Академический Документы

Профессиональный Документы

Культура Документы

P&F HX - Counter Flow: Plate & Frame Heat Exchanger Sizing Waterside Economizer (Wse) Formulas

Загружено:

jnmanivannanИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

P&F HX - Counter Flow: Plate & Frame Heat Exchanger Sizing Waterside Economizer (Wse) Formulas

Загружено:

jnmanivannanАвторское право:

Доступные форматы

Energy Efficient Building Design

College of Architecture

Illinois Institute of Technology (IIT), Chicago

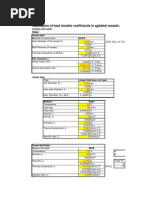

PLATE & FRAME HEAT EXCHANGER SIZING

WATERSIDE ECONOMIZER (WSE)

Operates from Nov-Mar when WB <= 40 F

FORMULAS

Heater in Clg Twr Basin or ByPass

to prevent freezing ??

CFM (ft3/min) x 7.48052 = GPM (gals/min)

CW-to-HX

GPM / 7.48052 (ft3/lb) x D (lbs/ft3) x 60 (min/hr) = M ( lbs/hr)

or GPM x 8.021 x D = M

To2 =

Q (mbh) = M x SH x (Ti - To) / 1000 =

Ti1 = Fluid-1 - In

(GPM x 8.021 x D) x SH x (Ti - To) /1000 = To1 = Fluid-1 - Out

48

CW-Out

GPM x 0.008021 x D x SH x (Ti - To)

Ti2 = Fluid-2 - In

LMTD (Log Mean Temp Diff) =

To2 = Fluid-2 - Out

CHW-In

[(To2-Ti1) - (Ti2-To1)] / [LN{(To2-Ti1) / (Ti2-To1)}]

To1 =

where (To2-Ti1) > (Ti2-To1)

LMTD = (DT1- DT2) / (LN (DT1/DT2))

DT1 = ABS ( Ti1 - To2 )

54

CHW-to

where DT1 > Dt2

DT2 = ABS ( Ti2 - To1 )

HX

Q = A x U x LMTD

Surface Area (A) = Q / (U x LMTD)

To1 = CHW-In

54

Ti1= CHW-Out

44

Ti2 = CW-In

Log Mean Temperature Difference (LMTD)

42

W

HX Plates

To2 = CW-Out

48

Cooling

CWR

2285 gpm

Tower

CWS

By-Pass

CW-to-HX

Ti2 =

42

P+F Heat

CW-In

Exchanger

(chiller)

CHW-Out

Ti1 =

44

CHW-Frm

HX

CHWR

Cooling

CHWS

Coils

1985 gpm

P&F HX - COUNTER FLOW

CWS

CW-in : Ti2

H

2. Primary Fluid

CW-from-HX

Ti2 =

42

CWR

2285 gpm

CW-to-HX

CHW-out : To1

To2 =

DT2 =

DT1 =

CW-out : To2

To1 =

CHW-in : Ti1

48

44

CHW-from-HX

CHWS

1985 gpm

1. Secondary Fluid

Ti1 =

54

CHW-to-HX

CHWR

Air Handling Unit (AHU) Cooling Coil

COILING-COIL - CROSS-FLOW

Cooling Coil

CHW-from-HX

CHWS

To1 =

54

Ti1 =

44

44 degF

DT2 =

Ti2 =

36

90

DT1 =

Air-IN

90 degF

Air-OUT

50 degF

To2 =

50

54 degF

CHW-to-HX

CHWR

Varkie C. Thomas, Ph.D., P.E.

Skidmore, Owings Merrill, LLP

Water-Side - Economizer

Energy Efficient Building Design

College of ArchitectureIllinois Institute of Technology (IIT), Chicago

Heat Exchanger Calculations

Two basic formulas are used in all heat exchanger calculations. These are:

Heat transfer Btu/hr = lbs/hr x sp ht x temp. change F

In the case of water, the specific heat can usually be considered as 1.0

and the formula expressed as:

Btu/hr = flow rate in GPM x 500 x temp. change F (1)

where: 500 = 8.33 lbs/gal x 60 min/hr

conversion to lbs/hr

Heat transfer in Btu/hr = (U)(A)(LMTD) (2)

where: U = overall heat transfer coefficient A = heat transfer area in sq. ft.

