Академический Документы

Профессиональный Документы

Культура Документы

Data Sheet Pressure Relief Valve

Загружено:

Anonymous UArnIEx0 оценок0% нашли этот документ полезным (0 голосов)

203 просмотров10 страниц1) The document provides specifications for pressure relief valves for a project to optimize a plant's VIT terminal in Coveñas, Colombia.

2) It specifies that pressure relief valves must be stamped with identification information and provides calculation, material, and certification requirements.

3) Pressure relief valves must be sized to relieve pressure at 285 psig at 100°F and be made of 316 stainless steel and other specified materials according to international standards.

Исходное описание:

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документ1) The document provides specifications for pressure relief valves for a project to optimize a plant's VIT terminal in Coveñas, Colombia.

2) It specifies that pressure relief valves must be stamped with identification information and provides calculation, material, and certification requirements.

3) Pressure relief valves must be sized to relieve pressure at 285 psig at 100°F and be made of 316 stainless steel and other specified materials according to international standards.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

203 просмотров10 страницData Sheet Pressure Relief Valve

Загружено:

Anonymous UArnIEx1) The document provides specifications for pressure relief valves for a project to optimize a plant's VIT terminal in Coveñas, Colombia.

2) It specifies that pressure relief valves must be stamped with identification information and provides calculation, material, and certification requirements.

3) Pressure relief valves must be sized to relieve pressure at 285 psig at 100°F and be made of 316 stainless steel and other specified materials according to international standards.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 10

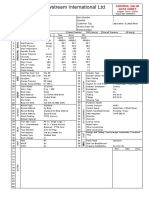

Notes:

DOCUMENTO NO.: 17412-01-DS-IE-4300

ECOPETROL # COV-5209124-11038-IB-INS-HD-004-B1 Contrato Marco de Ingeniera (CMI)

Ingeniera Bsica Para la

Optimizacin de la Planta VIT del Terminal Coveas Fase I

B1 Revision: Data Sheet for Pressure Relief Valves

1. Seller shall provide pressure relief valves with a permanently attached SS plate stamped with the following

information:Tag, P.O Number, connections, rating, and set pressure.

2. Seller shall confirm the valve size and shall provide area calculation with proposal.

3. Seller shall provide sizing calculation, calibration certificate, material and hydrotest certificate.

4. Seller shall provide pressure relief valve according to piping class VIT-GIT-P-ET-FE-001 Class AA1A22

designed to 285 psig @ 100F.

5. Certification not required.

6. For calculations details see Doc No. COV-5209124-11038-IB-INS-MC-002 "Memoria de Clculo Vlvulas de Alivio de

Presin"

COV-5209124-11038-IB-INS-HD-004-B1 Data Sheet for Pressure Relief Valves.pdf Page 2 of 10

Data Sheet for Pressure Relief Valve

Document No.: 17412-01-DS-IE-4300

Format: PDE-INS-F-084E

Page of

Dimensional Drawing

1

2

3

4

5

6

7

8

10

11

12

13

14

15

16

17

18

19

20

21

23

24

22

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

9

LINE

GENERAL

Material - Rating

Piping Class Design Press. Design Temp.

Design

Type

Service

Tag Number

Nozzle (Full, Semi)

Bonnet Type: Open or Closed

Cap: Screwed or Bolted screwed

Lever: None, Plain or Packed

Line or Vessel No.

Size and Schedule

P&ID No.

Insulation

psi-g

Safety, Relief, Safety-Relief

Conventional, Bellow

CONNECTIONS

Outlet: Size - Rating - Face

Inlet: Size - Rating - Face

Required Capacity

Flash Point

% Allow Overpress

Boiling Point

Oper. Pressure

Oper. Temperature

Back Pressure

Molecular Weight Specific Gravity

Set Pressure

RelievingTemperature

Constant

Superimposed Variable

Viscos. @Flow temp Compress. Factor Z

Process Fluid and State

Vapor Fraction

Latent Heat of Vaporization

Ratio of Specific Heats

Environmental Factor Pressure

MAWP Pressure

Cubical Expansion

Built-up Variable

Total

lb/h @ normal conditions

psi-g

psi-g

psi-g

VALVE TYPE

PROCESS

CONDITIONS

Body

Seat

Resilient Seat

Guide

Spring

Bonnet

Nozzle

Disc

Rings

Bellows

Liquid Filled Vessel

Design Code

Basis for Selection

MATERIALS

Mfr. Calculations Calibration

Material

Conformance

Hydrotest

Seat leak test

CERTIFICATES

in Calculated Orif. Area

Orifice Designation

Calculation Reference

Selected Orif. Area

BASIS OF

SELECTION

ORIFICE AREA

48

49

50

51

52

Manufacturer

Model

Serial Number

Notes:

MISC.

Revision:

36 in 20

Refer to General Notes for additional requirements.

