (Agrom) 2000 0.21 0.83 0.68

472) 1500 0.21 0.85 1.0

Vichnievsky IDI 2500 0.21 0.62 1.67 1.00 1.09

et al 1~ 0.36 0.51 1.73 1.00 1.27

there are some vari at i ons i n the reduct i on of

NO, but i n the case of smoke and CO there

are greater variations. Thi s is to be expected

since smoke and CO are much more sensitive

(in % terms) to changes of combust i on system

parameters t han is NO. For example the smoke

and CO results obt ai ned wi l l to some extent

depend on the increase of i nj ect i on period wi t h

W/ F ratio for the part i cul ar i nj ect i on system

used. There are also appreci abl e engi ne to

engi ne differences, for example the Mono 520

engi ne used by Vi chni evsky is likely to have

a relatively low rate of air swirl rotation

compared wi t h the medi um swirl engi ne used

i n the present work.

Both Val dmani s 6 and Vi chni evsky 1~ used

emul si fyi ng agents to prepare their injected

water-fuel mixtures whi l e i n the present work

no emul si fyi ng agents were used. There is no

concl usi ve evi dence from Tabl e III that the

different methods of prepari ng the water fuel

mixtures affect the NO, smoke or CO reduc-

tions. It shoul d be not ed that, i n all of the

systems used there must be consi derabl e

homogeni sat i on forces 3 as the f uel / wat er mix-

ture passes t hrough the hi gh pressure passages

of the i nj ect i on system to the nozzle holes.

It is possible, therefore, that similar spray

states were achieved for all of the data shown

i n Tabl e III.

7.3 Ignition Dela~ and Limiting Water~Fuel

Ratio

Igni t i on delay i ncreased wi t h all of the

met hods of water i nj ect i on whi ch were tried

and this leads to a large fraction of premi xed

bur ni ng, higher rates of cyl i nder pressure

rise, ~~ and increased combust i on noise. I n

addi t i on when i gni t i on del ay exceeds a critical

val ue the HC emi ssi ons will increase. The

results show that wi t h water i nj ect i on i n t he

inlet mani fol d there is less increase i n i gni t i on

delay t han that for water i nj ect i on with t he

fuel even when wat er / f uel ratios are chosen

to give the same NO reduct i on (Figs. 2, 3).

If we assume that some increase i n combus-

t i on noise can be tolerated t hen increase of

334 POWER SYSTEMS

i gni t i on de l a y t o t he cr i t i cal va l ue for HC l i mi t s

t he ma x i mu m us e f ul W/ F r at i o t o 0. 6 f or t he

t est c ondi t i ons of Fi g. 5. I n t he eas e of a

t ur boc ha r ge d di r e c t i nj ect i on di es el e n g i n e t he

l i mi t i ng W/ F r at i o wi l l be hi gher s i nc e i gni -

t i on del ays ar e s hor t e r a nd f ur t her f r om mar -

gi nal i gni t i on c ondi t i ons . 9 Eve n for n a t u r a l l y

as pi r at ed di r e c t i nj e c t i on engi nes i t s h o u l d be

pos s i bl e t o use W/ F r at i o of at l east 0. 8 b y

i ncr eas i ng e n g i n e c ompr e s s i on r at i o. At par t

l oad, however , i g n i t i o n c ondi t i ons ar e u s u a l l y

cl oser t o cr i t i cal c ondi t i ons a n d r e d u c e d W/ F

r at i o woul d be r e q u i r e d t o cont r ol not o n l y

c ombus t i on noi s e a n d HC but al so CO ( see

Ta bl e I a nd r e f e r e nc e 10).