U = overall heat transfer coefficient A = heat transfer area in sq. ft.

LMTD = log mean temperature difference = (large temp. diff.) - (small temp. diff.)

all divided by: the natural log of (large temp. diff - small temp. diff)

The range of the heat transfer coefficient "U" varies widely, depending upon the physical

conditions such as the solution viscosities, surface fouling, fluid velocities

and turbulence, involved, constant or change of state, and metal resistance.

For example, water-to-water heat exchangers typically have "U" value ranges like:

Plate-frame: 500 to 1,200 Btu/(hr x sq ft xF)

Shell and tube: 150 to 350 Btu/(hr x sq ft xF)

Plate-coil: 50 to 250 Btu/(hr x sq ft xF)

These can be contrasted to "U" values of 4 to 8 for air-to-air or steam-to-air heat transfer,

which is why these are usually plate-fin coils with very large surface areas

Q = U x A x LMTD x Cf

where: Q = Heat load in Btu/hr

U = Overall heat transfer coefficient in Btu/hrft2 oF A = Area (ft2)

LMTD = Log mean temperature difference (oF)

Cf = LMTD correction factor (0.85 - 1.0 for most geothermal applications).

Example selection: Application - radiant floor heating in 350,000 ft2 factory

Resource temperature - 170 oF

Available geothermal flow - 375 gpm

Load - 7,500,000 Btu/hr

Building loop supply water temperature - 135 oF max.

Geothermal temperature drop: = 7,500,000 Btu/hr (500 375 gpm) = 40 oF.

Geothermal exit temperature: = 170 oF - 40 oF = 130 oF.

Geothermal side 170 oF to 130 oF

Building side 135 oF to 120 oF

Dt1 = 170 oF - 135 oF = 35 oF

Dt2 = 130 oF - 120 oF = 10 oF

Q = U x A x LMTD x Cf

Using a LMTD convection factor of 0.90, required heat exchanger area is:

Area = 7,500,000 Btu/hr (19.9 oF 0.90 950 Btu/hrft2 oF) = 441 ft2

Varkie C. Thomas, Ph.D., P.E.

Skidmore, Owings Merrill, LLP

HX formulas

Energy Efficient Building Design

College of Architecture

Illinois Institute of Technology (IIT), Chicago

TRANTER

http://www.tranter.com/pd

TACO

http://www.taco-hvac.com/products.html?current_category=73

Varkie C. Thomas, Ph.D., P.E.

Skidmore, Owings Merrill, LLP

HX Pictures

Energy Efficient Building Design

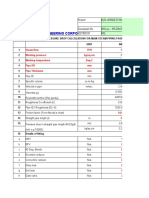

Properties

Temperature (F)

-30

Water

Density (lb/cu ft)

Specific Gravity = Dens/62.4

Kinematic Viscosity (sq ft/sec)

Specific Heat (Btu/lb oF)

Glycol

Density (lb/cu ft)

Specific Gravity = Dens/62.4

Kinematic Viscosity (sq ft/sec)

Specific Heat (Btu/lb oF)

Brine

Illinois Institute of Technology (IIT), Chicago

Kinematic Viscosity (sq.ft./sec) in Liquid Tables are: (value shown)/1,000,000

PROPERTIES OF LIQUIDS

Liquid

College of Architecture

Density (lb/cu ft)

Specific Gravity = Dens/62.4

Kinematic Viscosity (sq ft/sec)

Specific Heat (Btu/lb oF)