By ECP

By ECP

Crude Oil

15

285

86 F

86 F

cP

kcal IT/kg

Liquid

15.97

10 % 26896

98 F

0

Bellows

0.138 0.196

E

ASME

in

Yes

Yes Yes

Yes

Yes Yes

Yes

CONTRATO MARCO DE INGENIERIA (CMI)

Ingeniera Bsica

ECOPETROL # COV-5209124-11038-IB-INS-HD-004-B1

B1

3 10

Optimizacin de la Planta VIT del Terminal Coveas

Thermal Relief

Full

Thermal Relief

API 5L gr B PSL2

ANSI Class 150#

Closed

Sec VIII (Note 5)

Screwed

None

316 Stainless Steel

0 psi-g

316 Stainless Steel

15.97 psi-g

None

316 Stainless Steel

API 520

C. Steel A216 Gr WCB C. Steel A216 Gr WCB

316 Stainless Steel

38321.122 lb/h

2" - ANSI Class 150# - RF

Capacity

316 Stainless Steel

316 Stainless Steel

Inconel

285 psi-g

1" - ANSI Class 150# - RF

see list

see list

see list

see list

see list

see list

see list

see list

see list

see list

None

COV-5209124-11038-IB-INS-HD-004-B1 Data Sheet for Pressure Relief Valves.pdf

SERVICE

Alivio Termico en Linea Ingreso a

TK-0102

P&ID

COV-5209124-11038-IB-PRO-PID-029_1 TRV -0101

Revision:

Contrato Marco de Ingeniera (CMI) ECOPETROL # COV-5209124-11038-IB-INS-HD-004-B1

VALVE

Data Sheet for Pressure Relief Valves

AA1A22-36"-PRO-P00-TH000-1-002

1 E 2

SIZE

TRV -0102 1 E 2

TAG NUMBER

COV-5209124-11038-IB-PRO-PID-030_1

Alivio Termico en Linea Ingreso a

TK-0104

AA1A22-36"-PRO-P00-TH000-1-001

LINE

Ingeniera Bsica Para la

Optimizacin de la Planta VIT del Terminal Coveas Fase I

DOCUMENTO NO.: 17412-01-DS-IE-4300

B1

COV-5209124-11038-IB-INS-HD-004-B1 Data Sheet for Pressure Relief Valves.pdf Page 4 of 10

Data Sheet for Pressure Relief Valve

Document No.: 17412-01-DS-IE-4300

Format: PDE-INS-F-084E

Page of

Dimensional Drawing

1

2

3

4

5

6

7

8

10

11

12

13

14

15

16

17

18

19

20

21

23

24

22

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

9

LINE

GENERAL

Material - Rating

Piping Class Design Press. Design Temp.

Design

Type

Service

Tag Number

Nozzle (Full, Semi)

Bonnet Type: Open or Closed

Cap: Screwed or Bolted screwed

Lever: None, Plain or Packed

Line or Vessel No.

Size and Schedule

P&ID No.

Insulation

psi-g

Safety, Relief, Safety-Relief

Conventional, Bellow

CONNECTIONS

Outlet: Size - Rating - Face

Inlet: Size - Rating - Face

Required Capacity

Flash Point

% Allow Overpress

Boiling Point

Oper. Pressure

Oper. Temperature

Back Pressure

Molecular Weight Specific Gravity

Set Pressure

RelievingTemperature

Constant

Superimposed Variable

Viscos. @Flow temp Compress. Factor Z

Process Fluid and State

Vapor Fraction

Latent Heat of Vaporization

Ratio of Specific Heats

Environmental Factor Pressure

MAWP Pressure

Cubical Expansion

Built-up Variable

Total

lb/h @ normal conditions

psi-g

psi-g

psi-g

VALVE TYPE

PROCESS

CONDITIONS

Body

Seat

Resilient Seat

Guide

Spring

Bonnet

Nozzle

Disc

Rings

Bellows

Liquid Filled Vessel

Design Code

Basis for Selection

MATERIALS

Mfr. Calculations Calibration

Material

Conformance

Hydrotest

Seat leak test

CERTIFICATES

in Calculated Orif. Area

Orifice Designation

Calculation Reference

Selected Orif. Area

BASIS OF

SELECTION

ORIFICE AREA

48

49

50

51

52

Manufacturer

Model

Serial Number

Notes:

MISC.

Revision:

36 in

Refer to General Notes for additional requirements.

