Академический Документы

Профессиональный Документы

Культура Документы

TCP Docs RKPL

Загружено:

upesddn20100 оценок0% нашли этот документ полезным (0 голосов)

312 просмотров113 страницtcp

Оригинальное название

Tcp Docs Rkpl

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документtcp

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

312 просмотров113 страницTCP Docs RKPL

Загружено:

upesddn2010tcp

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 113

REV DATE DESCRIPTION BY APPD REVIEWD

01 07/06/2014 ISSUED FOR APPROVAL

00 15/04/2014 ISSUED FOR APPROVAL

NAME YOGESH JAYRAJ

RAYCHEM RPG KSS

TITLE

DESIGN DOCUMENT FOR TEMPORARY

CATHODIC PROTECTION SYSTEM FOR PHASE-I

CONTRACT NO- DOCUMENT NO -

R1

WORK ORDER NO- MH2145-C000-EL-SPC-SPC-0025, DATED 2/5/13

06-10-1403-DD-PH1

EPMC SERVICES FOR REWARI-KANPUR

PIPELINE PROJECT

OWNER

HINDUSTAN PETROLEUM CORPORATION LIMITED

MAIN CONTRACTOR

KSS Petron Private Limited

(Formerly KazStroy Service Infrastructure India Pvt.Ltd)

CONSULTANT

WORLEYPARSONS SEA INDIA PVT. LTD.

CP CONTRACTOR

RAYCHEM RPG (P) LIMITED

WORLEYPARSONS APPROVAL

Approved by

NAME SIGN

DESIGN DOCUMENT FOR TEMPORARY

CATHODIC PROTECTION SYSTEM FOR

PHASE-I

EPMC SERVICES FOR REWARI-KANPUR PIPELINE PROJECT

06-10-1403-DD-PH1, Rev-01 Page 2 of 113

Contents

1.0 INTRODUCTION .................................................................................................................................. 4

2.0 SCOPE ................................................................................................................................................. 4

3.0 ABBREVATIONS ................................................................................................................................. 5

4.0 SYSTEM OVERVIEW .......................................................................................................................... 7

5.0 CORROSION SURVEY REPORT ....................................................................................................... 8

5.1 OBJECTIVE OF THE SURVEY ........................................................................................................... 8

5.2 SCOPE OF WORK .............................................................................................................................. 8

5.3 SOIL RESISTIVITY SURVEY .............................................................................................................. 8

5.4 SOIL RESISTIVITY VS. DEGREE OF CORROSIVITY ....................................................................... 9

5.5 SOIL SAMPLES................................................................................................................................... 9

5.6 ADDITIONAL DATA COLLECTION ................................................................................................... 11

5.7 SURVEY RESULT ............................................................................................................................. 13

6.0 DESIGN DATA & CRITERIA ............................................................................................................. 13

6.1 INTRODUCTION ................................................................................................................................ 13

6.2 PIPELINE DETAILS ........................................................................................................................... 13

6.3 CATHODIC PROTECTION SYSTEM DESIGN LIFE ........................................................................ 13

6.4 CODES AND STANDARDS .............................................................................................................. 13

6.5 PHILOSOPHY OF CATHODIC PROTECTION SYSTEM ................................................................. 14

6.6 PROTECTION CURRENT DENSITY ................................................................................................ 15

6.7 CATHODIC PROTECTION DESIGN CRITERIA ............................................................................... 15

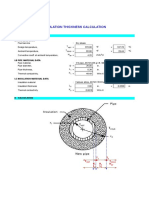

7.0 DESIGN CALCULATION ................................................................................................................... 16

7.1 TOTAL CURRENT REQUIREMENT ................................................................................................. 16

7.2 CURRENT REQUIREMENT .............................................................................................................. 17

7.3 ANODE WEIGHT REQUIREMENT ................................................................................................... 18

7.4 HORIZONTAL GROUNDBED RESISTANCE ................................................................................... 19

8.0 EHV / HV CROSSINGS ..................................................................................................................... 23

9.0 CATHODIC PROTECTION AT CASED CROSSINGS ...................................................................... 27

9.1 CATHODIC PROTECTION FOR CARRIER PIPE ............................................................................ 27

10.0 INSULATION JOINTS ...................................................................................................................... 30

11.0 EARTHING ELECTRODE ............................................................................................................... 30

12.0 POLARISATION COUPONS ........................................................................................................... 31

13.0 REFERENCE CELL ACCESS POINTS........................................................................................... 31

14.0 ER PROBE & READER ................................................................................................................... 31

DESIGN DOCUMENT FOR TEMPORARY

CATHODIC PROTECTION SYSTEM FOR

PHASE-I

EPMC SERVICES FOR REWARI-KANPUR PIPELINE PROJECT

06-10-1403-DD-PH1, Rev-01 Page 3 of 113

15.0 TEST STATION ............................................................................................................................... 32

16.0 CABLE LAYING DETAILS ............................................................................................................... 50

17.0 CABLE TO PIPE CONNECTIONS .................................................................................................. 50

18.0 INSTALLATION PROCEDURE ....................................................................................................... 51

18.1 FOR TEST STATION ....................................................................................................................... 51

18.2 FOR SACRIFICIAL ANODES .......................................................................................................... 55

18.3 FOR CABLE LAYING....................................................................................................................... 59

18.4 FOR SURGE DIVERTER ................................................................................................................ 63

18.5 FOR THERMIT WELD ..................................................................................................................... 66

18.6 FOR PIN BRAZING .......................................................................................................................... 71

18.7 FOR POLARISATION CELL ............................................................................................................ 75

18.8 FOR PERMANENT REFERENCE CELL ......................................................................................... 78

18.9 FOR POLARISATION COUPON ..................................................................................................... 82

18.10 FOR ZINC RIBBON ANODES ....................................................................................................... 85

18.11 FOR ER PROBE ............................................................................................................................ 88

19.0 INCOMING MATERIAL INSPECTION REPORT ............................................................................ 91

20.0 STANDARD QAP ............................................................................................................................. 92

21.0 RECORD OF CALIBRATION OF MEASURING INSTRUMENTS .................................................. 94

22.0 INTERFERENCE DETECTION AND MITIGATION ........................................................................ 95

22.1 PROCEDURE FOR AC INTERFERENCE SURVEY ...................................................................... 96

22.2 PROCEDURE FOR DC INTERFERENCE SURVEY ...................................................................... 99

23.0 TESTING AND COMMISIONING .................................................................................................. 105

24.0 SYSTEM MONITORING ................................................................................................................ 109

25.0 BILL OF MATERIAL ....................................................................................................................... 111

26.0 REFERENCE DRAWING LIST ..................................................................................................... 113

DESIGN DOCUMENT FOR TEMPORARY

CATHODIC PROTECTION SYSTEM FOR

PHASE-I

EPMC SERVICES FOR REWARI-KANPUR PIPELINE PROJECT

06-10-1403-DD-PH1, Rev-01 Page 4 of 113

1.0 INTRODUCTION

M/s Hindustan Petroleum Corporation Limited is setting up Multi-product pipeline of approx.

441 Km of 18 Dia from Rewar Dispatch Terminal to Kanpur Receipt terminal. The Entire

Pipeline works is divided into two different parts. The details are as follows:

PART Section

Approx.

Length (Km)

Dia.

(inch)

Part-1 Rewari Dispatch terminal to SV-6(Ch:228 km) 228 km 18

Part-2 SV-6 (Ch:228 km) to Receipt terminal Kanpur 213 km 18

M/s. HPCL is awarded the Contract to M/s KSS Petron Private Limited undertake

complete construction of pipeline.

M/s KSS Petron Private Limited awards Cathodic Protection works to M/s. Raychem RPG

Pvt. Ltd for Pipelines in Part I & II.

It is intended to provide a Temporary and Permanent Cathodic Protection System to these

Pipelines.

This document prepared by Raychem RPG Pvt. Ltd. present the design & Calculation

for the Temporary Cathodic Protection system using Galvanic Sacrificial anodes for

Part-I Pipeline.

2.0 SCOPE

The scope of work includes Corrosion survey, Design Detailed Engineering, supply,

Installation, Quality Assurance and Quality Control, Testing and commissioning of the

Temporary Cathodic Protection system with galvanic anode to protect external surface of the

pipeline against corrosion for the period of 2years or till commissioning of the Permanent

Cathodic Protection System whichever is later and all other common CP activities such as

measuring the soil resistivity along ROU, collection of CP related data along the ROU as per

specification no:MH2145-C000-EL-SPC-0025 RevA.

DESIGN DOCUMENT FOR TEMPORARY

CATHODIC PROTECTION SYSTEM FOR

PHASE-I

EPMC SERVICES FOR REWARI-KANPUR PIPELINE PROJECT

06-10-1403-DD-PH1, Rev-01 Page 5 of 113

3.0 ABBREVATIONS

SN Terms Description

1 Anode

An electrode placed in the electrolyte to apply Cathodic

protection to the structure

2 Backfill

Low resistance material surrounding the anode to reduce the

anode to electrolyte resistance

3 Cathode The structure that is to be protected by Cathodic protection

4

Cathodic

Protection

The prevention or reduction of corrosion of metal by making the

metal the cathode in a galvanic or electrolytic cell

5 Corrosion

The deterioration of metal caused by its electrochemical reaction

with its environment

6

Corrosion

Current

The current flowing in a corrosion cell & which is

electrochemically equivalent to the anode & cathode reactions

7 Current Density

Current flowing into the cathode divided by cathode surface

area.

