Академический Документы

Профессиональный Документы

Культура Документы

CR Modulare Sau Perete Uscat

Загружено:

ooviarОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

CR Modulare Sau Perete Uscat

Загружено:

ooviarАвторское право:

Доступные форматы

Deciding whether your cleanroom should be modular instead of drywall is not

the only decision a project team has to make when considering a cleanroom.

In most cases, the choice of panels is not as clear cut as once was the norm.

Once youve decided that you need a cleanroom, then what? For one, you have to

decide what type of clean-room you require. Many people within an organization will

not have the knowledge necessary to make an informed decision regarding their

cleanroom construction materials. An outside design and building firm is typically the

answer. They can help you with your clean-room design, lighting schemes, and HVAC

layouts, and also spearhead your construction. In addition to design and building firms,

many cleanroom vendors also offer these servicesas customers turn to vendors for

advice and turnkey solutions.

Before you set out to approve a cleanroom vendor, its important for you to understand

some basics. With so many vendors available youll want to know what makes one

vendor stand out from another. Various clean-room vendors supply a multitude of

different wall panels, insulation, ceiling systems, and floors. But which one is right for

you? Ill try to explain some of the different systems available to make you a more

informed shopper as you outsource your cleanroom.

MODULAR OR DRYWALL?

One of the first questions is modular or drywall? Modular offers the most flexibility. It

will allow you to expand as your business expands. Drywall has its economical

advantages but is quite permanent, and can be more expensive if all costvariables are

factored in.Lets look at the details:

Cost. Undoubtedly, the solution using drywall coated with epoxy paint looks, at first

glance, the most inexpensive option. In fact, while the level of initial investment could

be lower compared with the cost of square feet of installed wall using a modular

system, the picture may change looking at a wider scenario. The cost comparison

should also take into account the need for project supervision during assembly

(experienced and skilled site managers cost money!) and the need for training (and

making sure that supplied procedures are respected and enforced) of contractors who

usually are not familiar with the strict rules of a pharmaceutical, biotechnology, or any

company that needs to maintain clean environments and area separation. Project

management costs should also be compared: a modular cleanroom company should be

able to supply at least the architectural turnkey, including flooring, ceilings, furniture,

and accessories, using a drywall contractor for your partition; your project manager will

probably end up dealing with five or six different suppliers. Sometimes you will end up

paying more for single accessories or services. Your contractor will not get, most

probably, the same level of discounts for cleanroom products that a well marketed

modular cleanroom company would get. Most modular cleanroom vendors can supply

product resistant to scratches or hits. What would be the cost of shutting down your

cleanroom if a drywall, epoxy-coated partition is hit, gypsum is potentially spreading

into your clean environment, and you have to stop your production, fix the damage,

and revalidate?

Need of flexibility. A modular system is intrinsically a flexible system. Different suppliers

offer different levels of flexibility; but, in the end, you will be always be able to change

you partition layout before, during, and after wall assembly. Depending on the modular

cleanroom supplier of your choice, this might be more or less easy, but it will be

feasible; it will be done in a clean way without the need to create dust, debris, and any

type of scrap incompatible with production areas. Modular cleanroom modifications can

be done with the proper precautions while production is in process; drywall partition

modification needs a greater and much more careful approach.

Timing. Drywall can be supplied in a shorter time frame. A modular cleanroom company

might have the need to manufacture custom-made accessories, while the contractor

selected for drywall can be on site the next day. Then, timing reliability and project

milestones control might be better with a modular wall system ISO 9001 company than

with a small next door contractor. In this case, history and experience will play a

great role.

Project management resources. As mentioned above, going with drywall will mean the

need for more involvement of project management; if these resources are not available

internally, then outsourcing them might lead to communication or cost control issues. A

modular wall system company should supply project management as a part of its core

business.

Sterifoam insulation

Project environment. Creating partition and ceilings within an existing production area

might lead to a problem with ongoing production incompatible with material used for

erecting drywalls.