By ECP

By ECP

Crude Oil

15

285

86 F

86 F

cP

kcal IT/kg

Liquid

0

10 % 26896

98 F

0

Conventional

0.134 0.196

E

ASME

in

Yes

Yes Yes

Yes

Yes Yes

Yes

CONTRATO MARCO DE INGENIERIA (CMI)

Ingeniera Bsica

ECOPETROL # COV-5209124-11038-IB-INS-HD-004-B1

B1

5 10

Optimizacin de la Planta VIT del Terminal Coveas

Thermal Relief

Full

Thermal Relief

API 5L gr B PSL2

ANSI Class 150#

Closed

Sec VIII (Note 5)

Screwed

None

316 Stainless Steel

0 psi-g

316 Stainless Steel

0 psi-g

None

316 Stainless Steel

API 520

C. Steel A216 Gr WCB C. Steel A216 Gr WCB

316 Stainless Steel

39344.644 lb/h

2" - ANSI Class 150# - RF

Capacity

316 Stainless Steel

316 Stainless Steel

N/A

285 psi-g

1" - ANSI Class 150# - RF

see list

see list

see list

see list

see list

see list

see list

see list

see list

see list

None

COV-5209124-11038-IB-INS-HD-004-B1 Data Sheet for Pressure Relief Valves.pdf

TRV -0601 1 E 2

Alivio Termico en Linea Ingreso a

TK-0102

AA1A22-36"-PRO-P00-TH000-1-001 COV-5209124-11038-IB-PRO-PID-031_1

TRV -0602 1 E 2

Alivio Termico en Linea Ingreso a

TK-0104

AA1A22-36"-PRO-P00-TH000-1-002 COV-5209124-11038-IB-PRO-PID-031_1

Data Sheet for Pressure Relief Valves Revision: B1

TAG NUMBER

VALVE SIZE SERVICE LINE P&ID

Contrato Marco de Ingeniera (CMI) ECOPETROL # COV-5209124-11038-IB-INS-HD-004-B1

Ingeniera Bsica Para la

Optimizacin de la Planta VIT del Terminal Coveas Fase I

DOCUMENTO NO.: 17412-01-DS-IE-4300

COV-5209124-11038-IB-INS-HD-004-B1 Data Sheet for Pressure Relief Valves.pdf Page 6 of 10

Data Sheet for Pressure Relief Valve

Document No.: 17412-01-DS-IE-4300

Format: PDE-INS-F-084E

Page of

Dimensional Drawing

1

2

3

4

5

6

7

8

10

11

12

13

14

15

16

17

18

19

20

21

23

24

22

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

9

LINE

GENERAL

Material - Rating

Piping Class Design Press. Design Temp.

Design

Type

Service

Tag Number

Nozzle (Full, Semi)

Bonnet Type: Open or Closed

Cap: Screwed or Bolted screwed

Lever: None, Plain or Packed

Line or Vessel No.

Size and Schedule

P&ID No.

Insulation

psi-g

Safety, Relief, Safety-Relief

Conventional, Bellow

CONNECTIONS

Outlet: Size - Rating - Face

Inlet: Size - Rating - Face

Required Capacity

Flash Point

% Allow Overpress

Boiling Point

Oper. Pressure

Oper. Temperature

Back Pressure

Molecular Weight Specific Gravity

Set Pressure

RelievingTemperature

Constant

Superimposed Variable

Viscos. @Flow temp Compress. Factor Z

Process Fluid and State

Vapor Fraction

Latent Heat of Vaporization

Ratio of Specific Heats

Environmental Factor Pressure

MAWP Pressure

Cubical Expansion

Built-up Variable

Total

lb/h @ normal conditions

psi-g

psi-g

psi-g

VALVE TYPE

PROCESS

CONDITIONS

Body

Seat

Resilient Seat

Guide

Spring

Bonnet

Nozzle

Disc

Rings

Bellows

Liquid Filled Vessel

Design Code

Basis for Selection

MATERIALS

Mfr. Calculations Calibration

Material

Conformance

Hydrotest

Seat leak test

CERTIFICATES

in Calculated Orif. Area

Orifice Designation

Calculation Reference

Selected Orif. Area

BASIS OF

SELECTION

ORIFICE AREA

48

49

50

51

52

Manufacturer

Model

Serial Number

Notes:

MISC.

Revision:

30 in

Refer to General Notes for additional requirements.

By ECP

By ECP

Crude Oil

33

285

86 F

86 F

cP

kcal IT/kg

Liquid

0

10 % 4669

98 F

0

Conventional

0.024 0.11

D

ASME

in

Yes

Yes Yes

Yes

Yes Yes

Yes

CONTRATO MARCO DE INGENIERIA (CMI)

Ingeniera Bsica

ECOPETROL # COV-5209124-11038-IB-INS-HD-004-B1

B1

8 10

Optimizacin de la Planta VIT del Terminal Coveas

Thermal Relief

Full

Thermal Relief

API 5L gr B PSL2

ANSI Class 150#

Closed

Sec VIII (Note 5)