8 Electrolyte

A liquid or the liquid component in a composite material such as

soil, in which electric current may flow by ionic charge transfer

9

Instantaneous

off potential

A potential substantially free of voltage gradients

10 Polarization

A change in the potential of a metal from its natural steady state

value as a result of current flow

11

Polarized

Potential

The potential value of a metal after polarization reaches the

steady state

12

Reference

Electrode

An electrode that has a stable potential in one or more

electrolytes at a given temperature, thus enabling it to be used

for the measurement of other reference electrode

13 Structure A metal which has a surface in contact with an electrolyte

14 Dia Diameter

15 Ch Chainage

16 Km Kilometer

17 m Meter

18 mm Millimeter

19 Nos Number

20 V Voltage

DESIGN DOCUMENT FOR TEMPORARY

CATHODIC PROTECTION SYSTEM FOR

PHASE-I

EPMC SERVICES FOR REWARI-KANPUR PIPELINE PROJECT

06-10-1403-DD-PH1, Rev-01 Page 6 of 113

SN Terms Description

21 mV Milivolts

21 m2 Square meter

22 mg miligrams

23 Amps Ampere

24 PSP Pipe to Soil potential

25 CPS Cathodic Protection Station

26 HPCL Hindustan Petroleum Corporation Limited

27 KazStroy KSS Petron Private Limited

28 Raychem RPG Raychem RPG Pvt. Ltd.

DESIGN DOCUMENT FOR TEMPORARY

CATHODIC PROTECTION SYSTEM FOR

PHASE-I

EPMC SERVICES FOR REWARI-KANPUR PIPELINE PROJECT

06-10-1403-DD-PH1, Rev-01 Page 7 of 113

4.0 SYSTEM OVERVIEW

1) For RKPL Ph-1 Rewari Dispatch terminal to SV-6(Ch:228 km)Pipeline Section:

1 Design Life 2 Year or till PCP commissioning

2

P

i

p

e

l

i

n

e

D

e

t

a

i

l

s

RKPL Ph-1 to Murudeshwar

Dia (m) Length (m)

0.457 228

P

r

o

t

e

c

t

i

o

n

C

u

r

r

e

n

t

d

e

n

s

i

t

y

Pipeline Surrounding Current Density (mA/m

2

)

Soil Resistivity < 10 ohm-m 0.075

Soil Resistivity 10 ohm-m to 100 ohm- m 0.055

Soil Resistivity > 100 ohm-m 0.035

3

Total Current

Requirement

Dia

(m)

Length

(m)

Surface

Area (m

2

)

Current

Density

(mA/m

2

)

Current

required

(Amps)

Type of

Coating

0.457 228000 327341.3 0.055 23.40

3PE

coated

4

Total

nos of Mg

anodes

Total

Nos.

Type

Net Weight

of Anode (kg)

Dimension (mm)

Bare Prepacked Bare Prepacked

458

Low

Potential

2.5 40 approx.

38 x 38 x

1000 (Long)

150 (Dia) x

1500 (Long)

12

Low

Potential

10 90 approx.

76 x 76 x

1000 (Long)

200 (Dia) x

2000 (Long)

6 Configuration of Anode Installation Horizontal Installation

7

Distance between anode

from edge of pipeline

Mg Anode (mm)

Zn Anode

(mm)

Zn ribbon Anode for HT

line crossing (mm)

5000 2000 500

8 Zinc ribbon anode proposed for HT line crossing 116 mtr

9

Test Station

Proposed

Normal Size (Nos.) Pol cell (Nos.) ICCP (Nos.) CTSU (Nos.)

245 17 10 12

10 Cables Copper Conductor PVC/PVC Cable

11 Polarisation Coupon with Permanent Reference Cell (Cu-CuSO4) 02 Nos.

12

Polarisation Cell

Proposed

Total Nos. Type Rating

17 Solid-State 3.7 KA

DESIGN DOCUMENT FOR TEMPORARY

CATHODIC PROTECTION SYSTEM FOR

PHASE-I

EPMC SERVICES FOR REWARI-KANPUR PIPELINE PROJECT

06-10-1403-DD-PH1, Rev-01 Page 8 of 113

5.0 CORROSION SURVEY REPORT

5. 1 OBJECTIVE OF THE SURVEY

The survey aim to generate sufficient data and correlated information which will provide the

basis for designing of cathodic protection system. The same information shall be used as

input parameters with which the C.P. system has to eventually cope with.

The basic data and generated information shall be comprehensively analysied and

interpreted to lay down the guidelines for the C.P. system Design and Engineering.

5. 2 SCOPE OF WORK

The Corrosion Survey includes,

Soil Resisitivity survey

Additional data collection to generate design data for evaluation of interaction

possibilities due to presence of other services in ROU.

Soil samples shall be collected on an average for every 10 km along ROU.

5. 3 SOIL RESISTIVITY SURVEY

The Soil resistivity measurements have been carried out using 4 pins WENNER method. The

measurements were carried out at pin spacing of 1, 1.5 and 2.5 m.

INSTRUMENT USED FOR THE SURVEY

Soil Resistivity meter

Make: Nilsson Electrical Lab, INC. USA/MC Miller USA, NILSSON 400 & Motwane-DET-20

RESISTIVITY CALCULATIONS

d = 2 x x a x R

Where:

a = Consecutive distance in cm

R = Resistance measured as indicated by unit in ohms

d = Resistivity (ohm-cm)

DESIGN DOCUMENT FOR TEMPORARY

CATHODIC PROTECTION SYSTEM FOR

PHASE-I

EPMC SERVICES FOR REWARI-KANPUR PIPELINE PROJECT

06-10-1403-DD-PH1, Rev-01 Page 9 of 113

5. 4 SOIL RESISTIVITY VS. DEGREE OF CORROSIVITY

Soil resistivity (ohm-m) Degree of corrosivity

0-5 Very corrosive

5-10 Corrosive

10-20 Moderately Corrosive

20-100 Mildly Corrosive

Above 100 Negligible

As per the Soil Resistivity report attached in Annexure A.

5. 5 SOIL SAMPLES

Soil samples have been collected along the Row for analysis. Samples were collected from

two depths (1.0 M) and (2.0 M) of pipeline ROW at every 10 Km. Exact location shall be

decided at site depending on the type of soil, soil resistivity and in consultation with Owner

or his representative.

The major constituents that accelerates corrosion are chlorides, sulphates and the acidity pH

of the soil.

The effect of chlorides, sulphates and pH on corrosion of Buried Steel Pipelines.

(Refer Peabody control of pipeline corrosion second edition):

Sr. No. COMPONENT CONCENTRATION DEGREE OF CORROSITIVITY

1 Chloride

> 5000 PPM Severe

1500-5000 PPM Considerable

<500 PPM Threshold

2 Sulphate

> 10000 PPM Severe

1500-10000 PPM Considerable

150-1500 PPM Positive

0-150 PPM Negligible

3 PH

2

< 5.5 Severe

5.5-6.5 Moderate

6.5-7.5 Neutral

>7.5 None (Alkaline)

DESIGN DOCUMENT FOR TEMPORARY

CATHODIC PROTECTION SYSTEM FOR

PHASE-I

EPMC SERVICES FOR REWARI-KANPUR PIPELINE PROJECT

06-10-1403-DD-PH1, Rev-01 Page 10 of 113

Chainage wise chemical analysis report readings are tabulated below:

Sr.

No.

Chainage

(Km)

Chloride (ppm) Sulphate (ppm) pH (Digital mtr)

1.0 Mtr 2.0 Mtr 1.0 Mtr 2.0 Mtr 1.0 Mtr 2.0 Mtr

1 0 749 649 93 86 7.13 6.95

2 10 949 949 33 17 7.18 7.23

3 20 1199 1449 123 153 6.93 7.48

4 30 200 150 167 93 7.03 7.96

5 40 120 180 123 153 6.93 7.48

6 50 250 210 167 93 7.03 7.96

7 60 135 140 123 153 6.93 7.48

8 70 899 949 167 93 7.03 7.96

9 80 749 899 123 153 6.93 7.48

10 90 300 450 33 27 7.18 7.23

11 100 227 230 123 153 6.93 7.48

12 110 999 1049 18 9 7.4 4.14

13 120 1199 1449 123 153 6.93 7.48

14 130 200 250 167 93 7.03 7.69

15 140 649 699 227 212 7.6 7.58

16 150 600 500 19 41 7.01 7.05

17 160 200 150 5 6 8.08 8.03

18 170 250 899 17 95 7.31 7.21

19 180 500 350 123 153 6.93 7.48

20 190 150 150 123 153 6.93 7.48

21 200 250 253 167 93 7.03 7.96

22 210 200 300 123 153 6.93 7.48

23 220 200 250 167 93 7.03 7.96

24 228 699 550 123 153 6.93 7.48

As per the chemical analysis report attached in Annexure A we can conclude the following

points:

The Chloride content was less than 520 PPM.

The Sulphate content was less than 109 PPM.

The pH value varies from 6.93 to 8.8

The soil resistivity report, its graphs and soil samples chemical analysis report and

its graph are attached in Annexure A.

DESIGN DOCUMENT FOR TEMPORARY

CATHODIC PROTECTION SYSTEM FOR

PHASE-I

EPMC SERVICES FOR REWARI-KANPUR PIPELINE PROJECT

06-10-1403-DD-PH1, Rev-01 Page 11 of 113

5. 6 ADDITIONAL DATA COLLECTION

Additional data has been collected from Various sources like owner, consultant, contractor,

aligment sheet and from the field survey.

List of Major Road, River & Canal Crossings IN Phase-1 are as follows:

1) RKPL Ph-1 Rewari Dispatch Terminal to SV-4, Ch:228 km:

MAJOR RAILWAY CROSSING

Sr.

No.

Chainage

(km)

DESCRIPTION

Length Of

Crossing (Km)

1 98.111 RAILWAY XING (NCR) 35

2 141.972 WEASTERN CENTRAL RAILWAY 55

3 158.470 MATHUTA ACHNERA RAILWAY XING 30

4 162.395 CENTRAL RAILWAY CROSSING 47

5 163.213 RAILWAY XING-MATHURA TO FARAH 47

6 164.731 RAILWAY XING-MATHURA TO FARAH 47

7 165.759 RAILWAY XING-MATHURA TO FARAH 47

8 216.534 NORTHAN RAILWAY MAINLINE XING 74

2) RKPL Ph-1 Rewari Dispatch Terminal to SV-4, Ch:228 km:

MAJOR HT LINE CROSSING

Sr. No. Chainage (km) DESCRIPTION

1 2.885 110 KVA HT CROSSING

2 5.151 132 KVA HT LINE CROSSING

3 10.765

ASPHALTED ROAD GUJAR MAJARI TO GUJARI & 132 KVA

CROSSING

4 19.774 220 KVA HT LINE XING

5 33.054 220 KVA HT LINE XING NEAR BRICK KILN

6 34.248 220 KVA HT XING

7 34.850 110 KVA HT CROSSING, NEAR CHAMBORDA VILLAGE

8 63.010 400 KVA HT LINE XING

9 134.851 220KVA LINE XING NEAR ASPHALTED ROAD

DESIGN DOCUMENT FOR TEMPORARY

CATHODIC PROTECTION SYSTEM FOR

PHASE-I

EPMC SERVICES FOR REWARI-KANPUR PIPELINE PROJECT

06-10-1403-DD-PH1, Rev-01 Page 12 of 113

MAJOR HT LINE CROSSING

Sr. No. Chainage (km) DESCRIPTION

10 145.049 400KV HT LINE XING

11 158.270 400 KV HT LINE XING

12 166.385 440KVA HT LINE XING

13 177.354 220KV HT XING NEAR KHADERA VILLAGE

14 197.417 400 KVA HT LINE XING

15 199.079 200 KV HT LINE XING

16 201.754 220 KVA HT LINE XING

17 217.007 400KVA HT XING, NEAR GOWAL VILLAGE

3) RKPL Ph-1 Rewari Dispatch Terminal to SV-4, Ch:228 km:

MAJOR ROAD CROSSING

Sr. No. Chainage (km) Crossing

1 0.577 NH-71

2 3.387 NH-08

3 4.018 NATIONAL HIGHWAY JAIPUR-DELHI

4 33.876 STATE HIGHWAY-25

5 62.608 SH-35 XING

6 82.564 SH-45

7 92.680 STATE HIGHWAY-22

8 99.961 SH-14 XING

9 122.770 STATE HIGHWAY-14

10 136.215 STATE HIGHWAY-43

11

140.377 STATE HIGHWAY-24

12

161.957 NH-02 Farah To Mathura

13

226.000 STATE HIGHWAY-31

DESIGN DOCUMENT FOR TEMPORARY

CATHODIC PROTECTION SYSTEM FOR

PHASE-I

EPMC SERVICES FOR REWARI-KANPUR PIPELINE PROJECT

06-10-1403-DD-PH1, Rev-01 Page 13 of 113

5. 7 SURVEY RESULT

Soil resistivity report and graphs is attached in Annexure-A.

Average Soil Resistivity at 2m depth in Phase 1 is 22.23 ohms-m

6.0 DESIGN DATA & CRITERIA

6. 1 INTRODUCTION

The Tender Specifications indicate the type of Cathodic Protection System, Protection criteria

and input parameters for detailed design of the Cathodic Protection System.

The intent of this section is to propose design data and criteria for the Temporary Cathodic

Protection System.

6. 2 PIPELINE DETAILS

PART Section

Approx.

Length (Km)

Dia.

(inch)

Part-1 Rewari Dispatch terminal to SV-6(Ch:228 km) 228 km 18

6. 3 CATHODIC PROTECTION SYSTEM DESIGN LIFE

In accordance with the project specification, the Cathodic Protection System shall have a

design life of two year or till the commissioning of the PCP system whichever is later.

6. 4 CODES AND STANDARDS

The Design generally conforms to the Specification no:MH2145-C000-EL-SPC-0025 RevA

The design, selection and installation of equipment and materials shall also conform to the

requirements of the latest relevant applicable standards of:

NACE RP-0169 Recommended Practice control of external corrosion on

underground or submerged metallic piping systems

NACE RP-0286 Recommended Practice The electrical isolation of catholically

protected pipelines

DESIGN DOCUMENT FOR TEMPORARY

CATHODIC PROTECTION SYSTEM FOR

PHASE-I

EPMC SERVICES FOR REWARI-KANPUR PIPELINE PROJECT

06-10-1403-DD-PH1, Rev-01 Page 14 of 113

NACE RP-10A190 Measurement technique related to criteria for CP of Underground

or Submerged steel piping system

NACE RP-0177 Recommended Practice Mitigation of AC and Lighting Effects

on Metallic Structures and Corrosion Control Systems

NACE No. 54276 Cathodic Protection Monitoring For Buried Pipelines

NACE RP-0572 Recommended Practice Design, Installation, Operation and of

Impressed Current Deep Ground Beds

DNV RP-B403 Recommended Practice Monitoring of CP System

DNV RP-B401 Recommended Practice Cathodic Protection Design

IS 8062 Recommended Practice ICCP for Underground Pipe

VDE 0150 Protection against Corrosion due to stray current from DC

Installation

IS: 1554 Part1 PVC insulated (Heavy Duty) Cables.

BS:7361 Part I Code of Practice for Cathodic Protection for Land and

Marine applications

6. 5 PHILOSOPHY OF CATHODIC PROTECTION SYSTEM

As provided in the enquiry specifications, the cathodic protection system shall be a Galvanic/

Sacrificial Anodes system and shall be designed using pre-packed Magnesium anodes. The

prepacked Magnesium anodes shall be installed in a horizontal configuration in a trench of

depth 2 M. to ensure that it reach moist soil and it should be 2 to 5 M. away from the edge of

pipeline.Considering Minimum 2 Nos. of 2.5 Kg prepacked magnesium anode for soil

resistivity upto 90 ohm-M. and Minimum 3 Nos. of 2.5 Kg prepacked magnesium anode for

soil resistivity above 90 ohm-M. and upto 110 ohm-M.,for carrier pipe protection along the

pipeline route at every 1 km interval. However any unprotected Pipeline area is observed

during construction the same shall be protected by providing additional anodes.

DESIGN DOCUMENT FOR TEMPORARY

CATHODIC PROTECTION SYSTEM FOR

PHASE-I

EPMC SERVICES FOR REWARI-KANPUR PIPELINE PROJECT

06-10-1403-DD-PH1, Rev-01 Page 15 of 113

6. 6 PROTECTION CURRENT DENSITY

The Pipeline is coated with 3 layer PE Coating and the minimum protective current density for

Temporary Cathodic Protection system as per the Specification no: MH2145-C000-EL-SPC-

0025 RevA is as given below.

Pipeline Surrounding

Minimum Protection

Current Density (mA / m

2

)

Soil Resistivity < 10 ohm-m 0.075

Soil Resistivity 10 ohm-m to 100 ohm-m 0.055

Soil Resistivity > 100 ohm-m 0.035

A safety margin of 1.3 i.e. 30% has been provided for in the current calculations over and

above the specified protective current density.

Soil Resistivity in phase 1 of RKPL is in the range of 10 ohm-m to 100 ohm-m, The Average

soil resistivity at 2 m depth is 22.23 ohms-m in Phase1 of RKPL, hence current density of

0.055 mA / m

2

is considered.

6. 7 CATHODIC PROTECTION DESIGN CRITERIA

Cathodic Protection system shall be designed to meet the following any one of the criteria:

The pipe to Soil Potential measurements shall be in between (-) 0. 95 V ON to (-) 1.5

V ON as measured between the pipe surface and a saturated copper - copper sulfate

reference electrode.

The pipe to Soil Potential measurements shall be in between (-) 0. 95 V (IR Free) to (-)

1.18 V (IR Free) as measured between the pipe surface and a saturated copper -

copper sulfate reference electrode.

A positive potential swing of 100 mV or more shall be considered as the criteria for

presence of an interaction / interference situation requiring investigation and

incorporation of mitigation measures.

DESIGN DOCUMENT FOR TEMPORARY

CATHODIC PROTECTION SYSTEM FOR

PHASE-I

EPMC SERVICES FOR REWARI-KANPUR PIPELINE PROJECT

06-10-1403-DD-PH1, Rev-01 Page 16 of 113

7.0 DESIGN CALCULATION

The following calculations have been used to design the Temporary Cathodic Protection

system.

7. 1 TOTAL CURRENT REQUIREMENT

Surface Area

Where:

S

a

=

Surface area of Pipeline

(m

2

)

D = Diameter of pipeline (m)

L = Length of pipeline (m)

The surface area calculations are tabulated as under:

Pipeline Section

Dia.

(m)

Pipeline

Length (m)

Coating

Surface

Area (m

2

)

Rewari Dispatch terminal to SV-

6(Ch:228 km)

0.457 228000 3LPE 327341.3

DESIGN DOCUMENT FOR TEMPORARY

CATHODIC PROTECTION SYSTEM FOR

PHASE-I

EPMC SERVICES FOR REWARI-KANPUR PIPELINE PROJECT

06-10-1403-DD-PH1, Rev-01 Page 17 of 113

7. 2 CURRENT REQUIREMENT

The Pipeline is coated with 3 layer PE Coating and the current density considered for the

Temporary Cathodic Protection design is 0.055 mA / m

2

Based on the above current density, the total current requirement as per soil resistivity span is

calculated as follows:

Where

I

t

= C.P. current requirement (Amp)

S

a

= Surface area of Pipeline (m

2

)

C

d

= C.P. protective current density (mA/m

2

)

1.3 = Safety Margin

Chainage

Span

Soil

resistivity

(Ohms-m)

Dia

(m)

Pipeline

Length (m)

Surface

Area (m

2

)

Protective

Current Density

(mA/ m

2

)

Current

Required

(Amp.)

Rewari Dispatch terminal to SV-6(Ch:228 km)

0.00-228 Km 22.23 0.457 228000 327341.3 0.055 23.40

DESIGN DOCUMENT FOR TEMPORARY

CATHODIC PROTECTION SYSTEM FOR

PHASE-I

EPMC SERVICES FOR REWARI-KANPUR PIPELINE PROJECT

06-10-1403-DD-PH1, Rev-01 Page 18 of 113

7. 3 ANODE WEIGHT REQUIREMENT

The total anode weight requirement is calculated using the following formula:

Where

W

t

= Total Anode Weight (Kg.)

I

t

= C.P. current requirement (Amps)

C

t

=

Consumption Rate of Anode (7.9 Kg/Amp-Year)

L = Design Life (2 years)

U

f

= Anode Utilisation factor (0.85)

Pipeline

Section

Individual

Anode

Weight

(Kgs) (W)

Total

Current

(Amp)

(I

t

)

Total Anode

Requirement

(Kgs)

(W

t

)

Total Anode

Requirement

(Nos)

(N

a

)

Total No.

of Anode

Proposed

(Nos)

Rewari Dispatch terminal

to SV-6(Ch:228 km)

2.5 23.40 434.96 174 458

DESIGN DOCUMENT FOR TEMPORARY

CATHODIC PROTECTION SYSTEM FOR

PHASE-I

EPMC SERVICES FOR REWARI-KANPUR PIPELINE PROJECT

06-10-1403-DD-PH1, Rev-01 Page 19 of 113

7. 4 HORIZONTAL GROUNDBED RESISTANCE

a) Resistance of Single horizontal anode

Where:

R

ah

= Resistance of Single horizontal anode

P

s

= Soil Resistivity in (5 ohm-m)

L = Length of prepackaged anode in (1.5 m)

d = diameter of prepackaged anode in (0.15 m)

t = Depth of Anode in (2 m)

R

ah

= 1.068 ohms

b) Resistance of multiple horizontal

Where

R

gbh

= Resistance of multiple horizontal anodes in (ohms)

R

ah

= Resistivity of single horizontal anode in (1.068 ohms)

N = Number of anodes (2 Nos.)

