Академический Документы

Профессиональный Документы

Культура Документы

1607

Загружено:

Christian Pinto0 оценок0% нашли этот документ полезным (0 голосов)

12 просмотров3 страницыThe steel silo technology has been used for storing granular materials in China since the begmmng of 80's. The disadvantages of the Placing Steel S110 are: (1) steel strength used only about one third because of the buckling of It; (2) the pressure applied to the silo wall by the stored matenal WIll be doubled at time of unloading accordmg to the Silo Code. The national patent bureau has awarded the writer a patent right for this design.

Исходное описание:

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документThe steel silo technology has been used for storing granular materials in China since the begmmng of 80's. The disadvantages of the Placing Steel S110 are: (1) steel strength used only about one third because of the buckling of It; (2) the pressure applied to the silo wall by the stored matenal WIll be doubled at time of unloading accordmg to the Silo Code. The national patent bureau has awarded the writer a patent right for this design.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

12 просмотров3 страницы1607

Загружено:

Christian PintoThe steel silo technology has been used for storing granular materials in China since the begmmng of 80's. The disadvantages of the Placing Steel S110 are: (1) steel strength used only about one third because of the buckling of It; (2) the pressure applied to the silo wall by the stored matenal WIll be doubled at time of unloading accordmg to the Silo Code. The national patent bureau has awarded the writer a patent right for this design.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 3

Proceedings of the 7th International Working Conference an Stored-product Protection - Yolume 2

A hanging steel silo

Wang Rongshuar' and Yang Shizhong''

Abstract

Steel s110 is one of the main gram storage containers. All

types of steel s110sm use can be styled Placing Steel Silo; it

is placed on the supportmg bed or foundation Its

disadvantages are: (1) steel strength used only about one

third because of the buckling of It; (2) the pressure applied

to the silo wall by the stored matenal WIll be doubled at time

of unloading accordmg to the Silo Code. So, more steel and

fund are needed for construction. In order to overcome the

two disadvantages above mentioned of the Placing Steel S110,

the Hanging Steel S110was designed. It is hung at Its top

circumference. In tlusl case, less steel and capitals are

needed for the construction of the Hangmg Steel S110 The

National Patent Bureau has awarded the writer a patent right

for this design.

Introduction

The steel silo technology has been used for storing granular

materials in China since the begmmng of 80's, and it

attracted many scholars to concentrate their attention in

studying on this technology.

It is well known that the steel s110 belongs to thm-shell

structure, and when the friction of the storage matenal to

the s110wall apphes axial compression, it IS easy to buckle.

The structure design of steel SIlo is controlled by buckling

condmons mstead of by strength conditions and ItS buckling

critical compressive stress IS very smaller than ItS strength.

On the other hand, axial tension IS not to cause buckling, so

that the structural design of steel SIlo IS determined by ItS

strength conditions instead of by Its bucklmg condmons

All types of steel silo used now can be styled the placing

steel s110 that is located at the supporting bed or the s110

foundation. The fnction of the stored material makes It to

be compressed in axial direction. The disadvantages of the

placing steel s110are: (1) steel strength used only about one

thIrd because of the buckling of It, (2) the pressure applied

IZhengzhou Gram Science Research & Design Institute under the

Mmistry of Domestic Trade, 153 Nanyang Road, Zhengzhou

450053, China

2Forelgn Capital Management Office, Mnustry of Internal Trade, 45

Fuxmgmennei St , Benmg , Chma

to the silo wall by the storage material mcreases one times

when unloading according to the silo code. With unloading of

the storage material, the dynamic pressure on the silo wall

exerted by the storage material changes very much which

may result m the buckhng of the Hanging Steel S110. So,

more steel and capitals are needed for construction to

guarantee the safety of the Placing Steel S110.

In order to overcome the two disadvantages above

mentioned of the Placing Steel Silo, the Hanging Steel Silo

was designed.

Model of the Hanging Steel Silo

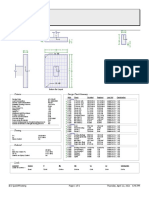

The sketch drawing of the Hanging Steel Silo IS shown in

Fig. 1. Mam idea 1S that we manage to make s110 wall be

hung at Its top circumference, IS this status in, the storage

material friction to the silo shell shall make It axial tensile.

As we know, axial tension will not cause the silo shell

buckhng, so, we can reasonably make use of the strength of

steel to design the s110 wall. And in order to hang the SIlo

wall, a compression support bin with radial steel cantilever

trusses for hanging silo wall and openmgs for grain flowing

in and out are set up in the center of the hanging steel silo.

