Академический Документы

Профессиональный Документы

Культура Документы

Ti e Protegol 32-55,-45 L Jul 08

Загружено:

A MahmoodОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Ti e Protegol 32-55,-45 L Jul 08

Загружено:

A MahmoodАвторское право:

Доступные форматы

Corrosion Protection Systems

P R O T E G O L

UR-Coating 32-55 / 45 L

Solvent-free, trowel-applied

two-component polyurethane coating compound

Date of issue 07/2008

TIB Chemicals AG | Muelheimer Strasse 16 -22 | 68219 Mannheim | P. O. Box 81 02 20 | 68202 Mannheim

Phone +49 621 8901-812 | Fax +49 621 8901-902 | info.protegol@tib-chemicals.com | www.tib-chemicals.com

This information is given to the best of our knowledge but without obligation. We are not liable for any wrong advice or any advice we may have failed to give.

This data sheet becomes invalid as soon as a new edition has been published. Please contact us for latest.

1/3

Description

Solvent-free two-component polyurethane coating

compound.

After mixing the material can be trowelled or, if

necessary, brush-applied.

Uses

Supplementary product to PROTEGOL

UR 32-

55/45 for manual application

Repair of defective areas and mechanical

damages

Pre-trowelling of parts with complicated design

and subsequent over coating by airless-hot spray-

method

Coating of welded field joints on factory-coated

steel pipes

Benefits

good corrosion protection

abrasion resistant

impact resistant

high chemical resistance

Product Data

The following data were determined at +20 C unless

otherwise stated:

Type internally plasticized two-

component material

Base PUR

Solvents None

Volume solids 100 %

Consistency

Comp. A

Pasty

Comp. B

Viscid

Density

Comp. A 1,7 g/cm

Comp. B 1,2 g/cm

Comp. A + B 1,6 g/cm

Mixing ratio

Comp. A : B 5 : 1 parts by weight

Application method by spatula, brushing if necessary

Application thickness 0.5 to 1.0 mm per operation on

vertical surfaces

Application temp. Substrate between 10C and 30C

Material between 15C and 25C

Pot life approx. 20 min.

Waiting periods between

applications

Minimum 1 hour. The previous

coating should still be slightly tacky

Curing time

after approx. 3 hours

after approx. 12 hours

touch dry

stackable

Full mechanical and

chemical load

after one week

Temperature limits without

simultaneous mechanical

stress

- 30 C up to 80 C

up to 110 C for short-term periods

(without temperature gradient to the

substrate)

Shore D

according to DIN 53 505

75 5 *

Cleaning material Solvent B or Solvent G

* after the coating has fully reacted and cured

Colours

Light ivory approx. RAL 1015

Capri blue approx. RAL 5019

Reseda green approx. RAL 6011

Feh grey approx. RAL 7000

Achat grey approx. RAL 7038

Graphite black approx. RAL 9011

and others on request

Coverage

Approx. 1,6 kg / mm dft. / m (theoretical value)

Corrosion Protection Systems

P R O T E G O L

UR-Coating 32-55 / 45 L

Solvent-free, trowel-applied

two-component polyurethane coating compound

Date of issue 07/2008

TIB Chemicals AG | Muelheimer Strasse 16 -22 | 68219 Mannheim | P. O. Box 81 02 20 | 68202 Mannheim

Phone +49 621 8901-812 | Fax +49 621 8901-902 | info.protegol@tib-chemicals.com | www.tib-chemicals.com

This information is given to the best of our knowledge but without obligation. We are not liable for any wrong advice or any advice we may have failed to give.

This data sheet becomes invalid as soon as a new edition has been published. Please contact us for latest.

2/3

Packaging

2 Kg double packs (10 x 2 Kgs per carton)

0,5 Kg double packs (45 x 0.5 Kgs per carton)

Storage

In a cool and dry place, approx. 12 months in tightly

closed original packs.

When stored below 0C Comp. B may partly

crystallize. In this case warm up to approx. 25 C in

an oven or by oil bath (do not use water bath as

Comp. B is sensitive to moisture!) in order to

redissolve the crystals. Comp. B with crystals should

on no account be used since the presence of crystals

interfers with the curing process.

Storage and Transport Data

Flash point RID/ADR ICAO/IATA-DGR

PROTEGOL

32-55 R

Comp. A > 100 C

Comp. B 220 C

Solvent B appr. 28 C cl. 3/fig. 31 c cl. 3/ UN 1263/ III

Solvent G appr. 7 C cl. 3/fig. 5 b cl. 3/UN 1263/III

Application

Substrate

The steel surfaces to be coated must be dry, clean,

free from dust, have a good key and be free from all

matter acting as release agents (e.g. oil, grease, old

paint etc.). In order to obtain the necessary

conditions, suitable substrate preparation methods

such as blasting must be used.