F = Crowding Factor (1.134)

R

gbh

=0.606 ohms

c) Crowing Factor

Where:

F = Crowding Factor

R

ah

= Resistance of Single horizontal anodes (1.068 ohms)

P

s

= Soil Resistivity in (5 ohm-mtr.)

S

= End to End spacing of Anode (3 mtr.)

N = Number of Anodes (2 Nos.)

F=1.134

DESIGN DOCUMENT FOR TEMPORARY

CATHODIC PROTECTION SYSTEM FOR

PHASE-I

EPMC SERVICES FOR REWARI-KANPUR PIPELINE PROJECT

06-10-1403-DD-PH1, Rev-01 Page 20 of 113

d) Cable Resistance

For the ground bed using 1 horizontal anode, the longest anode tail cable of 9 m ofPVC/PVC

single core copper conductor 6mm

2

cable shall be used.

The cable resistance of copper conductor single core 6 mm

2

size is 3.08 ohm/Km.

Therefore the cable resistance for 1 No. Anode tail cables of 9 mtr. Length shall be,

Where:

R

C

= Total Cable Resistance (ohms)

R

a

= Cable Resistance (0.00308 ohm-m)

L = Length of the Cable (9 m)

N = Number of anodes (2 Nos.)

R

C =

0.0139 ohms

e) Total Circuit Resistance

The total circuit resistance for each anode bed

Where:

R

t

= Total circuit resistance (ohms)

R

gbh

= Resistance of multiple horizontal anodes (0.606 ohms)

R

C

= Total Cable Resistance (0.0139 ohms)

R

t

= 0.620 ohms

f) The current output at each ground bed

Where:

I= Current Output per anode bed (Amps.)

V= Driving potential for Mg anodes with line polarized is

=1.55 - 0.95 = 0.6 V

R

t

= Total circuit resistance (0.620 ohms)

I=0.967 Amps

DESIGN DOCUMENT FOR TEMPORARY

CATHODIC PROTECTION SYSTEM FOR

PHASE-I

EPMC SERVICES FOR REWARI-KANPUR PIPELINE PROJECT

06-10-1403-DD-PH1, Rev-01 Page 21 of 113

Pipeline Coverage by Anodes at various Soil Resistivities for RKPL is as below:

Soil Resistivity

range Ohm-m

Using 2Nos of MG anode

Using 3Nos of MG anode

Total Circuit

Resistance

Current

O/P of

Anode

(Amps)

KM

Coverage

of Pipeline

Total Circuit

Resistance

Current

O/P of

Anode

(Amps)

KM

Coverage

of Pipeline

1 0.135 4.439 43.26 0.104 5.74 55.98

1-3 0.377 1.58 15.48 0.294 2.034 19.83

3-5 0.620 0.967 9.42 0.485 1.23 12.05

5-8 0.984 0.610 5.94 0.771 0.778 7.59

8-10 1.227 0.489 4.77 0.961 0.624 6.08

10-15 1.833 0.327 3.19 1.43 0.417 4.07

15-20 2.44 0.246 2.40 1.91 0.314 3.06

20-25 3.04 0.197 1.92 2.389 0.251 2.45

25-30 3.65 0.164 1.60 2.86 0.209 2.04

30-35 4.25 0.141 1.37 3.34 0.180 1.75

35-40 4.86 0.123 1.20 3.81 0.157 1.53

40-50 6.07 0.099 0.96 4.77 0.126 1.23

50-60 7.29 0.082 0.80 5.722 0.105 1.02

Hence, The anode ground bed locations and the number of anodes to be used for each location

has been decided considering 2 Nos. of 2.5 Kg prepacked magnesium anode for soil resistivity

upto 90 ohm-m. and 3 Nos. of 2.5 Kg prpacked magnesium anode for soil resistivity above 90

ohm-m and upto 110 ohm-m, for carrier pipe protection along the pipeline route at every 1

km interval.

However any unprotected pipeline area is obsreved during construction time, The same shall

be protected by providing additional anodes.

R-1

DESIGN DOCUMENT FOR TEMPORARY

CATHODIC PROTECTION SYSTEM FOR

PHASE-I

EPMC SERVICES FOR REWARI-KANPUR PIPELINE PROJECT

06-10-1403-DD-PH1, Rev-01 Page 22 of 113

The ground bed details are mentioned in the enclosed Schedule. The actual chainages may

vary as per actual site conditions at the time of selection of locations during installation.

DESIGN DOCUMENT FOR TEMPORARY

CATHODIC PROTECTION SYSTEM FOR

PHASE-I

EPMC SERVICES FOR REWARI-KANPUR PIPELINE PROJECT

06-10-1403-DD-PH1, Rev-01 Page 23 of 113

8.0 EHV / HV CROSSINGS

Zinc earthing anode & polarization cell shall be provided as per Project Specification MH2145-

C000-EL-SPC-0025 RevA.

For earthing of pipeline at the 66KV and above HT Line crossings, at 1 km interval of parallel

run (if horizontal distance of HT line is within 25 m. of the pipeline) and at the departure

points from the parallel run for earthing purpose Zinc ribbon anode so that the earthing

resistance is restricted within acceptable limit of 5 ohm.

The total meter of Zinc ribbon anode proposed (Size 12.7 X 14.28 mm) = 110 m

Sample calculation of resistance of Horizontal anode bed for Zinc Ribbon anode:

Where:

R

b

= Anode to Earth resistance (ohm)

P

s

= Soil Resistivity in ohm-M (2.885 ohm-m)

L = Length of prepackaged anode in m (3 m)

D = Diameter of prepackaged anode in m (0.15 m)

S = Twice the Depth of Anode (4 m)

R

b

=2.425 ohms

ii) Resistance of the anode to backfill:

Where:

R

bs

= Resistance of anode to backfill in ohms (ohms)

P

s

= Resistivity of backfill material (0.5 ohm-m)

L = Length of anode in m (3 m)

d = Effective diameter of anode in m (0.0151 m)

R

bs

=0.108 ohms

DESIGN DOCUMENT FOR TEMPORARY

CATHODIC PROTECTION SYSTEM FOR

PHASE-I

EPMC SERVICES FOR REWARI-KANPUR PIPELINE PROJECT

06-10-1403-DD-PH1, Rev-01 Page 24 of 113

iii) Cable resistance:

For the groundbed using 1 Zinc Ribbon anode of 10 m. Length, the anode tail cable of 8 m.

Of PVC/PVC single core copper conductor 25 mm

2

cable shall be used.

The cable resistance of copper conductor single core 25 mm

2

size is 0.727 ohm/Km.

Therefore, the cable resistance for 1 No. anode tail cables of 8 m. Length shall be calculated

as follow:

Where:

R

C

= Total Cable Resistance (ohms)

R

a

= Cable Resistance (0.000727 ohm-m)

L = Length of the Cable (8 m)

R

c

=0.0058 ohms

iv) Total circuit resistance:

Where:

R

T

= Total circuit resistance (ohms)

R

b

= Resistance of horizontal anode to electrolyte (2.425 ohms)

R

bs

= Resistance of Anode to backfill (0.108 ohms)

R

C

= Cable Resistance (0.0058 ohms)

N = Number of Anodes (2 No)

R

T

=1.270 ohms

R-1

DESIGN DOCUMENT FOR TEMPORARY

CATHODIC PROTECTION SYSTEM FOR

PHASE-I

EPMC SERVICES FOR REWARI-KANPUR PIPELINE PROJECT

06-10-1403-DD-PH1, Rev-01 Page 26 of 113

Detail calculation for zinc grounding anode for HT Line Xings are tabulated below:

SN

Chainage

(km)

Soil

Resistivit

y (Ohm-

M)

No. of

Anode

s (Zn)

Length

of the

Pre-

Packe

d

Anode

(Mt)

Anode

Dia

(mt)

Length

of

Bare

Anode

(mt)

Dia of

Bare

Anode

(mt)

Twice

the

Depth

of

Anod

e

Anode to

earth

Resistanc

e (ohm

Anode to

backfill

Resistanc

e (ohms)

Cable

Resistanc

e (ohms)

Total

circuit

Resistanc

e

No of Zinc

anode

Total

weigh

t of

Anod

e

Polarisati

on cell

(Solid

State-5.0

KA)

N L D l d S Rb Rbs Rc RT Nos (Kg) Nos

1 2.885 12.230 2 3 0.150 3 0.151 4.0 2.425 0.108 0.0058 1.270 3mtr x 2Nos 5.1 1

2 5.151 64.995 2 5 0.150 5 0.151 4.0 9.218 0.073 0.0058 4.648 5mtr x 2Nos 8.5 1

3 10.765 32.905 2 3 0.150 3 0.151 4.0 6.526 0.108 0.0058 3.320 3mtr x 2Nos 5.1 1

4 19.774 31.870 2 3 0.150 3 0.151 4.0 6.320 0.108 0.0058 3.217 3mtr x 2Nos 5.1 1

5 33.054 26.875 2 3 0.150 3 0.151 4.0 5.330 0.108 0.0058 2.722 3mtr x 2Nos 5.1 1

6 34.248 19.310 2 3 0.150 3 0.151 4.0 3.830 0.108 0.0058 1.972 3mtr x 2Nos 5.1 1

7 34.850 27.315 2 3 0.150 3 0.151 4.0 5.417 0.108 0.0058 2.765 3mtr x 2Nos 5.1 1

8 63.010 51.855 2 5 0.150 5 0.151 4.0 7.354 0.073 0.0058 3.716 5mtr x 2Nos 8.5 1

9 134.851 20.515 2 3 0.150 3 0.151 4.0 4.068 0.108 0.0058 2.091 3mtr x 2Nos 5.1 1

10 145.049 15.840 2 3 0.150 3 0.151 4.0 3.141 0.108 0.0058 1.627 3mtr x 2Nos 5.1 1

11 158.270 19.090 2 3 0.150 3 0.151 4.0 3.786 0.108 0.0058 1.950 3mtr x 2Nos 5.1 1

12 166.385 13.655 2 3 0.150 3 0.151 4.0 2.708 0.108 0.0058 1.411 3mtr x 2Nos 5.1 1

13 177.354 8.895 2 3 0.150 3 0.151 4.0 1.764 0.108 0.0058 0.939 3mtr x 2Nos 5.1 1

14 197.417 18.550 2 3 0.150 3 0.151 4.0 3.679 0.108 0.0058 1.896 3mtr x 2Nos 5.1 1

15 199.079 25.900 2 3 0.150 3 0.151 4.0 5.136 0.108 0.0058 2.625 3mtr x 2Nos 5.1 1

16 201.754 24.565 2 3 0.150 3 0.151 4.0 4.872 0.108 0.0058 2.493 3mtr x 2Nos 5.1 1

17 217.007 9.370 2 3 0.150 3 0.151 4.0 1.858 0.108 0.0058 0.986 3mtr x 2Nos 5.1 1

Total Length of Zinc Ribbon anode=110Mtrs

R-1

DESIGN DOCUMENT FOR TEMPORARY

CATHODIC PROTECTION SYSTEM FOR

PHASE-I

EPMC SERVICES FOR REWARI-KANPUR PIPELINE PROJECT

06-10-1403-DD-PH1, Rev-01 Page 27 of 113

9.0 CATHODIC PROTECTION AT CASED CROSSINGS

As per specification no MH2145-C000-EL-SPC-0025 RevA, Cathodic protection to casing shall

be provided if casing is coated. In This project all cased crossing are uncoated, therefore

additional protection is not Provided.

