Академический Документы

Профессиональный Документы

Культура Документы

Mine (Hydrau)

Загружено:

Roselle Jarden Añes0 оценок0% нашли этот документ полезным (0 голосов)

13 просмотров3 страницыtry this

Оригинальное название

Mine(Hydrau)

Авторское право

© © All Rights Reserved

Доступные форматы

DOCX, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документtry this

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOCX, PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

13 просмотров3 страницыMine (Hydrau)

Загружено:

Roselle Jarden Añestry this

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOCX, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 3

1.

Accumulator - A container which stores fluids under pressure as a source of

hydraulic power. It may also be used as a shock absorber

2. Bleed - The process by which air is removed from a hydraulic system.

3. Bypass - A secondary passage for fluid flow.

4. Circuit - A series of component parts connected to each other by fluid lines or

passages. Usually part of a "system".

5. Controller - A microprocessor that controls electro-hydraulic valve functions.

6. Cooler (Oil) - A heat exchanger which removes heat from a fluid. (See "Heat

Exchanger.")

7. Coupler - A device to connect two hoses or lines, or to connect hoses to valve

receptacles.

8. Cycle - A single complete operation of a compo- nent which begins and ends in a

neutral position.

9. Cylinder - A device for converting fluid power into linear or circular motion. An

"actuator". Basic design types include piston and vane units.

10. Displacement - The volume of oil displaced by one complete stroke or revolution (of

a pump, motor, or cylinder).

11. Drift - Motion of a cylinder or motor due to internal leakage past components in the

hydraulic system.

12. Filter (OIL )- A device which removes solids from a fluid.

13. Flow Meter - A testing device which gauges either flow rate, total flow, or both.

14. Flow Rate - The volume of fluid passing a point in a given time.

15. Fluid Power - Energy transmitted and controlled through use of a pressurized fluid.

16. Horsepower - The work produced per unit of time.

17. Hose - A flexible line.

18. Hydraulics - The engineering science of liquid pressure and flow.

19. Hydrodynamics - The engineering science of the energy of liquid pressure and

flow.

20. Inert Gas - A non-explosive gas.

21. Line - A tube, pipe, or hose for conducting a fluid.

22. Manifold - A fluid conductor which provides many ports.

23. O-Ring - A static and/or dynamic seal for curved or circular mating surfaces.

24. Packing - Any material or device which seals by compression. Common types are

U-packings, V- packings, "Cup" packings, and a-rings.

25. Pipe - A line whose outside diameter is standardized for threading.

26. Piston - A cylindrical part which moves or recip- rocates in a cylinder and transmits

or receives motion to do work.

27. Port - The open end of a fluid passage. May be within or at the surface of a

component.

28. Pressure - Force of a fluid per unit area, usually expressed in pounds per square

inch (psi).

29. Pump - A device which converts mechanical force into hydraulic fluid power. Basic

design types are gear, vane, and piston units.

30. Remote - A hydraulic function such as a cylinder which is separate from its supply

source. Usually connected to the source by flexible hoses.

31. Reservoir - A container for keeping a supply of working fluid in a hydraulic system.

32. Solenoid - An electro-magnetic device which positions a hydraulic valve.

33. Starvation - A lack of oil in vital areas of a sys- tem. Often caused by plugged filters,

etc.

34. Strainer - A coarse filter.

35. Stroke - Sometimes used to denote the changing of the displacement of a variable

delivery pump.

36. Surge - A momentary rise of pressure in a hy- draulic circuit.

37. Symbols, Schematic - Used as a short-hand representation on drawings to

represent hydraulic system components.

38. System - One or more series of component parts connected to each other. Often

made up of two or more "circuits".

39. Terminal Expansion - Expansion of the fluid volume due to heat.

40. Torque - The turning effort of a hydraulic motor or rotary cylinder. Usually given in

inch-pounds (in- Ibs) or foot-pounds (ft-lbs).

41. Tube - A line whose size is its outside diameter.

42. Valve - A device which controls either 1) pressure of fluid, 2) direction of fluid flow, or

3) rate of flow.

43. Valve Stack - A series of control valves in a stack with common end plates and a

common oil inlet and outlet.

44. Velocity - The distance which a fluid travels per unit time. Usually given as feet per

second.

45. Vent - An air breathing device in a fluid reservoir.

46. Viscosity - The measure of resistance of a fluid to flow.

47. Volume - The amount of fluid flow per unit time. Usually given as gallons per minute

(gpm).

48. Pressure Control Valve - A valve whose primary function is to control pressure.

(Includes relief valves, pressure reducing or sequencing valves, and unloading

valves.)

49. Pressure Reducing Valve - A pressure control valve which limits outlet pressure.

50. Pressure Sequence Valve - A pressure control valve which directs flow in a preset

sequence.

https://www.swtc.edu/ag_power/hydraulics/terms.htm

Вам также может понравиться

- Disadvantages of Internal SourcesДокумент1 страницаDisadvantages of Internal SourcesRoselle Jarden AñesОценок пока нет

- Air Conditioners June 2020 - 0 PDFДокумент5 страницAir Conditioners June 2020 - 0 PDFGuian LagundiОценок пока нет

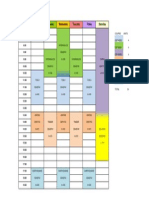

- SCHEDДокумент1 страницаSCHEDRoselle Jarden AñesОценок пока нет

- Floor PlanДокумент1 страницаFloor PlanRoselle Jarden AñesОценок пока нет

- TermshydrauДокумент7 страницTermshydrauRoselle Jarden AñesОценок пока нет

- Title Page RCDДокумент5 страницTitle Page RCDRoselle Jarden AñesОценок пока нет