Screwed

None

316 Stainless Steel

0 psi-g

316 Stainless Steel

0 psi-g

None

316 Stainless Steel

API 520

C. Steel A216 Gr WCB C. Steel A216 Gr WCB

316 Stainless Steel

22024.56 lb/h

2" - ANSI Class 150# - RF

Capacity

316 Stainless Steel

316 Stainless Steel

N/A

285 psi-g

1" - ANSI Class 150# - RF

Alivio Trmico en Cabezal Succin Bombas Principales

TRV-0401

COV-5209124-11038-IB-PRO-PID-032_1

see list

see list

see list

see list

see list

None

COV-5209124-11038-IB-INS-HD-004-B1 Data Sheet for Pressure Relief Valves.pdf

AA1A22-30-PRO-P00-TH000-4-096

Data Sheet for Pressure Relief Valve

Document No.: 17412-01-DS-IE-4300

Format: PDE-INS-F-084E

Page of

Dimensional Drawing

1

2

3

4

5

6

7

8

10

11

12

13

14

15

16

17

18

19

20

21

23

24

22

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

9

LINE

GENERAL

Material - Rating

Piping Class Design Press. Design Temp.

Design

Type

Service

Tag Number

Nozzle (Full, Semi)

Bonnet Type: Open or Closed

Cap: Screwed or Bolted screwed

Lever: None, Plain or Packed

Line or Vessel No.

Size and Schedule

P&ID No.

Insulation

psi-g

Safety, Relief, Safety-Relief

Conventional, Bellow

CONNECTIONS

Outlet: Size - Rating - Face

Inlet: Size - Rating - Face

Required Capacity

Flash Point

% Allow Overpress

Boiling Point

Oper. Pressure

Oper. Temperature

Back Pressure

Molecular Weight Specific Gravity

Set Pressure

RelievingTemperature

Constant

Superimposed Variable

Viscos. @Flow temp Compress. Factor Z

Process Fluid and State

Vapor Fraction

Latent Heat of Vaporization

Ratio of Specific Heats

Environmental Factor Pressure

MAWP Pressure

Cubical Expansion

Built-up Variable

Total

lb/h @ normal conditions

psi-g

psi-g

psi-g

VALVE TYPE

PROCESS

CONDITIONS

Body

Seat

Resilient Seat

Guide

Spring

Bonnet

Nozzle

Disc

Rings

Bellows

Liquid Filled Vessel

Design Code

Basis for Selection

MATERIALS

Mfr. Calculations Calibration

Material

Conformance

Hydrotest

Seat leak test

CERTIFICATES

in Calculated Orif. Area

Orifice Designation

Calculation Reference

Selected Orif. Area

BASIS OF

SELECTION

ORIFICE AREA

48

49

50

51

52

Manufacturer

Model

Serial Number

Notes:

MISC.

Revision:

24 in

Refer to General Notes for additional requirements.

By ECP

By ECP

Crude Oil

256

285

86 F

86 F

cP

kcal IT/kg

Liquid

0

10 % 1195

98 F

0

Conventional

0.006 0.11

D

ASME

in

Yes

Yes Yes

Yes

Yes Yes

Yes

CONTRATO MARCO DE INGENIERIA (CMI)

Ingeniera Bsica

ECOPETROL # COV-5209124-11038-IB-INS-HD-004-B1

B1

8 10

Optimizacin de la Planta VIT del Terminal Coveas

Thermal Relief

Full

Thermal Relief

API 5L gr B PSL2

ANSI Class 150#

Closed

Sec VIII (Note 5)

Screwed

None

316 Stainless Steel

0 psi-g

316 Stainless Steel

0 psi-g

None

316 Stainless Steel

API 520

C. Steel A216 Gr WCB C. Steel A216 Gr WCB

316 Stainless Steel

22024.569 lb/h

2" - ANSI Class 150# - RF

Capacity

316 Stainless Steel

316 Stainless Steel

N/A

285 psi-g

1" - ANSI Class 150# - RF

Alivio Trmico en Linea de Descarga Bombas Principales

TRV-0402

COV-5209124-11038-IB-PRO-PID-032_1

see list

see list

see list

see list

see list

None

COV-5209124-11038-IB-INS-HD-004-B1 Data Sheet for Pressure Relief Valves.pdf

AA1A22-24-PRO-P00-TH000-3-018

Data Sheet for Pressure Relief Valve

Document No.: 17412-01-DS-IE-4300

Format: PDE-INS-F-084E

Page of

Dimensional Drawing

1

2

3

4

5

6

7

8

10

11

12

13

14

15

16

17

18

19

20

21

23

24

22

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

9

LINE

GENERAL

Material - Rating

Piping Class Design Press. Design Temp.

Design

Type

Service

Tag Number

Nozzle (Full, Semi)

Bonnet Type: Open or Closed

Cap: Screwed or Bolted screwed

Lever: None, Plain or Packed

Line or Vessel No.

Size and Schedule

P&ID No.