9.1 CATHODIC PROTECTION FOR CARRIER PIPE

Carrier pipe inside casing shall be protected by Zinc ribbon anodes well connected to the

outer surface of bottom of carrier pipe extending between hour hand positions of 4 and 8 o

clock. The anodes shall be placed at close intervals as per design calculations and sized

based on the permanent CP design parameters for 35 years.

The calculations are as below,

i) Surface Area

Where:

S

a

=

Surface area of Pipeline

(m

2

)

D = Diameter of pipeline (m)

L = Length of pipeline (m)

ii) Current requirement

Where:

I

t

= Current requirement (Amps)

S

a

=

Surface area of Pipeline

(m

2

)

C

d

= CP protective current density (mA/m

2

)

1.3 = Safety factor

DESIGN DOCUMENT FOR TEMPORARY

CATHODIC PROTECTION SYSTEM FOR

PHASE-I

EPMC SERVICES FOR REWARI-KANPUR PIPELINE PROJECT

06-10-1403-DD-PH1, Rev-01 Page 28 of 113

The surface area & current requirement calculations are tabulated as under:

Chainage

(km)

Dia.

(m)

Pipeline

Length (m.)

Surface Area

(m

2

)

Current

Density (mA/m

2

)

Current Required

(Amps)

0.577 0.457 27 38.76 0.055 0.0028

3.387 0.457 74 106.24 0.055 0.0076

10.747 0.457 18 25.84 0.055 0.0018

22.865 0.457 18 25.84 0.055 0.0018

33.876 0.457 25 35.89 0.055 0.0026

62.608 0.457 32 45.94 0.055 0.0033

82.564 0.457 14 20.10 0.055 0.0014

92.680 0.457 20 28.71 0.055 0.0021

98.076 0.457 35 50.25 0.055 0.0036

99.961 0.457 22 31.59 0.055 0.0023

122.770 0.457 17 24.41 0.055 0.0017

127.241 0.457 16 22.97 0.055 0.0016

136.215 0.457 22 31.59 0.055 0.0023

140.377 0.457 36 51.69 0.055 0.0037

141.917 0.457 55 78.96 0.055 0.0056

158.440 0.457 30 43.07 0.055 0.0031

161.957 0.457 30 43.07 0.055 0.0031

162.348 0.457 47 67.48 0.055 0.0048

163.166 0.457 47 67.48 0.055 0.0048

164.684 0.457 47 67.48 0.055 0.0048

165.712 0.457 47 67.48 0.055 0.0048

216.460 0.457 74 106.24 0.055 0.0076

226.000 0.457 29 41.64 0.055 0.0030

DESIGN DOCUMENT FOR TEMPORARY

CATHODIC PROTECTION SYSTEM FOR

PHASE-I

EPMC SERVICES FOR REWARI-KANPUR PIPELINE PROJECT

06-10-1403-DD-PH1, Rev-01 Page 29 of 113

iii) Anode required by weight

Where:

W

t

= Weight of anode required (kg)

I

t

= Current requirement (Amps)

C

t

=

Consumption rate of anode

(11.24 Kg/Amp-Year)

L = Design Life (35 years)

U

f

= Anode Utilisation factor (0.5)

Type of anode: Zinc Ribbon Anode

Total

current

required

(Amps)

Anode

Weight as per

design (Kgs)

Weight

Of Anode

per mtr.

Total Length of

Anode required as

per design (m)

Individual length

of Anode proposed

(Between 2 spacer)

(m)

Total Length of Ribbon

proposed considering

1no zinc ribbon in

between 2 spacer (m)

0.0028 2.18 0.850 2.57 0.48 6.46

0.0076 5.98 0.850 7.03 0.48 17.71

0.0018 1.45 0.850 1.71 0.48 4.31

0.0018 1.45 0.850 1.71 0.48 4.31

0.0026 2.02 0.850 2.38 0.48 5.98

0.0033 2.58 0.850 3.04 0.48 7.66

0.0014 1.13 0.850 1.33 0.48 3.35

0.0021 1.62 0.850 1.90 0.48 4.79

0.0036 2.83 0.850 3.33 0.48 8.37

0.0023 1.78 0.850 2.09 0.48 5.26

0.0017 1.37 0.850 1.62 0.48 4.07

0.0016 1.29 0.850 1.52 0.48 3.83

0.0023 1.78 0.850 2.09 0.48 5.26

0.0037 2.91 0.850 3.42 0.48 8.61

0.0056 4.44 0.850 5.23 0.48 13.16

0.0031 2.42 0.850 2.85 0.48 7.18

0.0031 2.42 0.850 2.85 0.48 7.18

0.0048 3.80 0.850 4.47 0.48 11.25

0.0048 3.80 0.850 4.47 0.48 11.25

0.0048 3.80 0.850 4.47 0.48 11.25

0.0048 3.80 0.850 4.47 0.48 11.25

0.0076 5.98 0.850 7.03 0.48 17.71

0.0030 2.34 0.850 2.76 0.48 6.94

Total 187.12

DESIGN DOCUMENT FOR TEMPORARY

CATHODIC PROTECTION SYSTEM FOR

PHASE-I

EPMC SERVICES FOR REWARI-KANPUR PIPELINE PROJECT

06-10-1403-DD-PH1, Rev-01 Page 30 of 113

10.0 INSULATION JOINTS

The Surge Diverter Flame Proof type shall be connected across each Isolation Joints.

The proposed locations of IJ are as follows:

Sr.

No.

Pipeline Section

Chainage

(Km)

Location

Qty

(Nos.)

1

RKPL-Phase I

00 Rewari Dispatch Terminal 1

2 141.80 Bharatpur Terminal Receiver Side 1

3 141.80 Bharatpur Terminal Launcher Side 1

4 164.378 Mathura Terminal Receiver Side 1

5 164.378 Mathura Terminal Launcher Side 1

11.0 EARTHING ELECTRODE

The above ground unprotected portion of the pipeline at the pipeline terminal and

intermediate station shall be earthed through earthing system consisting of earth electrodes

and earthing conductor. All flanges on unprotected pipe shall be shorted with 25 Sq. mm

copper cables.The resistance of grounding shall be limited to 5 ohms.

The motor operated valves located on cathodically protected pipeline shall be separately

grounded with the help of 20kg zinc anode.

DESIGN DOCUMENT FOR TEMPORARY

CATHODIC PROTECTION SYSTEM FOR

PHASE-I

EPMC SERVICES FOR REWARI-KANPUR PIPELINE PROJECT

06-10-1403-DD-PH1, Rev-01 Page 31 of 113

12.0 POLARISATION COUPONS

The Polarisation coupons of pipeline material shall be provided along the pipeline to monitor

the adequacy of the cathodic protection. The Polarisation coupon shall be made as per

drawing no 06-10-1403-PCC & specification MH2145-C000-EL-SPC-0025 RevA

The coupon shall be installed as per table given below:

RKPL Ph-1 Pipeline Section:

Sr.

No.

Chainage

(Km)

Location

Test Station

Type

Qty

(Nos.)

1 5.151 132 KVA HT LINE CROSSING ML 1

2 158.270 400 KV HT LINE XING ML 1

13.0 REFERENCE CELL ACCESS POINTS

Reference cell access points shall be provided near insulating joint locations at SV stations

where the ground is paved, for measurement of pipe to soil potentials. A perforated PVC

pipe filled with native soil and buried at the location shall be provided for measurement

purpose. The length of the PVC pipe shall be adequate to reach the native soil below the

paving.

14.0 ER PROBE & READER

Electrical Resistance Probe and Reader shall be provided along the pipeline ROU for

monitoring the rate of metal loss due to corrosion. The ER Probes shall be implemented for

external corrosion monitoring. The lead wires of the probe shall be connected to pipeline

through test station and terminated inside test station enabling periodic resistance

measurement of the probe using a portable probe-measuring instrument.

The material of the E/R probe element shall be of same alloy as of the pipeline material.

Probe shall be provided preferably at the bottom portion of pipeline.

2 Nos ER Probe shall be considered with 2 Nos. Of Reader for pipeline in Phase I.

The location for installation of ER probe has been proposed, however exact location shall be

decided at site after post commissioning survey in consultation with consultant/owner.

The Proposed location of ER probe is as below:

DESIGN DOCUMENT FOR TEMPORARY

CATHODIC PROTECTION SYSTEM FOR

PHASE-I

EPMC SERVICES FOR REWARI-KANPUR PIPELINE PROJECT

06-10-1403-DD-PH1, Rev-01 Page 32 of 113

RKPL Ph-1 Pipeline Section:

SN

Chainage

(Km)

Location

Test Station

Type

Qty (Nos.)

1 33.054 220 KVA HT LINE XING NEAR BRICK KILN M 1

2 217.007 400KVA HT XING, NEAR GOWAL VILLAGE ML 1

15.0 TEST STATION

Test Station shall be provided along the pipeline ROU for monitoring the performance of the

Cathodic protection system at an interval of about 1000 m in inhabited areas and 2000 m in

Un-inhabited areas such as forests / deserts etc.

