Академический Документы

Профессиональный Документы

Культура Документы

Lecture 1

Загружено:

Gökhan ÇiçekИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Lecture 1

Загружено:

Gökhan ÇiçekАвторское право:

Доступные форматы

Types of materials

Properties of materials

Different levels of structure in materials

Relation among material processing, structure,

properties, and performance

The main objective is to understand the basic concepts

and language of Materials Science

Syllabus:

Historical Perspective

Stone Bronze Iron Advanced materials

What is Materials Science and Engineering ?

Processing Structure Properties Performance

Classification of Materials

Metals, Ceramics, Polymers, Semiconductors

Advanced Materials

Electronic materials, superconductors, etc.

Modern Material's Needs, Material of Future

Biodegradable materials, Nanomaterials, Smart

materials

Chapter Outline

Beginning of the Material Science - People began to make tools from stone

Start of the Stone Age about two million years ago.

Natural materials: stone, wood, clay, skins, etc.

The Stone Age ended about 5000 years ago with introduction of Bronze in the

Far East. Bronze is an alloy (a metal made up of more than one element),

copper + < 25% of tin + other elements.

Bronze: can be hammered or cast into a variety of shapes, can be made harder

by alloying, corrode only slowly after a surface oxide film forms.

The Iron Age began about 3000 years ago and continues today. Use of iron

and steel, a stronger and cheaper material changed drastically daily life of a

common person.

Historical Perspective

Age of Advanced materials: throughout the Iron Age many new types of

materials have been introduced (ceramic, semiconductors, polymers,

composites). Understanding of the relationship among structure,

properties, processing, and performance of materials.

Intelligent design of new materials.

A better understanding of structure-composition properties relations has

lead to a remarkable progress in properties of materials. Example is the

dramatic progress in the strength to density ratio of materials, that

resulted in a wide variety of new products, from dental materials to tennis

racquets.

Historical Perspective

Properties are the way the material responds to the environment and

external forces.

Mechanical properties response to mechanical forces, strength, etc.

Electrical and magnetic properties - response electrical and magnetic

fields, conductivity, etc.

Thermal properties are related to transmission of heat and heat capacity.

Optical properties include to absorption, transmission and scattering of

light.

Chemical stability in contact with the environment - corrosion resistance.

Properties

What is Materials Science and Engineering ?

Material science is the investigation of the relationship

among processing, structure, properties, and

performance of materials.

Subatomic level

Electronic structure of individual atoms that defines

interaction among atoms (interatomic bonding)

distribution of electrons within individual atoms and

interactions with their nuclei.

Atomic level

Arrangement and organization of atoms in materials

(for the same atoms can have different properties, e.g.

two forms of carbon: graphite and diamond)

Microscopic structure

Arrangement of small grains of material that can be

dentified by microscopy.

Macroscopic structure

Structural elements that may be viewed with the

naked eye.

Structure

Manufacturing processes

There are a large number of processes

available for manufacture to the

engineer. These processes can be

broadly classified into four categories:

a) Casting processes

b) Forming processes

c) Fabrication processes

d) Material removal processes (Machining)

Casting processes

These are the only processes where liquid metal is used. Casting is also the

oldest known manufacturing process. It requires preparation of a cavity

usually in a refractory material to resemble closely the final object to be

made. Molten metal is poured into this refractory mould cavity and is allowed

to solidify. The object after solidification is removed from the mould. Casting

processes are universally used to manufacture a wide variety of products. The

principal process among these is sand casting where sand is used as the

refractory material. The process is equally suitable for the production of a

small batch as well as on a large scale.

Some of the other casting processes for specialized needs are:

Shell mould casting

Precision investment casting

Plaster mould casting

Die casting

Centrifugal casting

Forming processes

These are solid state manufacturing processes involving minimum amount of

material wastage and faster production. In a forming process, metal may be

heated to a temperature which is slightly below the solidus temperature and

then a large force is applied such that the material flows and takes the desired

shape. The desired shape is controlled by means of a set of tools called dies

which may be completely closed or partially closed during manufacture. These

processes are normally used for large scale production rates. These are

generally economical and in many cases improve the mechanical properties

too.

