Академический Документы

Профессиональный Документы

Культура Документы

The Use of Coagents

Загружено:

cronoromАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

The Use of Coagents

Загружено:

cronoromАвторское право:

Доступные форматы

The Use of Coagents in the Radical Cure of Elastomers

Steven K. Henning

Sartomer Company, Inc.

Exton, PA, USA

610-363-8454 steve.henning@sartomer.com

Abstract

The present article will review the use of coagents in the radical

cure of elastomers, and introduce the concept of improving

vulcanizate performance by proper coagent selection through an

understanding of structure-property relationships. A wide variety

of commercially available coagent types will be discussed, along

with relevant application data supporting their use in peroxide

cured systems. Illustrative examples include elastomers used in

the wire and cable industry. A brief extension into electron beam

curing of elastomers offers a comparison between peroxide-

derived radical cure and cure initiated by incident radiation.

Keywords: coagent; peroxide; electron beam; cure; elastomer;

EPDM; CM; NBR; wire; cable

1. Introduction

By crosslinking elastomeric polymers, useful materials can be

formed which possess physical properties such as high tensile

strengths, low compression set, recoverable elongations, high tear

energies, and improved dynamic performance. The quantity and

quality of the linkages formed by the crosslinking reactions

determine the properties of the resulting network.

There are many types of vulcanization systems. Deciding which

system is optimal for a given application depends on the required

curing conditions, the elastomer or elastomer blend employed, and

the desired physical properties of the final vulcanizate. Often,

free radicals are used to facilitate cure. Radicals can be formed

either through the thermal decomposition of peroxides or

spontaneously by incident radiation. Peroxides are capable of

vulcanizing most polymer types, including standard unsaturated

and saturated elastomer grades, fluoroelastomers, and silicones.

Electron-beam irradiation is also a facile method. The synergistic

use of coagents in radical-cure systems helps expand the utility of

the vulcanization process.

Networks formed from radical vulcanization typically possess

good heat-ageing stability and low compression set. These

qualities are a direct manifestation of the chemical composition of

the crosslinks formed. Synergistic use of multifunctional

coagents can improve upon these properties by increasing the

crosslink density of the network and by altering the crosslink

composition. There are many functional compounds that have

been used as coagents for radical cure. The final properties of the

formed network will depend on the reactivity and structure of the

coagent. In the wire and cable market, application of radical-

cured thermoset components include insulation and jacketing.

The use of coagents can improve the physical properties of these

compounds, including modulus, tensile strength, tear, and even

adhesion and dynamic properties.

The present article will review the use of peroxides to cure

elastomer systems, and introduce the concept of improving

vulcanizate performance by proper coagent selection. Many

commercially available coagent types will be discussed, and their

utility demonstrated as a function of elastomer type. The use of

coagents in electron-beam curing will also be reviewed.

Particular attention will be focused on the understanding of

structure-property relationships to facilitate coagent selection.

2. Peroxide Cure Using Coagents

The basic chemistry of peroxide decomposition and subsequent

crosslink-forming reactions is well established for various

unsaturated and saturated elastomer systems.[ 1 , 2 , 3 , 4 ] An

excellent review article outlines the scope of peroxide cure and

discusses the complexity of reaction pathways in terms of

competing reactions, only some of which result in effective

crosslink formation.[5]

2.1 Coagent Utility

Of course the desired reaction pathway for a radical species is

crosslink formation. The competitive reactions include polymer

scission or other deleterious reactions. Unfortunately, many of

the destructive reactions are kinetically favored, and typically

only a very high concentration of reactive sites on the polymer

backbone allows for effective crosslink formation to occur at all.

However, productive crosslink formation can be favored through

the use of very reactive, multifunctional coagent products.

Coagents favor network formation by increasing the local

concentration of highly reactive groups. In borrowing the theme

of competing reactions, the utility of coagents is derived from

promoting more efficient crosslink formation by establishing a

higher concentration of reactive sites and reducing the chance of

deleterious radical side reactions. Of course, the incorporation of

coagents into the network can also favorably impact the physical

properties of the vulcanizate.

2.2 Coagent Structure-Property Relationships

Coagents are classified based on their contributions to cure and

thus divided into two basic types. Type I coagents increase both

the rate and state of cure. Type I coagents are typically polar, low

molecular weight multifunctional compounds which propagate

very reactive radicals through addition reactions. These

monomers can be homopolymerized or grafted to polymer

chains. Type I coagents include multifunctional acrylate and

methacrylate esters and phenylene dimaleimide (PDM). The zinc

salts of acrylic (ZDA) and methacrylic acid (ZDMA) also belong

to this class.

Type II coagents form less reactive radicals and contribute only to

the state of cure. They form radicals primarily through hydrogen

abstraction. Type II coagents can include allyl-containing

cyanurates, isocyanurates and phthalates, homopolymers of

dienes, and co-polymers of dienes and vinyl aromatics. Table 1

identifies commonly used coagent products. Figure 1

demonstrates the departures from a standard peroxide cure

rheometer profile when coagents from each Type are applied.

International Wire & Cable Symposium 587 Proceedings of the 56th IWCS

Figure 1. The influence on cure profiles of Type I

coagents (A), Type II coagents (B), compared with

peroxide alone (C). The shift in scorch time (t

s2

), cure

rate (t

90

), and state of cure (M

H

) is noted.