Durability. Modular cleanroom suppliers have a large variety of materials that differ in

terms of durability. Some offer materials that give a much higher reliability in terms of

robustness in comparison with drywalls. Drywalls might be faster to install, but in

certain situations, the walls will get worn faster.

Financing. Modular cleanrooms can be considered, from a financial standpoint, as

equipment. They can be leased or expensed in your financial statement as any other

piece of equipment.

What to decide?

Say for instance, you have decided to go with a modular system. Now you have to deal

with the wide selection of materials available with different suppliersor within the

assortment of a single supplier.

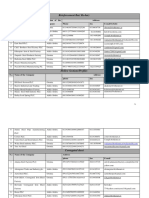

Lets take an overview of the main materials available. Here is a sketch showing the

main components of a modular panel. Next is a chart with a selectionof ten of the most

common panels available in the marketplace.

(Click Table For A Larger Image)

Panel schematic

SKINS

Wall panel skins are the surfaces of the wall panels that are exposed. Whattype of

modular panel skins should your cleanroom be constructed of? To answer this question,

you need to assess the purpose of the cleanroom along with how you plan on cleaning

your cleanroom. Are you going to use a wet or dry agent or both? Do you intend to

sterilize or sanitize? Answering these questions will give you a cleanroom matched to

you and not a cleanroom a vendor soldyou off the shelf. Lets look more closely at some

of the options available.

Flush interface with windows

uPVC: unplasticized polyvinyl chloride

Advantages:

-Very good resistance to all major cleaning agents

-Chemically welded joints and seams

-Available in different colors

-Average resistance to scratches

-Class A fire certification

Negatives:

-Need of skin supporting structure in case of scratches you lose the integrity of

your wall

-Once seams are welded, you lose modularity and flexibility

HPL 4 mm: high-pressure laminate impregnated with phe-nolic resins (also known as

phenolics)

Advantages:

-Very good resistance to all major cleaning agents

-Available in different colors

-High resistance to scratches

-Class A fire certification

-Easy to work for flush installation of accessories and for modification during

erection

-Solid, 4-mm panel; no need of supporting skin structure; in case of scratch or

wall chipping, no low class material exposed to the environment

Negatives:

-Cost might be higher for application where easy to clean flush surfaces are not

mandatory

-New to the industry in the North American marketplace

Epoxy powder coating: based on a epoxy resin with a hardener, such as

DICY(dicyandiamide) or special phe-nolic hardeners

Advantages:

-Very good resistance to all major cleaning agents

-Available in different colors

-Class A fire certification

-Depending on the skin, supporting structure may have competitive costs

Negatives:

-Low resistance to scratches

-Need of skin supporting structure, in case of scratches integrity of the wall is lost

Stainless steel: AISI 304 or AISI 316 are normally used in the industry

Advantages:

-Excellent resistance to all major cleaning agents

-Class A fire certification

-May or may not need skin supporting structure

In case of scratching or wall chipping, no low class material exposed to the

environment

Negatives:

-Low resistance to scratches and hand marks very visible. (Only aesthetic

problems)

-Not easy to work to allow flush applications of cov-ings and accessories

-Higher cost

Flush interface with covings and HPL panel

SKIN SUPPORTING STRUCTURE

Generally using a system that needs supporting skin structure presents thefollowing

pros and cons:

Advantages:

-It allows the use lower class material not exposed to the clean areas, thus

reducing costs

Negatives:

-In case of scratches or wall chipping low class material exposed to the

environment

Epoxy powder-coated walls

Carbon Steel: in most cases galvanized carbon steel is used

Advantages:

-Low cost

-It allows for Class A fire certification

-Good mechanical stability

Negatives:

-In case of scratches lower class material exposed to the clean area

-In case of scratches contact with water and cleaning agents may lead to rust and

corrosion

-Difficult to handle for modifications on site

-Difficult to handle for flush built accessories and covings

HPL 3 mm: high-pressure laminate impregnated with phe-nolic resins; generally used

as supporting structure for Stainless steel or PVC coating

Advantages:

-Consistency with the use of HPL 4 mm for integration with door and coving

profiles used in other areas

-Good mechanical stability

Negatives:

-High cost

INSULATION

Some modular wall manufacturers products include panels without insulation.

