Академический Документы

Профессиональный Документы

Культура Документы

Macro 1 Theory and Background - Rel 108 OM Format PDF

Загружено:

Bruno DenardinИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Macro 1 Theory and Background - Rel 108 OM Format PDF

Загружено:

Bruno DenardinАвторское право:

Доступные форматы

Rockfall protection system

MACRO 1

THEORY AND BACKGROUND MANUAL

Version 1.08 JANUARY 2014

MACRO 1 THEORY AND BACKGROUND Page | 2

MACRO 1

THEORY AND BACKGROUND

INDEX

1 INDRODUCTION 6

2 BASIC DEFINITONS 7

3 GENERAL CONCEPTS 8

3.1 COEXISTENCE OF ANCHOR AND MESH 8

3.2 CONCEPTUAL SOLUTION 9

3.3 DESIGN APPROACH 9

4 NAIL DIMENSIONING 11

4.1 FORCE INTO THE GEOMECHANICAL SYSTEM 11

4.2 STABILIZING CONTRIBUTION OF ANCHORS 16

4.3 EVALUATION OF NAIL LENGTH 17

5 MESH DIMENSIONING 18

5.1 ULTIMATE LIMIT STATE 18

5.2 MAXIMUM ROCK VOLUME VS PUSHING ON THE MESH 21

5.3 MESH DEFORMATION UNDER PUNCH LOAD AND SCALE EFFECT 21

5.4 MESH DIMENSIONING: SERVICEABILITY LIMIT STATE 23

6 GENERAL BIBLIOGRAPHY 24

7 END NOTES 26

LIST OF THE FIGURES

Figure 1 - Typical configuration of the secured drapery 6

Figure 4 - Conceptual solution for the calculation of anchors and mesh 9

Figure 5 - Thickness of the unstable slope "s" evaluated with geomechanical

survey (left), or with rough estimation of the detachment niches and

size boulders (right) 12

Figure 6 Rock masses with different lithology; left: non homogeneous rock mass

(for example flysch); right: homogeneous rock mass (for example

mudstone) 13

MACRO 1 THEORY AND BACKGROUND Page | 3

Figure 7 Left: the weathering quickly denudates the anchors. Right: despite of the

heavy jointed rock mass, the weathering is slow. If the weathering

velocity is negligible, the anchor length L

e1

and L

e2

into the sound

rock is enough to hold the unstable surficial portion for a long time. 13

Figure 8 - Left: even slope morphology: the mesh lies in contact to the slope

surface. Right: uneven slope morphology: the mesh touches the slope

surface in few points 14

Figure 9 - Left: even slope morphology: the mesh lies in contact to the slope

surface. Right: uneven slope morphology: the mesh touches the slope

surface in few points 14

Figure 10 - Anchor bar in the rock mass. Li = length crossing the unstable mass; Lp

length in the plasticized rock mass; Ls length in stable rock mass 17

Figure 12 - Scheme of the forces acting on the mesh 20

Figure 13 Shapes of the rock volumes that can move among the anchors:

triangular (left) and trapezium (right) 20

Figure 14 - Geometry of the volume between the anchors 20

Figure 15 - Volumes B and C between the anchors 21

Figure 16 - Sketch of the geometry of the mesh with punching load 22

Figure 17 - Plan view of the punch test according to UNI 11437:2012. Legend: 1 =

tested mesh; 2 = punching device (1.0 m in diameter); 3 = perimeter

constraint between the mesh and the frame. 22

Figure 18 - Example of a curve load-displacement used for the design of the mesh

at the Serviceability Limit State 23

LISTS OF THE TABLES

Table 1 - Recap of the safety coefficients for the reduction of the destabilizing

forces and of the resistances ............................................................................... 15

Table 2 - Global safety coefficients applied to the stabilizing end driving forces ................. 15

MACRO 1 THEORY AND BACKGROUND Page | 4

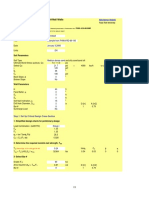

LIST OF THE MAIN SYMBOLS

Factor of safety Factor applied to Symbol used

in the

formulas

showed

below

Partial factor

applied on the

nail

Yield stress of the steel ST

Adhesion grout-rock GT

Partial factor

applied on the

mesh

Longitudinal tensile strength of the mesh M

Maximum displacement admitted on the mesh M-BULG

Partial factor

applied on the

instability/rock

Thickness of the instability T

Unit weight of the rock W

Rock behavior (i.e. weathering of the rock) B

Load factor

Slope morphology MO

External loads OL

Category of data Data and typical unit of measure Symbol used in

the formulas

shown below

Geotechnical and

geomechanical

data

Slope inclination [deg]

Thickness of instability [m] s

Unit weight of the rock [kN/m

3

]

Inclination of the most critical joint set [deg]

Roughness of the most critical joint set [-] JRC0

Compressive strength of the most critical joint set [MPa] JCS0

Nails Horizontal distance between nails [m] ix

Vertical distance between nails [m] iy

Nominal external diameter [mm] e

Nominal internal diameter [mm] (if the bar is hollow) i

Potential thickness of corrosion on the bar diameter [mm] tc

Yield stress of the steel [N/mm

2

] ST

Inclination from the perpendicular to the slope [deg] 0

Grout-rock adhesion (bond stress) [MPa] LIM

Mesh Type of mesh i.e. commercial

name

Ultimate longitudinal tensile strength [kN/m] Tm

Curve load displacement [kN / mm] P / PUNCH

Seismic action Horizontal seismic acceleration coefficient [-] c

MACRO 1 THEORY AND BACKGROUND Page | 5

Parameter of the

joint

In-situ tool to define the parameter Typical values

JRC (roughness) Barton Comb

Smooth joint: 0 to

2; Very rough joint:

18 to 20

JCS (joint

compressive

strength)

Schmidt Hammer From 3 to 200 MPa

depending on the

strength of the rock

(JCS is approx. 1/3

of UCS*)

Inclination () Geological compass Can vary from 0

deg to 90 deg

MACRO 1 THEORY AND BACKGROUND Page | 6

MACRO 1

THEORY AND BACKGROUND

1 INDRODUCTION

Macro 1 is the software of Officine Maccaferri aimed at calculating the pin drapery systems

for rockfall protection.