Some of the metal forming processes are:

Rolling

Drop forging

Press forging

Upset forging

Extrusion

Wire drawing

Sheet metal operations

Fabrication processes

These are secondary manufacturing processes where the starting raw

materials are processed by any of the previous manufacturing processes

described. It essentially involves joining pieces either permanently or

temporarily so that they would perform the necessary function. The joining

can be achieved by either or both of heat and pressure and/or a joining

material. Many of the steel structural constructions we see are first rolled and

then processes of interest in this category are:

Gas welding

Electric arc welding

Electric resistance welding

Thermit welding

Cold welding

Brazing

Soldering

Material removal processes

These are also the secondary manufacturing processes where the additional

unwanted material is removed in the form of chips from the blank material by

a harder tool so as to obtain the final desired shape. Material removal is

normally the most expensive manufacturing process because more energy is

consumed, and also a lot of waste material is generated in the process. Still

this is widely used because it delivers very good dimensional accuracy and

good surface finish. It also generates accurate contours. Material removal

processes are also called machining processes.

Various processes in this category are:

Turning

Drilling

Shaping and planning

Milling

Grinding

Broaching

Sawing

All these manufacturing processes have been continuously developed so as to

obtain better products at a reduced cost. Of particular interest is the

development of computers and their effect on the manufacturing processes.

The advent of computers has made a remarkable difference to most of the

above manufacturing processes. They have contributed greatly to both

automation and designing the process.

Casting

Powder metallurgy

Welding

Surface modification

Thin films

Extractive metallurgy

Polymerization

Diffusion

Heat treatment

Processing

Properties are the way the material responds to the environment and

external forces.

Mechanical properties response to mechanical forces, strength, etc.

Electrical and magnetic properties - response electrical and magnetic

fields, conductivity, etc.

Thermal properties are related to transmission of heat and heat

capacity.

Optical properties include to absorption, transmission and scattering of

light.

Chemical stability in contact with the environment - corrosion

resistance.

Properties

Вам также может понравиться

- MetalCasting 1Документ71 страницаMetalCasting 1P2109 Praphul HampapuramОценок пока нет

- EMS 223 Chapter 1Документ38 страницEMS 223 Chapter 1charles makasabiОценок пока нет

- MANUFACTURING TECHNOLOGY GUIDEДокумент46 страницMANUFACTURING TECHNOLOGY GUIDEMuthu BaskaranОценок пока нет

- Amt Module 1Документ66 страницAmt Module 1Edwin V MathewsОценок пока нет

- Bahan Kulaih Tech. MaufakturДокумент47 страницBahan Kulaih Tech. MaufakturNo BitОценок пока нет

- Advanced Manufacturing - Lec - 4 - Introduction 1Документ12 страницAdvanced Manufacturing - Lec - 4 - Introduction 1Hatem ShinkadaОценок пока нет

- Introduction To Manufacturing Technology: Instructor: HAILEДокумент19 страницIntroduction To Manufacturing Technology: Instructor: HAILEhaile mehariОценок пока нет

- Chapter Two CastingДокумент64 страницыChapter Two CastingahmadОценок пока нет

- ADVANCED MACHINING PROCESSESДокумент22 страницыADVANCED MACHINING PROCESSESfaizОценок пока нет

- 1 Sample PreparationДокумент490 страниц1 Sample PreparationVyakulShahОценок пока нет

- ElectroceramicsДокумент16 страницElectroceramicsaisveryaОценок пока нет

- Lecture 1 IntroductionДокумент59 страницLecture 1 IntroductionRaj BhirudОценок пока нет

- I. Materials in Manufacturing: Sand CastingДокумент3 страницыI. Materials in Manufacturing: Sand CastingKris EdoОценок пока нет

- Overview of Casting TechnologyДокумент5 страницOverview of Casting TechnologySK Kushwah RajputОценок пока нет

- MP 1Документ95 страницMP 1abdi debeleОценок пока нет

- 01 - Fundamentals of Metalworking-2017son01Документ92 страницы01 - Fundamentals of Metalworking-2017son01emreОценок пока нет