Steel surfaces must be abrasive blast clean to near

white (degree of cleanliness according to DIN EN

ISO 12944-4 at least Sa 2 or SSPC SP3 oder

ISO 8501/p 5T 2/3). The first coating must be applied

immediately after blast cleaning. Later application of

the base coat is only permissible if the original

degree of cleanliness has been maintained.

The constructional design of steel and iron shall

comply to DIN 28051 and DIN 28053 or to VDI

guideline 2532.

The surface profile shall range between 50 and 70

m. The blasting material shall be angled-shot.

Coating

Ensure that the temperature of the substrate is at

least 3 C above the dew point to avoid conden-

sation. The dew point can be determined with a

suitable dew point mirror.

Thoroughly mix both components at the indicated

mixing ratio with a slow-speed stirrer (e.g. a drill fitted

with a stirring paddle running at approx. 400 rpm) or

manually. Care should be taken to mix in the material

sticking to the walls of the container. Therefore,

transfer the mixture to a larger, clean vessel, all

material sticking to the walls of the original vessel

being scraped off with a palette knife, and being

added with renewed stirring. Once PROTEGOL

32-

55/45 L is mixed it may be applied by trowel or by

brush if applicable.

In order to repair defective areas in a PROTEGOL

32-55/45 coating the repair area shall be roughened.

When circular welding seams are to be coated,

PROTEGOL

UR

32-55/45 L is applied by brush if applicable or by

trowel in several operations until the thickness of the

factory-applied coating has been reached.

High voltage holiday tests can be carried out after

approx. 5 hours. The tension may be up to 10.000

volt per mm coating thickness. The high voltage

holiday test can only be carried out if the material

has been applied without any air trapping. Therefore

it is advisable to take this into consideration already

during the mixing process.

Relative humidity during application of the coating

must be < 80 %. (In case the relative humidity is

higher, then please ask for our special technical

advice.)

Corrosion Protection Systems

P R O T E G O L

UR-Coating 32-55 / 45 L

Solvent-free, trowel-applied

two-component polyurethane coating compound

Date of issue 07/2008

TIB Chemicals AG | Muelheimer Strasse 16 -22 | 68219 Mannheim | P. O. Box 81 02 20 | 68202 Mannheim

Phone +49 621 8901-812 | Fax +49 621 8901-902 | info.protegol@tib-chemicals.com | www.tib-chemicals.com

This information is given to the best of our knowledge but without obligation. We are not liable for any wrong advice or any advice we may have failed to give.

This data sheet becomes invalid as soon as a new edition has been published. Please contact us for latest.

3/3

Waiting periods

The waiting period between applications is approx.

1hour at 20 C, the previous coating should still be

slightly tacky. The seams of cured coating areas

shall be roughened to provide good adhesion.

Maintenance of tools

Immediately after use all instruments should be

cleaned with Solvent B or G.

Health and Safety

Although PROTEGOL

32-55/45 L is solvent-free, it

may, if processed at elevated temperatures, develop

vapours which may cause irritation to the skin. It

must be ensured by suitable measures, such as

continuous ventilation, mechanical extraction or

respiratory protection that such vapours are not

inhaled. Therefore we recommend to wear filter or

fresh air masks.

The unprotected skin should not be allowed to come

in contact with component B. If any of the material

has accidentally splashed onto the skin, the affected

area should immediately be washed thoroughly with

warm soapy water or better with warm non-alcaline

cleaners (e.g. Lutrol E 400, BASF). Clean again

thorougly with soap and water.

When using PROTEGOL

32-55/45 L all safety

precautions applicable to handling polyurethane

resins and their hardeners must be observed.. They

are listed in the Merkblatt fr den Umgang mit

Isocyanaten (Instructions for handling isocyanates)

which is available on request.

In addition, the health and safety precautions

mentioned in our Material Safety Data Sheets as well

as any regulations valid in the respective country

should be observed.

According to the regulations on dangerous

substances Component B of PROTEGOL

UR

32-55/45 L as well as Solvents B and G are liable to

danger identification.