2.3 Coagent Role in Network Formation

Because of their reactivity, coagents generally make more

efficient use of the radicals derived from peroxides, whether

acting to suppress non-network forming side reactions during

cure[6,7] or to generate additional crosslinks.[8] The mechanism

of crosslink formation using coagents appears to be at least

partially dependent on their class. Most Type I coagents can

homopolymerize and graft-to forming viable crosslinks through

radical addition reactions. Certain Type II coagents, containing

extractable allylic hydrogen, have been shown to participate in

intramolecular cyclization reactions as well as intermolecular

propagation reactions.[9] Trifunctional allylic coagents (TAC and

TAIC) may form crosslinks through the cyclopolymerization

products as well as grafting through pendant allyl groups. The

polymeric coagents, typically high vinyl poly(butadienes)

(HVPBD), simply increase the concentration of reactive pendant

unsaturation, further promoting crosslinking reactions.

Table 1. Examples of some commonly used coagent

products.

Chemical Name Code Type Commercial Product

trifunctional acrylate, scorch retarded TA Type I Saret SR519HP

trifunctional methacrylate, scorch retarded TMA Type I Saret SR517HP

zinc diacrylate, scorch retarded ZDA Type I Saret SR633

zinc dimethacrylate, scorch retarded ZDMA Type I Saret SR634

N, N-m-phenylene dimaleimide PDM Type I SR525

polybutadiene diacrylate PBDDA Hybrid SR307

triallyl cyanurate TAC TypeII SR507

triallyl isocyanurate TAIC Type II SR533

high vinyl polybutadiene HVPBD Type II Ricon 154

Network enhancement through the grafting of coagents between

polymer chains,[8, 10 ] the formation of an interpenetrating

network of homopolymerized coagents,[11] and the formation of

higher modulus filler-like domains of thermoset coagent [9,12]

has been suggested. Rather than the above cases being distinct

outcomes of vulcanization, the resulting network is likely defined

by a distribution of the above crosslink structures. The actual

population of the distribution is determined by a host a factors

including coagent loading, solubility of the coagent in the

elastomer, and the relative reactivity of the coagent compared to

the elastomer. Figure 2 provides an ideal representation of the

spectral nature of crosslink structures derived from peroxide cure

using coagents.

Figure 2. Idealized network derived from a peroxide-

coagent cure system. Crosslinks can be derived from

(A) polymer radicals, (B) coagent forming effective

crosslinks, and (C) thermoset domains of coagent

grafted to polymer chains.

3. Coagent Selection

While most coagents will increase the crosslink density in radical

cured thermoset systems, the relative amount of improvement in

the physical properties of the vulcanizate is determined by a

number of factors.[ 13 , 14 ] Again, coagent solubility and

reactivity in a particular system is important in determining the

quantity of crosslinks formed and typically drives the selection

process. However, the structure of the crosslink is also

determined by the coagent product and can be tuned to impart

certain adventitious properties to the compound. Thus, the quality

of the crosslinks can also be manipulated by proper coagent

selection.

3.1 Crosslink Quantity

The number of crosslinks formed is determined by several factors,

including the reactivity of the coagent, the number of reactive

groups (functionality), and the loading and solubility of the

coagent in the elastomer. The relationship between crosslink

density and tensile, compression, and tear has been previously

established.[15] Torque rheometry is a standard method used to

measure the amount of crosslink density by comparing the amount

of torque generated during cure (delta torque, M

H

-M

L

).

3.1.1 Differentiation by Elastomer. To demonstrate relative

improvements in crosslink density for a Type I and Type II

coagent, Figure 3 compares the addition of a trifunctional acrylate

ester monomer or HVPBD resin to a dicumyl peroxide cure

system in a variety of standard elastomer grades. The series offers

insight as to the importance of coagent selection as a function of

elastomer structure. The elastomers used in the study are defined

in Table 2.

Table 2. ASTM designations of commonly used

elastomers.

ASTM Polymer

Designation Structure

NR natural rubber

NBR nitrile rubber

EPDM ethylene propylene diene rubber

HNBR hydrogenated nitrile rubber

CSM chlorosulfonated polyethylene

CM chloronated polyethylene

International Wire & Cable Symposium 588 Proceedings of the 56th IWCS

Moving left to right in Figure 3 the elastomer grades become

more saturated, and were less effectively cured by peroxide alone.

The overall state of cure decreased as a function of elastomer

saturation. The addition of a Type I coagent provided a

measurable improvement in the state of cure for all elastomers,

but the percent improvement was greatest for the fully saturated

grades (CM, CSM). The use of a Type II coagent only provided

appreciable improvement in the less reactive grades (HNBR,

EPDM, CSM, CM). Coagents with less reactive groups (allylic,

Type II) could not compete effectively with the high

concentration of unsaturation in the diene-based elastomers (NR,

NBR) and their contribution to cure state was minimized.

Figure 3. Influence on crosslink density (delta torque,

M

H

-M

L

) for a Type I (TA) or Type II (HVPBD) coagent

compared to peroxide cure as a function of elastomer

grade. (ASTM D 5289)

3.1.2 Differentiation by Coagent. Two of the most

common elastomers used in wire and cable applications are

EPDM and CM. Model compounds using these elastomer grades

were prepared to highlight the effects of various coagent

structures on cure kinetics and physical properties. Highlighted in

the figure below are both a comparison between grades of

elastomers (EPDM, 5% unsaturation and CM, fully saturated),

and the influence of coagent addition on properties in these grades

as a function of coagent structure.

Figure 4 provides a comparison of crosslink density (delta torque)

as a function of coagent type in these elastomers. Again, EPDM

displyed higher baseline crosslink density compared to CM.

Density increased with coagent addition for both grades. In

EPDM, increases were greater for Type I coagents versus Type II.

However in the case of CM, the highest increase in crosslink

density was found for TAC, a Type II coagent.