- Hydro SubdPLAN FinalДокумент45 страницHydro SubdPLAN FinalRoselle Jarden AñesОценок пока нет

- Seismic Vibration ControlДокумент1 страницаSeismic Vibration ControlRoselle Jarden AñesОценок пока нет

- Tire WreДокумент23 302 страницыTire WreRoselle Jarden AñesОценок пока нет

- Color TestДокумент1 страницаColor TestRoselle Jarden AñesОценок пока нет

- TermshydrauДокумент7 страницTermshydrauRoselle Jarden AñesОценок пока нет

- TermshydrauДокумент7 страницTermshydrauRoselle Jarden AñesОценок пока нет

- TermshydrauДокумент7 страницTermshydrauRoselle Jarden AñesОценок пока нет

- Guide LinesДокумент3 страницыGuide LinesRoselle Jarden AñesОценок пока нет

- Drawing 1Документ1 страницаDrawing 1Roselle Jarden AñesОценок пока нет

- Computer VirusДокумент27 страницComputer VirusRoselle Jarden AñesОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Birla Institute of Technology & Science, Pilani Practice School Division Session 2018 PSI Assignment HandoutДокумент3 страницыBirla Institute of Technology & Science, Pilani Practice School Division Session 2018 PSI Assignment Handouttarun chauhanОценок пока нет

- Fieldbus FoundationДокумент38 страницFieldbus FoundationFelipe Andrés Espinoza RivasОценок пока нет

- Optimize Magnetic GapДокумент45 страницOptimize Magnetic GapteomondoОценок пока нет

- Marine BoilersДокумент29 страницMarine BoilersAshish YadavОценок пока нет

- Design Simulation Manufacture and Testingof A Free-Piston Stirling Engine - Ivan Niell Deetlefs PDFДокумент138 страницDesign Simulation Manufacture and Testingof A Free-Piston Stirling Engine - Ivan Niell Deetlefs PDFJorge ValianteОценок пока нет

- Experimental Study On The Thermal Performance of R600a PDFДокумент9 страницExperimental Study On The Thermal Performance of R600a PDFEdy MesinОценок пока нет

- 2 - WCDMA Power ControlДокумент50 страниц2 - WCDMA Power ControlSabrine Chahbi100% (1)

- Instruction Manual Fisher Ed Ead Easy e Valves Cl125 Through Cl600 en 124776Документ40 страницInstruction Manual Fisher Ed Ead Easy e Valves Cl125 Through Cl600 en 124776LeonardОценок пока нет

- M4700Документ4 страницыM4700kylegazeОценок пока нет

- Datasheet Sunedison 330W PDFДокумент2 страницыDatasheet Sunedison 330W PDFDarilho Batista IgnacioОценок пока нет

- BMW HUD Factory SchematicДокумент4 страницыBMW HUD Factory SchematicGreg Wade100% (1)

- Fxe-400s Control PC: ApparatusДокумент2 страницыFxe-400s Control PC: ApparatusCristian Gabriel CordaryОценок пока нет

- EMC For Functional Safety: Introductory Manager's Guide ToДокумент2 страницыEMC For Functional Safety: Introductory Manager's Guide ToentindanОценок пока нет

- Weinig Rondamat 960 PDFДокумент16 страницWeinig Rondamat 960 PDFCimpean AlexandruОценок пока нет

- Service Manual HP Ze4900 SchematicsДокумент39 страницService Manual HP Ze4900 SchematicseduardosceОценок пока нет

- SAP BI BO Presentation TorrentДокумент36 страницSAP BI BO Presentation TorrentRajab Ali Jiwani100% (1)

- Earthquake Design Presentation (M.sleiman)Документ20 страницEarthquake Design Presentation (M.sleiman)JunnoKaiserОценок пока нет

- 1465914490CL June 2016 PDFДокумент48 страниц1465914490CL June 2016 PDFCoolerAdsОценок пока нет

- Nte 123 AДокумент4 страницыNte 123 AAndres Mauricio Quiceno BetancourtОценок пока нет

- (XENO-360) Quick ManualДокумент2 страницы(XENO-360) Quick ManualYousef SyОценок пока нет

- Indian Standard - Fire Safety of Buildings (General) - Details of Construction-Code of PracticeДокумент32 страницыIndian Standard - Fire Safety of Buildings (General) - Details of Construction-Code of PracticeJyoti SinghОценок пока нет

- Work Method Bridge Sleeper Replacement - 2014Документ8 страницWork Method Bridge Sleeper Replacement - 2014Irham M AFОценок пока нет

- PW5 Basic Double Busbar Dis 20Документ12 страницPW5 Basic Double Busbar Dis 20Shanthiyaah ArumugamОценок пока нет

- Highway Planning Manual Volume 8 PDFДокумент72 страницыHighway Planning Manual Volume 8 PDFHanz Maca-ayanОценок пока нет

- Foam-Water Spray Extinguishing System, Powerhouse Diesel EngДокумент10 страницFoam-Water Spray Extinguishing System, Powerhouse Diesel EngdheerajdorlikarОценок пока нет

- RL - AM-,WWY-: TRV Rating Concepts and Iec Standards TRV EnvelopesДокумент17 страницRL - AM-,WWY-: TRV Rating Concepts and Iec Standards TRV EnvelopesDestinifyd Mydestiny100% (1)

- c3 PDFДокумент29 страницc3 PDFHrithik IGОценок пока нет

- BMS-HSS-F-113 - Lift Plan Rev 03Документ11 страницBMS-HSS-F-113 - Lift Plan Rev 03Fariz SafarullaОценок пока нет

- NEMA Enclosure TypeДокумент6 страницNEMA Enclosure TypeKumar MadhuОценок пока нет

- IP OP DevicesДокумент9 страницIP OP DevicesMalik Ali BiadОценок пока нет