- Electrical Engineering Materials (Em) 1Документ26 страницElectrical Engineering Materials (Em) 1Hezron gibronОценок пока нет

- Manufacturing Process: I Semester ES-119Документ170 страницManufacturing Process: I Semester ES-119sayan halderОценок пока нет

- Assignment: Submitted To: Miss Sobia Anwar Submitted By: Uzair Khan (2018-CH-01)Документ12 страницAssignment: Submitted To: Miss Sobia Anwar Submitted By: Uzair Khan (2018-CH-01)Uzair KhanОценок пока нет

- Advance Engineering Materials OverviewДокумент5 страницAdvance Engineering Materials OverviewRana UzairОценок пока нет

- Home Assignment No, 4Документ29 страницHome Assignment No, 4umarОценок пока нет

- Joining ProcessesДокумент10 страницJoining ProcessesSachin KhotОценок пока нет

- Importance of Study: Challenger DisasterДокумент39 страницImportance of Study: Challenger DisasteryashvantОценок пока нет

- Materials in Metal FormingДокумент42 страницыMaterials in Metal Formingasif100% (1)

- Chapter 5Документ14 страницChapter 5Phuc Truong DucОценок пока нет

- Unit - 1 Metal Casting Processes-NVRДокумент287 страницUnit - 1 Metal Casting Processes-NVRPrashon GОценок пока нет

- Manufacturing Engineering ProcessesДокумент29 страницManufacturing Engineering ProcessesAbi DemОценок пока нет

- CH 1 MPTДокумент28 страницCH 1 MPTmolla biyadgieОценок пока нет

- Explosive FormingДокумент16 страницExplosive FormingAshutoshSingh100% (1)

- Modern Manufacturing Methods: Unit IДокумент17 страницModern Manufacturing Methods: Unit IharinathОценок пока нет

- Lecture 7 - Common Manufacturing Processes IIДокумент41 страницаLecture 7 - Common Manufacturing Processes IIKamal SurenОценок пока нет

- Basic Manufacturing ProcessesДокумент60 страницBasic Manufacturing Processesggrhg72Оценок пока нет

- Group 5 ScriptДокумент28 страницGroup 5 ScriptCarl Jay R. IntacОценок пока нет

- HVFДокумент23 страницыHVFFRANCIS THOMASОценок пока нет

- Foundry 1Документ17 страницFoundry 1Raghav MohtaОценок пока нет

- Manufacturing Engineering I Chapter 1Документ29 страницManufacturing Engineering I Chapter 1Abiyot egataОценок пока нет

- Why study materials engineering in 40 charactersДокумент15 страницWhy study materials engineering in 40 charactersDuaa GadoraaОценок пока нет

- Chapter 2 - Advanced Construction MaterialsДокумент43 страницыChapter 2 - Advanced Construction Materialsaddis zewdОценок пока нет

- Cold Hot Working AnnealingДокумент40 страницCold Hot Working AnnealingBaljeet KaurОценок пока нет

- Chapter 2 General Introduction About Advanced Construction MaterialsДокумент44 страницыChapter 2 General Introduction About Advanced Construction Materialseyob yohannesОценок пока нет

- Metal Manufacturing Processes ExplainedДокумент5 страницMetal Manufacturing Processes Explainedyeng botzОценок пока нет

- Manu - Process (Unit 1-4)Документ223 страницыManu - Process (Unit 1-4)vrinda.bhardwaj.52Оценок пока нет

- MP-I-Lecture No. 15-16Документ27 страницMP-I-Lecture No. 15-16Osaid AhmadОценок пока нет

- Materials For MoldДокумент52 страницыMaterials For MoldSnowy DoveОценок пока нет

- ME6352 Manufacturing Technolgy: Unit I Casting 8Документ54 страницыME6352 Manufacturing Technolgy: Unit I Casting 8Aravind PhoenixОценок пока нет

- Machine Design Group Work Heat Treatment ProcessesДокумент5 страницMachine Design Group Work Heat Treatment ProcessesErnest ForsonОценок пока нет