PROPERTIES OF HIGH TEMPERATURE HOT WATER

30

62.42

60

62.37

100

62.00

150

61.20

210

59.81

1.00

1.00

0.99

0.98

0.96

19.31

12.17

7.39

4.76

Temp

Satr Pr

Density

Specific

Kin Visc

Sp. Heat

3.20

deg F

T

psig

P

lb/cu ft

D

Gravity

D/62.4

sqft/sec

V

Btu/lb-F

H

1.00

1.00

1.00

1.00

1.01

212

0.0

59.81

0.96

3.20

1.0055

67.98

67.55

67.11

66.55

65.74

64.68

63.12

220

2.5

59.63

0.96

3.00

1.0068

1.09

1.08

1.08

1.07

1.05

1.04

1.01

240

10.3

59.10

0.95

2.70

1.0104

595.00

190.00

85.40

48.60

22.60

12.50

6.40

260

20.7

58.51

0.94

2.50

1.0148

0.70

0.73

0.76

0.78

0.81

0.85

0.88

280

34.5

57.94

0.93

2.30

1.0200

78.59

78.21

77.71

77.21

76.09

300

52.3

57.31

0.92

2.10

1.2600

1.26

1.25

1.25

1.24

1.22

350

119.9

55.59

0.89

1.90

1.0440

171.70

77.50

34.70

21.80

8.90

400

232.6

53.65

1.70

1.0670

0.66

0.67

0.68

0.69

0.71

450

407.9

51.55

0.86

0.83

1.50

1.0950

PROPERTIES OF STEAM

Density = 1 / Specific Volume

Press

Temp

Sp. Vol.

Density

Sp. Gr

psig

0

deg F

212.0

cuft/lb

26.80

lbs/cuft

0.03731

D/62.4

0.00060

Liquid

180.1

Latent

970.3

Density of Water @ 40 F =

Sp. Ht.

Kin Visc

Specific Gravity = Density of Fluid / Density of Water @ 40 F

Total

1150.4

Btu/lb-F

0.45300

sqft/sec

0.00023

Specific Heat (btu/lb.F) @ 0 psig & 212 F =

Enthalpy btu/lb

Sp. Ht. @ 15 psig & 250 F =

62.4

0.453

(TH @ 250F -TH @ 240F) / (250 - 240)

227.3

20.34

0.04916

0.00079

195.5

960.5

1156.0

0.36601

0.00017

Viscosity (Centipoise) of Steam @ 0 psig & 212 F =

0.0125

10

240

16.46

0.06075

0.00097

207.9

952.5

1160.4

0.34646

0.00014

Viscosity (Centipoise) of Steam @ ? psig & 932 F =

0.028

15

250

13.86

0.07215

0.00116

218.3

945.6

1163.9

0.35000

0.00012

20

258.8

11.98

0.08347

0.00134

227.5

939.5

1167.0

0.35227

0.00010

Kinematic Viscosity (Centistokes) = Viscosity (Centipoise) / Specific Gravity

0.00001076

Centistokes = 1.0 sq mm / sec =

sq ft / sec

25

266.9

10.56

0.09470

0.00152

235.6

934.0

1169.6

0.32099

0.00009

Kin Visc (sqft/sec) = Viscosity (Centipoise) x 0.0000108 / Specific Gravity

30

274.1

9.45

0.10582

0.00170

243.0

928.9

1171.9

0.31944

0.00008

35

280.7

8.56

0.11682

0.00187

249.8

924.2

1174.0

0.31818

0.00007

40

286.8

7.83

0.12771

0.00205

256.0

919.8

1175.8

0.29508

0.00007

U : btu/hr.ft2.F

45

292.4

7.20

0.13889

0.00223

261.8

915.7

1177.5

0.30357

0.00006

U = 1 / ( 1/Ho + t/K + 1/Hi)