Insulation

psi-g

Safety, Relief, Safety-Relief

Conventional, Bellow

CONNECTIONS

Outlet: Size - Rating - Face

Inlet: Size - Rating - Face

Required Capacity

Flash Point

% Allow Overpress

Boiling Point

Oper. Pressure

Oper. Temperature

Back Pressure

Molecular Weight Specific Gravity

Set Pressure

RelievingTemperature

Constant

Superimposed Variable

Viscos. @Flow temp Compress. Factor Z

Process Fluid and State

Vapor Fraction

Latent Heat of Vaporization

Ratio of Specific Heats

Environmental Factor Pressure

MAWP Pressure

Cubical Expansion

Built-up Variable

Total

lb/h @ normal conditions

psi-g

psi-g

psi-g

VALVE TYPE

PROCESS

CONDITIONS

Body

Seat

Resilient Seat

Guide

Spring

Bonnet

Nozzle

Disc

Rings

Bellows

Liquid Filled Vessel

Design Code

Basis for Selection

MATERIALS

Mfr. Calculations Calibration

Material

Conformance

Hydrotest

Seat leak test

CERTIFICATES

in Calculated Orif. Area

Orifice Designation

Calculation Reference

Selected Orif. Area

BASIS OF

SELECTION

ORIFICE AREA

48

49

50

51

52

Manufacturer

Model

Serial Number

Notes:

MISC.

Revision:

24 in

Refer to General Notes for additional requirements.

By ECP

By ECP

Crude Oil

70

285

86 F

100 F

cP

kcal IT/kg

Liquid

0

10 % 2391

98 F

0

Conventional

0.012 0.11

D

ASME

in

Yes

Yes Yes

Yes

Yes Yes

Yes

CONTRATO MARCO DE INGENIERIA (CMI)

Ingeniera Bsica

ECOPETROL # COV-5209124-11038-IB-INS-HD-004-B1

B1

9 10

Optimizacin de la Planta VIT del Terminal Coveas

Thermal Relief

Full

Thermal Relief

API 5L gr B PSL2

ANSI Class 150#

Closed

Sec VIII (Note 5)

Screwed

None

316 Stainless Steel

0 psi-g

316 Stainless Steel

0 psi-g

None

316 Stainless Steel

API 520

C. Steel A216 Gr WCB C. Steel A216 Gr WCB

316 Stainless Steel

22024.569 lb/h

2" - ANSI Class 150# - RF

Capacity

316 Stainless Steel

316 Stainless Steel

N/A

285 psi-g

1" - ANSI Class 150# - RF

Alivio Trmico lnea de entrada a mltiple Nuevo desde MS-0301

TRV-0403

COV-5209124-11038-IB-PRO-PID-028_1

see list

see list

see list

see list

see list

None

COV-5209124-11038-IB-INS-HD-004-B1 Data Sheet for Pressure Relief Valves.pdf

AA1A22-24-PRO-P00-TH000-4-120

1

2

3

4

5

6

7

8

9

10

1

2

3

4

5

6

7

8

9

10

1

2

3

4

Variable Backpressure (Note 1) psi-g 17,42

Variable Backpressure (Note 1) psi-g 14,96

Contrato Marco de Ingeniera (CMI) ECOPETROL # COV-5209124-11038-IB-INS-HD-004-B1

Ingeniera Bsica Para la

Optimizacin de la Planta VIT del Terminal Coveas Fase I

DOCUMENTO NO.: 17412-01-DS-IE-4300

Data Sheet for Pressure Relief Valves Revision: B1

CRUDO MEZCLA CASTILLA

Units @ Norm. Flow

Required capacity lb/h See Data Sheet

Oper Pressure psi-g

Temperature normal / max F 86

Specific Gravity - 0,9348

CRUDO CUSIANA

Density lb/ft 58,36

Viscosity cP 280,7

Units @ Norm. Flow

Cubical Expansion 0,0004235

Required capacity lb/h

Oper Pressure psi-g See Data Sheet

Temperature normal / max F 86

Specific Gravity - 0,803

Density lb/ft 50,13

Viscosity cP 1,6

Cubical Expansion 0,00054

CRUDO CAO LIMON

Units

Ratio of Specific Heats 1,1

0,7

Ratio of Specific Heats

@ Norm. Flow

Flash Point F 69,4

Flash Point F

Required capacity lb/h

Oper Pressure psi-g

Temperature normal / max F 86

Specific Gravity - 0,857 4

5

6

7

8

9

10

1

2

3

4

5

6

7

8

9

10

Variable Backpressure (Note 1) psi-g 15,97

Variable Backpressure (Note 1) psi-g 18,65

Ratio of Specific Heats 1

Ratio of Specific Heats 1,3

Flash Point F 253,4

Specific Gravity - 0,857

Density lb/ft 53,52

Viscosity cP 16

Cubical Expansion 0,0005419

CRUDO COMBUSTOLEO

Flash Point F 9,2

Units @ Norm. Flow

Required capacity lb/h

Oper Pressure psi-g

Temperature normal / max F 86

Specific Gravity - 1,005

Density lb/ft 62,64

Viscosity cP 466,8

Cubical Expansion 0,000337

Notes

1. Applies only to TRV-0101 and TRV-0102 pressure relief valves.

COV-5209124-11038-IB-INS-HD-004-B1 Data Sheet for Pressure Relief Valves.pdf Page 10 de 10