In addition to the above Test Stations shall be provided at the following points,

At the locations of Anode ground beds.

At all Insulation Joints.

At vulnerable locations with drastic changes in Soil Resistivity.

At locations of Surge diverters, Polarisation Coupons, pipeline grounding through

polarization cells, Zinc & Mg Anodes.

At EHV/HV AC/DC overhead line crossings and selected locations where EHV/HV

overhead lines are in the vicinity of the pipeline.

At Railway Line crossing and at selected location along lines running parallel to

pipeline.

At both sides of major river crossings.

At EHV/HV cable crossings or along routes where EHV/HV cables are running in

parallel.

In the vicinity of DC network or grounding systems and HVDC grounding systems

where interference problems are suspected.

At crossing of other pipelines / structures

At the Location of Reference cell and ER Probe Installation.

At both sides of Cased crossings.

Locations where interference is expected.

At locations of Sectionalizing Valves (SV) Stations.

At any other locations considered necessary by Owner/Owners Representative.

DESIGN DOCUMENT FOR TEMPORARY

CATHODIC PROTECTION SYSTEM FOR

PHASE-I

EPMC SERVICES FOR REWARI-KANPUR PIPELINE PROJECT

06-10-1403-DD-PH1, Rev-01 Page 33 of 113

Test Station Connection Scheme as given below:

Purpose Type

Pipe to soil potential measurement A

Pipe to soil potential measurement with Galvanic Anode Connection AL

Line Current measurement B

Line Current measurement with Galvanic Anode Connection BL

Isolating Joint, Line Current measurement with Galvanic Anode Connection BFL

Cased crossing with uncoated casing C

Uncoated cased crossing with Galvanic Anode Connection CL

Cased crossing with coated casing D

coated cased crossing with Galvanic Anode Connection DL

Insulating Joint F

Intermediate CP station impressed current drainage point. G

Intermediate CP station impressed current drainage point with galvanic anode

connection.

GL

Intermediate CP station impressed current drainage point with Insulating Joint

and galvanic anode connection.

GFL

Foreign pipeline crossing E

Foreign pipeline crossing with Galvanic Anode Connection EL

HT Line crossings Grounding Through Polarisation Cell and Zinc ribbon anode M

HT Line crossings Grounding Through Polarisation Cell, Zinc ribbon anode with

Galvanic Anode Connection

ML

HT line crossing & cased crossing with uncoated casing CM

HT line crossing & cased crossing with coated casing DM

HT Line crossings Grounding Through Polarisation Cell, Zinc ribbon anode &

foreign pipeline crossing

ME

Cased Crossing with uncoated casing & foreign pipeline crossing CE

DESIGN DOCUMENT FOR TEMPORARY

CATHODIC PROTECTION SYSTEM FOR

PHASE-I

EPMC SERVICES FOR REWARI-KANPUR PIPELINE PROJECT

06-10-1403-DD-PH1, Rev-01 Page 34 of 113

Cased Crossing with coated casing & foreign pipeline crossing DE

HT Line crossings Grounding Through Polarisation Cell and Zinc ribbon anode

& Foreign pipeline crossing with Galvanic Anode Connection

MEL

Coated cased crossing with HT Line crossings Grounding Through Polarisation

Cell, Zinc ribbon anode with Galvanic Anode Connection

DML

Un-Coated cased crossing with HT Line crossings Grounding Through

Polarisation Cell, Zinc ribbon anode with Galvanic Anode Connection

CML

Test Station installation chainage & types are mentioned in the schedule. All the chainage are

indicative only. The test stations shall be installed as per the actual details like HT Line/

Pipeline crossings, cased crossings, MOV etc., at site during actual execution of the job.

DESIGN DOCUMENT FOR TEMPORARY

CATHODIC PROTECTION SYSTEM FOR

PHASE-I

EPMC SERVICES FOR REWARI-KANPUR PIPELINE PROJECT

06-10-1403-DD-PH1, Rev-01 Page 35 of 113

1) The Schedule of Test stations for RKPL Ph-1 are as follows:

SN Location

Chainage

(km)

Test

Station

Type

(TS)

CP

Statio

n Size

Test

station

(ICTS)

(Nos.)

Normal

Size

Test

station

(TS)

(Nos.)

Pol

cell

Size

Test

Station

(PCTS)

(Nos.)

CTSU

Size

Test

Station

(CTS)

(Nos.)

Perman

ent Ref.

Cell

CuCuSo

4 (Nos)

Mg

Anode

(2.5

KG)

(Nos.)

Mg

Anode

(10

KG)

(Nos.)

Bare Zn

Ribbon

Anode

for HT

Line

crossing

(m.)

ZN

Anode

(20

KG)

(Nos.)

Polarisa

tion cell

(solid

state)

(Nos.)

Polaris

ation

Coupon

(Nos.)

ER

probe

(Nos.)

1 HPCL Rewari Terminal 0.000 GFL 1 2 2 1

2 NH-71 0.577 C 1

3 NH-71 0.604 C 1

4 IN FIELD 1.000 AL 1 2

5 KARNAWAS TO DODHI ROAD XING 2.000 AL 1 2

6 110 KVA HT CROSSING 2.885 M 1 4 1

7 IN FIELD 3.000 AL 1 2

8 NH-08 3.387 C 1

9 NH-08 3.461 C 1

10 NATIONAL HIGHWAY JAIPUR-DELHI 4.018 AL 1 3

11 132 KVA HT LINE CROSSING 5.151 ML 1 1 3 24 1 1

12 IN FIELD NEAR DHANI VILLAGE 6.151 AL 1 3

13 KHERIMOLTA DISTRIBUTORY 7.167 AL 1 2

14 IN FIELD 8.167 AL 1 2

15 IN FIELD 9.167 AL 1 2

16 NEAR GUJRAS CART TRACK 10.000 AL 1 2

17

ASPHALTED ROAD GUJAR MAJARI

TO GUJARI

10.747 C 1

19

HPCL PIPELINE CROSSING, NEAR

GUJARI BUS

11.851 EL 1 2

R-1

DESIGN DOCUMENT FOR TEMPORARY

CATHODIC PROTECTION SYSTEM FOR

PHASE-I

EPMC SERVICES FOR REWARI-KANPUR PIPELINE PROJECT

06-10-1403-DD-PH1, Rev-01 Page 36 of 113

SN Location

Chainage

(km)

Test

Statio

n Type

(TS)

CP

Statio

n Size

Test

station

(ICTS)

(Nos.)

Normal

Size

Test

station

(TS)

(Nos.)

Pol

cell

Size

Test

Station

(PCTS)

(Nos.)

CTSU

Size

Test

Station

(CTS)

(Nos.)

Perman

ent Ref.

Cell

CuCuSo

4 (Nos)

Mg

Anode

(2.5

KG)

(Nos.)

Mg

Anode

(10

KG)

(Nos.)

Bare Zn

Ribbon

Anode

for HT

Line

crossing

(m.)

ZN

Anode

(20

KG)

(Nos.)

Polarisa

tion cell

(solid

state)

(Nos.)

Polarisa

tion

Coupon

(Nos.)

ER

probe

(Nos.)

20 IN FIELD 12.851 AL 1 2

21 CART TRACK JAKAPUR BHAGANA 13.778 AL 1 2

22 IN FIELD 14.778 AL 1 2

23 IN FIELD 15.778 AL 1 2

24 IN FIELD 16.778 AL 1 2

25 IN FIELD 17.778 BL 1 1 2

26 NEAR SAHIBI RIVER 18.691 AL 1 3

27 220 KVA HT LINE XING 19.774 ML 1 2 8 1

28 IN FIELD 20.774 AL 1 2

29 IN FIELD 21.774 AL 1 2

30 MAJOR DISTRICT ROAD XING-61 22.865 CL 1 3

31 MAJOR DISTRICT ROAD XING-61 22.883 C 1

32 CART TRACK JAKAPUR BHAGANA 23.883 AL 1 2

33

IN FIELD NEAR PUR VILLAGE &

BHADUKA

24.883 AL 1 2

34 IN FIELD 25.883 AL 1 2

35 IN FIELD NEAR KASWAR VILAGE 26.883 AL 1 2

36 NEAR NALLAH XING 27.883 AL 1 2

37 HPCL PIPELINE CROSSING, NEAR 28.754 EL 1 2

38 IN FIELD 29.754 AL 1 2

39 IN FIELD 30.754 AL 1 2

R-1

R-1

DESIGN DOCUMENT FOR TEMPORARY

CATHODIC PROTECTION SYSTEM FOR

PHASE-I

EPMC SERVICES FOR REWARI-KANPUR PIPELINE PROJECT

06-10-1403-DD-PH1, Rev-01 Page 37 of 113

SN Location

Chainage

(km)

Test

Statio

n Type

(TS)

CP

Statio

n Size

Test

station

(ICTS)

(Nos.)

Normal

Size

Test

station

(TS)

(Nos.)

Pol

cell

Size

Test

Station

(PCTS)

(Nos.)

CTSU

Size

Test

Station

(CTS)

(Nos.)

Perman

ent Ref.

Cell

CuCuSo

4 (Nos)

Mg

Anode

(2.5

KG)

(Nos.)

Mg

Anode

(10

KG)

(Nos.)

Bare Zn

Ribbon

Anode

for HT

Line

crossing

(m.)

ZN

Anode

(20

KG)

(Nos.)

Polarisa

tion cell

(solid

state)

(Nos.)

Polarisa

tion

Coupon

(Nos.)

ER

probe

(Nos.)