Pin drapery (called also secured drapery, or cortical strengthening, or superficial

stabilization) is composed of anchors and steel mesh (rockfall net). The goal of this system is

improving the surficial rock face stability and maintaining the debris/rock on place (Figure 1).

Figure 1 - Typical configuration of the secured drapery

The pin draperies could be included into the active protection measures, because they are

directly applied on the unstable zone in order to prevent the rockfall. In these terms they

absolutely differ from the rockfall barriers that are placed far from the detachment area and

can only mitigate the effect of the rockfall. But from the geomechanical point of view they

should be classified as passive interventions because they generate forces as the rockfall

displacement takes places

1

.

The design of secured drapery is not at all easy because of numerous variables, including

topography, rock mass properties, joint geometry and properties, mesh type and related

restraint conditions. Often the solution to the problem may require complex numerical

modelling which is not practical for every project, especially if the design is aimed at

interventions of modest size. Because of that, at the present, limit equilibrium models are

preferable. Taking this into consideration and incorporating field experience, Officine

Maccaferri has developed MacRo1, the limit equilibrium approach for the design of secured

drapery. The procedure is quite rough, but it is sufficient when considering the low accuracy

level of the input data, the reliability of the results and the speed of the calculations.

MACRO 1 THEORY AND BACKGROUND Page | 7

2 BASIC DEFINITONS

The materials intended to the software are the following:

Mesh: steel meshes produced by Officine Maccaferri. The software contains a library with

the behaviour of the mesh under punch and tensile load. The knowledge of these behaviours

derives from a series of laboratory test carried out in accordance with standard UNI

11437:2012

2

. The software does not allow inserting any other mesh type.

Anchors: in the description the terms anchors, and nail are interchangeable. The steel

bars used for pin drapery applications are preferably full threaded. They are installed in a

drilled hole, previously realized with specific drilling machines. They have to be centred into

the hole and then grouted along their entire length. Normally the grout has a compression

resistance of 20 to 50 MPa in order to guarantee an efficient bond stress between the steel

bar and the rock

3

. The grout has also the function to protect the steel against corrosion. The

diameter of these bars is generally 20 to 50 mm. Frequently the drilling diameter is approx.

2.0-2.5 times the diameter of the bar. The length of the nails (L) in most of the cases is

between 2.5 to 4.0 m, and the spacing (ix and iy

4

see Figure 1) ranges between 2.0 and

4.0 m. On the rock slopes, nails mainly works in shear condition, because often they are

installed perpendicular to the sliding surface. Thus, the nail design requires the definition of

the type of steel and diameter. The software admits any steel anchor type.

Pin drapery: in these text pin drapery, secured drapery, cortical strengthening, are

interchangeable. In the pin drapery the anchor and the mesh should cooperate, and the

anchor should really stabilize the slope face. Very frequently the effective anchor spacing

ranges between 2 and 3 m: The designer should remember that the larger the spacing is, the

lower the interlocking between the instable block. Large anchor spacing means frequent

rockfall and heavy loads on the mesh facing. It is always possible choose spacing larger

than 3.0 m, but the intervention progressively loose effectiveness and smokes to something

else.

MACRO 1 THEORY AND BACKGROUND Page | 8

3 GENERAL CONCEPTS

3.1 Coexistence of anchor and mesh

The calculation approach considers that on the slope there is a surficial weathered (or heavy

jointed, blasted, or disturbed) rock mass. The weathered mass is conveniently approximated

as pseudo continuous

5

; this continuous body most frequently generates shallow instabilities

and rockfalls. It has thickness s and inclination parallel to the slope. Several sets of

joints cross the surficial body; the most unfavourable has inclination (Figure 2).

The forces of mesh and nails are passively generated when one of these two conditions

happens:

- the whole weathered body slides down on the plane inclined . This is the problem of

the global stability of the weathered surface; it is solved by the raster of anchors

(Figure 3 on the left).

- one or more block move out from the weathered body. The dynamic of the instability

could be any one (planar or wedge sliding, toppling, bucking, fall). The software only

considers the planar sliding on the plane , which is the most unfavourable case.

Because this instability can happen only among the nails, it can be defined as local

instability of the weathered surface; the mesh fixed with the anchors answers to the

local instability (Figure 3 on the right).

-

Figure 2 - Slope with the weathered unstable surface

MACRO 1 THEORY AND BACKGROUND Page | 9

3.2 Conceptual solution

Both mesh and anchors can only develop reactions as the rock mass moves (passive

system). Macro 1 separately analyses the mechanisms anchors and mesh facing. But

because the spacing between the anchors dramatically changes the load on the mesh

facing, the user follows this iterative process (Figure 4):

Figure 4 - Conceptual solution for the calculation of anchors and mesh

3.3 Design approach

The adopted design approach only follows the general concepts of Eurocodes (UNI ENV

1997-1:2005). In these terms Macro 1 allows increasing the destabilizing forces and

reducing the resistances by mean of suitable safety coefficients, which should be calibrated

with probabilistic methodology. Unfortunately the Eurocodes cannot correctly be applied on

the geomechanical field

6

, and the secured draperies are quite far from the standard

problems. That is why the coefficients of Macro 1 have been based on specific parameters

like the slope morphology or the mesh behaviour. The user has to find out the suitable

Figure 3 - Elements of the pin drapery systems. Nails (left) stabilize the superficial portion. Mesh

(right) keeps in place the unstable material between the nail.

MACRO 1 THEORY AND BACKGROUND Page | 10

coefficients considering what he has directly seen on site. This approach is more realistic

and helps in designing the secured draperies.

Macro 1 calculates the raster of anchors in order to get a more favourable equilibrium

condition of the weathered rock mass.