Scorch times provide a measurement of process safety, indicating

the latent period at a given temperature before appreciable

vulcanization occurs. The data in Figure 5 demonstrates that

Type I coagents typically reduce scorch times while Type II

coagents minimize the loss of scorch safety. Also, scorch times

are reduced more dramatically when coagents were applied to less

inherently reactive elastomer grade (CM).

Figure 4. Delta torque (M

H

-M

L

) for EPDM and CM based

compounds as a function of coagent type. Coagent

loading at 1 phr. (ASTM D 5289)

Figure 5. Scorch times (t

s2

) for EPDM and CM based

compounds as a function of coagent type. Coagent

loading at 1 phr. (ASTM D 5289)

Modulus values typically follow delta torque, as both can be

directly correlated to crosslink density. Figure 6 provides 100%

modulus data for the previous EPDM and CM series. All the

coagents surveyed increase the modulus of the compound

compared to the peroxide control. The differences in the absolute

values of modulus are related to the composition of the model

formulations themselves and are not attributable to elastomer-

coagent interactions.

Figure 6. 100% modulus for EPDM and CM based

compounds as a function of coagent type. Coagent

loading at 5 phr. (ASTM D 412)

International Wire & Cable Symposium 589 Proceedings of the 56th IWCS

While increasing the quantity of crosslinks is perhaps the single

most important attribute of applied coagent technology,

differentiation in certain physical properties of the vulcanizate can

further be attained by changing the quality of crosslinks as well.

3.2 Crosslink Quality

By judicious selection of coagent structure, the quality of

crosslinks can be influenced along with the quantity. When a

coagent is incorporated as a crosslink in the network, it becomes a

load bearing member. By changing the chemical structure of the

coagent, the response of the entire network to induced strains can

be favorably altered. Measurable physical properties such as tear

strength, dynamic flexural fatigue, and compression set are

affected. In addition, surface properties such as adhesion can also

be promoted.

The zinc salts of acrylic and methacrylic acid (ZDA, ZDMA) are

unique in the field of coagents as they contain an ionic bond.

When included in a peroxide cure system, the zinc-based coagents

form crosslinks and manifest physical properties attributable to

the ionic nature of their structure. The dissociation energy of the

Zn-O bond has been calculated to lie between carbon-carbon

bonds and polysulfidic bonds (Table 3.) Peroxide cure generates

mainly carbon-based linkages, and heat resistance and low

compression set are well-known attributes static applications. The

use of polysulfidic crosslinks dominates dynamic applications, as

the labile linkages are known to break and reform under strain to

alleviate stress.[ 16 ] As a result, networks comprised of

polysulfidic linkages display excellent tear and flexural fatigue

properties.

Table 3. Bond dissociation energies for selected

crosslink structures.

Dissociation Energy

Cure System Bond Type Structure (kJ/mol)

Peroxide -C-C- carbon 335

Sulfur -S-C monosulfidic 314

Sulfur -Sx- polysulfidic 147

Peroxide, Coagent -Zn-O- ionic 293

3.2.1 Tear Strength. Tear properties can be improved by

incorporating ionic crosslink density into the network.[17] An

illustrative example is provided in Figure 7. For a series of Type I

and Type II coagents in an EPDM formulation, only ZDMA

improves tear strength as a function of increasing modulus.

Figure 7. Tear strength as a function of modulus for

ZDMA, TA, TAC, and HVPBD in an EPDM compound.

Coagent loadings at 1, 5, and 10 phr. (ASTM D 624-C)

3.2.2 Flexural Fatigue. It has also been demonstrated that the

flexural fatigue properties of peroxide-cured materials can be

improved thought the incorporation of ionic crosslinks from

ZDMA.[ 18 , 19 ] A peroxide control, peroxide with ZDMA

coagent, and a semi-efficient sulfur vulcanization system were

each used to cure an EPDM compound to constant modulus.

Crack growth was measured on a Demattia flex tester. The results

are summarized in Figure 8.[4] When incorporating ionic

crosslinks into the network, flexural fatigue was significantly

improved over the peroxide control and compared favorably to the

sulfur vulcanized sample.

Figure 8. Number of cycles to 12.7 mm crack width as

measured on a Demattia flex tester at 300 cpm in an

EPDM compound. ZDMA loading at 5 phr. (ASTM D

430-B) [4]

3.2.3 Adhesion. Adhesion of rubber to most metals must be

engineered as it is not an inherent property. With the notable

exception of sulfur cured rubber and brass, most rubber systems

must utilize applied adhesives or functional additives to facilitate

an adhesive bond to metal. It has been found that zinc-based

coagents can establish a strong bond to most metal substrates, and

also improve the adhesion of peroxide-cured rubber to treated

polar fabrics.[ 20 ] In Figure 9, several Type I and Type II

coagents have been added to a peroxide cured EPDM compound

at 5 phr. Lap shear adhesion to steel was measured. Coagents

ZDMA and ZDA provided a high level of adhesion with samples

exhibiting cohesive failure. The use of other coagents resulted in

adhesive failure.

Figure 9. Lap shear adhesion of a peroxide-cured

EPDM compound with cold rolled steel. Coagent

loading at 10 phr. (ASTM D 816-B)

International Wire & Cable Symposium 590 Proceedings of the 56th IWCS

Producing adhesion through the use of zinc-based coagents is a

technology which is dependent on the cure process. Adhesion is

only adequately generated if the rubber sample is cured-in-place

adjacent to the substrate to which is to be adhered.

3.2.4 Compression Set. While compression set is largely

determined by the number of crosslinks formed (quantity), the

bond strength of the crosslinks also influences the amount of

permanent set. ZDMA contains an ionic bond with significantly

lower calculated dissociation energy than the other monomeric

and polymeric coagents. Whereas this structural feature is

advantageous for other physical properties, it can negatively affect

compression set. Figure 10 demonstrates the influence of coagent

addition on compression set in EPDM and NBR formulations.