50

297.7

6.68

0.14970

0.00240

267.2

911.8

1179.0

0.28302

0.00006

60

307.3

5.83

0.17153

0.00275

277.2

904.6

1181.8

0.29167

0.00005

Applic

Heatg

Ht Trans Materl

Copper

t

0.0747

Ho

300

Hi

1000

K-value

2680

U-value

229

70

316.4

5.18

0.19305

0.00309

286.2

898.0

1184.2

0.26374

0.00004

Water

Aluminum

0.0747

300

1000

1570

228

80

323.9

4.66

0.21459

0.00344

294.4

891.9

1186.3

0.28000

0.00004

with

Carbon Steel

0.0747

300

1000

312

219

90

331.2

4.24

0.23585

0.00378

301.9

886.1

1188.0

0.23288

0.00004

Steam

Stainless Steel

0.0747

300

1000

113

200

100

337.9

3.89

0.25707

0.00412

308.9

880.7

1189.6

0.23881

0.00003

110

344.2

3.59

0.27855

0.00446

315.5

875.5

1191.0

0.22222

0.00003

Heatg

Copper

0.0747

300

300

2680

149

120

350.1

3.34

0.29940

0.00480

321.7

870.7

1192.4

0.23729

0.00003

Water

Aluminum

0.0747

300

300

1570

149

130

355.6

3.12

0.32051

0.00514

327.6

865.9

1193.5

0.20000

0.00003

with

Carbon Steel

0.0747

300

300

312

145

140

360.9

2.93

0.34130

0.00547

333.1

861.5

1194.6

0.20755

0.00002

HW

Stainless Steel

0.0747

300

300

113

136

150

365.9

2.76

0.36232

0.00581

338.4

857.2

1195.6

0.20000

0.00002

170

375.2

2.47

0.40486

0.00649

348.3

848.9

1197.2

0.17204

0.00002

Heatg

Copper

0.0747

1000

2680

4.97

200

387.8

2.13

0.46948

0.00752

361.9

837.4

1199.3

0.16667

0.00002

Air

Aluminum

0.0747

1000

1570

4.97

220

395.5

1.95

0.51282

0.00822

370.1

830.3

1200.4

0.14286

0.00002

with

Carbon Steel

0.0747

1000

312

4.97

250

406.1

1.74

0.57471

0.00921

381.6

820.1

1201.7

0.12264

0.00001

Steam

Stainless Steel

0.0747

1000

113

4.96

Instructor: Varkie C. Thomas, Ph.D., P.E.

PROPERTIES OF HEAT TRANSFER MATERIALS & SURFACES

Skidmore, Owings Merrill LLP

K : btu/hr.ft2.F/in

Film Coeff Ho,Hi : btu/hr.ft2.F

t = Thickness of Material (inches)

Fluid-Properties

Вам также может понравиться

- EIND 3184 15 Liquid Flash Vessel SizingДокумент20 страницEIND 3184 15 Liquid Flash Vessel SizingzamijakaОценок пока нет

- Thermal 3TPH 12Kg FO Fired Boiler R0Документ6 страницThermal 3TPH 12Kg FO Fired Boiler R09913489806Оценок пока нет

- Shell Side Fluid Heat Load and Tube Side Fluid Heat Transfer CalculationsДокумент6 страницShell Side Fluid Heat Load and Tube Side Fluid Heat Transfer CalculationsrajachemОценок пока нет

- Calculation Overall Heat TransferДокумент4 страницыCalculation Overall Heat TransferDavid LambertОценок пока нет

- Heat Exchanger CalcДокумент34 страницыHeat Exchanger Calcميثة الغيثيةОценок пока нет

- 3 - Heating - Calculation - Tool - EmptyДокумент7 страниц3 - Heating - Calculation - Tool - EmptyThaigroup CementОценок пока нет

- Double Pipe Heat Exchanger Analysis (Example 5.1) : Water WaterДокумент3 страницыDouble Pipe Heat Exchanger Analysis (Example 5.1) : Water WaterBagusRekaОценок пока нет

- Radiation and Convection Heat TransferДокумент5 страницRadiation and Convection Heat TransfergsdaundhОценок пока нет

- Circulating Fluidized Bed Boiler Design and OperationДокумент9 страницCirculating Fluidized Bed Boiler Design and OperationSanket BhaleraoОценок пока нет

- Round Tube and Plate Fin Air Cooled Condenser CalculationДокумент8 страницRound Tube and Plate Fin Air Cooled Condenser Calculationjamil100% (1)