- Introduction To Structural Materials: Prof Prashant P Date F13, 1 Floor Mech Engg. Phone 7511 Email: Ppdate@iitb - Ac.inДокумент53 страницыIntroduction To Structural Materials: Prof Prashant P Date F13, 1 Floor Mech Engg. Phone 7511 Email: Ppdate@iitb - Ac.inOm DesaiОценок пока нет

- 4 - Cold Working Processes of MetalsДокумент13 страниц4 - Cold Working Processes of MetalsHussein SaeedОценок пока нет

- MP Lecture Unit 3 FormingДокумент21 страницаMP Lecture Unit 3 Formingaakash sharmaОценок пока нет

- Fabrication of MetalДокумент22 страницыFabrication of MetalaurangzaibОценок пока нет

- NTM Module 1Документ10 страницNTM Module 1Sahil GaudeОценок пока нет

- 1a - EP108 BEP1033 IntroductionДокумент39 страниц1a - EP108 BEP1033 IntroductionHongОценок пока нет

- Recent Advances in Sand CastingДокумент25 страницRecent Advances in Sand Casting9591007896Оценок пока нет

- Report On Metal Forming ProcessДокумент10 страницReport On Metal Forming Processorangeideas7Оценок пока нет

- PROSES MANUFAKTUR LOGAMДокумент27 страницPROSES MANUFAKTUR LOGAMNathanaelОценок пока нет

- Manufacturing Technology (MEC - 205) : Unit - 1 Introduction To Manufacturing and Metal CastingДокумент74 страницыManufacturing Technology (MEC - 205) : Unit - 1 Introduction To Manufacturing and Metal CastingShridhar SavatОценок пока нет

- MatscienceДокумент13 страницMatscienceapi-73325304Оценок пока нет

- Metal WorkingДокумент7 страницMetal WorkingJulio OchoaОценок пока нет

- Chapter 4 - Casting ProcessesДокумент40 страницChapter 4 - Casting ProcessesErnawati ZailiОценок пока нет

- DIN en 10305-5-Steel Tubes For Precision Applications-Technical Delivery ConditionsДокумент23 страницыDIN en 10305-5-Steel Tubes For Precision Applications-Technical Delivery ConditionsGökhan ÇiçekОценок пока нет

- DIN en 10305-6-Steel Tubes For Precision Applications-Technical Delivery ConditionsДокумент21 страницаDIN en 10305-6-Steel Tubes For Precision Applications-Technical Delivery ConditionsGökhan ÇiçekОценок пока нет

- En 10305-1 PDFДокумент28 страницEn 10305-1 PDFVlad100% (3)

- BS Iso 1940-2Документ24 страницыBS Iso 1940-2Gökhan ÇiçekОценок пока нет

- Process Control and Automation Developments in WeldingДокумент9 страницProcess Control and Automation Developments in WeldingGökhan ÇiçekОценок пока нет

- DIN en 10305-3-Steel Tubes For Precision Applications-Technical Delivery ConditionsДокумент23 страницыDIN en 10305-3-Steel Tubes For Precision Applications-Technical Delivery ConditionsGökhan ÇiçekОценок пока нет

- DIN 00471-Circlips, Retaining Rings, For ShaftsДокумент12 страницDIN 00471-Circlips, Retaining Rings, For ShaftsGökhan ÇiçekОценок пока нет

- DIN EN ISO 10642-Hexagon Socket Countersunk Head ScrewsДокумент10 страницDIN EN ISO 10642-Hexagon Socket Countersunk Head ScrewsGökhan Çiçek100% (1)

- DIN 00385-Studs, With A Length of Engagement Equal To About 2dДокумент4 страницыDIN 00385-Studs, With A Length of Engagement Equal To About 2dGökhan ÇiçekОценок пока нет

- DIN 00908-Hexagon Socket Screw PlugsДокумент3 страницыDIN 00908-Hexagon Socket Screw PlugsGökhan ÇiçekОценок пока нет