Advantages:

-Avoid use of product that may lead to fumes in case of fire

-Cost

-Easier use of wall interior for utilities or electrical wiring

Negatives:

-Risk of condensate build up within walls

-No noise or heat insulation

Aluminum honeycomb: cell size, grade of aluminum, depth of the material, and

thickness of the cell wall are all variable that can vary based on different application

and requirements

Advantages:

-High fire resistance

-Very well accepted by FM

-Low weight/high strength

-Mechanical stability

Negatives:

-Higher cost

-Low thermal and noise insulation

Flush interface with covings and HPL panels

Flush interface with HPL and interlock indicator light

Styrofoam is a trademarked name for a specific form of insulation manufactured by The

Dow Chemical Company; "styrofoam" is not synonymous with "polystyrene;"

polystyrene is a vinyl polymer

Advantages:

-Very good insulation performances (noise and heat)

-No problem if exposed to installer during cutting for modifications on site

-Very good mechanical stability

-Competitive price

Negatives:

-Fire resistance not as good as other insulating material

-FM requires stricter anti fire measures if polystyrene is used.

-Due to fire resistance codes, it requires enclosing structure

Rockwool: a mass of fine intertwined fibers with a typical diameter of 6 to 10

micrometers; mineral wool may contain a binder and an oil to reduce dustingand

making it water repellent (hydrophobic)

Advantages:

-Good insulation performances (noise and heat)

-Good fire resistance performance; well accepted by FM

Negatives:

-Poor mechanical stability performance; it normally requires enclosing and

supporting structure

-Light precaution must be taken if operators are exposed to rock wool fibers

Polyurethane: a polymer consisting of a chain of organic units joined by urethane,used

for this purpose as rigid foam

Advantages:

-Good insulation performances (noise and heat)

-No problem if exposed to installer during cutting for modifications on site

-Very good mechanical stability

-Competitive price

Negatives:

-Fire resistance not as good as other insulating

-FM may require stricter anti fire measures if polyurethane is used

-Due to fire resistance codes, it requires enclosing structure

ENCLOSING SUPPORTING STRUCTURES

The selection of one or another of the above materials may lead to the needof using

supporting or enclosing material. Soft or easy to disaggregatematerial, such as

rockwool, may require an enclosing structure to provide thepanel with the necessary

mechanical stability or to prevent the gravity fallingeffect of the disaggregation over

time. Clean area SOP requirements may requirethe enclosure of any insulating material

within the panel. The choice of thematerial used for the supporting/ enclosing structure

may be dictated by theconsistency with the material used for skin support. It will not

make sense touse a higher quality material, such as aluminum, if the supporting skin is

galvanizedsteel.

CONCLUSION

All the material listed above has been used and approved within the pharma-biotech-

semiconductor industries worldwide. There are no general standards that prevent the

use of any the above materials. The choice then will be dictated by the needand the

requirements of every single project.

Price might be a leading factor in choosing; but then, as for the drywall/modular

comparison, sometimes little upfront savings may lead to either higher expenses later

or poor aesthetic results after a few months of operation.

The HPL system has a great advantage of not needing a supporting structure, thus

avoiding the risk of exposing the cleanroom to easy to degrade materials. HPL is easy

to be worked and cut on site, and allows for modification during the erection/installation

process. HPL can be milled and or grooved in order to allow for the flush mounting of

most accessories and covings. The easy to clean installations and final results are,

according to my opinion, a great plus in an environment where cleanliness is the

primary goal.

With regards to insulation material, if noise and thermal insulation is a requirement,

then rockwool might be the best choice. If cleanliness of all components and fire

reaction performance is the goal, the aluminum honey comb might be considered the

best choice. The final choice can then be driven by the overall quality of the supplier

providing one or more of the above-listed panel types. Price, unique technical solutions,

existence of QA procedures, supporting service during the DQ process, overall

flexibility, delivery terms, installation support and quality, and reliability are then the

usual factors to be evaluated when selecting a supplier.