- Heat ExchangerДокумент53 страницыHeat ExchangerNurulHidayahОценок пока нет

- Wet Air Properties Calculation Sheet: at Low PressureДокумент2 страницыWet Air Properties Calculation Sheet: at Low Pressurezsmith0% (1)

- Heat Loss Insulated PipeДокумент14 страницHeat Loss Insulated PipeJonson CaoОценок пока нет

- WHB Calculation for Flue Gas Heat RecoveryДокумент1 страницаWHB Calculation for Flue Gas Heat RecoveryDavid LambertОценок пока нет

- Shell and Tube VaporizerДокумент17 страницShell and Tube VaporizercontinentalflossОценок пока нет

- Psychrometric CalculatorДокумент4 страницыPsychrometric CalculatorArie Emmanuel ListonОценок пока нет

- Cooling Load CalculationДокумент32 страницыCooling Load CalculationHenry San PedroОценок пока нет

- Heat Transfer in Jacketed VesselДокумент2 страницыHeat Transfer in Jacketed VesselMuthuKumar Arunachalam0% (1)

- Process Calculations For DesignДокумент26 страницProcess Calculations For DesignOmprakaash MokideОценок пока нет

- Shell Tube Heat Exchanger DesignДокумент7 страницShell Tube Heat Exchanger DesignAbhijeet JhaОценок пока нет

- Heat Loss From An Insulated Pipe: ParametersДокумент4 страницыHeat Loss From An Insulated Pipe: ParametersMohan BabuОценок пока нет

- Perhitungan Dan Disain HeaterДокумент19 страницPerhitungan Dan Disain HeatersehonoОценок пока нет

- Pipe Flow Friction Factor CalculationsДокумент11 страницPipe Flow Friction Factor CalculationsVictor ValenciaОценок пока нет

- Jacketed Vessel Heat Transfer (Half Pipe Coil) : MM Inch MM RPM MM M /HДокумент30 страницJacketed Vessel Heat Transfer (Half Pipe Coil) : MM Inch MM RPM MM M /Hmanoj67% (3)

- Condenser & EvaporatorДокумент21 страницаCondenser & EvaporatorfitratulqadriОценок пока нет

- Condensation Calculation for Dubai Airport BuildingДокумент40 страницCondensation Calculation for Dubai Airport Buildingwado11Оценок пока нет

- Condenser Calculation - Shell and TubeДокумент3 страницыCondenser Calculation - Shell and TubedeeptimisraОценок пока нет

- Reciprocating Compressor Calculation Sheet: Gas Properties, Flowrate and ConditionsДокумент9 страницReciprocating Compressor Calculation Sheet: Gas Properties, Flowrate and ConditionsSlim Toumi0% (1)

- Heat Transfer Excel Calculations 1Документ39 страницHeat Transfer Excel Calculations 1Mahendra VadavaleОценок пока нет

- Steam Coil SizingДокумент21 страницаSteam Coil SizingMildogg100% (1)

- Process Water Scrubber Cooling Exchanger ProjectДокумент1 страницаProcess Water Scrubber Cooling Exchanger ProjectDavid Muñoz CastroОценок пока нет

- Thermal Insulation Thickness Calculation (By James)Документ1 страницаThermal Insulation Thickness Calculation (By James)Ah BengОценок пока нет

- Chiller Size CalculatorДокумент4 страницыChiller Size CalculatormpokeОценок пока нет

- Cooling tower design parameters and heat balance calculationДокумент47 страницCooling tower design parameters and heat balance calculationDavid LambertОценок пока нет

- NT42 Calculation Heat Transfer of Storage Tank Rail TankДокумент2 страницыNT42 Calculation Heat Transfer of Storage Tank Rail TankAnonymous v5uipHОценок пока нет

- Boiler CalculationsДокумент6 страницBoiler CalculationsJesther Marlou C. OrongОценок пока нет

- Method of Heat Exchanger Sizing Kern MethodДокумент10 страницMethod of Heat Exchanger Sizing Kern Methodvazzoleralex6884Оценок пока нет