Standard coagents, regardless of type, reduced permanent set as

crosslink density increases. However, despite increased crosslink

density, the addition of ZDMA did not follow the same trend and

resulted in increased permanent set.

Figure 10. Compression set for EPDM and NBR based

compounds as a function of delta torque (M

H

-M

L

).

Coagent loading at 5 phr. (ASTM D 5289, 395)

Spatial homogeneity of the crosslink density is also an important

factor in minimizing compression set. The solubility parameter of

the coagent should be well matched to the elastomer to which it is

applied to maximize dispersion of the coagent and promote

effective crosslinking.

Most Type I coagents show poor solubility in hydrocarbon-based

elastomers (dienes, EPM, EPDM) as they are quite

polar.[ 21 , 22 , 23 ] The largest impact on cure kinetics and

vulcanizate properties are often derived from structures having the

least solubilitymultifunctional acrylates or zinc salts with a high

reactive group densitytranslating to a high molar concentration

of reactivity per phr of coagent. The addition of hydrocarbon

character to improve solubilitylonger alkyl bridging groups,

pendant methyl to tertiary butyl structures, etc.may also

decrease the apparent reactivity by either steric hindrance or

molar dilution effects. The polymeric Type II coagents tend not

to increase modulus upon curing to the extent of the Type I diene-

based coagents. These materials are typically much more soluble

in the elastomeric matrix, as the difference in solubility

parameters is much less pronounced. Domain formation is

typically not exhibited. They can provide moderate

improvements in tensile properties and compression set while not

adversely effecting elongation or tear strength.

3.3 Physical Property Optimization

As noted above, the proper selection of coagents for a given

application sometimes involves reaching a balance between

mutually exclusive properties. Improved properties such as

modulus and tensile strength are known to correlate with

increased crosslink density. However, modulus improvements

may often lead to decreased tear strength when using standard

coagents (Figure 7). The notable exception in the latter case is the

use of zinc-based coagents. The addition of ZDA and ZDMA can

also increase compression set, a property normally improved

when applying other coagent products (Figure 10). Other

properties such as elongation and flexibility are inversely

proportional to crosslink density. Figure 11 demonstrates such a

trend in both the EPDM and CM formulations used previously.

Figure 11. Elongation as a function of modulus for a

series of coagents in an EPDM compound. Coagent

loadings at 1, 5, and 10 phr. (ASTM D 412)

A reduction in scorch protection has been demonstrated when

applying Type I coagents. However, the loss in scorch safety

exhibited by the Type I coagents can be mediated by the use of

cure retarders. The application of retarding species in peroxide

cure has been reviewed.[1,9] Type I coagents are often available

as proprietary mixtures including radical-scavenging retarders,

providing prolonged scorch safety while maintaining cure rate and

greater crosslink density.[24] Figure 12 summarizes the benefits

in using scorch retarded coagents. As shown, the addition of a

scorch retarder to the coagent can mitigate a reduction in process

safety. With a slight increase in coagent or peroxide level, total

crosslink density and final vulcanizate properties can be

maintained.

Figure 12. Scorch times (t

s2

) for several Type I

coagents both with retarder package (Saret

) and

without (coagent only) in EPDM compound. Coagent

loading at 5 phr. (ASTM D 5289)

International Wire & Cable Symposium 591 Proceedings of the 56th IWCS

The common trade-offs in physical properties highlighted above

must be managed relative to the desired performance targets of the

compound in a given application. Coagent selection is critical to

the optimization process. By understanding the advantages and

disadvantages of specific coagent structures, an acceptable

balance in physical properties can be achieved.

4. Electron Beam Cure Using Coagents

Radiation curing has historically been used as an alternative to

peroxides in applications where the curatives themselves or side-

products of vulcanization are viewed as impurities in the final

product. As previously noted, peroxide cure progresses through a

series of radical intermediates, each of which can undergo side

reactions which may not necessarily contribute to crosslink

density. Radiation cure, on the other hand, has been promoted as

a cleaner and more homogeneous cure process.

Electron beam irradiation has been used in the wire and cable

industry for longer than 30 years and applied to a wide range of

commodity and specialty elastomers. A survey of the types of

elastomers susceptible to radiation curing is available, as are

review articles describing the electron-beam curing of

commercially significant grades.[ 25 , 26 ] Variables such as

radiation dosage and the effect of polymer microstructure and

chemical additives on the efficiency of electron beam cure have

been studied.

4.1 Comparing Peroxide and Electron Beam Curing

While both peroxide and electron beam cure involve radical-based

intermediates, differences between the mechanisms do exist.

While peroxide cure is a thermally initiated event with cure

temperatures routinely in the 160C to 180C range, electron beam

cure is performed at room temperature. Peroxide cure is initiated

by oxygen-centered radicals that can be differentiated from the

carbon-centered radicals produced by polymer excitation in

radiation cure. The length of cure time in each system is also very

different. In peroxide cure, cure time is governed by the half life

of the peroxide at a given temperature, and can be longer than 30

minutes to reach > 99% decomposition. In contrast, electron

beam cure is practically instantaneous. The cure temperature and

cure time differences can result in significantly less energy

applied to the electron beam cure process, a fact which may

contribute to variations in coagent performance between the

disparate systems.

4.2 Coagent Utility

The addition of coagents to the electron beam cure of various

elastomer grades has also been studied.[ 27, 28, 29] Crosslink

density is found to be not only a function of radiation dose

(parallel to peroxide loading) but also coagent loading. Like

peroxide cure, the response of the base elastomer to electron beam

cure correlates primarily with the level of unsaturation in the

polymer backbone. The more highly reactive Type I coagents

have demonstrated the most utility when unsaturated polymers

have been used (HNBR, EPDM).