ThIS bin can be used as the pressure reduction pipe to

decrease the dynamic actions as far as possible when

unloading the storage materials. And this bin can also be

used for the ventilation of the whole s110.

1 s-to bose

2 Ploc.ng St" ..1 S,lo

J 5.10 roof

4 Hongohg Steel S,lo

5 supper t b,n

b s'tgeo\ trl)SS

7 COt'loeoct,og JOInt

8 hon9,ng Jo,nt

9 open,ng

JO .ol"t

11 .9ut'l>[

Note

Fig. 1. Diagram of the placing steel silo and the hanging

steel Silo.

In a word, the Hanging Steel Silo can overcome the two

disadvantages of the Placmg Steel Silo mentioned above

Therefore, less steel and capitals are needed for the

construction of the Hanging Steel S110.

1607

Proceedings of the 7th lnternoiumal Workmg Conference on Stored-product Protection - Yolume 2

The basic structural elements

Main structural elements are a compression support bin,

radial steel cantilever trusses set on the bin for hangmg of

the steel silo and a tensile steel silo.

These structure elements are descnbed respectively as

follows:

The compresswn support bin.

On the compression support bin are set the ramal steel

cantilever trusses to hang the steel silo, so, It IS the pillar

strength of the whole silo. On the compression support bm,

opemngs are also designed m all directions and various

heights. Through these openmgs, the storage matenal flows

mside or outside the compression support bin to unload or

load the steel silo.

In consideration of too low strength of bnck and stone,

concrete structure WIll be used for the compression support

bm. The diameter of the compression support bin, Dl , will

be D

o

/4 - D

o

/3, and Willnot be smaller than Zm, m wluch,

Do ISthe diameter of the steel silo The compression support

bin ISsupported by the foundation.

The compression support bm can be used as the pressure

(storage material to steel silo wall) reduction pipe and for

the ventilation of the whole silo.

The radial steel cantilever trusses set on the compression

support bin

The radial steel cantilever trusses are set upon the upper

part of the compression support bin to hang the Hanging

Steel Silo and support the root of the Hanging Steel SIlo.

They are rooted in the upper and lower ring beams, which

are inlaid in the near-top part of the compression support

bm.

The tenstle steel silo

Steel plates welding or other fittmg method can be used

for the construction of the Hangmg Steel SIlo wall

However, the LIPP Patent SIlo wall should not be used for

the Hanging Steel SIlo wall, as ItSrollmg construction joints

are not favorable to endure tension action. The top

cIrcumference of the Hanging Steel SIlo is hangmg under the

radial steel cantilever trusses set on the compreSSIonbm;

the bottom of the Hangmg Steel Silo is connected with the

base bed. The diameter and heIghts of the Hangmg Steel

SIlo WIll be determmed accormng to the applIcation

conmtIOnsand the conmtions of the foundatIOnbed

Work Principle

Loading, unloading operations

When loading, the storage material goes mto the

compreSSIon support bm from the top conveyor of the

Hanging Steel SIlo, and ItS level nses gradually When the

matenal level IS higher than the bottom openmgs on the

compression bm, the matenal flows mto the Hangmg Steel

1608

SIlo through the bottom openmgs on the compresston support

bm After a penod of time, the material level in the bm

nses again, the above procedure repeats time and agam from

the lower opemngs on the bm to the upper opemngs

successively until the silo becomes full of gram last through

the highest openings on the bin. Of course, the bin also

becomes full of gram.

When unloadmg, as the storage matenal flows out of the

silo hopper, the material level drops gradually. When it is

lower than the highest opemngs on the bin, the matenal in

the silo flows mto the bin. After a penod of time, the

matenallevel m the bin drops again, above process repeats

time and agam from the upper openmgs on the bin to the

lower openmgs successively, until the silo becomes empty

last through the lowest openmgs on the bm, finally the bin

also becomes empty

Structure mechanical status

When the silo and bin are empty, the silo is subjected to

the lateral wmd load and transfers It to the Trusses at the

silo top circumference and the base bed at the silo bottom.

When the SIloand bin are filled With the storage material,

the matenallateral pressure produces circumferential tensile

stress m the silo wall, but It produces circurnferential

compressive stress in the bm wall. The storage matenal

vertical Inction produces vertical tension in the SIlo wall,

but to the bin wall, produces vertical compression. That is

to say, the Hangmg Steel SIlo is tensile m both directions

and the concrete bm is compressive m both directions.