Вам также может понравиться

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- GlassДокумент22 страницыGlassAnonymous RgKKzKGIX3Оценок пока нет

- Concrete Mix Design DOE PDFДокумент15 страницConcrete Mix Design DOE PDFkarthiksamp100% (2)

- Al. Alloy Chemical CompositionДокумент9 страницAl. Alloy Chemical Compositionketan1965Оценок пока нет

- 1 ChrisBridgesRetainingwallsandSoilNailing PDFДокумент70 страниц1 ChrisBridgesRetainingwallsandSoilNailing PDFRivaiОценок пока нет

- A Brief Guide To Calculating Embodied CarbonДокумент6 страницA Brief Guide To Calculating Embodied Carbonmatt calvertОценок пока нет

- Method Statement of Static Tension Load Test PLTU Suralaya Jawa 9 & 10 - Page 9 Rev PDFДокумент12 страницMethod Statement of Static Tension Load Test PLTU Suralaya Jawa 9 & 10 - Page 9 Rev PDFFendi Rang TigorОценок пока нет

- НАУЧНОЕ НАСЛЕДИЕ АКАДЕМИКА КАШГАЯ PDFДокумент364 страницыНАУЧНОЕ НАСЛЕДИЕ АКАДЕМИКА КАШГАЯ PDFAnver AkperovОценок пока нет

- Presentation 1Документ5 страницPresentation 1Eziah Pearl Joy AlaveraОценок пока нет

- Cobalt: Definition, Mineralogy and DepositsДокумент19 страницCobalt: Definition, Mineralogy and DepositsJesusSalamancaОценок пока нет

- Recent Advances in Active Metal Brazing of Ceramics and Process-S12540-019-00536-4Документ12 страницRecent Advances in Active Metal Brazing of Ceramics and Process-S12540-019-00536-4sebjangОценок пока нет

- What Differentiates Coiled Pins?: Prior To InstallationДокумент2 страницыWhat Differentiates Coiled Pins?: Prior To Installationarda akkayaОценок пока нет

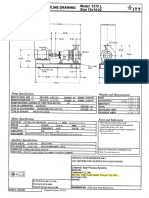

- Model 3175L Goulds Pumps Outline Drawing Size 12x14-22: Weights and SpecificationДокумент6 страницModel 3175L Goulds Pumps Outline Drawing Size 12x14-22: Weights and SpecificationJavier Fernando Agudelo GómezОценок пока нет

- Phosphorus, Reactive, PhosVer 3 Method 8048, 02-2009, 9th EdДокумент7 страницPhosphorus, Reactive, PhosVer 3 Method 8048, 02-2009, 9th EdzvjesosОценок пока нет

- Failure Analysis of A High-Speed Shaft Crack: Technicalarticle-Peer-ReviewedДокумент12 страницFailure Analysis of A High-Speed Shaft Crack: Technicalarticle-Peer-RevieweddouglasncamiloОценок пока нет

- 2023 Productcatalogue 2Документ35 страниц2023 Productcatalogue 2Trevor NaidooОценок пока нет

- Clarkson - KGVДокумент8 страницClarkson - KGVbloggerparthiОценок пока нет

- ChemДокумент2 страницыChemDBANJAN MAITYОценок пока нет

- Drawing & Catalogue-Kumwell PDFДокумент15 страницDrawing & Catalogue-Kumwell PDFDevis RipomoОценок пока нет

- Polymer Chemistry For B.SC - Sem-6th PDFДокумент49 страницPolymer Chemistry For B.SC - Sem-6th PDFSohel Ansari0% (1)

- Slide 11 Extrusion and Wire DrawingДокумент53 страницыSlide 11 Extrusion and Wire Drawingjohn doeОценок пока нет

- Hxe ImДокумент61 страницаHxe ImHồ Viết DuyОценок пока нет

- 0002-SPC-HOBWT03-ME-8006 - C General Mechanical Specification Bryn Estyn Water Treatment PlantДокумент35 страниц0002-SPC-HOBWT03-ME-8006 - C General Mechanical Specification Bryn Estyn Water Treatment PlantzufriateguiОценок пока нет

- Behavior of Geogrid Reinforced Sand and Effect of Reinfor - 2014 - Geotextiles A PDFДокумент15 страницBehavior of Geogrid Reinforced Sand and Effect of Reinfor - 2014 - Geotextiles A PDFRsmoothОценок пока нет

- Petrochemicals An Overview (STUDENT) (3of3)Документ175 страницPetrochemicals An Overview (STUDENT) (3of3)Chuah Chong Yang100% (1)

- Wilo 352996Документ21 страницаWilo 352996John Rodolfo BultronОценок пока нет

- Qualicoat Specifications 2023 - Master Version - V01Документ92 страницыQualicoat Specifications 2023 - Master Version - V01idelcio rochaОценок пока нет

- Standard For Colour Coding of Pipework For Identification of Fluids & ServicesДокумент13 страницStandard For Colour Coding of Pipework For Identification of Fluids & Servicessudeesh kumarОценок пока нет

- Ashrae 62-73Документ20 страницAshrae 62-73Jose Luis ZIMICОценок пока нет

- SimXpert R3.2 Crash Workspace GuideДокумент344 страницыSimXpert R3.2 Crash Workspace Guidepaulkastle100% (1)

- Calculation Condition Box CulvertДокумент11 страницCalculation Condition Box CulvertRafael ObusanОценок пока нет