Francesco Nigris is the Vice President of Nico-mac Srl,Italy,manufacturer of modular

systems, and President of Nicomac,Inc.,since 1991,dis-tributor of the NICOMAC Srl

products in USA, Canada,and Puerto Rico;80 Oak Street,Norwood, NJ 07648.He can be

reached at ph.201-768-9501, ext.12;francesco.nigris@nicomac.it; www.nicomac.com.

TOPICS

MODULAR CLEANROOMS

NOVEMBER 2006

Вам также может понравиться

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionОт EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionОценок пока нет

- Selecting The Proper Coating For Concrete Floors: By: Robert R. CainДокумент0 страницSelecting The Proper Coating For Concrete Floors: By: Robert R. CainAhmed Emad AhmedОценок пока нет

- Spray Paint Booths Purchasing GuideДокумент18 страницSpray Paint Booths Purchasing Guidefurtan100% (1)

- Flooring Solutions - Seamless Flooring Systems - SaДокумент28 страницFlooring Solutions - Seamless Flooring Systems - SajakovОценок пока нет

- Technical Manual 2011Документ49 страницTechnical Manual 2011Francisco Castillo100% (1)

- Choosing The Right Conformal Coating The Facts & MythsДокумент4 страницыChoosing The Right Conformal Coating The Facts & Mythssdfdfs7253Оценок пока нет

- MH Snap 20110506Документ220 страницMH Snap 20110506Nimeni AltulОценок пока нет

- CE CenterДокумент19 страницCE CenterQAQC GCCОценок пока нет

- Types of Flooring in HospitalДокумент6 страницTypes of Flooring in HospitalFiza Amim KhanОценок пока нет

- M3U5Документ18 страницM3U5agama1188Оценок пока нет

- Timetable He or WДокумент2 страницыTimetable He or Wmilkbelief4Оценок пока нет

- Cleanroom Brochure New LoResДокумент24 страницыCleanroom Brochure New LoResMusab HashmiОценок пока нет

- Adhesive BondingДокумент45 страницAdhesive Bondingizantux100% (2)

- Hospital Flooring FinalДокумент18 страницHospital Flooring FinalEiadKhamis100% (1)

- Color Capabilities: Solutions Through Global ExperienceДокумент4 страницыColor Capabilities: Solutions Through Global Experienceyoki_triwahyudiОценок пока нет

- Boral4Builders No7Документ14 страницBoral4Builders No7mutazsalihОценок пока нет

- Division 9 - Materials and Finishes: Page 1 of 8Документ8 страницDivision 9 - Materials and Finishes: Page 1 of 8UmarОценок пока нет

- Twelve Things That Should No Longer Be Seen in Cleanrooms: Surface IssuesДокумент4 страницыTwelve Things That Should No Longer Be Seen in Cleanrooms: Surface IssuespuneetoguptaОценок пока нет

- Performance Coatings - Greenheck FansДокумент12 страницPerformance Coatings - Greenheck Fansprsum_572100% (1)

- NUFORM Wall Finishing GuideДокумент20 страницNUFORM Wall Finishing GuidemartadijayaОценок пока нет

- Wallboard Finished Appearance Managing Expectations Best Practices White Paper en WB2625Документ5 страницWallboard Finished Appearance Managing Expectations Best Practices White Paper en WB2625Katyhuska NunezОценок пока нет

- R K Construction and Manpower ServicesДокумент11 страницR K Construction and Manpower ServicesR K Construction and Manpower ServicesОценок пока нет

- List of Exterior WallДокумент6 страницList of Exterior WallArwin ZamoraОценок пока нет

- AДокумент234 страницыAAdrian HurmuzacheОценок пока нет

- Commercial Carpet GuideДокумент19 страницCommercial Carpet GuideAghy Farid HidayatullahОценок пока нет

- Architect's Facade ManualДокумент240 страницArchitect's Facade ManualLaura Gardner93% (15)