Accordmg to the strength theory, these stress statuses are

respectively favorable to the steel silo and the concrete bm.

Furthermore, when unloading, as the material flows

through the bin, Its dynamic effects on the Hanging Steel

SIlo will be near zero. ThIScondition ISalso favorable to the

steel silo.

Construction Details

The steel silo hanging on the cantilever trusses

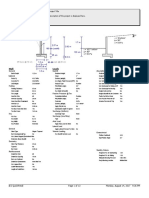

As shown in FIg. 2, a tensIle nng of angle iron is set up at

the outer jomts of the cantilever trusses. The steel silo IS

connected WIth a wmg of the angle Iron nng by means of

high strength bolts.

The steel silo connecting with the base bed at its

bottom

As shown in Fig. 2, a band plate rmg IS welded WIth the

embedded parts in the base bed. The steel sIlo bottom IS

bolted to the band plate nng and the bolt hole on the steel

sIlo will be ellipSOIdalto allow the steel sIlowall move up and

down freely.

Proceedings of the 7th Iruemaiumal Working Conference on Stored-product Protection - Volume 2

NotE'

1 st!?!?1 truss

2 .r on ongl!?

3 Horoq,ng Steel $,10

4 h'gh s+rength bo't

5 band pto t e r ,nq

b eMbedded r:cr+

7 bol+

8 "eld,ng

Fig. 2 0 Structure details of the top and the bottom end of the

hanging steel s110

Procedure in Construction

o Construction of the base bed.

o Slip fore or prefabncated construction of the compression

support bin.

o Assembly of jack hft frame.

o LIft the cantilever trusses and the steel silo wall every

time hfts a certam height, assembles a CIrcle plate of the

steel silo wall, which IS pre-assembled on the ground.

o After assembly and lift of the whole steel silo fuushed,

manages to anchor the cantilever trusses to the

compression support bm at the exact posi tion

o Layout the roof plates of the steel silo.

Conclusion

The Hanging Steel SIlo has advantages of structural

properties, as It is tensile 10 both direction and the

compression bm IS compressive in both directions. So we can

reasonably make use of the mechamcal properties of steel

and concrete materials, and the storage material unloading

dynamic effects to the hanging Steel SIlo will be near zero.

Also the compression support bin with many openings can be

used for ventilation, therefore, the hanging Steel Silo is not

only less expensive, but also safer. However the

construction penod of the Hanging Steel SIlo may be a little

longer.

References

M . L. Reimbert and A. M. Reimbert, 1976. SIlo Theory

and Practice, Trans Tech Pubhcations, Germany, 239p.

Sun Xunfang etc. 1979. Material Mechamcs (in Chmese);

People's Education Press, Belling, 442p.

Zhou Iiajun etc, 1988 Design Code for Remforced

Concrete SIlo (GBJ77 - 85) (in Chinese). Chma Iihua

Press, Belling, 52p.

1609

Вам также может понравиться

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- HVAC Installation ManualДокумент215 страницHVAC Installation Manualmeeng2014100% (5)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Carnatic Music NotationДокумент6 страницCarnatic Music Notationksenthil kumar100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Preview-90187 Pno H UnlockedДокумент5 страницPreview-90187 Pno H UnlockedFilip SuciuОценок пока нет

- STAAD PRO - Bridge TutorialДокумент18 страницSTAAD PRO - Bridge Tutorialsaisssms9116100% (6)

- Regaining Sand Control: Ricky J. Armentor Michael R. WiseДокумент10 страницRegaining Sand Control: Ricky J. Armentor Michael R. WiseChristian PintoОценок пока нет

- Earthquake Behaviour of BuildingsДокумент268 страницEarthquake Behaviour of BuildingsChristian PintoОценок пока нет

- Cottle Taylor Case StudyДокумент10 страницCottle Taylor Case Studyydukare100% (2)

- Organic Agriculture Gr12 - Module2.final For StudentДокумент20 страницOrganic Agriculture Gr12 - Module2.final For Studentapril jean cahoyОценок пока нет

- Lipoproteins in Diabetes Mellitus: Alicia J. Jenkins Peter P. Toth Timothy J. Lyons EditorsДокумент468 страницLipoproteins in Diabetes Mellitus: Alicia J. Jenkins Peter P. Toth Timothy J. Lyons EditorsFELELОценок пока нет

- Design Detail: Ingenieros Inasa 123 Main St. Anytown, Usa 00000 (000) 000-0000Документ6 страницDesign Detail: Ingenieros Inasa 123 Main St. Anytown, Usa 00000 (000) 000-0000Christian PintoОценок пока нет