See Data Sheet

See Data Sheet

See Data Sheet

See Data Sheet

See Data Sheet

See Data Sheet

1,2

Вам также может понравиться

- WPI-KE-1104-SP141-QM5433 (Datasheet)Документ4 страницыWPI-KE-1104-SP141-QM5433 (Datasheet)Jèfrì PìnémОценок пока нет

- Safety Relief Valve DatasheetДокумент1 страницаSafety Relief Valve Datasheetalmandhari330% (1)

- Fsi Catalog Filter VesselsДокумент35 страницFsi Catalog Filter VesselsarietilangОценок пока нет

- Calculation Worksheet: Completed in Accordance With Discipline Qa ProceduresДокумент2 страницыCalculation Worksheet: Completed in Accordance With Discipline Qa ProceduresCast Ed Iv100% (1)

- Liquid Orifice SizingДокумент8 страницLiquid Orifice SizingrmaganОценок пока нет

- Control Valves Specification Sheet PDFДокумент2 страницыControl Valves Specification Sheet PDFjhonjimenez87Оценок пока нет

- InstruCalc Control Valve Sizing03Документ1 страницаInstruCalc Control Valve Sizing03Dinesh KumarОценок пока нет

- API STD 676-2009 - Hoja de RequisiciónДокумент28 страницAPI STD 676-2009 - Hoja de RequisiciónRicardo CastroОценок пока нет

- Control Valve Hydraulics-GasДокумент6 страницControl Valve Hydraulics-GasganeshdhageОценок пока нет

- Float Board Level GaugeДокумент6 страницFloat Board Level GaugeanaismariaОценок пока нет

- Datasheet PSV PDPDEДокумент8 страницDatasheet PSV PDPDERicardo NapitupuluОценок пока нет

- Control Valve CalcДокумент7 страницControl Valve Calcartneves100% (1)

- BE-WI-248-01-F12 Datasheet Level Instrument Displacer or FloatДокумент3 страницыBE-WI-248-01-F12 Datasheet Level Instrument Displacer or Floatmika cabelloОценок пока нет

- Control Valve SizingДокумент21 страницаControl Valve Sizingtiwarishailendra2198Оценок пока нет

- 14-A Fluid Flow GeneralДокумент26 страниц14-A Fluid Flow GeneralSuara84Оценок пока нет

- Control Valve Press Drop CalculationДокумент3 страницыControl Valve Press Drop CalculationAntony AbirawaОценок пока нет

- Restriction Orifice Final CalculationДокумент1 страницаRestriction Orifice Final CalculationJasperTanОценок пока нет

- Flame ArrestorДокумент10 страницFlame ArrestorAdnan Khan100% (1)

- Actuator Sizing ProgramДокумент11 страницActuator Sizing ProgramAttyubОценок пока нет

- Datasheet of Deluge ValveДокумент2 страницыDatasheet of Deluge ValveAlvin SmithОценок пока нет

- Control Valve SizingДокумент9 страницControl Valve Sizingjmclaug502Оценок пока нет

- DatasheetДокумент17 страницDatasheetHimawan Sigit NugrohoОценок пока нет

- Safety Valve Blowback Calculation (Optimization2)Документ18 страницSafety Valve Blowback Calculation (Optimization2)Durjoy ChakrabortyОценок пока нет

- Flash TanksДокумент8 страницFlash TanksOwen HizriawanОценок пока нет

- Rupture Disk SizingДокумент2 страницыRupture Disk Sizingabhishek shindeОценок пока нет

- Complete CV CalculationДокумент42 страницыComplete CV Calculationgalant_pp100% (1)

- Relief Valve - TypesДокумент2 страницыRelief Valve - Typesyushveer002Оценок пока нет

- 377 Series Trip Valves: Product BulletinДокумент3 страницы377 Series Trip Valves: Product BulletinIsmail AhmadОценок пока нет

- Control Valve Data SheetДокумент6 страницControl Valve Data SheetsisesetОценок пока нет

- Orifice Calc Gas Rev 0Документ1 страницаOrifice Calc Gas Rev 0edufragaОценок пока нет

- Rev A. Magnetic Level Gauge With Level Transmitter Datasheet PDFДокумент15 страницRev A. Magnetic Level Gauge With Level Transmitter Datasheet PDFNguyễnQuíTrọngОценок пока нет

- Control Valve Failure Relief Rate - Liquid ServiceДокумент2 страницыControl Valve Failure Relief Rate - Liquid ServiceSaeid Rahimi MofradОценок пока нет

- 05 Wake Frequency Calculation - 09 DG 005 Rev 0Документ11 страниц05 Wake Frequency Calculation - 09 DG 005 Rev 0vivek_enggОценок пока нет