According to the common design practice, Macro 1 purposes the calculation of the mesh

facing for the ultimate and the serviceability limit states. The ultimate limit state allows

understanding if the mesh can be broken because of the load, whereas the serviceability

allows foreseeing the facing deformation perpendicular to the mesh plane. The knowledge of

deformation is very useful because:

- when the deformation reaches the design limit, it means that the maintenance

(cleaning) of the secured drapery is needed before that further displacements

determine the mesh rupture. A simple visual monitoring let the owner programs the

interventions.

- Too much deformed mesh implicates easy stripping on the anchors and lower

durability of the intervention. The designer must be aware of this and foresee the

right mesh type accordingly.

- Since the meshes are largely deformable, the facing of the secured drapery could

interfere with close infrastructures or vehicles.

MACRO 1 THEORY AND BACKGROUND Page | 11

4 NAIL DIMENSIONING

4.1 Force into the geomechanical system

Considering passive behaviour, the nail calculation must assume the unstable portion of the

slope lies in condition of limit equilibrium, where the safety factor is equal to 1.0. Therefore,

the resisting forces have the same value of the driving forces and the following equation is

true (Figure 4):

Resisting forces = W sin = driving forces [1]

where

W = weight of the unstable rock mass to be consolidated

= inclination of the slope surface, where the sliding of the unstable rock mass can

occur.

Using the resistance criteria of Barton-Bandis

7

for the joints, equation [1] can be rewritten to

describe the improved stability condition:

W (sin c sin tan ) + R W (sin + c cos ) [2]

assuming

R = stabilizing contribution of the nails

c = seismic coefficients

= residual friction angle of the joint

The equation [2] is written in accordance with the concept of passive intervention

8

.

Setting tan 1 (friction angle = 45)

9

, and posing the safety factors for reducing the

stabilizing forces (

RW

) and increasing the driving ones (

DW

), the stability condition simply

becomes:

W sin (1- c) /

RW

+ R W

DW

(sin + c cos ) [3]

or

F

Sslp

> = F

Dslp

[4]

assuming

F

Dslp

= W (sin + c cos )

DW

= Sum of the driving forces [5]

and

F

Sslp

= W sin (1- c) /

RW

+ R = Sum of stabilizing forces [6]

Equation [3] allows determining the nail force that consolidates a rock mass in the limit

equilibrium state. It is a conservative equation and it is simple to be used since it basically

requires simple geometric variables.

The safety coefficients (

RW

,

DW

) depend on several factors. The rock mass features affect

the size of the stabilizing forces, so that their safety coefficient can be described as

MACRO 1 THEORY AND BACKGROUND Page | 12

RW

=

THl

WG

BH

[7]

where

10

-

THl

describes the uncertainties in determining the surficial instability thickness s.

Its value ranges between 1.20, when the estimation is based on a geomechanical

survey, and 1.30, when it is based on rough estimation (Figure 5). It must be

considered that the thickness of the unstable layer is not homogeneous, locally its

thickness could be thicker.

-

WG

describes the uncertainties in the unitary weight determination of the rock

mass. Usually it is assumed to equal 1.00, but if there are severe uncertainties it

can be assumed to equal 1.05. For instance it can be noticed that for non

homogenous rocks (e.g. flysch rock masses where there are thin layered clay

stone alternated to hard mudstone), the mesh and the nails can locally be heavy

loaded, whereas in other places the load is lower being the same volume of

instability (Figure 6).

-

BH

describes the uncertainties related to the rock mass behaviour. High erodibility

of the rock surface can cause stripping of the nails and weakness of the whole

system (Figure 7). One consequence is that the unstable portion held by the nails

(or by the mesh) could become quickly deeper. Usually the value is assumed

equal to 1.00, but if there are severe environmental conditions or the rock mass is

easily weathered (it is the case of several rock types containing clay), it can be

assumed to equal 1.05.

Figure 5 - Thickness of the unstable slope "s" evaluated with geomechanical survey (left), or with rough

estimation of the detachment niches and size boulders (right)

MACRO 1 THEORY AND BACKGROUND Page | 13

Figure 6 Rock masses with different lithology; left: non homogeneous rock mass (for example flysch);

right: homogeneous rock mass (for example mudstone)

Figure 7 Left: the weathering quickly denudates the anchors. Right: despite of the heavy jointed rock

mass, the weathering is slow. If the weathering velocity is negligible, the anchor length Le1 and Le2

into the sound rock is enough to hold the unstable surficial portion for a long time.

External conditions, especially slope morphology, play an important role in the magnitude of

the driving forces, whose safety coefficient is defined as

DW

=

MO

OL

[8]

where:

-

MO

describes the uncertainties related to slope morphology. If the slope is very

rough, then the mesh facing is not in continuous contact with the surface, and the

unstable blocks can freely move; in that case a safety coefficient of 1.30 should

be applied. If the slope surface is even, the mesh facing lies in better contact with

MACRO 1 THEORY AND BACKGROUND Page | 14

the ground; in the case, the unstable block movement is limited, and a safety

coefficient of 1.10 is used (Figure 8 and Figure 9).

-

OL

describes the uncertainties related to additional loads applied on the facing

system. The additional loads could be related to the presence of ice or snow, or to

vegetation growing on the slope. Usually it is assumed to equal 1.00, but if severe

conditions are foreseen, it can be assumed to equal 1.20.

Figure 8 - Left: even slope morphology: the mesh lies in contact to the slope surface. Right: uneven slope

morphology: the mesh touches the slope surface in few points

Figure 9 - Left: even slope morphology: the mesh lies in contact to the slope surface. Right: uneven slope

morphology: the mesh touches the slope surface in few points

MACRO 1 THEORY AND BACKGROUND Page | 15

Table 1 - Recap of the safety coefficients for the reduction of the destabilizing forces and of the

resistances

The above safety coefficients (formula [7] and [8]) have been calibrated in order to get the

following range of values (Table 2):

Table 2 - Global safety coefficients applied to the stabilizing and driving forces

Safety coefficient Minimum value Maximum value

For stabilizing forces 1.20 1.43

For driving forces 1.10 1.56

With this procedure the global safety coefficient applied on the geomechanical system very

roughly ranges between 1.5 and 3.2 according to the most common experience and design

codes.