In order to quantify the effects of coagent addition on the electron

beam cure of EPDM, several Type I and Type II coagents were

evaluated. As a measure of crosslinking efficiency, the modulus

of samples irradiated at 50, 100, and 150 kGy dosing were

compared. Figure 13 provides the results of the initial study.

Increased radiation dose resulted in higher modulus regardless of

coagent Type. Differentiation based on coagent structure is also

readily apparent.

Figure 13. Modulus as a function of coagent type and

radiation dose in an electron-beam cured EPDM

formulation. Coagent loading at 5 phr. (ASTM D 412)

Figure 14 demonstrates the effect of increased coagent loading at

a given radiation dose. Most coagent types increased modulus as

a function of loading, but Type I coagents provided the most

improvement. The trifunctional methacrylate ester provided the

highest modulus increase in the compound, both as a function of

radiation dose and coagent loading.

Figure 14. Modulus as a function of coagent type and

loading in an electron-beam cured EPDM formulation.

150 kGy dose of radiation. (ASTM D 412)

The same coagents were studied in a peroxide cured EPDM

formulation. Again, tensile modulus was tested to provide a

comparative measure of crosslink density. The results are

provided in Figure 15. Unlike the results in radiation cured

samples, the relative efficiency of the coagents did not strictly

follow trends based on Type, but were likely more influenced by

the variety of complex factors related to solubility and reactivity

outlined previously.

Although the formulations were identical save for the cure

chemistry and process, the data in Figures 14 and 15 demonstrate

that there are clear differences in the efficiency with which certain

coagent structures contribute to crosslink density. In both cure

systems the correct application of coagent technology can

contribute to higher crosslink density and improved physical

properties. As a corollary, the addition of coagents can also

reduce the dosage of radiation required to produce adequate cure.

International Wire & Cable Symposium 592 Proceedings of the 56th IWCS

Figure 15. Modulus as a function of coagent type and

loading in a peroxide cured EPDM formulation. Dicumyl

peroxide at 3 phr actives. (ASTM D 412)

5. Conclusion

Coagents are used to increase the crosslink density of peroxide-

cured systems by increasing the efficiency of productive radical

reactions. The technology has progressed forward such that today

the improvements in crosslink density are generally taken for

granted, and coagent selection is now driven by the desire to

improve more than just the modulus or tensile strength of the

compound.

It is now clear that many of the beneficial properties associated

with coagent use are directly related to the chemical structure of

the products. Reactivity and cure kinetics, the inherent strength

and flexibility of the formed network, and the affinity of the

resulting compound for polar substrates can in large part be

accounted for by an inventory of the structural components of the

coagent molecule.

The use of coagents provides benefits in both peroxide and

radiation cure mechanisms. However, there are clear differences

in the efficiency with which certain coagent structures contribute

to crosslink density based on cure chemistry and process. To

realize the greatest improvements in a given application or cure

type, it is crucial to understand the structure-property relationships

directing coagent performance.

6. Acknowledgments

The author would like to thank the Sartomer Company, Inc. for

the permission to make the information contained in this paper

available. Gratitude must also be extended to William Boye for

his detailed work in comparing coagent types in various cure

systems and elastomers. An ongoing joint project with E-Beam

Services, Inc. made possible the radiation curing data provided.

7. References

1. W. C. Endstra and C. T. J. Wreesman in Elastomer Technology

Handbook, N. P. Cheremisinoff, ed., CRC Press, Ann Arbor, 1993.

2. B. Class, Paper # 1, Spring Technical Meeting, Rubber Division, ACS,

Indianapolis, IN, May 5-8, 1998.

3. A. H. Johansson, Paper # 10, Fall Technical Meeting, Rubber

Division, ACS, Cleveland, OH, Oct. 14-17, 2003.

4. L. H. Palys and P. A. Callais, Rubber World 229 (3), 35 (2003).

5. P. R. Dluzneski, Rubber Chem. Technol. 74, 451 (2001).

6. J. C. Garcia-Quesada and M. Gilbert, J. Appl. Polym. Sci. 77, 2657

(2000).

7. A. Busci and F. Szocs, Macromol. Chem. Phys. 201, 435 (2000).

8. R. C. Keller, Rubber Chem. Technol. 61, 238 (1988).

9. H. G. Dikland, Coagents in Peroxide Vulcanizations of EP(D)M

Rubber, Gegevens Koninklije Bibliotheek, Netherlands, 1965.

10. Z. H. Murgic, J. Jelencic and L. Murgic, Polym. Eng. Sci. 38, 689

(1998).

11. J. Class, Rubber World 220 (11), 35 (1999).

12. L. Liu, Y. Luo, D. Jia and B. Guo, Intern. Polymer Processing

XIX(4), 374 (2004).

13. S. K. Henning and R. Costin, Rubber World 233 (5), 28 (2006).

14. S. K. Henning and J. Klang, Rubber World 235 (6), 30 (2007).

15. A. Y. Coran in Science and Technology of Rubber, F. R. Eirich, ed.,

Academic Press, 1978, p. 291.

16. W. L. Cox and C. R. Parks, Rubber Chem. Technol. 39, 785 (1966).

17. R. Costin, W. Nagel, and R. Ekwall, Rubber Chem. Technol. 64, 152

(1991).

18. C. B. McElwee and J. S. Burke, Rubber World 228 (5), 36 (2003).

19. S. X. Guo and W. von Hellens, Rubber World 225 (5), 51 (2002).

20. R. Costin in Handbook of Rubber Bonding, B. Crowther, ed.,

RAPRA Technology Ltd., Shawbury, United Kingdom, 2003.

