Академический Документы

Профессиональный Документы

Культура Документы

TAMKO® TAM-GUARD White Elastomeric Coating Data Sheet

Загружено:

Novly Ibrahim0 оценок0% нашли этот документ полезным (0 голосов)

68 просмотров2 страницыSplash Guard

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документSplash Guard

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

68 просмотров2 страницыTAMKO® TAM-GUARD White Elastomeric Coating Data Sheet

Загружено:

Novly IbrahimSplash Guard

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 2

tamko.

com

Rev. 08/12

Information included in this product data sheet was current at time of printing. To obtain a copy of the most current version of this product data sheet, visit us online at tamko.com or call us at 800-641-4691.

For information regarding or a copy of TAMKOs limited warranty, contact your local TAMKO representative, visit us online at tamko.com, or call us at 800-641-4691.

TAMKO

is a registered trademark of TAMKO Building Products, Inc.

Central District 220 West 4th Street, Joplin, Missouri 64801 800-641-4691

Northeast District 4500 Tamko Drive, Frederick, Maryland 21701 800-368-2055

Southeast District 2300 35th Street, Tuscaloosa, Alabama 35401 800-228-2656

Southwest District 7910 South Central Expressway, Dallas, Texas 75216 800-443-1834

Western District 5300 East 43rd Avenue, Denver, Colorado, 80216 800-530-8868

APPLICATION

SURFACE PREPARATION

To prepare the surface for application,

thoroughly sweep and rinse the roof to

remove all dust and dirt. If necessary,

scrub the roof with a solution of TSP

(trisodium phosphate) or other mild

detergent to remove any oil or grease

that may be on the surface.

PONDED WATER

This product is not suitable for ponded

water applications. Proper and adequate

roof drainage is required.

METAL ROOFS

Remove all rust by scraping or brushing

with a wire brush to clean the affected

areas. Replace and/or tighten screws

or fasteners as necessary. Prior to

applying white acrylic primer, apply a

quality metal primer that includes rust

inhibitive pigmentation to rust areas

only. A quality rust inhibitive primer will

include one or more of the following:

calcium borosilicate, strontium zinc

phosphosilicate, or zinc chromate.

Follow metal primer manufacturers

application instructions.

DESCRIPTION

A bright-white blend of 100% acrylic copolymers and ultraviolet and infrared reective

pigments. The combination of titanium dioxide pigment and acrylic copolymers

provides years of protection from harmful effects of sunlight, extending the life of most

roofs. It beauties and protects, reducing energy consumption by reecting greater

than 80% of the suns rays. 100% ASBESTOS FREE. 5-year limited warranty.

USES

This quality white coating is ideal for coating over asphalt rolled roong and metal

roong (including galvanized aged at least 6 months and prepainted metal) such as

grain silos and ambient-temperature storage tanks. It can also be used over mobile

homes, truck trailers, and school bus tops. It provides a weather-resistant shield over

the surfaces and reects harmful ultraviolet and infrared waves. It prolongs the life of

the roong system and its highly-reective surface reduces surface temperatures and

cooling costs. Staining of light oils is possible over some asphalt surfaces.

PRECAUTIONS

Wear protective clothing, gloves, and OSHA-approved eye protection.

When not in use, securely replace lids on open containers. Store in a cool,

dry place (above 32F) away from heat and corrosion sources..

APPLICATION RATE

BUR/Modied Roong: 2 gallons per 100 sq. ft.

Metal Surfaces: 1.25 gallons per 100 sq. ft.

Condition of roof surface will affect coverage rates.

Stated application rates are intended as minimums.

PRODUCT NUMBER

30001361 - 5 gal.

TAM-GUARD

WHITE ELASTOMERIC COATING

PRODUCT DATA

COATING APPLICATION

A three-step process of Prime,

Patch/Reinforce (as required),

and Coat should be utilized in

ALL applications. Use TAM-STAR

White Acrylic Primer, TAM-STAR White

Patching Cement and TAM-STAR White

Mesh to help prepare the surface prior

to application of the coating. Apply

according to application instructions.