Partial/Load

factor

Description Value

T If the superficial instability thickness is defined by:

- geomechanical survey:

- rough/visual estimation:

1.20

1.30

W If the rock unit weight is:

- homogeneous:

- not-homogeneous (i.e. flysh):

1.00

1.05

B If the rock:

- does not present any anomalous behavior (i.e. compact rock):

- is subjected to erosion and/or environmental condition that can create

weakness of the rock mass (i.e. weathering rock):

1.00

1.05

MO If the morphology of the rock is:

- regular (the mesh lies in better contact with the slope, thus the rock

movement are limited):

- rough (the mesh cannot be in adherence with the slope, thus the unstable

block can easily move):

1.10

1.30

OL If there are/are not external loads acting on the system:

- not significant loads are applied:

- additional external loads are applied (i.e. snow, ice, vegetation, etc.)

1.00

1.20

MACRO 1 THEORY AND BACKGROUND Page | 16

4.2 Stabilizing contribution of anchors

The reinforcing nail bars work principally in proximity to the sliding joint, where it is

subjected to shear stresses together with tensile stresses. The resisting force R, due to the

bar along the sliding plane

11

, is derived utilising the maximum work principal

12

:

[9]

where:

m = cotg ( + ) [10]

= angle between the bar axis and the horizontal. It is equal to

= 90 -

o

, [11]

where

o

is the angle between the bar axis and the normal to the sliding plane.

= sliding surface dilatancy

N

e

= bar strength (elasticity limit condition) = ESS

adm

= ESS

ST

/

ST

[12]

ST

= coefficient of reduction for the steel resistance.

ESS = effective area of the steel bar = / 4 ((fe - 2 fc)

2

- fi

2

) [13]

fe = external diameter of the steel bar

fc = thickness of corrosion on the external crown

fi = minor diameter of the steel bar

In accordance with the Barton Bandis resistance criteria, the value is approximated as

13

[14]

where

14

:

[15]

= inclination of the most unfavourable sliding plane

plan

= sliding plane normal stress

JRC = joint roughness coefficient

15

= [15]

JCS = joint uni-axial compression resistance

16

= [16]

JCS

0

= joint compression strength referred to the scale joint sample

JRC

0

= roughness referred to scale joint sample

L

0

= joint length (assumed to be 0.1 m for lack of available data)

L

g

= sliding joint length (assumed to be equal to vertical nail spacing.

e N

m

m

R

+

+

=

2

1

2

2

4

1

16

1

JRC log

JCS

plan

#

$

%

&

'

(

3

( ) 0 02 . 0

0

0

JRC

g

L

L

JRC

( ) 0 03 . 0

0

0

RC J

g

L

L

JCS

plan =

ix iy s cos

ix iy

MACRO 1 THEORY AND BACKGROUND Page | 17

The equations from [14] to [16] are exclusively aimed at determining the dilatancy that

increases the stabilizing contribution R of the anchor especially when it is put perpendicular

to a very rough plane

17

. Macro 1 must adopt a conservative approach because on surficial

rock masses the joints are often opened, or with filling of clay, sometime with advanced

weathering process, the uniaxial compressive strength is very low; other times the rock mass

is disturbed by the excavation

18

. In these conditions the anchors mostly works with the shear

resistance of the anchor bar. In lack of input data, the user should remember the followings:

- the roughness JRC and the uniaxial compression resistance JCS should be estimated

on the most unfavourable joints inclined . Macro 1 assumes that the joint (parallel to

the slope face) has such most unfavourable resistance, and the anchors are calculated

accordingly.

- If JRC is unknown

19

it can be set at 0.

- If JCS is unknown

20

, it can be set at 5 MPa.

- If the joint inclination is unknown, it can be assumed between 40 and 50 in order to

get al large volume sliding on a very steep plane.

4.3 Evaluation of nail length

The evaluation of nail length should consider the following:

a) The nail plays the most important role in superficial consolidation of the slope. Its

length must be deeper than the instability thickness, and should allow the bar to

reach into the stable section.

b) The steel bar and the grout are exposed to weathering actions (ice, rain, salinity,

temperature variations, etc.).

c) The steel bar can develop the shear resistance because rock and grout develop the

same opposite strength. But because rock and grouting are weaker than the steel,

generally the rock plasticizes close the sliding plane

21

. The plasticized volume

depends on the rock type.

Figure 10 - Anchor bar in the rock mass. Li = length crossing the unstable mass; Lp length in the

plasticized rock mass; Ls length in stable rock mass

MACRO 1 THEORY AND BACKGROUND Page | 18

The minimum theoretical length is derived by

L

t

= L

s

+ L

i

+ L

p

[17]

assuming:

L

s

= length in the stable part of the mass = P / (

drill

lim

/

gt

) [18]

L

i

= length in the weathered mass = s / cos

dw

[19]

L

P

= length of hole with plasticity phenomena in firm part of the rock mass. The values

ranges between 0.05 m for hard rock (e.g. granite or basalt) up to 0.30 m for weak rock (e.g.

marl), and exceptionally up to to 0.45 m for very weak rock (e.g. claystone or tuff).

With

drill

= diameter of the hole for the bar

lim

= bound stress (adherence tension) between grout rock

22

gt

= safety coefficient of the adhesion grout rock. According to the Eurocode EC7, it

should not be taken lower than 1.8

23

.

P = pullout force; it is the greater of the following:

P

Mesh

= ((W

Sbar

- W

Dbar

) cos ( +

o

)) i

x

= pull out due to the mesh [20]

P

Rock

= (F

Sslp

R F

Dslp

) cos (+

o

) = pull out due to the slope instability[21]

The length of the nail must be intended as a preliminary value. The final suitable length of

the bars has to be evaluated while drilling and confirmed with pull out tests.