7.4 Water Inj ect i on f or Emi ssi ons Control

Wi t h an i nc r e a s e d c ompr e s s i on r at i o a n d

var i abl e wa t e r / f u e l r at i o t o cont r ol i g n i t i o n

del ay at par t l oa d i t s houl d be p o s s i b l e t o

achi eve NO r e d u c t i o n s of up t o 70% f or l i t t l e

or no i ncr eas e i n S F C t oget her wi t h a s i gni f i -

cant i mp r o v e me n t i n s moke l i mi t e d p o we r

out put . The NO r e duc t i ons a c hi e ve d wi t h

wat er i nj ect i on ar e l i kel y t o be c o n s i d e r a b l y

great er t han can be a c hi e ve d wi t h e xha us t gas

r eci r cul at i on f or t he s ame s moke l i mi t e d p o we r

out put . I n pr act i ce, however , t her e ar e ma j or

pr obl e ms wi t h wa t e r i nj ect i on s uch as an

i ncr ease of c o mb u s t i o n noi se, t he ef f ect of

wat er on i nj e c t i on e q u i p me n t a nd e ngi ne ,

pr obl ems wi t h ope r a t i on i n s ub- zer o t e mpe r a -

t ures, a nd t he cos t of t he neces s ar y a d d i t i o n a l

equi pment . I t is d o u b t f u l i f wat er i nj e c t i on

has a pr act i cal f ut ur e for e mi s s i ons c ont r ol

on a ut omot i ve di e s e l engi nes .

8. Ap p e n d i x I

Model of the Di esel Combust i on Process

The c o mp u t e r mo d e l of di es el c o mb u s t i o n

des cr i bed i n r e f e r e nc e 11 has been p r e v i o u s l y

used t o c a l c ul a t e f uel e c o n o my a nd soot a n d

NO f or mat i on f or f uel onl y i nj ect i on i n di r e c t

i nj ect i on di es el e ngi ne s . Thi s mode l c a l c ul a t e s

t he t i me hi s t or i es f or t he c o mb u s t i o n pa r t of

t he engi ne cycl e. An e mpi r i c a l c or r e l a t i on is

used to c a l c ul a t e t he de l a y of i gni t i on f r om

t he st art of i nj e c t i on a nd af t er i gni t i on i t i s

as s umed t hat d r o p l e t va por i s a t i on t i me s ar e

short r el at i ve t o t i me s for gas pha s e t u r b u l e n t

mi xi ng. The t u r b u l e n t mi xi ng pr oces s es ar e

quant i f i ed b y t he e n t r a i n me n t of ai r i nt o t he

fuel s pr ay v o l u me a n d b y mi c r o mi x i n g wi t h i n

t he ent r ai ned s pr a y vol ume.

The r at e of e n t r a i n me n t is d e t e r mi n e d b y

t he mo me n t u m of t he i nj ect ed f uel a n d b y

t he ai r char ge pr ope r t i e s . Mi c r omi xi ng is

pr opor t i ona l t o a d i f f u s i v i t y c ons t a nt a n d t o

t he s pr a y t i p ve l oc i t y a nd is us ed t o d e f i n e

t he e q u i v a l e n c e r at i os i n a n u mb e r of zones

wi t h i n t he s pr a y vol ume . Thi s mi xi ng mo d e l

is t hen us ed t o c a l c ul a t e heat r el ease, c y l i n d e r

pr es s ur e, t e mpe r a t ur e s a nd pol l ut a nt f or ma-

t i on.

For NO f or ma t i on t he Ze l d o v i e h me c h a n i s m

is a s s u me d t oge t he r wi t h e q u i l i b r i u m oxyge n

at om c onc e nt r a t i on.

The ki net i cs of soot f or ma t i on have not b e e n

e s t a bl i s he d so t he a va i l a bl e i nf or ma t i on was

r e vi e we d a n d Khan, Gr eeves a nd Pr obe r t 1~

p r o p o s e d t he f o l l o wi n g s e mi - e mphi r i c a l e qua -

t i on for t he r at e of soot f or ma t i on i n an el e-

me nt a r y v o l u me of r e a c t i ng f u e l / a i r mi xt ur e.

d$

- - = c o n s t a n t P , ~ b 3 e 200(O/T

dt

whe r e S = s oot mas s f or me d pe r uni t vol -

u me

P, = pa r t i a l pr e s s ur e of t he u n b u r n t

f uel

T = t e mp e r a t u r e (~

d~, = e q u i v a l e n c e r at i o for t he un-

b u r n t f uel a nd u n u s e d oxygen.