Prime the surface according to primer

application instructions. Use fabric

and patching cement to repair cracks,

holes, open seams, or around ashings.

Apply coating with a roong brush,

long nap roller, or suitable airless

spray equipment. To ensure optimum

performance, apply two coats, each

coat at 1/2 the total coverage rate and

applied perpendicular to each other.

Allow rst coat to dry 2-4 hours prior to

application of second coat.

Outside temperature must be 50F

and rising before application. In

hot conditions, when ambient air

temperature is 95F or above, lightly

spray the roof with water to prevent

rapid drying. It is OK to apply coating

over damp surfaces but not on standing

water. Allow 46 hours to dry before

being subjected to rain, heavy dew, or

temperatures below 50F. If rain or dew

develops within 46 hours prior to the

roof drying and coating run off occurs,

the affected areas must be recoated.

NOTE: STIR THOROUGHLY BEFORE AND

DURING USE. KEEP FROM FREEZING.

PRODUCT FREEZES AT 32F

AND MUST NOT BE USED

OR STORED ABOVE 140F.

CONTINUED

tamko.com

Rev. 08/12

Information included in this product data sheet was current at time of printing. To obtain a copy of the most current version of this product data sheet, visit us online at tamko.com or call us at 800-641-4691.

For information regarding or a copy of TAMKOs limited warranty, contact your local TAMKO representative, visit us online at tamko.com, or call us at 800-641-4691.

TAMKO

is a registered trademark of TAMKO Building Products, Inc.

Central District 220 West 4th Street, Joplin, Missouri 64801 800-641-4691

Northeast District 4500 Tamko Drive, Frederick, Maryland 21701 800-368-2055

Southeast District 2300 35th Street, Tuscaloosa, Alabama 35401 800-228-2656

Southwest District 7910 South Central Expressway, Dallas, Texas 75216 800-443-1834

Western District 5300 East 43rd Avenue, Denver, Colorado, 80216 800-530-8868

Initial Weathered

Solar Reectance 0.80 0.61

Thermal Emittance 0.93 0.91

Rated Product ID 0714-0001

Licensed Manufacturer ID 0714

Classication Production Line

Cool Roof Rating Council ratings are determined for a xed set of conditions, and may not be appropriate

for determining seasonal energy performance. The actual effect of solar reectance and thermal emittance

on building performance may vary.

Manufacture of product stipulates that these ratings were determined in accordance with the applicable

Cool Roof Rating Council procedures.

TYPICAL PROPERTIES

TEST METHOD RESULT

Wt/gal, lbs. D2939 10.3-10.7

Solids % by wt. D1644 54-58

% by vol. D2697 44-48

Viscosity @ 77 cps Brookeld RVT, 10 rpm, #4 spindle 12,000-16,000

pH N/A 8-10

Flash Point, F PMCC None

Color, Cured Visual white

Drying time, Touch 70F/50% R.H. 4-6 hours

Solar Reectance C1549 .80

Shelf Life 70F/50% R.H. 1 year

VOC EPA Method 24A 20 gm/liter max.

TAM-GUARD

WHITE ELASTOMERIC COATING

PRODUCT DATA

APPLICATION METHOD

Roong Brush, Long Nap Roller or Airless Sprayer

AIR ATOMIZED SPRAY

METHOD ATOMIZING PRESSURE

Pressure 1500 PSI

FLUID TIP FLUID DELIVERY

.035" .055" 13 Gal per Min.

CAUTION: This product contains crystalline silica. Crystalline silica has been classifed as a known human carcinogen by

the International Agency for Research on Cancer (IARC) and the National Toxicology Program. This product also contains

titanium dioxide. IARC has classifed titanium dioxide as a possible human carcinogen. The physical nature of this product

may help limit any inhalation or dermal hazard during application and/or removal. However, physical forces such as sawing,

grinding or drilling during installation and demolition work and heating or burning may increase the inhalation or dermal

exposure hazard of this product. Take precautions to prevent breathing dust from the product.