- DIN 00127 Etc Maryland MetricsДокумент9 страницDIN 00127 Etc Maryland MetricsGökhan ÇiçekОценок пока нет

- BS EN ISO 7539-3-Corrosion of Metals and Alloys-Stress Corrosion Testing-Preparation and Use of U-Bend SpecimensДокумент12 страницBS EN ISO 7539-3-Corrosion of Metals and Alloys-Stress Corrosion Testing-Preparation and Use of U-Bend SpecimensGökhan ÇiçekОценок пока нет

- Mil-Std-1948 Nötron Radyografi̇ Testi̇ Teri̇mler Ve Tanimlar Onay DökümaniДокумент1 страницаMil-Std-1948 Nötron Radyografi̇ Testi̇ Teri̇mler Ve Tanimlar Onay DökümaniGökhan ÇiçekОценок пока нет

- MIL-STD-1949A Magnetic Particle Inspection StandardДокумент35 страницMIL-STD-1949A Magnetic Particle Inspection StandardErik HuangОценок пока нет

- BS EN ISO 2639-Steels-Determination and Verification of The Depth of Carburized and Hardened CasesДокумент16 страницBS EN ISO 2639-Steels-Determination and Verification of The Depth of Carburized and Hardened CasesGökhan Çiçek100% (2)

- 410 Types PDFДокумент18 страниц410 Types PDFGökhan ÇiçekОценок пока нет

- Mil-Std-2032 Shborularin Eddy Current KontroluДокумент35 страницMil-Std-2032 Shborularin Eddy Current KontroluGökhan ÇiçekОценок пока нет

- Mil-Std-1948 Nötron Radyografi̇ Testi̇ Teri̇mleri̇ Ve TanimlariДокумент21 страницаMil-Std-1948 Nötron Radyografi̇ Testi̇ Teri̇mleri̇ Ve TanimlariGökhan ÇiçekОценок пока нет

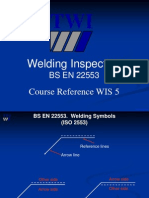

- BS en 22553 Welding Arrow SymbolДокумент13 страницBS en 22553 Welding Arrow SymbolErcan Akkaya100% (3)

- Mil-Std-1949a Notice 1Документ1 страницаMil-Std-1949a Notice 1Gökhan ÇiçekОценок пока нет

- STANAG - 4569 - AEP-55v02 - STN 4569Документ51 страницаSTANAG - 4569 - AEP-55v02 - STN 4569Gökhan Çiçek88% (8)

- Mil-Std-1949a NoticeДокумент3 страницыMil-Std-1949a NoticeGökhan ÇiçekОценок пока нет

- Automizing The Design of Francis Turbine Spiral CaseДокумент10 страницAutomizing The Design of Francis Turbine Spiral CaseGökhan ÇiçekОценок пока нет

- Def Stan 03-21Документ44 страницыDef Stan 03-21Gökhan ÇiçekОценок пока нет

- Astm E1444-16 PDFДокумент22 страницыAstm E1444-16 PDFWaldo Arellano100% (2)

- Def Stan 03-34Документ30 страницDef Stan 03-34Gökhan ÇiçekОценок пока нет

- Basic WeldingДокумент40 страницBasic WeldingVishnu Vardhan . C100% (8)

- Gökhan MakaleДокумент7 страницGökhan MakaleGökhan ÇiçekОценок пока нет

- Mil DTL 12560KДокумент52 страницыMil DTL 12560KGökhan ÇiçekОценок пока нет

- File Down Load, 23186, enДокумент14 страницFile Down Load, 23186, enGökhan ÇiçekОценок пока нет

- Wireless Water Level ControllerДокумент23 страницыWireless Water Level ControllerSankeerthana GadeОценок пока нет

- Solid State Chemistry 13102066Документ43 страницыSolid State Chemistry 13102066Loveroop Singh62% (13)

- Fully Reused VLSI Architecture of FMO/Manchester Encoding Using SOLS Technique For DSRC ApplicationsДокумент16 страницFully Reused VLSI Architecture of FMO/Manchester Encoding Using SOLS Technique For DSRC ApplicationssnehaОценок пока нет