- Evaporator ExcelДокумент44 страницыEvaporator ExcelawenskieОценок пока нет

- Shell Tube Heat Exchanger CalculationДокумент20 страницShell Tube Heat Exchanger CalculationĐoàn TrangОценок пока нет

- Steam Coil DesignДокумент2 страницыSteam Coil DesignHendri SinagaОценок пока нет

- Heat Exchanger Design 1Документ9 страницHeat Exchanger Design 1Rajeev SaxenaОценок пока нет

- Heat Loss Calculation for Insulating Organic Liquid Storage TanksДокумент4 страницыHeat Loss Calculation for Insulating Organic Liquid Storage TanksCorrado CannellaОценок пока нет

- CALCULATIONS FOR VENTILATION OF INVERTER ROOMДокумент1 страницаCALCULATIONS FOR VENTILATION OF INVERTER ROOMHoney TiwariОценок пока нет

- Rigours Preheater: Feed - 1694.44 2.85 21.14 792.89 0.05 0.00Документ14 страницRigours Preheater: Feed - 1694.44 2.85 21.14 792.89 0.05 0.00semarasik_651536604100% (1)

- Humidifier Duty Calculation For in Duct or Air Handling Unit ApplicationДокумент3 страницыHumidifier Duty Calculation For in Duct or Air Handling Unit ApplicationEngFaisal AlraiОценок пока нет

- Case 2 - Tank Heat LossДокумент84 страницыCase 2 - Tank Heat Lossahmad santosoОценок пока нет

- Design of Heat ExchangersДокумент23 страницыDesign of Heat ExchangersKhalid Turki100% (2)

- Heat Exchanger Specification Sheet: MM M? M? Performance of One UnitДокумент9 страницHeat Exchanger Specification Sheet: MM M? M? Performance of One UnitGladys ZiSing LeeОценок пока нет

- Heat Exchanger Calculation Version 2Документ2 страницыHeat Exchanger Calculation Version 2huangjlОценок пока нет

- Shell & Tube Heat Exchanger Rating ProjectДокумент20 страницShell & Tube Heat Exchanger Rating ProjectFareeha HasanОценок пока нет

- REFREG CHARGE CALCДокумент12 страницREFREG CHARGE CALCKhadija MirajОценок пока нет

- Half Pipe Coil AgitatedДокумент1 страницаHalf Pipe Coil AgitatedNITINОценок пока нет

- Heat Transfer Coeficient in ReactorДокумент2 страницыHeat Transfer Coeficient in ReactorDavid LambertОценок пока нет

- Shell and Tube Heat Exchangers - Basic CalculationsДокумент31 страницаShell and Tube Heat Exchangers - Basic Calculations이가람97% (118)

- Heat Exchanger PerformanceДокумент31 страницаHeat Exchanger PerformanceFA AyОценок пока нет

- Design Heat Exchanger Shell and Tube TheДокумент8 страницDesign Heat Exchanger Shell and Tube ThezatamaqeelОценок пока нет

- Proposed Design of a 30-Ton Ice PlantДокумент8 страницProposed Design of a 30-Ton Ice Planteafz111Оценок пока нет

- Cooling Tower Formulae-ImpДокумент4 страницыCooling Tower Formulae-ImptpplantОценок пока нет

- A Proposed Design of Ice PlantДокумент8 страницA Proposed Design of Ice PlantNirob MahmudОценок пока нет

- REFRIGERATION CYCLE ANALYSISДокумент32 страницыREFRIGERATION CYCLE ANALYSISRome John FranciscoОценок пока нет

- Dola Char AnalysisДокумент3 страницыDola Char AnalysisS V NAGESHОценок пока нет

- Long Span PrattДокумент36 страницLong Span PrattCarmel Buniel SabadoОценок пока нет

- Larsen and Toubro Cement Plant Equipment ListДокумент14 страницLarsen and Toubro Cement Plant Equipment ListjnmanivannanОценок пока нет