21. Y. Lu, L. Zhang, Y. Wu and L. Liu, Paper # T5, IRC, Beijing, China,

Sept. 22-24, 2004.

22. E. S. Castner and M. P. Mallamaci, Paper # 85, Fall Technical

Meeting, Rubber Division, ACS, Orlando, FL, Sept. 21-24, 1999.

23. J. R. Beatty, Rubber Chem. Technol. 37, 1341 (1964).

24. US 4857571, Reiter, et al. Sartomer Company, Inc., 1989.

25. G. C. A. Bhm and J. O. Tveekrem, Rubber Chem. Technol. 55, 575

(1982).

26. A. K. Bhowmick and V. Vijayabaskar, Rubber Chem. Technol. 79,

402 (2006).

27. R. J. Eldred, Rubber Chem. Technol.47, 924 (1974).

28. G. L. M. Vroomen and G. W. Visser, Rubber World 205 (2), 23

(1991).

29. M. La Rosa, C. Wrana, D. Achten, Electron Beam Curing of EVM

and HNBR for Cable Compounds, presented at the 55th

International Wire and Cable Symposium Conference, Providence, RI,

Nov. 12-15, 2006.

Steven K. Henning

steve.henning@sartomer.com

Steven K. Henning received a Bachelors Degree in Material

Science and Engineering from the Pennsylvania State University

in 1994 and was conferred a Masters Degree in Polymer Science

from the University of Akron in 2003.

Between 1995 and 2004 he was employed at The Goodyear Tire

and Rubber Company (Akron, OH) developing new tire

elastomers for the Chemical Division as Team Leader for Anionic

and Emulsion Polymer Development.

Since 2004, he is the Senior Chemist in charge of Sartomerss

Rubber Lab (Exton, PA) coordinating projects which focus on the

development of functional additives for improved elastomers cure.

International Wire & Cable Symposium 593 Proceedings of the 56th IWCS

Вам также может понравиться

- Modified Polymers, Their Preparation and Properties: Main Lectures Presented at the Fourth Bratislava Conference on Polymers, Bratislava, Czechoslovakia, 1-4 July 1975От EverandModified Polymers, Their Preparation and Properties: Main Lectures Presented at the Fourth Bratislava Conference on Polymers, Bratislava, Czechoslovakia, 1-4 July 1975A. RomanovРейтинг: 5 из 5 звезд5/5 (1)

- Polymer Syntheses: Organic Chemistry: A Series of Monographs, Vol. 3От EverandPolymer Syntheses: Organic Chemistry: A Series of Monographs, Vol. 3Оценок пока нет

- Margma 2020Документ42 страницыMargma 2020Kai Yuan TeoОценок пока нет

- Hafsah 2001 Some Factors AffectingДокумент14 страницHafsah 2001 Some Factors Affectingtrader123Оценок пока нет

- Colloid and Interface Science V5: Biocolloids, Polymers, Monolayers, Membranes, And General PapersОт EverandColloid and Interface Science V5: Biocolloids, Polymers, Monolayers, Membranes, And General PapersОценок пока нет

- P LifeДокумент20 страницP LifeLoc Q. NguyenОценок пока нет

- Accelerators Part TwoДокумент10 страницAccelerators Part Twoalperen52Оценок пока нет

- 441 HN MSDSДокумент5 страниц441 HN MSDSAnandababuОценок пока нет

- Denka Evolmer Bro 1Документ5 страницDenka Evolmer Bro 1mouds22Оценок пока нет

- How to Name an Inorganic Substance: A Guide to the Use of Nomenclature of Inorganic Chemistry: Definitive Rules 1970От EverandHow to Name an Inorganic Substance: A Guide to the Use of Nomenclature of Inorganic Chemistry: Definitive Rules 1970Рейтинг: 5 из 5 звезд5/5 (1)

- Chemistry on Modified Oxide and Phosphate Surfaces: Fundamentals and ApplicationsОт EverandChemistry on Modified Oxide and Phosphate Surfaces: Fundamentals and ApplicationsОценок пока нет

- Aquanox-LДокумент5 страницAquanox-LaaddОценок пока нет

- Effect of Latex Compound Dwell Time For The Production of Prototyped Biodegradable Natural Rubber Latex GlovesДокумент8 страницEffect of Latex Compound Dwell Time For The Production of Prototyped Biodegradable Natural Rubber Latex GlovesMohd Hasrol NizamОценок пока нет

- Polyvinylchloride — 2: Main Lectures Presented at the Second International Symposium on Polyvinylchloride, Lyon-Villeurbanne, France, 5 - 9 July 1976От EverandPolyvinylchloride — 2: Main Lectures Presented at the Second International Symposium on Polyvinylchloride, Lyon-Villeurbanne, France, 5 - 9 July 1976A. GuyotОценок пока нет

- Tokusil PDFДокумент1 страницаTokusil PDFAndrek Queck100% (1)

- Vamac Formulating and Compounding OverviewДокумент6 страницVamac Formulating and Compounding Overviewchethugowda7Оценок пока нет

- D. C. Blackley B.sc. Ph.D. F.P.R.I. Auth. - Synthetic Rubbers Their Chemistry and Technology-Springer Netherlands 1983Документ380 страницD. C. Blackley B.sc. Ph.D. F.P.R.I. Auth. - Synthetic Rubbers Their Chemistry and Technology-Springer Netherlands 1983Minh Tran100% (2)

- Chenghong Li Siloxane Magnetic FluidДокумент150 страницChenghong Li Siloxane Magnetic FluidniebelungenОценок пока нет

- Blocked and Deblocked Isocyanate With Sodium BisulfiteДокумент19 страницBlocked and Deblocked Isocyanate With Sodium BisulfiteAdlyLubis100% (1)