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- World Currency White Paper Vol 1. by H.I.M Dr. Lawiy-Zodok Shamuel, D.D.Документ11 страницWorld Currency White Paper Vol 1. by H.I.M Dr. Lawiy-Zodok Shamuel, D.D.:Lawiy-Zodok:Shamu:-El50% (2)

- Laboratorio de Microondas - Medicion en Lineas de TX Usando Lineas RanuradasДокумент5 страницLaboratorio de Microondas - Medicion en Lineas de TX Usando Lineas RanuradasacajahuaringaОценок пока нет

- Types of CameraДокумент18 страницTypes of CameraVijay Ravi100% (1)

- ALL SYSTEMS GO by Zenovia AndrewsДокумент225 страницALL SYSTEMS GO by Zenovia AndrewsTanya Gillie100% (3)

- SAP MM Module OverviewДокумент15 страницSAP MM Module OverviewAmit Kumar100% (1)

- kp-57-65wv600 SONYДокумент33 страницыkp-57-65wv600 SONYdjcamdtvОценок пока нет

- Coal JourneyДокумент2 страницыCoal JourneyasnandyОценок пока нет

- Colphenebswh 1816Документ2 страницыColphenebswh 1816vinoth kumar SanthanamОценок пока нет

- Regulatory Compliance and Generator ControlДокумент59 страницRegulatory Compliance and Generator ControlsulemankhalidОценок пока нет

- Journal Approval WorkflowДокумент46 страницJournal Approval Workflowvarachartered283Оценок пока нет

- Practice Test 3Документ13 страницPractice Test 3Ngân Hà NguyễnОценок пока нет

- Wwii Aircraft Vol 2Документ50 страницWwii Aircraft Vol 2Virág Árpád100% (5)

- TELEC-Dwg-Al Khater Plastic FactoryДокумент8 страницTELEC-Dwg-Al Khater Plastic FactoryRENJITH K NAIRОценок пока нет

- O21350 CMMKKДокумент2 страницыO21350 CMMKKwade.hynesoutlook.comОценок пока нет

- Click and Learn How To Get Free TikTok FansДокумент4 страницыClick and Learn How To Get Free TikTok FansFreedmanMcFadden9Оценок пока нет

- TUPT AdmissionDegreeLadderizedДокумент1 страницаTUPT AdmissionDegreeLadderizedromerqazwsxОценок пока нет

- Block Diagram: PowerДокумент96 страницBlock Diagram: PowerBrennan GriffinОценок пока нет

- Ahsmrw30dam SD101Документ48 страницAhsmrw30dam SD101ibrahimОценок пока нет

- Digital Data, Digital SignalДокумент8 страницDigital Data, Digital SignalBastomi Adi NugrohoОценок пока нет

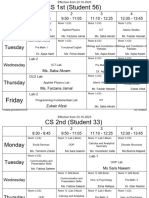

- 3b - Classwise Time Table - 2Документ15 страниц3b - Classwise Time Table - 2Hamza khalidОценок пока нет

- SFP Module PDFДокумент2 страницыSFP Module PDFMario PatarroyoОценок пока нет

- Domus Ventilation Guide 2019Документ96 страницDomus Ventilation Guide 2019Regie CayasОценок пока нет

- Active Suspension System of Quarter CarДокумент70 страницActive Suspension System of Quarter CarMarcu SorinОценок пока нет

- Sika Cemflex 1Документ3 страницыSika Cemflex 1rasasiОценок пока нет

- Aspect Oriented ArchitectureДокумент43 страницыAspect Oriented ArchitectureerzhanbaiОценок пока нет

- Specification For HDPE MANHOLES PDFДокумент4 страницыSpecification For HDPE MANHOLES PDFPipeline EngineerОценок пока нет

- History of HypnosisДокумент3 страницыHistory of Hypnosisbutterfly975k100% (1)

- Core Insights: Advances in 12G-SDIДокумент3 страницыCore Insights: Advances in 12G-SDIHedsdasОценок пока нет

- Physics 2Документ2 страницыPhysics 2MarcusKlahnTokoeJr.Оценок пока нет

- Your Profile 16personalitiesДокумент3 страницыYour Profile 16personalitiesapi-583293897Оценок пока нет