- Steam Trap EstimatorДокумент9 страницSteam Trap EstimatorjnmanivannanОценок пока нет

- Average values and data qualifiers from literature on wastewater constituentsДокумент46 страницAverage values and data qualifiers from literature on wastewater constituentsjnmanivannanОценок пока нет

- COAL COMBUSTION CALCULATIONS AND FLUE GAS ANALYSISДокумент5 страницCOAL COMBUSTION CALCULATIONS AND FLUE GAS ANALYSISDenny ThomasОценок пока нет

- Brown Field Pipe Rack Design ForcesДокумент7 страницBrown Field Pipe Rack Design ForcesjnmanivannanОценок пока нет

- AHU Supply Front PackageДокумент10 страницAHU Supply Front PackagejnmanivannanОценок пока нет

- Structural Sections SpreadsheetДокумент74 страницыStructural Sections Spreadsheetpiper1985Оценок пока нет

- EI2009Документ717 страницEI2009jnmanivannanОценок пока нет

- 22268Документ290 страниц22268jnmanivannanОценок пока нет

- Soil Resistivity1Документ12 страницSoil Resistivity1jnmanivannanОценок пока нет

- GiwlistДокумент1 страницаGiwlistjnmanivannanОценок пока нет

- Emiss Calc HotmixДокумент37 страницEmiss Calc HotmixjnmanivannanОценок пока нет

- Plant SpecificationsДокумент4 страницыPlant SpecificationsjnmanivannanОценок пока нет

- GEMI Equations ToolДокумент10 страницGEMI Equations TooljnmanivannanОценок пока нет

- Chimney Qty ReinforcementДокумент25 страницChimney Qty ReinforcementjnmanivannanОценок пока нет

- EI2009Документ717 страницEI2009jnmanivannanОценок пока нет

- DFMEA analysis of Sand Bed Turnover Monitor projectДокумент2 страницыDFMEA analysis of Sand Bed Turnover Monitor projectjnmanivannanОценок пока нет

- EH GPR Checklist v1-2Документ8 страницEH GPR Checklist v1-2jnmanivannanОценок пока нет

- GEMI Equations ToolДокумент10 страницGEMI Equations TooljnmanivannanОценок пока нет

- Normality Acid, N Sample Vol: ML PHДокумент10 страницNormality Acid, N Sample Vol: ML PHjnmanivannanОценок пока нет

- 보온재두께계산Документ2 страницы보온재두께계산Sharon LambertОценок пока нет

- H 2 EauДокумент4 страницыH 2 EaujnmanivannanОценок пока нет

- H 2 EauДокумент4 страницыH 2 EaujnmanivannanОценок пока нет

- Journal of Engineering Physics and Thermophysics Volume 47 Issue 1 1984 (Doi 10.1007 - bf00832588) E. N. Pis'Mennyi - Study of Flow On The Surface of Fins On Cross-Finned TubesДокумент5 страницJournal of Engineering Physics and Thermophysics Volume 47 Issue 1 1984 (Doi 10.1007 - bf00832588) E. N. Pis'Mennyi - Study of Flow On The Surface of Fins On Cross-Finned TubesjnmanivannanОценок пока нет

- Fluid HeatДокумент83 страницыFluid HeatjnmanivannanОценок пока нет

- FEMA Equip ScheduleДокумент14 страницFEMA Equip SchedulejnmanivannanОценок пока нет

- Busbar Size Calculation (22.8.12)Документ16 страницBusbar Size Calculation (22.8.12)Jeya KannanОценок пока нет

- Calculation Form CombustionДокумент2 страницыCalculation Form CombustionjnmanivannanОценок пока нет

- G2 SolubilityДокумент3 страницыG2 SolubilityBryan AliОценок пока нет

- Differentiate Mixtures and SolutionsДокумент12 страницDifferentiate Mixtures and SolutionsKirk KinoОценок пока нет

- Session 14 - Conductometric Titration PDFДокумент26 страницSession 14 - Conductometric Titration PDFVidya Gujar100% (1)