- Highly Efficient Methods for Sulfur Vulcanization Techniques, Results and Implications: Selection and Management of Rubber CurativesОт EverandHighly Efficient Methods for Sulfur Vulcanization Techniques, Results and Implications: Selection and Management of Rubber CurativesОценок пока нет

- New Regulation 10-2011-EC Plastic Materials and Articles in Contact With FoodДокумент89 страницNew Regulation 10-2011-EC Plastic Materials and Articles in Contact With Foodebarre1Оценок пока нет

- Defoamer Test Method: 1 Ross-Miles Foam TesterДокумент2 страницыDefoamer Test Method: 1 Ross-Miles Foam Testeradnan aslamОценок пока нет

- EU Regulation For Plastic Material For Food ContactДокумент21 страницаEU Regulation For Plastic Material For Food ContactIke InumerableОценок пока нет

- Phosphorus-Nitrogen Compounds: Cyclic, Linear, and High Polymeric SystemsОт EverandPhosphorus-Nitrogen Compounds: Cyclic, Linear, and High Polymeric SystemsОценок пока нет

- Emulsion PolymerizationДокумент8 страницEmulsion PolymerizationRyan VasquezОценок пока нет

- AcceleratorsДокумент25 страницAcceleratorsDaniel MartinsОценок пока нет

- ND04o063 02 Nitrosamines in BallonnenДокумент21 страницаND04o063 02 Nitrosamines in BallonnenOlivia2201Оценок пока нет

- Global Adhesives and Sealants MarketДокумент2 страницыGlobal Adhesives and Sealants MarketMahesh ChaudhariОценок пока нет

- Dpta v18 3 PDFДокумент24 страницыDpta v18 3 PDFchayanunОценок пока нет

- D906 6156 PDFДокумент4 страницыD906 6156 PDFJEISON ESTEBAN YUCUMA MARTINEZОценок пока нет

- Rubber 1571Документ20 страницRubber 1571Paradiso SitorusОценок пока нет

- 40 Aqualink UДокумент5 страниц40 Aqualink UTifano KhristiyantoОценок пока нет

- Easily Dispersible PigmentsДокумент44 страницыEasily Dispersible PigmentsGwen WalkerОценок пока нет

- Highlights in Colloid ScienceОт EverandHighlights in Colloid ScienceDimo PlatikanovОценок пока нет

- Surface & Coatings Technology: Papers Presented at the Third International Conference on Plasma Surface Engineering, Garmisch-Partenkirchen, Germany, October 26–29, 1992От EverandSurface & Coatings Technology: Papers Presented at the Third International Conference on Plasma Surface Engineering, Garmisch-Partenkirchen, Germany, October 26–29, 1992Оценок пока нет

- Applications of Polyhedral Oligomeric SilsesquioxanesДокумент449 страницApplications of Polyhedral Oligomeric SilsesquioxanesLuigi MazzuccoОценок пока нет

- Hybrid Silane CoatingДокумент35 страницHybrid Silane CoatingmadavanОценок пока нет

- Analytical Applications of EDTA and Related Compounds: International Series of Monographs in Analytical ChemistryОт EverandAnalytical Applications of EDTA and Related Compounds: International Series of Monographs in Analytical ChemistryОценок пока нет

- PolymerДокумент36 страницPolymersabetОценок пока нет

- Unsaturated Polyester ResinДокумент2 страницыUnsaturated Polyester Resingunawan refiadi0% (1)

- Brochure LatamДокумент2 страницыBrochure LatamShelby_CobraxОценок пока нет

- HoltacДокумент8 страницHoltacdargil66Оценок пока нет

- Characteristics, Applications and Processing of Polymers Chapter 15Документ53 страницыCharacteristics, Applications and Processing of Polymers Chapter 15tjandelkier100% (1)

- Self-Cleaning Materials and Surfaces: A Nanotechnology ApproachОт EverandSelf-Cleaning Materials and Surfaces: A Nanotechnology ApproachWalid A. DaoudРейтинг: 5 из 5 звезд5/5 (1)

- Epoxy - WikipediaДокумент11 страницEpoxy - Wikipediaramthecharm_46098467Оценок пока нет

- Carboxylic Ortho Acid Derivatives: Preparation and Synthetic Applications: Preparation and Synthetic ApplicationsОт EverandCarboxylic Ortho Acid Derivatives: Preparation and Synthetic Applications: Preparation and Synthetic ApplicationsОценок пока нет

- Glucopon 225 DK: Technical InformationДокумент4 страницыGlucopon 225 DK: Technical InformationrotulcmОценок пока нет

- How Ingredients Influence Unsaturated Polyester PropertiesДокумент28 страницHow Ingredients Influence Unsaturated Polyester Propertiesresinc100% (4)

- Tyre Compounding For Improved PerformanceДокумент139 страницTyre Compounding For Improved Performancecronorom100% (1)

- RMA Handbook RubberДокумент58 страницRMA Handbook RubbercronoromОценок пока нет

- Firestone ReportДокумент85 страницFirestone ReportcronoromОценок пока нет

- Replacing Process OilsДокумент9 страницReplacing Process OilscronoromОценок пока нет

- Comparatie Retete Cu Aceeasi Duritate Filler Diferiti PDFДокумент5 страницComparatie Retete Cu Aceeasi Duritate Filler Diferiti PDFcronoromОценок пока нет

- Caracteristici CR Cu Epdm PDFДокумент8 страницCaracteristici CR Cu Epdm PDFcronoromОценок пока нет

- Articol Privind Diferenta Data de Negru FumДокумент10 страницArticol Privind Diferenta Data de Negru FumcronoromОценок пока нет