- InstruCalc Flow Element SizingДокумент1 страницаInstruCalc Flow Element SizingerjainrachitОценок пока нет

- Pressure RELIEF VALVE DATA SHEETДокумент4 страницыPressure RELIEF VALVE DATA SHEETAlvin SmithОценок пока нет

- Positioner SpecsДокумент1 страницаPositioner Specsbiswasdipankar05Оценок пока нет

- Relief Valve Sizing - FireДокумент2 страницыRelief Valve Sizing - Firevlcmstne04Оценок пока нет

- 3206 - RotameterДокумент9 страниц3206 - RotameterVidya MuthukrishnanОценок пока нет

- Ip060-45!20!02 Orifice Plate Assembly (Buyer's Scope)Документ5 страницIp060-45!20!02 Orifice Plate Assembly (Buyer's Scope)Rahul DevaОценок пока нет

- PSV Scenario and CalculationДокумент35 страницPSV Scenario and Calculationminhphuongpham100% (9)

- Pressure Drop (Two Phases)Документ38 страницPressure Drop (Two Phases)PROCESOS PROCESOS100% (1)

- Liquid Control Valve SizingДокумент9 страницLiquid Control Valve SizingDesiree MolinaОценок пока нет

- DS-21-J-0026 - 2 TPCDR Approved PDFДокумент40 страницDS-21-J-0026 - 2 TPCDR Approved PDFsumant.c.singh1694Оценок пока нет

- Prosertec Srl. 4to Anillo #3880 y Av. Roca y Coronado: Fluid PropertiesДокумент1 страницаProsertec Srl. 4to Anillo #3880 y Av. Roca y Coronado: Fluid PropertiesAlba Duaneth Rocabado MendietaОценок пока нет

- PSV Sizing (Steam)Документ2 страницыPSV Sizing (Steam)Saeid Rahimi Mofrad100% (1)

- Pilot Valve SizingДокумент4 страницыPilot Valve SizingJason ThomasОценок пока нет

- 13205-PPE-DS-V-003-1 - DataSheet - CVДокумент7 страниц13205-PPE-DS-V-003-1 - DataSheet - CVAnggun RushОценок пока нет

- Pressure Safety Valve DatasheetДокумент1 страницаPressure Safety Valve DatasheetAlvin Smith100% (5)

- Folio p01195 Rev 1Документ26 страницFolio p01195 Rev 1Ernesto VazquezОценок пока нет

- Ip Pressure Transmitter Data SheetДокумент2 страницыIp Pressure Transmitter Data Sheetneurolepsia3790Оценок пока нет

- Air CompressorДокумент48 страницAir CompressorMarius Condurache0% (1)

- B5720Документ4 страницыB5720ayuzme123Оценок пока нет

- Masoneilan Equipment DataДокумент3 страницыMasoneilan Equipment DataalvimranОценок пока нет

- Flushing Drying FormДокумент17 страницFlushing Drying FormWisnu WardhanaОценок пока нет

- PSV SizingДокумент6 страницPSV SizingBui Khoi Nguyen100% (1)

- 2749 - Carrier 30 GH 095Документ16 страниц2749 - Carrier 30 GH 095Mohammad Amer100% (2)

- ACUMULADORESДокумент18 страницACUMULADORESJuan GuillermoОценок пока нет

- Booster & Sump Pumps SubmittalДокумент93 страницыBooster & Sump Pumps SubmittalTyson BartlettОценок пока нет

- Hoja ISA.Документ5 страницHoja ISA.jhonjimenez87Оценок пока нет

- Gate Valve DSДокумент5 страницGate Valve DSkhaireddin100% (1)

- Awwa d103 PotableДокумент9 страницAwwa d103 PotableAnonymous UArnIExОценок пока нет

- PDF - Js ViewerДокумент11 страницPDF - Js ViewerAnonymous UArnIExОценок пока нет

- Awwa d103 PotableДокумент9 страницAwwa d103 PotableAnonymous UArnIExОценок пока нет

- The Effect of Na2ZrO3 Synthesis Method On The CO2 - 2022 - Carbon Capture ScienДокумент8 страницThe Effect of Na2ZrO3 Synthesis Method On The CO2 - 2022 - Carbon Capture ScienAnonymous UArnIExОценок пока нет

- High Selective Separation Performance of CO2 From CH4 by - 2022 - Carbon CapturДокумент11 страницHigh Selective Separation Performance of CO2 From CH4 by - 2022 - Carbon CapturAnonymous UArnIExОценок пока нет

- Series D: API 6D & API 6A Trunnion Mounted Ball ValveДокумент28 страницSeries D: API 6D & API 6A Trunnion Mounted Ball ValveAnonymous UArnIExОценок пока нет

- Understanding The Competition Between Carbonation and S - 2022 - Carbon CaptureДокумент8 страницUnderstanding The Competition Between Carbonation and S - 2022 - Carbon CaptureAnonymous UArnIExОценок пока нет