5 MESH DIMENSIONING

5.1 Ultimate limit state

Some secondary blocks could slide among the nails on a plane with inclination , where is

smaller than the slope inclination , and push on the mesh facing. The maximum block size

pushing per horizontal linear meter of facing depends on the thickness s and the vertical

spacing i

y

between two nails. Since the load pushing is asymmetric and the mesh deforms

unevenly, the forces acting on the facing are represented with the following simplified

scheme (Figure 11 and Figure 12):

Figure 11 - Deformed mesh with forces

MACRO 1 THEORY AND BACKGROUND Page | 19

F - the force developed by the blocks sliding between the nails on a plane inclined at

.

T - the force acting on the facing plane, which rises when the sliding blocks push on

the facing. The force can develop because there is a large friction between mesh

and blocks, and a pocket is formed. The facing, which is considered to be nailed

on the upper part only, reacts to T with the tensile resistance of the mesh.

M the punch force developed by the blocks perpendicular to the facing plane. The

force is developed since there are several lateral restraints, like the nailing (strong

restraint) and the next meshes (weak restraint). The magnitude of M largely

depends on the stiffness of the mesh: the higher the membrane stiffness of the

mesh is, the more effectiveness the facing is.

In the case of the mesh, the ultimate limit state is satisfied when

T

adm

- T > = 0 [22]

where

T

adm

= admissible tensile strength of the mesh

which is

T

adm

= T

m

/

MH

[23]

where

T

m

= Tensile resistance of the mesh

MH

= safety coefficient for the reduction of the tensile resistance of the mesh. Taking into

account the inhomogeneous stress acting on the loaded mesh, the minimum safety

coefficient should be not lower than 2.50. This safety coefficient is based upon

empirical observations on the punch tests carried out in Pont Boset with Torino Tech

University

24

and Lab IUAV Venice University

25

, where it has been noticed that the

mesh between the anchors does not give a full contribution to hold the lower facing,

and the stress basically is absorbed by the nails. Those last hold a force Q ranging

between 30 and 55 kN per anchor

26

.

The real distribution of the stress has been seen with numerical analysis

27

. The stress acting

on the mesh depends on the membrane stiffness: the higher the stiffness is, the higher the

capacity of the mesh to be like a restrain between the anchors is. The stiffer mesh is more

effective, accordingly. From the theoretical point of view, the lower the stiffness is, the higher

the safety coefficient should be, since the stress in mainly concentrated on the anchors and

not homogenously distributed on the mesh.

The stress T on the mesh depends on the force pushing on the mesh (M Figure 12), which

can be calculated using the same principles as formula [3]:

M = F sin () i

x

= (M

bdrv

M

bstb

) sin () i

x

[24]

MACRO 1 THEORY AND BACKGROUND Page | 20

Figure 12 - Scheme of the forces acting on the mesh

Where:

M

bdrv

= Mb (sin + c cos )

DW

= driving forces [25]

M

bstb

= (Mb sin (1- c))

RW

= resisting forces [26]

Mb = V = weight of the unstable rock mass [27]

V = maximum unstable volume between nails (Figure 13, Figure 14, Figure 15) which

is calculated in accordance with the next paragraph 5.2.

Figure 13 Shapes of the rock volumes that can move among the anchors: triangular (left) and

trapezium (right)

Figure 14 - Geometry of the volume between the anchors

MACRO 1 THEORY AND BACKGROUND Page | 21

Figure 15 - Volumes B and C between the anchors

5.2 Maximum rock volume VS pushing on the mesh

Macro 1 assumes that the maximum volume pushing on the mesh has the following

boundaries (Figure 14):

- top: top and anchor (for simplicity the anchors are always considered perpendicular to

the sliding plane)

- bottom: sliding surface inclined . The plane intersects the surface at the head of the

lower anchor.

- Back: sliding surface inclined

There are several procedures for the calculation of the maximum rock volume that could

move among the anchors. Hereby is described the one followed by the analytical algorithm

of Macro 1.

If (arctan (s/i

y

)) and < [28]

Then the volumes simply becomes (triangular shape in Figure 13 left)

Volume A [29]

else, if < arctan (s/i

y

) [30]

can be distinguished the following volumes (Figure 15)

Volume B V = i

y

s

- s

2

/ tan () [31]

And volume C V = 0.5 s

2

/ tan () [32]

Macro 1 determines the maximum theoretical volume as the sum of

V = Volume A + Volume B + Volume C [33]

5.3 Mesh deformation under punch load and scale effect

Macro 1 assumes that in any case the punch load on the mesh can be greater than the

weight of the rock volume among the anchors. Then Macro 1 check if

M/i

x

/sin ( p) < Mb sen [34]

then

T = M / i

x

/ sin (

p

)

else

) tan(

2

1

2

= y i V

MACRO 1 THEORY AND BACKGROUND Page | 22

T = Mb sen [35]

With

Z

bulg

= displacement related to the punch load M.

p

= angle of deformation of the mesh arctg (2

bulg

/ i) [36]

= average spacing between the anchors = (ix * iy)

0.5

[37]

Figure 16 - Sketch of the geometry of the mesh with punching load

Figure 17 - Plan view of the punch test according to UNI 11437:2012. Legend: 1 = tested mesh; 2 =

punching device (1.0 m in diameter); 3 = perimeter constraint between the mesh and the frame.

When the load induces the maximum displacement Z

bulg

, the process of the mesh rupture

stars. The maximum punch displacement Z

bulg

is related to the sample size: in accordance

with the results of the tests carried out

28

, it is possible to roughly say that the larger the

sample size is, the larger the displacement is (scale effect). The general law of the scale

effect is assumed in the simplified form

x = x

0

x

[38]

y = y

0

y

[39]

where

(x, y) = generic coordinate of the scaled graphic

(x

0

, y

0

) = generic coordinate of the reference graphic

(

x

,

y

) = constants correlating the scaled to the reference graphic

As the curves have been determined following the standard UNI 11437 (a sample size 3.0 x

3.0 m), the reference size for the description of scale effect is 3.0 m (Figure 17).

Macro 1 automatically modifies the typical load vs displacement curves considering the

scale effect.

MACRO 1 THEORY AND BACKGROUND Page | 23

Figure 18 - Example of a curve load-displacement used for the design of the mesh at

the Serviceability Limit State

5.4 Mesh dimensioning: serviceability limit state

The serviceability limit state provides information concerning the following:

- required maintenance activity on the facing;

- risks of stripping because of anchor necking;

- interference between infrastructure and facing as consequence of excessive

displacements.