- Comparatie Retete Cu Aceeasi Duritate Filler Diferiti PDFДокумент5 страницComparatie Retete Cu Aceeasi Duritate Filler Diferiti PDFcronoromОценок пока нет

- Efectul Parametrilor de Injectie Asupra PieselorДокумент12 страницEfectul Parametrilor de Injectie Asupra PieselorcronoromОценок пока нет

- Blend NR-BRДокумент12 страницBlend NR-BRcronoromОценок пока нет

- EP0569995B1Документ18 страницEP0569995B1cronoromОценок пока нет

- TA083Документ21 страницаTA083cronoromОценок пока нет

- Understanding BLOOM (Revised) PDFДокумент24 страницыUnderstanding BLOOM (Revised) PDFEr Roxstar ParitoshОценок пока нет

- MLX90614Документ44 страницыMLX90614ehsan1985Оценок пока нет

- Church and Community Mobilization (CCM)Документ15 страницChurch and Community Mobilization (CCM)FreethinkerTianОценок пока нет

- Chapter 2 Short-Term SchedulingДокумент49 страницChapter 2 Short-Term SchedulingBOUAZIZ LINAОценок пока нет

- (EN 10348) - Steel For The Reinforcement of Concrete. Galvanized Reinforcing SteelДокумент24 страницы(EN 10348) - Steel For The Reinforcement of Concrete. Galvanized Reinforcing Steelbagusu_6Оценок пока нет

- Electronic Diversity Visa ProgrambДокумент1 страницаElectronic Diversity Visa Programbsamkimari5Оценок пока нет

- Aditya Academy Syllabus-II 2020Документ7 страницAditya Academy Syllabus-II 2020Tarun MajumdarОценок пока нет

- Agma MachineДокумент6 страницAgma Machinemurali036Оценок пока нет

- BSS Troubleshooting Manual PDFДокумент220 страницBSS Troubleshooting Manual PDFleonardomarinОценок пока нет

- Cause Analysis For Spun Pile Crack and BrokenДокумент11 страницCause Analysis For Spun Pile Crack and BrokenRony LesbtОценок пока нет

- DLP English 10 AIRAДокумент8 страницDLP English 10 AIRAMae Mallapre100% (1)

- Sensitivity of Rapid Diagnostic Test and Microscopy in Malaria Diagnosis in Iva-Valley Suburb, EnuguДокумент4 страницыSensitivity of Rapid Diagnostic Test and Microscopy in Malaria Diagnosis in Iva-Valley Suburb, EnuguSMA N 1 TOROHОценок пока нет

- BPS C1: Compact All-Rounder in Banknote ProcessingДокумент2 страницыBPS C1: Compact All-Rounder in Banknote ProcessingMalik of ChakwalОценок пока нет

- Basic Terms/Concepts IN Analytical ChemistryДокумент53 страницыBasic Terms/Concepts IN Analytical ChemistrySheralyn PelayoОценок пока нет

- Philo Q2 Lesson 5Документ4 страницыPhilo Q2 Lesson 5Julliana Patrice Angeles STEM 11 RUBYОценок пока нет

- Gas Compressor SizingДокумент1 страницаGas Compressor SizingNohemigdeliaLucenaОценок пока нет

- Types of Chemical Reactions: Synthesis and DecompositionДокумент3 страницыTypes of Chemical Reactions: Synthesis and DecompositionAlan MartínОценок пока нет

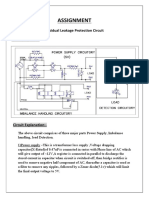

- Assignment: Residual Leakage Protection Circuit Circuit DiagramДокумент2 страницыAssignment: Residual Leakage Protection Circuit Circuit DiagramShivam ShrivastavaОценок пока нет

- Probation Period ReportДокумент17 страницProbation Period ReportMiranti Puspitasari0% (1)

- Michael Clapis Cylinder BlocksДокумент5 страницMichael Clapis Cylinder Blocksapi-734979884Оценок пока нет

- Leveriza Heights SubdivisionДокумент4 страницыLeveriza Heights SubdivisionTabordan AlmaeОценок пока нет

- Group Case Study Rubric 3Документ3 страницыGroup Case Study Rubric 3Saraswathi Asirvatham67% (3)

- D E S C R I P T I O N: Acknowledgement Receipt For EquipmentДокумент2 страницыD E S C R I P T I O N: Acknowledgement Receipt For EquipmentTindusNiobetoОценок пока нет

- Construction Project - Life Cycle PhasesДокумент4 страницыConstruction Project - Life Cycle Phasesaymanmomani2111Оценок пока нет

- Eccentric FootingДокумент3 страницыEccentric FootingVarunn VelОценок пока нет

- Prediction of Compressive Strength of Research PaperДокумент9 страницPrediction of Compressive Strength of Research PaperTaufik SheikhОценок пока нет

- Banking Ombudsman 58Документ4 страницыBanking Ombudsman 58Sahil GauravОценок пока нет

- Bridge Over BrahmaputraДокумент38 страницBridge Over BrahmaputraRahul DevОценок пока нет

- Department of Education: Consolidated Data On Learners' Grade Per QuarterДокумент4 страницыDepartment of Education: Consolidated Data On Learners' Grade Per QuarterUsagi HamadaОценок пока нет

- The Bio-Based Economy in The NetherlandsДокумент12 страницThe Bio-Based Economy in The NetherlandsIrving Toloache FloresОценок пока нет

- E7d61 139.new Directions in Race Ethnicity and CrimeДокумент208 страницE7d61 139.new Directions in Race Ethnicity and CrimeFlia Rincon Garcia SoyGabyОценок пока нет