- 1st Summative Test - SCIENCE 5Документ3 страницы1st Summative Test - SCIENCE 5Jeric Rodriguez LiquiganОценок пока нет

- RPS NF3Документ121 страницаRPS NF3Kim, Sung LakОценок пока нет

- Mass SpectrometryДокумент35 страницMass Spectrometrynowaby100% (6)

- Crop Nutrition - Integrated Nutrient ManagementДокумент12 страницCrop Nutrition - Integrated Nutrient ManagementDevashish NarayanОценок пока нет

- Interference of Light Waves..Документ17 страницInterference of Light Waves..Aditya Kumar DwivediОценок пока нет

- Antioxidants Feb 2016 enДокумент6 страницAntioxidants Feb 2016 enPhilip Blair OngОценок пока нет

- Patente GasificaciónДокумент126 страницPatente GasificaciónJuanma FernandezОценок пока нет

- Null 2Документ29 страницNull 2Samaseen PrabhatОценок пока нет

- First Term SS 2 Chemistry Scheme of WorkДокумент74 страницыFirst Term SS 2 Chemistry Scheme of Workangus ogwucheОценок пока нет

- The Special Theory of Relativity: Class Notes On Applied Modern Physics - ECEG 2101Документ16 страницThe Special Theory of Relativity: Class Notes On Applied Modern Physics - ECEG 2101Gébrè Sîllãsíê100% (1)

- Calcium AnalysisДокумент4 страницыCalcium Analysisjignesh_panОценок пока нет

- Chapter 2 Atomic Structure Notes Class 9 BДокумент6 страницChapter 2 Atomic Structure Notes Class 9 Bगोविंद माहेश्वरीОценок пока нет

- Lab Report Experiment 2b Separation MicetДокумент10 страницLab Report Experiment 2b Separation MicetAbdul QayyumОценок пока нет

- CE-1A ENSC1013 MRR2 PadillaДокумент2 страницыCE-1A ENSC1013 MRR2 PadillaThone Carl Padilla100% (2)

- P1 Jan18 QPДокумент32 страницыP1 Jan18 QPJovian AlvinoОценок пока нет

- Electrochemistry QuestionsДокумент8 страницElectrochemistry QuestionsSarthak KawatraОценок пока нет

- English for Oil and Gas Solomchak Ozarko Moiseyenko ІДокумент186 страницEnglish for Oil and Gas Solomchak Ozarko Moiseyenko ІNeonila KryvtsunОценок пока нет

- İzmir Kâtip Çelebi University Department of Mechanical Engineering ME 262 Strength of Materials II Final Exam (Spring)Документ8 страницİzmir Kâtip Çelebi University Department of Mechanical Engineering ME 262 Strength of Materials II Final Exam (Spring)Bengü MОценок пока нет

- Short Note On Fuel CellДокумент3 страницыShort Note On Fuel CellM Umar ChatthaОценок пока нет

- Ang MomTutsДокумент3 страницыAng MomTutsf20230796Оценок пока нет

- Herbal Medicines Compendium - Pelargonium Sidoides Root - 2013-07-26Документ3 страницыHerbal Medicines Compendium - Pelargonium Sidoides Root - 2013-07-26xumbalОценок пока нет

- Study Material Class 10 Chapter 4 2017Документ14 страницStudy Material Class 10 Chapter 4 2017Shreyash VishwakarmaОценок пока нет

- Lesson Plan - Carrom BoardДокумент20 страницLesson Plan - Carrom BoardPrashant SakharkarОценок пока нет

- Explosive Detection TheoryДокумент131 страницаExplosive Detection TheoryHans HanszeroОценок пока нет

- Biochemical Test of BacteriaДокумент33 страницыBiochemical Test of Bacteriaaziskf100% (2)

- 2nd Sem Food Science NotesДокумент46 страниц2nd Sem Food Science Notesponavnit85% (13)

- Project Report On Active Zinc OxideДокумент6 страницProject Report On Active Zinc OxideEIRI Board of Consultants and PublishersОценок пока нет