Thi s e qua t i on is i n t e n d e d t o cor r el at e t he

ef f ect of t he p h y s i c a l f act or s ( t emper at ur e,

pr e s s ur e a n d c onc e nt r a t i on) on t he r at e of

f or ma t i on of a pa r t i c ul a r s peci es of ga s e ous

pr e c ur s or wh i c h cont r ol s t he mass r at e of

p r o d u c t i o n of soot , but not t he ef f ect of

changes i n t he c h e mi s t r y s uch as a c h a n g e

of f uel c o mp o s i t i o n or t he ef f ect of a c he mi c a l -

l y act i ve f uel a ddi t i ve . Al so t he e q u a t i o n ap-

pl i es t o a pa r t i c ul a r r ange of ope r a t i ng c o n d i -

t i ons wher e gas pha s e r eact i ons c ont r ol s oot

f or mat i on.

The cons t ant s f or soot f or ma t i on a n d f or

t ur bul e nt d i f f u s i o n i n t he c ompl e t e c o mb u s -

t i on mode l ar e d e t e r mi n e d b y c o mp a r i s o n wi t h

e xpe r i me nt f or one e ngi ne t est c ondi t i on. Go o d

qua l i t a t i ve a g r e e me n t of p r e d i c t e d a n d exper i -

ment al t r ends f or soot a nd NO c onc e nt r a t i on

i n t he engi ne e xha us t have be e n a c hi e ve d f or

changes of i nj e c t i on t i mi ng, i nj ect i on r at e,

f uel i ng, e ngi ne s p e e d a nd ai r swi r l vel oci t y.

For wat er i nj e c t i on i n t he ai r i nl et t he ai r

char ge pr ope r t i e s ar e r e de f i ne d i n t er ms of

a wat er v a p o u r / a i r mi xt ur e. For wat er i nj e c t i on

wi t h t he f uel t he i nj e c t e d f l ui d pr ope r t i e s ar e

r e de f i ne d i n t er ms of a wa t e r / f u e l mi xt ur e.

Co n s e q u e n t l y t he wa t e r c onc e nt r a t i on i n a ny

gi ven c o mb u s t i o n z one d e p e n d s on t he r e l a t i ve

quant i t i es of a s p i r a t e d a n d i nj ect ed f l ui ds

EF F ECTS OF WATER I NTRODUCTI ON 335

wh i c h h a v e d i f f u s e d i n t o t h e z one . T h e a d d e d

wa t e r i s a s s u me d t o a c t i n a c h e mi c a l l y i n e r t

wa y e x c e p t i n so f a r as i t p a r t a k e s i n d i s s o c i a -

t i o n r e a c t i o n s i n t h e h i g h t e mp e r a t u r e r e g i o n s .

T h e mo d e l l e d e f f e c t of t h e a d d e d wa t e r i s t o

a c t as a n i n e r t d i l u t a n t , t o i n c r e a s e t h e i n j e c t e d

f l u i d v o l u me a n d h e n c e i n j e c t e d f l u i d mo me n -

t u m, a n d t o mo d i f y i n t e r n a l e n e r g y a n d h e n c e

t e mp e r a t u r e s i n t h e v a r i o u s z o n e s of c o mb u s -

t i o n d e f i n e d i n t h e f u e l a i r mi x i n g mo d e l .

