Академический Документы

Профессиональный Документы

Культура Документы

Call For Tenders Castings

Загружено:

Hirenkumar Shah0 оценок0% нашли этот документ полезным (0 голосов)

20 просмотров14 страницCall for kind of tenders for Casting

Оригинальное название

Call for Tenders Castings

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документCall for kind of tenders for Casting

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

20 просмотров14 страницCall For Tenders Castings

Загружено:

Hirenkumar ShahCall for kind of tenders for Casting

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 14

Call for tenders

Guide to request for quotation

Shortly

You provide all the needed information that

foundry need that they can make you offer how

much it is going to cost to produce your product.

The foundry relay the calculations on your

information, so the more you can provide the

information the more specific offer you will get.

What there should be at least

Name of your company (and contact details)

Short description of what you are looking for

How many products you will need

when are you going to need the products

What is the material for your product

What standard it is based on

What are the tolerances

What standard it is based on

How you will proceed with the tools

How the products should be inspected that the basic requirements are

met

What is standard it is based on

Other needed information

Drawings

Example

Additional requirements

The foundry is able to make castings in such a

way that basic requirements are met (based

on the standards), but it may not be enough.

The test piece gives an indication of the

casting mechanical characteristics, but only

references. Critical properties are defined in

the order specifically the so-called additional

requirements.

Additional requirements

Additional requirements should be recorded clearly

and unambiguously as possible.

What is the required feature and how it will be tested.

If there is a standard for testing, reference is made to it.

Use the test samples if you want to find out that

additional requirements have been met.

Open and honest communication through the process

of both parties save time and money.

The foundry Guidelines should be taken into account.

There might be problems that can not be solved in any

other way than by modifying the construction.

Additional requirements

Additional requirements could be such as:

Additional features defined in the standard, determined, for example,

elongation in the specified location on the casting and the elongation of the

test piece directly

Other special tests in foundry

Criteria for acceptable number of casting defects and quality

Special requirements such as structure, corrosion resistance, and

machinability

Inspection and testing methods, evaluation criteria and how to test cast items

Inspections and tests, and how to report them

Special measures, such as castings for the production of stressed weld

inspections

Traceability, charge number, etc.

Agreement on production welding

Machining of products by foundry

Surface protection and packaging

How to follow ISO 9000 standards

Casting drawing

Tells what kind of products comes out from

the foundry

IT IS NOT THE END PRODUCT

Casting drawing

Cast drawing shows the

external dimensions of the casting,

the required drafts and rounding

required machining allowances (RMA-value) of the surfaces to

be machined.

It shall also communicate verbally, for example, what kind

of dimensional tolerance stein (CT value) cast product be

prepared.

Required machining allowances, machining allowance

grades, dimensional tolerances and dimensional tolerance

rates can be found from the standard (ISO-8062-3) The

dimensions of the casting, the casting and the casting

material.

Casting Drawing

Unmarked roundings R3

Unmarked drafts 3 degrees

Delivered as Cast

Casting tolerance ISO 8062

Grade of the tolerance CT 10

Machining allowance RMA 2,5

Machining allowance grade (F)

Machining drawing

Tells what the END product looks like

Cast product is machined to end product

Machining drawing

There must be presented in machining

drawing all the relevant information, what the

machinist needs:

the required dimensions

surface roughness

machining marks

tolerances.

Machining Drawing

Summary

In the end it is all about communication!

You will communicate what you need

The foundry will communicate what they can do

to satisfy your need

Drawings is the part of the call for tender, with

drawings you communicate what your product

looks like

Вам также может понравиться

- Wheels BusДокумент2 страницыWheels BusHirenkumar ShahОценок пока нет

- Emergency Vehicles WheelДокумент2 страницыEmergency Vehicles WheelHirenkumar ShahОценок пока нет

- Feathers For LunchДокумент34 страницыFeathers For LunchHirenkumar ShahОценок пока нет

- Humpty Dumpty CompleteДокумент25 страницHumpty Dumpty CompleteSvetik RotaruОценок пока нет

- Jolly Good HockeyДокумент20 страницJolly Good HockeyHirenkumar Shah100% (2)

- Animal SensesДокумент14 страницAnimal SensesHirenkumar ShahОценок пока нет

- Clever JohnДокумент20 страницClever JohnHirenkumar Shah100% (1)

- Scholasticnews Indepth War-Iraq Expert AdviceДокумент1 страницаScholasticnews Indepth War-Iraq Expert AdviceHirenkumar ShahОценок пока нет

- G1V1 U1 T1Документ37 страницG1V1 U1 T1Hirenkumar Shah100% (2)

- Activity Book KДокумент325 страницActivity Book KManuel Antonio Lazo Velasquez100% (1)

- English Language Arts Test: Book 1Документ16 страницEnglish Language Arts Test: Book 1Lena KovalenkoОценок пока нет

- Expert Answers: A Child Psychologist Helps You Field The Tough Questions Your Students May AskДокумент1 страницаExpert Answers: A Child Psychologist Helps You Field The Tough Questions Your Students May AskHirenkumar ShahОценок пока нет

- Scholasticnews Indepth War-Iraq Militaryquestions PDFДокумент1 страницаScholasticnews Indepth War-Iraq Militaryquestions PDFHirenkumar ShahОценок пока нет