- FP-70 Angus Ficha TecnicaДокумент2 страницыFP-70 Angus Ficha TecnicaAnonymous UArnIExОценок пока нет

- Amercan Marsh PumpДокумент9 страницAmercan Marsh PumpAnonymous UArnIExОценок пока нет

- Project Earned Value Analysis1Документ4 страницыProject Earned Value Analysis1Anonymous UArnIExОценок пока нет

- Costo AbandonoДокумент70 страницCosto AbandonoAnonymous UArnIExОценок пока нет

- BlastingДокумент138 страницBlastingcklconОценок пока нет

- PhysicsДокумент28 страницPhysicsamritam yadavОценок пока нет

- Designing A MixerДокумент12 страницDesigning A MixerPrasanna KumarОценок пока нет

- Material Balance: Lecture By: Ir. Dewi Tristantini Mt. Phd. University of IndonesiaДокумент29 страницMaterial Balance: Lecture By: Ir. Dewi Tristantini Mt. Phd. University of IndonesiaEdward Gustaf100% (3)

- Answer of Midterm Exam 2 PDFДокумент6 страницAnswer of Midterm Exam 2 PDFFaisal Al-assafОценок пока нет

- Single Phase Matrix ConverterДокумент9 страницSingle Phase Matrix Converteranahope93Оценок пока нет

- Engine Control SystemДокумент7 страницEngine Control SystemFaisal Al HusainanОценок пока нет

- Sound Power and IntensityДокумент8 страницSound Power and Intensitymandeep singhОценок пока нет

- Guyton and Hall Medical PhysiologyДокумент34 страницыGuyton and Hall Medical PhysiologyFul VianaОценок пока нет

- Positioning of Air Cooled CondensersДокумент9 страницPositioning of Air Cooled CondensersAlexОценок пока нет

- Algebra2 Glenco EOCДокумент62 страницыAlgebra2 Glenco EOCDeborah LeeОценок пока нет

- CNTH Skema Fizik Paper 3Документ3 страницыCNTH Skema Fizik Paper 3Norfadila Mat JusofОценок пока нет

- Appendix B Laplace Transform: Time Domain, E.G. If We Have A Voltage V Which Is AДокумент6 страницAppendix B Laplace Transform: Time Domain, E.G. If We Have A Voltage V Which Is AulaganathanОценок пока нет

- 7UT51x Manual UsДокумент232 страницы7UT51x Manual UsMtdb Psd100% (1)

- Quality Assurance Plan For Civil4mДокумент3 страницыQuality Assurance Plan For Civil4mMohammed Abdul BaseerОценок пока нет

- General Solution For U-ShapeДокумент12 страницGeneral Solution For U-ShapeDiana SoareОценок пока нет

- Shaft Locking DeviceДокумент24 страницыShaft Locking DevicechienhamthepОценок пока нет

- Is 2974 Part 4 1979 Indian Standard Code of Practice For Design and Construction of Machine Foundations - Part 4 Foundations For Rotary Type Machines of Low Frequency PDFДокумент23 страницыIs 2974 Part 4 1979 Indian Standard Code of Practice For Design and Construction of Machine Foundations - Part 4 Foundations For Rotary Type Machines of Low Frequency PDFBibhu DattaОценок пока нет

- Gates Timing Belt Product TrainingДокумент25 страницGates Timing Belt Product TrainingRoberto FernandesОценок пока нет

- Analysis and Design of Asynchronous Sequential CircuitsДокумент30 страницAnalysis and Design of Asynchronous Sequential CircuitsBeulah JacksonОценок пока нет

- Umass Lowell Computer Science 91.503: Graduate AlgorithmsДокумент46 страницUmass Lowell Computer Science 91.503: Graduate AlgorithmsShivam AtriОценок пока нет

- Condensate System ProtectionДокумент8 страницCondensate System ProtectionmnasiroleslamiОценок пока нет

- Stepper Motors VsServo MotorsДокумент2 страницыStepper Motors VsServo MotorsEhab MohamedОценок пока нет

- Formsat 5Документ6 страницFormsat 5gramuiitmОценок пока нет

- An Elin Load Tap Changer Diagnosis by DgaДокумент4 страницыAn Elin Load Tap Changer Diagnosis by Dgamartinez_joselОценок пока нет

- CV 101Документ4 страницыCV 101frco1504Оценок пока нет

- Estimating Hydropower Potential of An Ungauged Stream: January 2013Документ10 страницEstimating Hydropower Potential of An Ungauged Stream: January 2013sisay dejenieОценок пока нет

- Mod. 1 Basic ElectricalДокумент21 страницаMod. 1 Basic Electricalderping lemon100% (1)

- Notes - Transformation (Enlargement)Документ5 страницNotes - Transformation (Enlargement)Samhan Azamain0% (1)

- Conclusion and Recommendations HTДокумент1 страницаConclusion and Recommendations HTAdiel AdrieОценок пока нет