9. Acknowledgments

The aut hor s woul d l i ke t o t ha nk t he Di rect ors

of CAV Li mi t ed and Dr Ewe n Mc Ewe n, Vi ce Chai r -

ma n - - En g i n e e r i n g , J os e ph Lucas Li mi t ed, for per-

mi s s i on t o publ i s h t hi s paper . They are i nde bt e d

t o Dr B. A, Jarret t , Di r ect or of Engi neer i ng, CAV

Li mi t ed for hi s e nc our a ge me nt a nd di scussi ons. The

aut hor s woul d al so l i ke t o acknowl edge t he wor k

of t hei r col l eagues i nc l udi ng Mr. P. D. War ner a nd

Mr. P. Sul l i van who car r i ed out t he comput at i ons.

10. RE F E RE NCE S

1. SCHERER, G. AND TaArqE, L. A. Pol l ut i on r educ-

t i on by c ombus t i on of f uel - oi l wat er emul si ons.

Pol l ut ant f or mat i on a nd des t r uct i on i n fl ames

a nd i n c ombus t i on syst ems, paper no. 83 Four -

t eent h I nt er nat i onal Sympos i um on Combus -

t i on, Penn. State Uni ver s i t y, August 20- 25 1972.

(Not publ i s he d i n t he Pr oceedi ngs) .

2. BARRETT, R. E. ET AL. Summar y r epor t on

pr epar at i on a nd f i r i ng of No. 2 fuel oi l a nd wat er.

Bat t el l e Memor i al I ns t i t ut e, Cont r act No. 86-68-

84, Task Or der No. 8, 1968.

3. DmCER, F. L. Fu n d a me n t a l concept s on t he use

of emul s i ons as fuel s. Pr i ncet on Uni ver si t y,

Aer ospace a nd Me c ha ni c a l Sci ences, Report No.

1224, Apri l 1975.

4. ABTrtOVV, J. a nn LUTHER, H. The me a s ur e me nt

of oxi de of ni t r ogen e mi s s i on f r om di esel engi nes

a nd i t s cont r ol by mode s of engi ne oper at i on.

Auto. Zei t s: 71 (4), 1969.

5. MARSHALL, W. F. AND HURN, R. W. Modi f yi ng

di esel engi ne oper at i ng par amet er s t o r educe

emi ssi ons. Bur eau of Mi nes. RI 7579, 1971.

6. VALDMaNIS, E. AND WULFnORST, D. E. The effect

of emul s i f i ed fuel s a nd wat er i nduc t i on on di esel

combus t i on. SAE Paper 700736, 1970.

7. WALDER, C. J. Reduct i on of emi s s i ons f r om di esel

engi nes. SAE pa pe r 730214, 1973.

8. WILSON, R. P. ET AL. Emi s s i ons st udy of a si ngl e-

cyl i nder di esel engi ne. SAE paper 740123, 1974.

9. TORPEY, P. M., WHITEHEAD, M. J. AND WRIGHT,

M. Exper i ment s i n t he cont r ol of di esel emi s-

si ons. Sympos i um on Ai r pol l ut i on cont rol i n

t r ans por t engi nes. I. Mech. E., 9- 11t h Nov. 1971.

10. VICHNIEVSKY, R. ET AL. Use of wat er - f uel emul -

si ons i n di esel engi nes. CI MAC Congr ess 1975,

Bar cel ona.

11. KHAN, I. M., GREEVES, G. AND WANG, C. H. T.

Fact or s af f ect i ng smoke a n d gaseous emi ssi ons

f r om di r ect i nj ect i on engi nes a nd a met hod of

cal cul at i on. SAE pa pe r 730169, 1973.

12. KHAN, I. M., GREEVES, G., RUSSELL, M. F., CAVA-

.~ACH, E. J. A~O WAaNEa, P. D. Pr edi ct i on of di esel

engi ne noi se. To be p u b l i s h e d at conf er ence

on La nd Tr ans por t Engi ne s , I. Mech. E., J anuar y

1977.

13. Krthr,, I. M. AND GREEt,', A. C. Schedul i ng i nj ec-

t i on t i mi ng for r e duc t i on of di esel emi ssi ons.

SAE paper 750337, 1975.