- Damp Proof Course Didn WorkДокумент4 страницыDamp Proof Course Didn Workf5a1eam9100% (2)

- CertainTeed STM 10th EdДокумент46 страницCertainTeed STM 10th EdJustinFinneran100% (6)

- Spray Painting Unit 1.4Документ18 страницSpray Painting Unit 1.4arun3kumar00_7691821Оценок пока нет

- Waterborne Epoxy Curatives: High Performance. Low Emissions. Cost-EffectiveДокумент12 страницWaterborne Epoxy Curatives: High Performance. Low Emissions. Cost-EffectiverafchemОценок пока нет

- DesigningДокумент6 страницDesigningOrlando1949Оценок пока нет

- Precast Panel 1Документ61 страницаPrecast Panel 1ghion kebedeОценок пока нет

- Insulating MaterialsДокумент31 страницаInsulating Materialsحساب تجاريОценок пока нет

- Joint Free Slabs: The ConceptДокумент4 страницыJoint Free Slabs: The ConceptRoberto CarlosОценок пока нет

- Advantages of Powder Coating vs. Wet PaintДокумент6 страницAdvantages of Powder Coating vs. Wet PaintAlekxОценок пока нет

- Elite Crete Systems - 2010 Email CatalogДокумент17 страницElite Crete Systems - 2010 Email CatalogHunjo Femi100% (1)

- Rooftop Pipe Support EBookДокумент22 страницыRooftop Pipe Support EBookdhanu_lagwankarОценок пока нет

- 98985exactly How To Bid A Roof Covering Job, Just How To Estimate & Rate A Roofing JobДокумент2 страницы98985exactly How To Bid A Roof Covering Job, Just How To Estimate & Rate A Roofing Jobdearusr12hОценок пока нет

- Why Modular Cleanrooms?Документ2 страницыWhy Modular Cleanrooms?Yash KarkhanisОценок пока нет

- Stretch Ceiling System Newmat Uk Midlands LTDДокумент24 страницыStretch Ceiling System Newmat Uk Midlands LTDNewmatUKОценок пока нет

- Advanced Framing: B e N e F I T SДокумент12 страницAdvanced Framing: B e N e F I T STanja DjordjevicОценок пока нет

- Direct Applied Exterior Finish SystemsДокумент3 страницыDirect Applied Exterior Finish SystemsdssprateОценок пока нет

- Residential Construction SpecificationsДокумент10 страницResidential Construction Specificationsnhoniepogi100% (1)

- Residential Construction SpecificationsДокумент15 страницResidential Construction SpecificationsRico EdureseОценок пока нет

- Custom Home Builders 1Документ2 страницыCustom Home Builders 1Roy ReichowОценок пока нет

- Basement ConstructionДокумент2 страницыBasement ConstructionDevinder Chawla100% (2)

- Tank Coatings Covering The Basics of Selection and SpecificationДокумент4 страницыTank Coatings Covering The Basics of Selection and SpecificationHugo Fernando Solis100% (1)

- تصنيع PDFДокумент10 страницتصنيع PDFعبدالمؤمن خالد محمودОценок пока нет

- تصنيع PDFДокумент10 страницتصنيع PDFعبدالمؤمن خالد محمودОценок пока нет

- Do Chemical Damp Proof Courses WorkДокумент7 страницDo Chemical Damp Proof Courses Workqrsirljbf100% (2)

- Design CommunicationДокумент27 страницDesign CommunicationabinmaceОценок пока нет

- Repairing ConcreteДокумент19 страницRepairing ConcreteMKOZERDEMОценок пока нет

- Technology and Concepts For Joint Sealing PDFДокумент32 страницыTechnology and Concepts For Joint Sealing PDFyvanmmuОценок пока нет

- Embed and Relish The Comfort!Документ14 страницEmbed and Relish The Comfort!Gurcan PehlivanОценок пока нет

- Glass Fibre NonwovensДокумент4 страницыGlass Fibre NonwovensSachin ShindeОценок пока нет