- By T. Bart Quimby, P.E., Ph.D. Quimby & AssociatesДокумент5 страницBy T. Bart Quimby, P.E., Ph.D. Quimby & AssociatesChristian PintoОценок пока нет

- Building Structures 1: Antonín LupíšekДокумент25 страницBuilding Structures 1: Antonín LupíšekChristian PintoОценок пока нет

- Unitec Conex I OnesДокумент185 страницUnitec Conex I OnesChristian PintoОценок пока нет

- 2 ND Order Analysis ExampleДокумент76 страниц2 ND Order Analysis ExampleChristian Pinto100% (1)

- Castillo Muro CalculosДокумент13 страницCastillo Muro CalculosChristian PintoОценок пока нет

- Tutorial Mastan2Документ68 страницTutorial Mastan2Christian PintoОценок пока нет

- 175 YibrinДокумент13 страниц175 YibrinChristian PintoОценок пока нет

- Rectangular Concrete TanksДокумент190 страницRectangular Concrete TanksChristian Pinto100% (2)

- Steel Rebar Industry ProfileДокумент34 страницыSteel Rebar Industry ProfileChristian PintoОценок пока нет

- Factor Affecting Child Dental Behaviour PedoДокумент19 страницFactor Affecting Child Dental Behaviour PedoFourthMolar.comОценок пока нет

- Sleeping GarmentsДокумент1 страницаSleeping GarmentsRosalie LazaroОценок пока нет

- Youth Policy Manual: How To Develop A National Youth StrategyДокумент94 страницыYouth Policy Manual: How To Develop A National Youth StrategyCristinaDumitriuAxyОценок пока нет

- Main Book LR X PDFДокумент192 страницыMain Book LR X PDFjay danenjeyanОценок пока нет

- Friday Night Mishaps, Listening Plus TasksДокумент3 страницыFriday Night Mishaps, Listening Plus TasksCristina Stoian100% (1)

- Practice 3Документ7 страницPractice 3NinhОценок пока нет

- Chemistry: Presented By: Mrs. Marie Nella T. VictoriaДокумент75 страницChemistry: Presented By: Mrs. Marie Nella T. VictoriaJESPHER GARCIAОценок пока нет

- Amma Vun - Bala AshtagamДокумент4 страницыAmma Vun - Bala AshtagamSHIV RAMОценок пока нет

- BM - GoPro Case - Group 6Документ4 страницыBM - GoPro Case - Group 6Sandeep NayakОценок пока нет

- The Liberal Welfare Reforms 1906Документ5 страницThe Liberal Welfare Reforms 1906Skye G-sОценок пока нет

- Law Sample QuestionДокумент2 страницыLaw Sample QuestionknmodiОценок пока нет

- DAR Provincial Office: On-the-Job Training (OJT) Training PlanДокумент3 страницыDAR Provincial Office: On-the-Job Training (OJT) Training PlanCherry Jean MaanoОценок пока нет

- Machine Tools Design: InstructorsДокумент31 страницаMachine Tools Design: InstructorsAladdin AdelОценок пока нет

- Aci - The Financial Markets Association: Examination FormulaeДокумент8 страницAci - The Financial Markets Association: Examination FormulaeJovan SsenkandwaОценок пока нет

- The Mystery of The Secret RoomДокумент3 страницыThe Mystery of The Secret RoomNur Farhana100% (2)

- Guidelines On Setting Up A Newman Fellowship 2017-2018Документ6 страницGuidelines On Setting Up A Newman Fellowship 2017-2018Liz McFeelyОценок пока нет

- Corruption CricketДокумент21 страницаCorruption CricketAshwin NaraayanОценок пока нет

- Culvert StatementДокумент4 страницыCulvert StatementRubul Prasad DasОценок пока нет

- Back To School Proposal PDFДокумент2 страницыBack To School Proposal PDFkandekerefarooqОценок пока нет

- Fallout Unwashed Assets Monsters and NpcsДокумент4 страницыFallout Unwashed Assets Monsters and NpcsVeritas VeritatiОценок пока нет

- Republic of The Philippines: Paulene V. Silvestre Personal DevelopmentДокумент3 страницыRepublic of The Philippines: Paulene V. Silvestre Personal DevelopmentPau SilvestreОценок пока нет

- JournalДокумент3 страницыJournalJuvz BezzОценок пока нет

- Audit QuestionnaireДокумент7 страницAudit QuestionnaireEmz Pleños ValerosoОценок пока нет