The serviceability limit state is satisfied if

B

ulg

- Z

bulg

>= 0

where

B

ulg

= D

mbulg

/

mbulg

= admissible displacement

D

mbulg

= maximum design displacement

mbulg

= safety coefficient. Its value ranges between

29

1.50 (facing installed properly on a

slope with an even surface) and 3.00 (facing installed improperly on a slope with

uneven morphology). The safety coefficient decreases the desired maximum

deformation and automatically gets the related admissible load.

bulg

= deformation of the facing as derived from the results of Maccaferri tests on the

base due to punch force M (Figure 18).

MACRO 1 THEORY AND BACKGROUND Page | 24

6 GENERAL BIBLIOGRAPHY

AICAP, (1993): Anchor in soil and rock: recommendations (in Italian).

Bertolo P. , Giacchetti G., 2008 - An approach to the design of nets and nails for surficial

rock slope revetment in Interdisciplinary Workshop on Rockfall Protection, June 23-25

2008, Morshach, Switzerland.

Bertolo P., Ferraiolo F., Giacchetti G., Oggeri C., Peila D., e Rossi B., (2007): Metodologia

per prove in vera grandezza su sistemi di protezione corticale dei versanti GEAM

Geoingegneria Ambientale e mineraria, Anno XLIV, N. 2, Maggio-Agosto 2007.

Besseghini F., Deana M., Di Prisco C., Guasti G., 2008 Modellazione meccanica di un

sistema corticale attivo per il consolidamento di versanti di terreno, Rivista GEAM

Geoingegneria ambientale e Mineraria, Anno XLV, N. III dicembre 2008 (125) pp. 25-30

(in Italian)

Bonati A., e Galimberti V., (2004): Valutazione sperimentale di sistemi di difesa attiva dalla

caduta massi in atti Bonifica dei versanti rocciosi per la difesa del territorio - Trento

2004, Peila D. Editor.

Brunet G., Giacchetti G., (2012) - Design Software for Secured Drapery- Proceedings of the

63rd Highway Geology Symposium, May 7-10, 2012, Redding, California.

Castro D., (2008) Proyetos de investigacin en la Universidad de Cantabria - II Curso

sobre proteccin contra caida de rocas Madrid, 26 27 de Febrero. Organiza STMR

Servicios tcnicos de mecnica de rocas.

Cravero M., Iabichino G., Oreste P.P., e Teodori S.P. 2004: Metodi di analisi e

dimensionamento di sostegni e rinforzi per pendii naturali o di scavo in roccia in atti

Bonifica dei versanti rocciosi per la difesa del territorio Trento 2004, Peila D. Editor.

Ferrero A.M., Giani G.P., Migliazza M., (1997): Interazione tra elementi di rinforzo di

discontinuit in roccia - atti Il modello geotecnico del sottosuolo nella progettazione

delle opere di sostegno e degli scavi IV Conv. Naz. Ricercatori universitari

Hevelius pp. 259 275.

Flumm D., Ruegger R. (2001): Slope stabilization with high performance steel wire meshes

with nails and anchors International Symposium Earth reinforcement, Fukuoka, Japan.

Goodman, R.E. and Shi, G. (1985), Block Theory and Its Application to Rock Engineering,

Prentice-Hall, London.

Jacob V., (2009): Engineering, unpublished thesis, Technical University Torino.

LCPC, (2001) : Parades contre les instabilits rocheuses - Guide technique - Paris.

Phear A., Dew C., Ozsoy B., Wharmby N.J., Judge J., e Barley A.D., (2005): Soil nailing

Best practice guidance - CIRIA C637, London, 2005.

Ribacchi R., Graziani A. e Lembo Fazio A. (1995). Analisi del comportamento dei sistemi di

rinforzo passivi in roccia, XIX Convegno Nazionale di Geotecnica: Il Miglioramento e il

Rinforzo dei Terreni e delle Rocce, Pavia, pp. 239-268

Ruegger R., e Flumm D., (2000): High performance steel wire mesh for surface protection in

combination with nails and anchors Contribution to the 2

nd

colloquium Contruction in

soil and rock Accademy of Esslingen (Germany).

MACRO 1 THEORY AND BACKGROUND Page | 25

Saderis A., (2004): Reti in aderenza su versanti rocciosi per il controllo della caduta massi:

aspetti tecnologici e progettuali Tesi di Laurea in Ingegneria per lAmbiente e il

Territorio, unpublished thesis, Technical University Torino.

Torres Vila J.A., Torres Vila M.A., e Castro Fresno D., (2000): Validation de los modelos

fisicos de analisis y diseno para el empleo de membranas flexibile Tecco G65 como

elemento de soporte superficial en la estabilizacion de taludes.

Valfr A., (2007): Dimensionamento di reti metalliche in aderenza per scarpate rocciose

mediante modellazioni numeriche GEAM Geoingegneria Ambientale e mineraria,

Anno XLIII, N. 4, Dicembre 2006.

MACRO 1 THEORY AND BACKGROUND Page | 26

7 END NOTES

1

See pag. 570 of Turner A.K, Schuster R.L. Editors (2012) Rockfall Characterization

Rockfall Characterization and control Transportation Research Board, Washington D.C.

2

UNI 11437 (2012). Rockfall protection measures : Tests on meshes for slope coverage -

UNI Ente Nazionale Italiano di Unificazione. It is the first worldwide norm that describes the

procedures for the two basic resistances of a mesh (punch and tensile). It considers and

extends the pre existing standards (ASTM 975-97 2003 and EN 15381:2008).

3

The following graph shows the effect of water content on the compressive strength, bleed

and flow resistance of grout mixes (Littlejohn and Bruce, 1975, from pag 322 of Wyllie D.C.

(1999) Foundations on Rock Second edition E & FN SPON, London and New York).