14. GREEVES, G. AND MEEHAN, J. O. Me a s ur e me nt

of i ns t ant aneous soot concent r at i on i n a di esel

c ombus t i on chamber . Conf er ence on Combus -

t i on i n Engi nes , I. Mech. E., Cr anf i el d 7- gt h

Jul y 1975.

15. DODD, A. E. A~D HOLUBECKI, Z. The me a s ur e me nt

of di esel exhaust smoke. Mot or I ndus t r y Re-

sear ch Associ at i on, Repor t No. 1965/ 10.

16. KHAN', I. M., WANG, C. H. T. AND LANGRIDGE,

B. E. Coagul at i on a nd c ombus t i on of soot par t i -

cles i n di esel engi nes . Combus t i on a nd Fl ame,

17, 409- 419 (1971).

17. KrtAN, I. M., GREEVES, G. AND PROBERS, D. M.

Pr edi ct i on of soot a nd ni t r i c oxi de concent r a-

t i ons i n di esel e ngi ne exhaust . Sympos i um on

Ai r Pol l ut i on Cont r ol i n Tr ans por t Engi nes , I.

Mech. E., 1971.

COMMENTS

F. L. Dryer, Princeton Universit~j, USA. Some of

t hi s r esear ch has be e n di s cus s ed i n an earl i er art i cl e 1

wher e i t was suggest ed t ha t some of t he i mpr ove me nt

i n smoke r educt i on r eal i zed t hr ough co- i nj ect i on of

wat er a nd f uel may be a r es ul t of s econdar y at omi za-

t i on f r om mi cr o- expl osi ons of a fuel e mul s i on

f or med i n t he di esel i nj ect or. Resul t s r epor t ed her e

wh i c h have at t empt ed t o de t e r mi ne t he t ype a n d

i nt er nal di sper sed pha s e si ze di s t r i but i on of t he

e mul s i on appear t o me t o be less t ha n concl us i ve

si nce t he freezi ng, i mpa e t a t i on a nd di l ut i on t ech-

ni ques us ed mi ght be s us pect ed t o r esul t i n some

336 P OWER SYSTEMS

changes i n t he s ampl ed emul s i on char act er i st i cs.

Has t hi s pr obl e m b e e n i nvest i gat ed, a nd ha ve you

ever added s t abi l i zi ng emul si f i er s t o t he f uel d u r i n g

engi ne t est s t o s ubs t ant i at e whet her fuel e mul s i on

char act er i st i cs are i mpor t ant t o meas ur ed e mi s s i on

r educt i ons ?

i n t he hi gh pr es s ur e par t of i nj ect i on syst em t h a n

by t he pr es ence or abs ence of added e mul s i f yi ng

agent s. Fur t her i nves t i gat i ons are needed t o cl ar i f y

t hese det ai l s.

RE F E RE NCE S

1. D~YER, F. L. (1975). Funda me nt a l concept s on

t he use of e mul s i ons as fuel s. Aer ospace a n d

Mechani cal Sci ences Repor t No. 1224, Pr i nc e t on

Uni ver si t y. Pr e s e nt e d at t he J oi nt We s t e r n / Ce n -

t ral States Sect i on Meet i ng of t he Co mb u s t i o n

I nst i t ut e, San Ant oni o, Texas, Apri l 21, 22.

Authors" Reply. The spr ay dr opl et si ze r esul t s

obt ai ned wi t h f uel onl y, us i ng t he l i qui d Nz t ech-

ni que, agree r e a s ona bl y wi t h t hose pr evi ous l y ob-

t ai ned by s pr ayi ng mol t en wax i nt o a ver y l arge

c ha mbe r whi c h pe r mi t t e d t he wax dr opl et s t o sol i di -

fy i n ai r at a mbi e nt t emper at ur e. It seems unl i kel y,

t her ef or e, t hat f r eezi ng a nd i mpact i on wer e gr eat l y

af f ect i ng t he r esul t s now r epor t ed.