- Eco-Friendly Material: Natural Red ClayДокумент9 страницEco-Friendly Material: Natural Red Clayapi-246050324Оценок пока нет

- Designerguide enДокумент46 страницDesignerguide endan20050505Оценок пока нет

- Sandwich Panel ThesisДокумент6 страницSandwich Panel Thesislaurenbarkeringlewood100% (2)

- Useful Construction ChemicalsДокумент4 страницыUseful Construction Chemicalsjustine8448Оценок пока нет

- Design of Composite Steel DeckДокумент1 страницаDesign of Composite Steel DeckAndro Rebuyas0% (1)

- Sub-Sectort Industries by ProductsДокумент9 страницSub-Sectort Industries by ProductsAlemu Regasa100% (2)

- Lighting Natural Daylighting 2021-22Документ51 страницаLighting Natural Daylighting 2021-22Pushkar100% (1)

- Cement Manufacturing ProcessДокумент15 страницCement Manufacturing ProcessJHON LHOYD CORPUZОценок пока нет

- Cau 2014Документ25 страницCau 2014vinay1999Оценок пока нет

- Shibaura N843Документ44 страницыShibaura N843wayne kiwicylinderheadsОценок пока нет

- A436-2020 Standard Specification For Austenitic Gray Iron CastingsДокумент5 страницA436-2020 Standard Specification For Austenitic Gray Iron CastingsPablo C. T.Оценок пока нет

- Layher Allround - Description and Technical SpecificationДокумент3 страницыLayher Allround - Description and Technical SpecificationYogesh WadhwaОценок пока нет

- Annexure-I & II in Fovor of Anandi Specialities & Service PVT LTDДокумент2 страницыAnnexure-I & II in Fovor of Anandi Specialities & Service PVT LTDLOGIN ANIMOОценок пока нет

- D Instruction To TenderersДокумент11 страницD Instruction To TenderersHUI NEE ONGОценок пока нет

- CorbelsДокумент5 страницCorbelsRakesh HarahОценок пока нет

- C1398Документ3 страницыC1398Jorge Luis Arevalo Lopez100% (1)

- Flange Leakage Checking in Caesar II Using ASME Section VIII MethodДокумент7 страницFlange Leakage Checking in Caesar II Using ASME Section VIII MethodZhiqiang Gu100% (1)

- Base Isolation For Multi Storey Buildings PDFДокумент311 страницBase Isolation For Multi Storey Buildings PDFRal GLОценок пока нет

- Offshore Piping Design CriteriaДокумент1 страницаOffshore Piping Design CriteriaDhakshina K100% (1)

- Renewable Energy Technologies (Elective) Sample Question Paper (Msbte Study Resources)Документ4 страницыRenewable Energy Technologies (Elective) Sample Question Paper (Msbte Study Resources)Lakshman Naik100% (1)

- MoRTH Circular Value Engineering 22.02.2023 PDFДокумент2 страницыMoRTH Circular Value Engineering 22.02.2023 PDFHimanshu PatelОценок пока нет

- Pipe Bender MachineДокумент3 страницыPipe Bender MachineNaman PrajapatiОценок пока нет

- KAT NX KSA 2020 EN WebДокумент220 страницKAT NX KSA 2020 EN WebSULISTYOWATIОценок пока нет

- Uet LahoreДокумент43 страницыUet LahoreMunawwar KhanОценок пока нет

- Production RateДокумент50 страницProduction RateFührer Magdi Badran100% (2)

- PMGSY INspection FormatДокумент15 страницPMGSY INspection FormatKrishan KumarОценок пока нет

- FABRICS Manelius Afhandling Og DataДокумент328 страницFABRICS Manelius Afhandling Og DatacarlossegoviaОценок пока нет

- E20s HAP50 - Manual HAP PDFДокумент144 страницыE20s HAP50 - Manual HAP PDFAnonymous XhkjXCxxsT100% (1)

- Jaisalmer: Case StudyДокумент27 страницJaisalmer: Case Studyhudco kaamОценок пока нет