4

In Macro 1 the notation of the anchor spacing is referred to the horizontal inter-axis i

x

and

the vertical one i

y

(measured on the slope face). The Figure 1 shows the configuration of the

anchor pattern spaced i

x

and i

y

. In reality the anchor pattern could be also diamond, as

represented in following figure. Macro 1 only accepts the input with the concept of square

pattern (left in the figure). If the user wants to change from square to diamond, he has to

input a fictitious square pattern that respects the anchor density (number of anchor per area

unit).

Area per 1 anchor in the squared pattern Area = i

y

i

x

If i

y

=

i

x

, the squared area can be rewritten Area = i

x

2

Area per 1 anchor in the diamond pattern Area = d

y

d

x

/ 2

It must be that i

x

2

= d

y

d

x

/ 2

And then i

x

= (d

y

d

x

/ 2)

0.5

The last relationship allows adopting the diamond pattern in Macro 1 too.

Example: the diamond pattern to be calculated is d

y

= 5.5 m and d

x

= 2.9 m. The equivalent

square pattern to be inserted in Macro 1 is

i

x

= i

y

= (d

y

d

x

/ 2)

0.5

= (5.5 2.9

/ 2)

0.5

= 2.8 m

MACRO 1 THEORY AND BACKGROUND Page | 27

The best position of the anchors happens when they can cooperate each other and interfere

with the rock mass. Then the best theoretical pattern should be the diamond one, with

anchor axis spaced in order to form an equilateral triangle. But more simply, it is important

that the areal distribution of the anchor is as homogeneous as possible. In these terms it is

strongly recommended to avoid irregular pattern (examples: diamond 3.0 m x 8.0 m or

rectangular 2.5 m x 4.8 m).

For practical reasons many contractors prefer the squared pattern.

5

Ferraiolo F., Giacchetti G. (2004) Rivestimenti corticali: alcune considerazioni

sullapplicazione delle reti di protezione in parete rocciosa, in proceedings Bonifica di

versanti rocciosi per la protezione del territorio Trento 2004 Peila D. editor. In Italian.

6

At the present has been instituted a work group for the proposal of a new Eurocode for the

rock masses. For instance see: Alejano L.R., Bedi A., Bond A., Ferrero A.M., Harrison J.P.,

Lamas L., Migliazza M.R., Olsson R., Perucho ., Sofianos A., Stille H., Virely D. (2013).

Rock engineering design and the evolution of Eurocode 7. In Rock Mechanics for

Resources, Energy and Environment Kwasniewsky & Lydzba (eds.) 2013 Taylor & Francis

Group, London, ISBN 978-1-138-00080-3, pag. 777-782

Anyway, with special reference to the DIN 1054:2010-12 (Subsoil Verification of the safety

of earthworks and foundations Supplementary rules to DIN EN 1997-1 - table A 2.1 for the

approach B-SP, GEO-2), and more generally to the EC7 concepts, the user can introduce

the coefficients 1.35 for the estimation of the stabilizing forces, and 1.00 for the estimation of

the driving ones (see Tabelle Teilsicherheitsbeiwerte F1 bzw. E2 fr Einwirkungen und

Beanspruchungen, B-SP, STR und GEO-2: Grenzzustand des Versagens von Bauwerken,

Bauteilen und Baugrund, pag 30 DIN EN 1997-1). This approach implicate that the

efficiency for the system (Maccaferri internal report):

= F

Dslp

/ F

Sslp

is equals or greater than 0.77 (see equations [5] and [6]). In order to respect this efficiency,

the safety coefficient

DW

and

RW

(see Table 2) have to respect at least the following value:

DW

= (W sen /

RW

+ Rd / W sen )

(for the meaning of W, and R, please see the symbol list table)

MACRO 1 THEORY AND BACKGROUND Page | 28

The relation between

DW

and

RW

has been plot in the above graph for immediate use, as the

following examples shows:

Example 1: if

DW

is equals to 1.20, in order to get an efficiency not lower than 0.77,

RW

shall not be lower than 1.25.

Example 2: if

RW

is equals to 1.50, in order to get an efficiency not lower than 0.77,

DW

shall not be lower than 1.10.

The user can modulate the partial safety coefficients (see Error! Reference source not

found.) according to his knowledge of the slope until

DW

and

RW

(see the input data menu of

safety coefficients in the software) do not satisfy the required efficiency of the system, as per

the graph above.

7

The Barton-Bandis criteria does not consider the cohesion on the joints, but a peak friction

angle, which depends on a base friction angle (related to the rock type) and an increment

angle (related to JRC and JCS).

Main references:

Barton, N.R. and Choubey, V. (1977). The shear strength of rock joints in theory and

practice. Rock Mech. 10(1-2), 1-54.

Barton, N.R. and Bandis, S.C. (1982). Effects of block size on the shear behaviour of

jointed rock. 23rd U.S. symp. on rock mechanics, Berkeley, 739-760

Practical synthesis can be found in

- chapter 2 of Hoek E. (2000). Course Notes for Rock Engineering (CIV 529S) in

www.rocscience.com

8

see pag. 352 354 of Hoek, E. and Bray, J.W. 1981. Rock Slope Engineering . 3rd edn.

London: Institution of Mining and Metallurgy 402 pages.

9

According to the Barton-Bandis failure criteria, the friction angle commonly ranges between

28 and 70. Most frequently the value of 45 can be considered conservative.

MACRO 1 THEORY AND BACKGROUND Page | 29

10

Grimod A., Giacchetti G. and Peirone B., 2013. A new design approach for pin drapery

systems. Proceedings of GeoMontreal 2013. 29

th

Spetember 3

rd

October 2013, Montreal

(QC). Paper n. 491.

11

The stabilizing contribution of a steel bar crossing a sliding plane can be described with

the following typical graphics:

The graph, developed for a specific type of steel bar, shows the effect of the dilatancy on the

stabilizing contribution R is higher when the bar perpendicular the sliding plane.

See also pag. 337- 339 of Giani G. P. (1992), Rock slope stability analysis Balkema,

Rotterdam

12

pag. 95 96 of Pellet F., e Egger P., (1995): Analytical model for the behaviour of bolded

rock joints and practical applications. In proceedings of international symposium Anchors

theory and practice. Widmann R. Editor, Balkema, Rotterdam.