40 IN FIELD AFTER METALLED ROAD 31.754 AL 1 2

41 IN FIELD 32.754 AL 1 2

42

220 KVA HT LINE XING NEAR BRICK

KILN

33.054 M 1 1 6 1 1

43 STATE HIGHWAY-25 33.876 CL 1 2

44 STATE HIGHWAY-25 33.901 C 1

45 220 KVA HT XING 34.248 M 1 4 1

46

110 KVA HT CROSSING, NEAR

CHAMBORDA VILLAGE

34.850 M 1 6 1

47 SV-1 34.913 GL 1 2 2 1

48 IN FIELD 35.913 AL 1 2

49 IN FIELD 36.913 AL 1 2

50 IN FIELD 37.913 AL 1 2

51

IN FIELD NEAR BAMBREADY

VILLAGE

38.913 AL 1 2

52 IN FIELD NEAR MANDPUR VILLAGE 39.913 AL 1 2

53

IN FIELD BEFOR MANPUR VILLAGE

RD

40.913 AL 1 2

54 NEAR DHAMUKAD VILLAGE 41.913 AL 1 2

55 DHAMUKAD VILLAGE NER MASJID 42.913 AL 1 2

56 DHAMUKAD VILLAGE 43.913 AL 1 2

57 IN FIELD NEAR CHACHARA VILLAGE 44.913 AL 1 2

58 IN FIELD NEAR BAGODA VILLAGE 45.913 AL 1 2

59

IN FIELD NEAR BAYADIWAS 7

JHAMPADIWAS VILLAGE

46.913 BL 1 1 2

DESIGN DOCUMENT FOR TEMPORARY

CATHODIC PROTECTION SYSTEM FOR

PHASE-I

EPMC SERVICES FOR REWARI-KANPUR PIPELINE PROJECT

06-10-1403-DD-PH1, Rev-01 Page 38 of 113

SN Location

Chainage

(km)

Test

Statio

n Type

(TS)

CP

Statio

n Size

Test

station

(ICTS)

(Nos.)

Normal

Size

Test

station

(TS)

(Nos.)

Pol

cell

Size

Test

Station

(PCTS)

(Nos.)

CTSU

Size

Test

Station

(CTS)

(Nos.)

Perman

ent Ref.

Cell

CuCuSo

4 (Nos)

Mg

Anode

(2.5

KG)

(Nos.)

Mg

Anode

(10

KG)

(Nos.)

Bare Zn

Ribbon

Anode

for HT

Line

crossing

(m.)

ZN

Anode

(20

KG)

(Nos.)

Polarisa

tion cell

(solid

state)

(Nos.)

Polarisa

tion

Coupon

(Nos.)

ER

probe

(Nos.)

60 IN FIELD NEAR MEDAWAS VILLAGE 47.913 AL 1 2

61

AFTER CANEL XING, NER MEDAWAS

VILLAG

48.913 AL 1 2

62

AFTER ROAD XING, NER GUNDIWA

VILLAGE

49.913 AL 1 2

63

ASPHALTED ROAD NER GUNDIWA

VILLAGE

50.959 AL 1 2

64 NER KALAANI VILLAGE 51.913 AL 1 2

65 NER KALAANI VILLAGE 52.913 AL 1 2

66 NER KALAANI VILLAGE 53.913 AL 1 2

67 NER SLIKAWAS VILLAGE 54.913 AL 1 2

68 NER MUBARAKPUR VILLAGE 55.913 AL 1 2

69

NER MUBARAKPUR VILLAGE &

TRANSFARMER

56.913 AL 1 2

70 NER MUBARAKPUR VILLAGE 57.913 AL 1 2

71 SV-2 59.022 BL 1 1 2 1

72 NEAR NALLAH,BARAMBO VILLAGE 60.008 AL 1 3

73 NEAR NAGARAMB POLIC CHOWKI 61.022 AL 1 3

74 NEAR NAGARAMB VILLAGE 62.022 AL 1 2

75 SH-35 XING 62.608 C 1

76 SH-35 XING 62.640 C 1

77 400 KVA HT LINE XING 63.010 ML 1 3 18 1

78 NEAR NOGAANB VILLAGE 64.022 AL 1 2

79 NEAR TIKRI VILLAGE 65.022 AL 1 2

R-1

R-1

DESIGN DOCUMENT FOR TEMPORARY

CATHODIC PROTECTION SYSTEM FOR

PHASE-I

EPMC SERVICES FOR REWARI-KANPUR PIPELINE PROJECT

06-10-1403-DD-PH1, Rev-01 Page 39 of 113

SN Location

Chainage

(km)

Test

Station

Type

(TS)

CP

Statio

n Size

Test

station

(ICTS)

(Nos.)

Normal

Size

Test

station

(TS)

(Nos.)

Pol

cell

Size

Test

Station

(PCTS)

(Nos.)

CTSU

Size

Test

Station

(CTS)

(Nos.)

Perman

ent Ref.

Cell

CuCuSo

4 (Nos)

Mg

Anode

(2.5

KG)

(Nos.)

Mg

Anode

(10

KG)

(Nos.)

Bare Zn

Ribbon

Anode

for HT

Line

crossing

(m.)

ZN

Anode

(20

KG)

(Nos.)

Polarisa

tion cell

(solid

state)

(Nos.)

Polaris

ation

Coupon

(Nos.)

ER

probe

(Nos.)

80 IN FIELD NEAR TIKRI VILLAGE 66.022 AL 1 2

81

ASPHALTED RD XING, NEAR

SHERPUR VILLAGE

67.008 AL 1 2

82 IN FIELD NEAR SUNERA VILLAGE 68.022 AL 1 2

83

IN FIELD NEAR BORE WELL &

SUNERA VILLAGE

69.022 AL 1 2

84 IN FIELD NEAR RAWAKA VILLAGE 70.022 AL 1 2

85

ASPHALTED ROAD, NEAR RAWAKA

VILLAGE

71.128 AL 1 2

86 IN FIELD NEAR INDPWARA VILLAGE 72.128 AL 1 2

87

CART TRACK NEAR INDPWARA

VILLAGE

73.128 AL 1 2

88

ASPHALTED ROAD, NEAR SHERPURA

VILLAGE

74.235 AL 1 2

89

NEAR ASPHATED RD XING

(JOTHPUR-SHERPUR)

75.165 AL 1 2

90 IN FIELD DAYANA KAWAS VILLAGE 76.165 BL 1 1 2

91

IN FIELD DAYANA KAWAS VILLAGE

AFETR METALICA RD XING

77.165 AL 1 2

92 METEL ROAD, KHELI VILLAGE 78.087 AL 1 2

93 IN FIELD KHELI VILLAGE 79.165 AL 1 2

94 METEL ROAD, KHELI VILLAGE 80.129 AL 1 2

95 RUPARE RIVER 80.522 B 1 1 2

96 RUPARE RIVER 80.742 B 1 2

DESIGN DOCUMENT FOR TEMPORARY

CATHODIC PROTECTION SYSTEM FOR

PHASE-I

EPMC SERVICES FOR REWARI-KANPUR PIPELINE PROJECT

06-10-1403-DD-PH1, Rev-01 Page 40 of 113

SN

Location

Chainage

(km)

Test

Station

Type

(TS)

CP

Statio

n Size

Test

station

(ICTS)

(Nos.)

Normal

Size

Test

station

(TS)

(Nos.)

Pol

cell

Size

Test

Station

(PCTS)

(Nos.)

CTSU

Size

Test

Station

(CTS)

(Nos.)

Perman

ent Ref.

Cell

CuCuSo

4 (Nos)

Mg

Anode

(2.5

KG)

(Nos.)

Mg

Anode

(10

KG)

(Nos.)

Bare Zn

Ribbon

Anode

for HT

Line

crossing

(m.)

ZN

Anode

(20

KG)

(Nos.)

Polarisa

tion cell

(solid

state)

(Nos.)

Polaris

ation

Coupon

(Nos.)

ER

probe

(Nos.)

97 NEAR CHAMARBARA VILLAGE 81.342 AL 1 3

98

IN FIELD BETWEEN BARDI-

CHAMARBARA VILLAGE

82.378 AL 1 3

99 SH-45 82.564 C 1

100 SH-45 82.578 C 1

101

AFTER SH-4X, NEAR BAROLI

VILLAGE

83.478 AL 1 2

102 IN FIELD NEAR DOMRAKI VILLAGE 84.578 AL 1 2

103

BFOR METALIC ROAD XING NEAR

KHESTI VILLAGE

85.578 AL 1 2

104

ASPHALTED ROAD XING NEAR

KHESTI VILLAGE

86.500 AL 1 2

105 IN FIELD NEAR KHESTI VILLAGE 87.500 AL 1 2

106 IN FIELD NEAR DHUTKA VILLAGE 88.500 AL 1 2

107 IN FIELD BEFORE REVER 89.400 AL 1 2

108 RUPARE RIVER 89.485 B 1 1 2

109 RUPARE RIVER 89.695 B 1 2

110 IN FIELD AFTER RIVER 90.395 AL 1 2

111 MUD ROAD XING NEAR BOARWELL 91.448 AL 1 2

112 IN FIELD 92.448 AL 1 2

113 STATE HIGHWAY-22 92.680 C 1

114 STATE HIGHWAY-22 92.700 C 1

R-1

DESIGN DOCUMENT FOR TEMPORARY

CATHODIC PROTECTION SYSTEM FOR

PHASE-I

EPMC SERVICES FOR REWARI-KANPUR PIPELINE PROJECT

06-10-1403-DD-PH1, Rev-01 Page 41 of 113

SN Location

Chainage

(km)

Test

Station

Type

(TS)

CP

Statio

n Size

Test

station

(ICTS)

(Nos.)

Normal

Size

Test

station

(TS)

(Nos.)

Pol

cell

Size

Test

Station

(PCTS)

(Nos.)

CTSU

Size

Test

Station

(CTS)

(Nos.)

Perman

ent Ref.

Cell

CuCuSo

4 (Nos)

Mg

Anode

(2.5

KG)

(Nos.)

Mg

Anode

(10

KG)

(Nos.)

Bare Zn

Ribbon

Anode

for HT

Line

crossing

(m.)

ZN

Anode

(20

KG)

(Nos.)

Polarisa

tion cell

(solid

state)

(Nos.)

Polaris

ation

Coupon

(Nos.)

ER

probe

(Nos.)

115 SV-3 93.532 GL 1 2 2 1

116

IN FIELD KUTAKPUR TO ARSI

VILLAGE

94.532 AL 1 2

117

ASPLATED ROAD XING ARSI TO

NAGAR MARKET

95.643 AL 1 2

118

METAL ROAD XING BHUKI TO ARSI

VILLAGE

96.678 AL 1 2

119 IN FIELD 97.700 AL 1 2

120 RAILWAY XING (NCR) 98.076 C 1

121 RAILWAY XING (NCR) 98.111 C 1

122 METAL ROAD XING 98.805 AL 1 2

123 SH-14 XING 99.961 CL 1 2

124 SH-14 XING 99.983 C 1

125

IN FIELD AFTER SH-14, NEAR BURJA

VILLAGE

100.983 AL 1 2

126 IN FIELD NEAR GANGABAK VILLAGE 101.983 AL 1 2

127

IN FIELD AFTER RD, NR GANGABAK

VILLAGE

102.983 AL 1 2

128 KENDALE TO MOBAI RD XIG 103.933 AL 1 2

129

METAL ROAD XING DABHARA TO

WOBAI

105.088 BL 1 1 2

130

NEAR MORLI VILLAGE & BADESRA

ROAD

106.000 AL 1 2

131

NEAR MOBAIT TOMORALI

ASPHALTED RD

107.000 AL 1 2

DESIGN DOCUMENT FOR TEMPORARY

CATHODIC PROTECTION SYSTEM FOR

PHASE-I

EPMC SERVICES FOR REWARI-KANPUR PIPELINE PROJECT

06-10-1403-DD-PH1, Rev-01 Page 42 of 113

SN Location

Chainage

(km)

Test

Station

Type

(TS)

CP

Statio

n Size

Test

station

(ICTS)

(Nos.)