Di l ut i on was neces s ar y i n order t o pe r mi t mea-

s ur ement of t he dr opl et si ze di s t r i but i ons : i n al l

cases, care was t a ke n t o avoi d st i r r i ng act i on d u r i n g

di l ut i on a nd s ubs equent l y. We cons i der t ha t di l ut i on

was of great he l p ( by el i mi nat i ng coal escence) i n

ar r i vi ng at a mor e pr eci se me a s ur e me nt of t he dr opl et

si zes but cannot , at t hi s stage, pr ovi de f or mal evi -

dence t hat it di d not have ot her effects. We can,

however , conf i r m t ha t di l ut i on dur i ng s a mpl i ng ha d

no i nf l uence on t he concl us i ons r el at i ng t o t he st at e

of t he di s per s i on a ppl i e d to t he i nj ect i on pump.

Undi l ut e d sampl es wer e exami ned whi ch, t h o u g h

uns ui t abl e for dr opl et si ze meas ur ement s , s howe d

cl ear l y t he gener al nat ur e of t he di sper si ons. Gr eat er

errors, we cons i der c oul d be due t o our use of spr ays

pr oduced at mu c h l ower pr essur es a nd t e mpe r a t ur e s

t ha n appl i ed i n e ngi ne condi t i ons.

We have not c ons i de r e d a ddi ng emul s i f yi ng agent s

t o t he fuel d u r i n g e ngi ne t est s but some degr ee of

cont r ol over t he degr ee a nd t ype of emul s i f i cat i on

is pr oba bl y exer ci sed b y means of sur f ace act i ve

mat er i al s i nhe r e nt i n t he fuel. Thi s pos s i bi l i t y mi ght

b/~ pur s ued at a l at er stage.

Al so i f we compar e t he emi s s i ons r esul t s a c hi e ve d

by Vi chni evs ky ( who us ed an emul si f i er ) i n t abl e

I I I of our paper wi t h our own dat a t he n i t is a ppa r e nt

t hat si mi l ar r educt i ons of smoke can be a c hi e ve d

wi t h or wi t hout a s t abi l i s i ng emul si f i er . I n t he

abs ence of me c ha ni c a l st i r r i ng met hods , t he f unc t i on

of t he emul s i f i er ma y b e t o ens ur e t hat a uni f or m

wa t e r / f ue l mi xt ur e i s f ed t o t he i nj ect i on pump.

Gi ve n a uni f or m wa t e r / f u e l mi xt ure, t he n t he f i nal

spr ay st at e may be de t e r mi ne d mor e by t he h i g h

rat es of shear a n d f or ma t i on a nd col l apse of cavi t i es

Vito Agosta, Polytechnic Institute of New York,

USA. It is r ecogni zed t ha t f uel mi xt ures yi el d t her -

modyna mi c pr oper t i es t hat are not avai l abl e t o neat

fuel s. Such a n exampl e is t he possi bl e occur ance

of secondar y at omi zat i on i n an oi l -wat er emul s i on.

I n t hese t i mes of ener gy cri si s, it is e nc our a gi ng

t hat wor k is pr ogr es s i ng on t he expl oi t at i on of ne wl y

devel oped pr oper t i es whi c h may offer mor e ef f i ci ent

ener gy ut i l i zat i on wi t h accept abl e e nvi r onme nt a l

i mpact .

Recent t est s on a 65 hor sepower Konat su Di esel

Model 4D92 pr oduc e d encour agi ng resul t s. The

engi ne fuel syst em was modi f i ed t o i nc l ude an

oi l -wat er emul s i f i er ( Pat ent No. 3, 937, 445, V.