- Scholasticnews Indepth War-Iraq Brodkin12Документ1 страницаScholasticnews Indepth War-Iraq Brodkin12Hirenkumar ShahОценок пока нет

- Scholasticnews Indepth Shuttle PiecesДокумент1 страницаScholasticnews Indepth Shuttle PiecesHirenkumar ShahОценок пока нет

- Scholasticnews Indepth Special Olympics SpecialolympicsДокумент1 страницаScholasticnews Indepth Special Olympics SpecialolympicsHirenkumar ShahОценок пока нет

- Scholasticnews Indepth Space Space2Документ1 страницаScholasticnews Indepth Space Space2Hirenkumar ShahОценок пока нет

- Scholasticnews Indepth Space Space3Документ1 страницаScholasticnews Indepth Space Space3Hirenkumar ShahОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Summer Project at Bhilai Steel PlantДокумент32 страницыSummer Project at Bhilai Steel PlantNiteshRaiОценок пока нет

- Vintage Airplane - Jun 1989Документ36 страницVintage Airplane - Jun 1989Aviation/Space History LibraryОценок пока нет

- Steelcraft Spec f1Документ9 страницSteelcraft Spec f1Moises SandovalОценок пока нет

- Common Datasheets Ampco Gas Metal-Arc WeldingДокумент2 страницыCommon Datasheets Ampco Gas Metal-Arc WeldingMaulana Mufti MuhammadОценок пока нет

- Building/Structure Inspection and Assesment ReportДокумент2 страницыBuilding/Structure Inspection and Assesment ReportRozel Herrera AguinaldoОценок пока нет

- Underground Infrastructure of Urban AreasДокумент302 страницыUnderground Infrastructure of Urban AreasErick Alan100% (1)

- Aung Kyaw Moe-Task (1) - Unit (3) ProcurementДокумент7 страницAung Kyaw Moe-Task (1) - Unit (3) ProcurementAung Kyaw Moe100% (2)

- Tablet Defects-DosageДокумент3 страницыTablet Defects-DosageLea PesiganОценок пока нет

- D1834 SERIES (NAS1834) : Table 1Документ1 страницаD1834 SERIES (NAS1834) : Table 1blackhawkОценок пока нет

- E R DiagramsДокумент5 страницE R DiagramsDivansh Sood0% (1)

- Logistics in International MarketingДокумент211 страницLogistics in International Marketingmonish1760% (1)

- A340 Ata 25Документ34 страницыA340 Ata 25Abdelaziz AbdoОценок пока нет

- Introduction To Transportation Engineering 2015-2016Документ19 страницIntroduction To Transportation Engineering 2015-2016Allain DungoОценок пока нет

- Ra Elevatorr Maintenance ManualДокумент8 страницRa Elevatorr Maintenance ManualBahman MatouriОценок пока нет

- Procurement Supply Chain Manager in Denver CO Resume Manuel BenДокумент3 страницыProcurement Supply Chain Manager in Denver CO Resume Manuel BenManuelBen100% (1)

- Material Management For HospitalsДокумент88 страницMaterial Management For HospitalsDr. Rakshit Solanki75% (12)

- Opportunities in Agricultural Value Chain Digitisation: Learnings From GhanaДокумент32 страницыOpportunities in Agricultural Value Chain Digitisation: Learnings From GhanaKuuku SamОценок пока нет

- SCM Batch B - Group 3 - Madura Accessories LTDДокумент35 страницSCM Batch B - Group 3 - Madura Accessories LTDSHILPA GOPINATHAN100% (1)

- Airport RetailingДокумент3 страницыAirport Retailingvinitha.ajiОценок пока нет

- Astm A992Документ2 страницыAstm A992Harley Ilave IlaveОценок пока нет

- BoxДокумент8 страницBoxJack Danielz LubisОценок пока нет

- Forging Drawing ProcessesДокумент5 страницForging Drawing ProcessesSanam PuriОценок пока нет

- ASTM A27 Spec For General Steel CastingsДокумент4 страницыASTM A27 Spec For General Steel CastingsKarthik Nagendra0% (1)

- Appendix 27 Alternative Requirements For Glass-Lined VesselsДокумент2 страницыAppendix 27 Alternative Requirements For Glass-Lined VesselsBinay K SrivastawaОценок пока нет

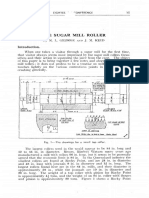

- The Sugar Mill Roller: BV R. I,. Geokge MДокумент9 страницThe Sugar Mill Roller: BV R. I,. Geokge MuksrajОценок пока нет

- Bro Aero Hero 14 Rev 1.19Документ2 страницыBro Aero Hero 14 Rev 1.19max72ggoОценок пока нет

- Asme Ix QuizДокумент5 страницAsme Ix Quizamalhaj2013Оценок пока нет

- Esab BrochureДокумент82 страницыEsab BrochureMahmud MaherОценок пока нет

- 專業術語Документ21 страница專業術語Tsun-Wu LiuОценок пока нет

- CablesДокумент7 страницCablesHari PidikitiОценок пока нет