Normal

Size

Test

station

(TS)

(Nos.)

Pol

cell

Size

Test

Station

(PCTS)

(Nos.)

CTSU

Size

Test

Station

(CTS)

(Nos.)

Perman

ent Ref.

Cell

CuCuSo

4 (Nos)

Mg

Anode

(2.5

KG)

(Nos.)

Mg

Anode

(10

KG)

(Nos.)

Bare Zn

Ribbon

Anode

for HT

Line

crossing

(m.)

ZN

Anode

(20

KG)

(Nos.)

Polarisa

tion cell

(solid

state)

(Nos.)

Polaris

ation

Coupon

(Nos.)

ER

probe

(Nos.)

132 NEAR BOAR WELL 108.000 AL 1 2

133 IN FIELD NEAR 11 KV LINE 109.000 AL 1 2

134 IN FIELD NEAR JANUTHER VILLAGE 110.000 AL 1 2

135 IN FIELD NEAR JANUTHER VILLAGE 111.000 AL 1 2

136 METALICA ROAD XING 111.958 AL 1 2

137 METALED ROAD XING 113.184 AL 1 2

138 IN FIELD SINSINI VILLAGE 114.184 AL 1 2

139 IN FIELD NEAR SONGAANB VILLAGE 115.184 AL 1 2

140 IN FIELD NEAR SONGAANB VILLAGE 116.184 AL 1 2

141

IN FIELD NEAR BADANGASH

VILLAGE

117.184 AL 1 2

142 SV-4 118.254 GL 1 2 2 1

143 IN FIELD 119.190 AL 1 2

144 IN FIELD PALA VILLAGE 120.190 AL 1 2

145 IN FIELD PALA VILLAGE 121.190 AL 1 2

146 NEAR CART TRACK PALA VILLAGE 122.190 AL 1 2

147 STATE HIGHWAY-14 122.770 C 1

148 STATE HIGHWAY-14 122.787 C 1 2

149 ASPHALTED ROAD XING 123.190 AL 1 2

150 IN FIELD, NEAR SAINTHRI VILLAGE 124.190 AL 1 2

151

AFTER MUD ROAD, NEAR KUMHER

VILLAGE

125.190 AL 1 2

DESIGN DOCUMENT FOR TEMPORARY

CATHODIC PROTECTION SYSTEM FOR

PHASE-I

EPMC SERVICES FOR REWARI-KANPUR PIPELINE PROJECT

06-10-1403-DD-PH1, Rev-01 Page 43 of 113

SN Location

Chainage

(km)

Test

Station

Type

(TS)

CP

Statio

n Size

Test

station

(ICTS)

(Nos.)

Normal

Size

Test

station

(TS)

(Nos.)

Pol

cell

Size

Test

Station

(PCTS)

(Nos.)

CTSU

Size

Test

Station

(CTS)

(Nos.)

Perman

ent Ref.

Cell

CuCuSo

4 (Nos)

Mg

Anode

(2.5

KG)

(Nos.)

Mg

Anode

(10

KG)

(Nos.)

Bare Zn

Ribbon

Anode

for HT

Line

crossing

(m.)

ZN

Anode

(20

KG)

(Nos.)

Polarisa

tion cell

(solid

state)

(Nos.)

Polaris

ation

Coupon

(Nos.)

ER

probe

(Nos.)

152 IN FIELD, NEAR SAINTHRI VILLAGE 126.100 AL 1 2

153 MAJOR DISTRICT ROAD-71 127.241 CL 1 2

154 MAJOR DISTRICT ROAD-71 127.257 C 1

155 IN FIELD BEFORE ASPHALTED ROAD 128.257 AL 1 2

156 IN FIELD 129.257 AL 1 2

157

NAAR ALEYA VILLAGE & BOMBO

PLACE

130.024 B 1 1

158 IN FIELD 130.257 AL 1 2

159 IN FIELD NEAR DERAA VILLAGE 131.257 AL 1 2

160 DERAA VILLAGE ROAD XING 132.159 AL 1 2

161 IN FIELD 133.159 AL 1 2

162 ASPHALTED ROAD 134.057 AL 1 2

163

220KVA LINE XING NEAR

ASPHALTED ROAD

134.851 ML 1 2 4 1

164 ASPHLATED ROAD XING 135.894 AL 1 2

165 STATE HIGHWAY-43 136.215 C 1

166 STATE HIGHWAY-43 136.237 C 1

167 IN FIELD NEAR MEGHAYA VILLAGE 136.894 AL 1 2

168 FOREGIN PL XING (WRPL IOCL) 137.705 EL 1 2

169 CART TRACK 138.724 AL 1 2

170 IN FIELD 139.724 AL 1 2

DESIGN DOCUMENT FOR TEMPORARY

CATHODIC PROTECTION SYSTEM FOR

PHASE-I

EPMC SERVICES FOR REWARI-KANPUR PIPELINE PROJECT

06-10-1403-DD-PH1, Rev-01 Page 44 of 113

SN Location

Chainage

(km)

Test

Station

Type

(TS)

CP

Statio

n Size

Test

station

(ICTS)

(Nos.)

Normal

Size

Test

station

(TS)

(Nos.)

Pol

cell

Size

Test

Station

(PCTS)

(Nos.)

CTSU

Size

Test

Station

(CTS)

(Nos.)

Perman

ent Ref.

Cell

CuCuSo

4 (Nos)

Mg

Anode

(2.5

KG)

(Nos.)

Mg

Anode

(10

KG)

(Nos.)

Bare Zn

Ribbon

Anode

for HT

Line

crossing

(m.)

ZN

Anode

(20

KG)

(Nos.)

Polarisa

tion cell

(solid

state)

(Nos.)

Polaris

ation

Coupon

(Nos.)

ER

probe

(Nos.)

171 STATE HIGHWAY-24 140.377 C 1

172 STATE HIGHWAY-24 140.413 CL 1 2

173 IOCL MBPL P/L XING 141.136 E 1

174 BPCL MBPL P/L XING 141.369 EL 1 2

175 BHARATPUR TERMINAL 141.800 GF 1 2

176 BHARATPUR TERMINAL 141.800 GF 1 2

177 WEASTERN CENTRAL RAILWAY 141.917 C 1

178 WEASTERN CENTRAL RAILWAY 141.972 CL 1 2

179 NEAR DAURAMKI VILLAGE 142.972 AL 1 2

180 NEAR DAURAMKI VILLAGE 143.972 AL 1 2

181 400KV HT LINE XING 145.049 ML 1 2 4 1

182 NEAR BILOTHI VILLAGE 146.049 AL 1 2

183 HPCL P/L XING 147.051 EL 1 2

184

NEAR KARAUTI VILLAGE &

BILWATHI VILLAGE

148.051 AL 1 2

185 IN FIELD 149.051 AL 1 2

186 NEAR SANTRAUK VILLAGE 150.051 AL 1 2

187 NEAR OLL VILLAGE 151.051 AL 1 2

188 NEAR HASANPUR VILLAGE 152.051 AL 1 2

189 NEAR HASANPUR VILLAGE 153.051 BL 1 1 2

190 NEAR IKDONIA VILLAGE 154.051 AL 1 2

DESIGN DOCUMENT FOR TEMPORARY

CATHODIC PROTECTION SYSTEM FOR

PHASE-I

EPMC SERVICES FOR REWARI-KANPUR PIPELINE PROJECT

06-10-1403-DD-PH1, Rev-01 Page 45 of 113

SN Location

Chainage

(km)

Test

Station

Type

(TS)

CP

Statio

n Size

Test

station

(ICTS)

(Nos.)

Normal

Size

Test

station

(TS)

(Nos.)

Pol

cell

Size

Test

Station

(PCTS)

(Nos.)

CTSU

Size

Test

Station

(CTS)

(Nos.)

Perman

ent Ref.

Cell

CuCuSo

4 (Nos)

Mg

Anode

(2.5

KG)

(Nos.)

Mg

Anode

(10

KG)

(Nos.)

Bare Zn

Ribbon

Anode

for HT

Line

crossing

(m.)

ZN

Anode

(20

KG)

(Nos.)

Polarisa

tion cell

(solid

state)

(Nos.)

Polaris

ation

Coupon

(Nos.)

ER

probe

(Nos.)

191 NEAR PILWA VILLAGE 155.051 AL 1 2

192 NEAR PILWA VILLAGE 156.051 AL 1 2

193 NEAR BORI VILLAGE 157.150 AL 1 2

194 400 KV HT LINE XING 158.270 ML 1 1 2 4 1 1

195 MATHUTA ACHNERA RAILWAY XING 158.440 C 1

196 MATHUTA ACHNERA RAILWAY XING 158.470 C 1

197 IN FIELD 159.261 AL 1 2

198 NEAR DHAMA SHASABAD VILLAGE 160.261 AL 1 2

199 ASPHALTED ROAD XING 161.289 AL 1 2

200 NH-02 Farah To Mathura 161.957 C 1

201 NH-02 Farah To Mathura 161.987 C 1

202 CENTRAL RAILWAY CROSSING 162.348 CL 1 2

203 CENTRAL RAILWAY CROSSING 162.395 C 1

204 RAILWAY XING-MATHURA TO FARAH 163.166 C 1

205 RAILWAY XING-MATHURA TO FARAH 163.213 CL 1 2

206 NEAR LADPUR VILLAGE 164.213 AL 1 2

207 MATHURA TERMINAL 164.378 GF 1 2

208 MATHURA TERMINAL 164.378 GF 1 2

209 RAILWAY XING-MATHURA TO FARAH 164.684 C 1