Agosta) i n t he pr i ma r y p u mp ci rcui t . Oi l a nd wat er

is s uppl i ed t o t he e ngi ne a nd t he e mul s i on is pr o-

duced i n real t i me whi l e t he engi ne is r unni ng. The

emul si f i er is smal l , a bout 3 / 1 6 i nch i n di amet er

by 3 / 4 i nch l ong; i t is passi ve r equi r i ng no ext er nal

ener gy source. Th e wat er par t i cl es i n t he e mul s i on

wer e meas ur ed b y opt i cal met hods. Sampl es of t he

emul s i on wer e t aken bot h pr i or and aft t he Di esel

i nj ect i on nozzl e. I n bot h t hese cases t he wat er

par t i cl e sizes i n t he e mul s i on wer e about 3 mi cr ons .

The engi ne was r un at maxi mum t or que condi t i ons

at 1600 r pm a nd 18 ~ a nd 22 ~ fuel i nj ect i on t i mi ng.

A series of s t eady st at e t est r uns was t aken. The

par amet er var i ed was t he wat er rat i o i n t he e mul s i on

for ma xi mum t or que r pm a nd t he br ake s peci f i c

fuel c ons umpt i on, BSFC, was det er mi ned. The

BSFC vs. per cent wat er was a r ef l ect ed " S" cur ve.

At a bout 11% wat er r at i o t he BSFC cur ve decr eas ed

and t he n l evel ed off at a bout 20% wat er ratio. The

decr ease i n BSFC was a bout 9. 5% a nd r e ma i ne d

at t hat decr eas ed val ue f r om about 20% t o 30% wat er

ratio. At 35% wat er r at i o i nver s i on occur r ed i n t he

emul s i on, i.e., oi l par t i cl es became s us pe nde d vi a

a mat r i x of wat er.

(NO) x r eadi ngs a nd smoke n u mb e r wer e al so

obt ai ned dur i ng t hes e r uns. (NO), concent r at i ons

of 1600 ppm at zer o per cent wat er rat i o decr eas ed

t o200 p p m at 28% wat er ratio, a nd t he smoke n u mb e r

decr eased f r om 2. 5 t o 1.9.

At 22 ~ fuel i nj ect i on t i mi ng si mi l ar BSFC r esul t s

were obt ai ned but t he (NO)x concent r at i ons var i ed

f r om 1600 ppm t o 740 ppm a nd t he smoke n u mb e r

f r om 3. 0 t o 1.19. At l arge val ues of wat er rat i o, t he

engi ne r pm b e g a n t o hunt . At zero wat er rat i o, t he

engi ne speed var i ed by -*-2 r pm, at 30% wat er rat i o

t he engi ne s peed var i ed by -+20 rpm. It is envi s i ged

t hat t he rol e of e ngi ne s peed i.e., i gni t i on del ay

t i me wi l l be a s i gni f i cant par amet er to be s t udi ed.

Вам также может понравиться

- 50Документ1 страница50dipali2229Оценок пока нет

- Reduction of Pollutants in CI Engine Using Emulsion Fuels To Reduce Overall Traffic-Induced EmissionsДокумент7 страницReduction of Pollutants in CI Engine Using Emulsion Fuels To Reduce Overall Traffic-Induced Emissionsdipali2229Оценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- Crua PHD ThesisДокумент271 страницаCrua PHD ThesisAbdelkader Faklani DouОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Experimental Investigations of Diesel Emulsions As Fuel in Small Direct Injection Compression Ignition EnginesДокумент6 страницExperimental Investigations of Diesel Emulsions As Fuel in Small Direct Injection Compression Ignition Enginesdipali2229Оценок пока нет

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- 36Документ8 страниц36dipali2229Оценок пока нет

- 43Документ5 страниц43dipali2229Оценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- 47Документ6 страниц47dipali2229Оценок пока нет

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- 49Документ11 страниц49dipali2229Оценок пока нет

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- APT Emulsion Fuels: Environmental Management PresentationДокумент33 страницыAPT Emulsion Fuels: Environmental Management Presentationdipali2229Оценок пока нет

- 42Документ8 страниц42dipali2229Оценок пока нет

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- 45Документ12 страниц45dipali2229Оценок пока нет

- 34Документ6 страниц34dipali2229Оценок пока нет