- Catalogo BVMДокумент16 страницCatalogo BVMLeonardo Rachen RodriguezОценок пока нет

- 5822 2004 PDFДокумент19 страниц5822 2004 PDFSuresh CОценок пока нет

- Is 4877 1968Документ48 страницIs 4877 1968Dhan Singh RajputОценок пока нет

- List of Articles & BooksДокумент2 страницыList of Articles & BooksHarshil SafiОценок пока нет

- WO Mechanical Car ParkДокумент27 страницWO Mechanical Car ParkrohanbagadiyaОценок пока нет

- Analog Design and Simulation Using OrCAD Capture and PSpiceОт EverandAnalog Design and Simulation Using OrCAD Capture and PSpiceОценок пока нет

- Electrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tОт EverandElectrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tРейтинг: 4.5 из 5 звезд4.5/5 (27)

- Articulating Design Decisions: Communicate with Stakeholders, Keep Your Sanity, and Deliver the Best User ExperienceОт EverandArticulating Design Decisions: Communicate with Stakeholders, Keep Your Sanity, and Deliver the Best User ExperienceРейтинг: 4 из 5 звезд4/5 (19)

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureОт EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureРейтинг: 4.5 из 5 звезд4.5/5 (2)

- The Jobs To Be Done Playbook: Align Your Markets, Organization, and Strategy Around Customer NeedsОт EverandThe Jobs To Be Done Playbook: Align Your Markets, Organization, and Strategy Around Customer NeedsРейтинг: 5 из 5 звезд5/5 (1)

- The Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsОт EverandThe Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsОценок пока нет

- Laws of UX: Using Psychology to Design Better Products & ServicesОт EverandLaws of UX: Using Psychology to Design Better Products & ServicesРейтинг: 5 из 5 звезд5/5 (9)

- The Age of Agile: How Smart Companies Are Transforming the Way Work Gets DoneОт EverandThe Age of Agile: How Smart Companies Are Transforming the Way Work Gets DoneРейтинг: 4.5 из 5 звезд4.5/5 (5)

- Design for How People Think: Using Brain Science to Build Better ProductsОт EverandDesign for How People Think: Using Brain Science to Build Better ProductsРейтинг: 4 из 5 звезд4/5 (8)

- CATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchОт EverandCATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchРейтинг: 4 из 5 звезд4/5 (10)

- Lean vs Agile vs Design Thinking: What You Really Need to Know to Build High-Performing Digital Product TeamsОт EverandLean vs Agile vs Design Thinking: What You Really Need to Know to Build High-Performing Digital Product TeamsРейтинг: 4 из 5 звезд4/5 (2)

- Heat Exchanger Design Guide: A Practical Guide for Planning, Selecting and Designing of Shell and Tube ExchangersОт EverandHeat Exchanger Design Guide: A Practical Guide for Planning, Selecting and Designing of Shell and Tube ExchangersРейтинг: 4 из 5 звезд4/5 (13)

- The Maker's Field Guide: The Art & Science of Making Anything ImaginableОт EverandThe Maker's Field Guide: The Art & Science of Making Anything ImaginableОценок пока нет

- 507 Mechanical Movements: Mechanisms and DevicesОт Everand507 Mechanical Movements: Mechanisms and DevicesРейтинг: 4 из 5 звезд4/5 (28)

- The Art of Welding: Featuring Ryan Friedlinghaus of West Coast CustomsОт EverandThe Art of Welding: Featuring Ryan Friedlinghaus of West Coast CustomsОценок пока нет

- Understanding Automotive Electronics: An Engineering PerspectiveОт EverandUnderstanding Automotive Electronics: An Engineering PerspectiveРейтинг: 3.5 из 5 звезд3.5/5 (16)

- Basic Electric Circuits: Pergamon International Library of Science, Technology, Engineering and Social StudiesОт EverandBasic Electric Circuits: Pergamon International Library of Science, Technology, Engineering and Social StudiesРейтинг: 3 из 5 звезд3/5 (1)