- TCS3400 DS000411 4-00Документ34 страницыTCS3400 DS000411 4-00Miguel_Angel92Оценок пока нет

- Capacitive Discharge GeneratorsДокумент6 страницCapacitive Discharge Generatorsbarnowl999Оценок пока нет

- Oscilloscope Marking SchemeДокумент3 страницыOscilloscope Marking SchemeleotakesleoОценок пока нет

- Kazuaki ToyouraДокумент7 страницKazuaki ToyouraEstudiante2346Оценок пока нет

- Manual Microstep MD2U MD20 enДокумент1 страницаManual Microstep MD2U MD20 enJose M RojasОценок пока нет

- VLSI - Silicon Gate TechnologyДокумент18 страницVLSI - Silicon Gate TechnologyK.R.RaguramОценок пока нет

- Mts 3200Документ4 страницыMts 3200Carlos TorresОценок пока нет

- Making a Difference with MIPsДокумент8 страницMaking a Difference with MIPsAvinashОценок пока нет

- Switchboard Instruments Data Sheet 4921210012 UKДокумент8 страницSwitchboard Instruments Data Sheet 4921210012 UKEdi LeeОценок пока нет

- Low-Frequency Antennas (Chapter 19) by C.A. Martin and Phillip S. Carter (RCA Laboratories)Документ19 страницLow-Frequency Antennas (Chapter 19) by C.A. Martin and Phillip S. Carter (RCA Laboratories)Bob Laughlin, KWØRLОценок пока нет

- SCAP - Power InverterДокумент14 страницSCAP - Power InverterFolorunso AbiodunОценок пока нет

- Slus 028 AДокумент28 страницSlus 028 Asubhash_tuhhОценок пока нет

- Solar Energy Lecture Notes Modeling and Analysis of Photovoltaic and Electrochemical Solar Energy SystemsДокумент137 страницSolar Energy Lecture Notes Modeling and Analysis of Photovoltaic and Electrochemical Solar Energy SystemsBigyan BhattaraiОценок пока нет

- HT 24 LC 04Документ10 страницHT 24 LC 04gomositoОценок пока нет

- Geiger Test ProcДокумент25 страницGeiger Test ProcIriantoОценок пока нет

- General Operational Amplifier Stages and Internal Circuit Diagrams of IC 741Документ5 страницGeneral Operational Amplifier Stages and Internal Circuit Diagrams of IC 741VENKATESWARLU MUVVA (PA2111004040011)Оценок пока нет

- Shunt ReactorДокумент4 страницыShunt ReactorShruti JoshiОценок пока нет

- Samsung's Reaction To Chinese CompetitionДокумент11 страницSamsung's Reaction To Chinese CompetitionTinakhaladze100% (6)

- Elecas8621 3+Документ2 страницыElecas8621 3+skywalker_handsomeОценок пока нет

- Module 4.5 Voltage Sources in SeriedДокумент11 страницModule 4.5 Voltage Sources in SeriedGeneva Mira AlvarezОценок пока нет

- What Is Processor ?Документ8 страницWhat Is Processor ?Arya SinghОценок пока нет

- Een 202 Lab 8 ReportДокумент5 страницEen 202 Lab 8 Reportapi-296881750Оценок пока нет

- Siddharth Group of Institutions Question Bank 2016Документ33 страницыSiddharth Group of Institutions Question Bank 2016Kandula DevipriyankaОценок пока нет

- Bhel Haridwar - Training Report - 800 MW Bar CIM Block 4 (EEE)Документ27 страницBhel Haridwar - Training Report - 800 MW Bar CIM Block 4 (EEE)Amit Kumar67% (6)

- Be Summer 2021Документ2 страницыBe Summer 2021Sandip SolankiОценок пока нет

- Why There Is No Igbt Traction RectifiersДокумент9 страницWhy There Is No Igbt Traction RectifiersLaurence MichaelОценок пока нет

- Electronic Door Lock1Документ26 страницElectronic Door Lock1smahesh_1980Оценок пока нет