13

Giani G. P. see note 11

14

see the following references:

Singh B., Goel R.K. (1999) Rock mass Classification A practical approach in civil

engineering - Elsevier

pag 69 of Bell F.G. (2007). Engineering Geology Elsevier BH

MACRO 1 THEORY AND BACKGROUND Page | 30

15

See pag 37 38 of Barton N. (1992): Scale effects or sampling bias? Proc. Int. Workshop

Scale Effects in Rock Masses, Balkema Publ., Rotterdam

16

Barton N. - see note 15

17

See pag. 169 171 of Goodman, R.(1989) - Rock Mechanics Second edition. John

Wiley.

18

An idea of grade of disturbance can be found on the chapter describing the rock mass

properties of Hoek E. (2000). Course Notes for Rock Engineering (CIV 529S) in

www.rocscience.com

19

The value of JRC can be measured by the Barton comb and comparing the roughness

profile to the typical of the table (from Barton, N.R. and Choubey, V. , 1977 see note 7).

20

The value of JCS can be measured with the Schmidt hammer, or in lack o information,

deduced from the uniaxial compressive strength (UCS = c) of the rock. The following table

gives the compressive frame of the most common values (from Appendix 3 of Palmstrom A.,

(1995) RMi - a system for characterization of rock masses for rock engineering purposes.

Ph. Thesis, University of Oslo, Norway. In www.rockmass.net)

MACRO 1 THEORY AND BACKGROUND Page | 31

21

See the references:

pag 139-141 of Wyllie D.C., e Mah C.W., (2004): Rock slope engineering civil and

mining - 4th edition Spon Press London and New York.

ITASCA (2004). UDEC universal distinct element Code User manual: Special

features Minneapolis, USA.

22

The following table the approximate relationship between rock type and working bond shear

strength for cement grout anchorages (from pag 331 of Wyllie D.C. (1999) Foundations on Rock

Second edition E & FN SPON, London and New York.)

MACRO 1 THEORY AND BACKGROUND Page | 32

See also:

Littlejohn, G.S. and Bruce, D.A. (1975a) Rock anchors state of the art. Part 1: Design.

Ground Eng., 8(4), 418.

Littlejohn, G.S. and Bruce, D.A. (1975b) Rock anchors - state of the art. Part 2: Construction.

Ground Eng., 8(4), 3645.

Littlejohn, G.S. and Bruce, D.A. (1976) Rock anchors state of the art. Part 3: Stressing and

testing. Ground Eng., 9(5), 33141.

23

UNI ENV 1997-1:2005

24

Bertolo P., Oggeri C., Peila D., 2009 Full scale testing of draped nets for rock fall

protection - Canadian Geotechnical Journal, No. 46 pp. 306-317.

25

The typical load vs displacement curves of the mesh have been implemented in the library

of Macro 1.

26

The values have been seen with specific tests in Cottbus University test i.e. Test 2011-

MPZ05SG/B-06 13/ May 2011

27

See the following references:

Muhunthan B., Shu S., Sasiharan N., Hattamleh O.A., Badger T.C., Lowell S.M.,

Duffy J.D., (2005): Analysis and design of wire mesh/cable net slope protection -

Final Research Report WA-RD 612.1 - Washington State Transportation Commission

Department of Transportation/U.S. Department of Transportation Federal Highway

Administration.

Sasiharan N., Muhunthan B., Badger T.C., Shu S., Carradine D.M.(2006)

Numerical analysis of the performance of wire mesh and cable net rockfall protection

systems. Engineering Geology 88, 121-132. Elsevier

28

See the following references:

Majoral R., Giacchetti G., Bertolo P., 2008 Las mallas en la estabilizacin de

taludes II Curso sobre proteccin contra caida de rocas Madrid, 26 27 de

Febrero. Organiza STMR Servicios tcnicos de mecnica de rocas.

Grimod A., Giacchetti G. , 2013, New design software for rockfall simple drapery

systems. Proceedings 23

nd

World Mining Congress & Expo, Montreal. Paper No.

MACRO 1 THEORY AND BACKGROUND Page | 33

255.

29

The safety coefficients for the diplacement normal to the mesh plane should be always

quite large in order to compensate for all the uncertainties that affect the mesh. The

installation accuracy generates one of the largest uncertainties. The most relevant research

to analyze the performance of the mesh stressed by a punch test was done by the

Polytechnic of Turin (see note 24 and the figures below with the cross section of the punch

device acting on the tested meshes). The goal of the research was to study the real behavior

of different type of mesh installed on a rock slope. The meshes were anchored to the rock by

4 nails distributed in a squared configuration. The distance between the nails was 3m x 3m.

The falling block was simulated by a piston connected to a punch device (diameter = 1.5 m);

the piston was installed in order to develop a 45 degree pressure against the mesh. The

maximum elongation of the piston was approx. 1.2 m ! The best way to reduce the

deformation is inserting cables into the mesh as suggested by Muhunthan ( see note 26).

.

Вам также может понравиться

- Hydraulic System Trainer AS-10Документ13 страницHydraulic System Trainer AS-10Tanlets Gery100% (1)

- Biaxial GeogridsДокумент20 страницBiaxial GeogridsLiliana RibeiroОценок пока нет

- P-Y Criterion For Rock Mass: Robert Liang, M.ASCE Ke Yang, M.ASCE and Jamal Nusairat, M.ASCEДокумент11 страницP-Y Criterion For Rock Mass: Robert Liang, M.ASCE Ke Yang, M.ASCE and Jamal Nusairat, M.ASCEAltan ErdemОценок пока нет

- Evaluation of Soil & Rock Properties (FHWA-IF-02-034)Документ386 страницEvaluation of Soil & Rock Properties (FHWA-IF-02-034)paduco100% (2)

- Empirical Estimation of Rock Mass Modulus PDFДокумент15 страницEmpirical Estimation of Rock Mass Modulus PDFIvo FritzlerОценок пока нет

- Design of Rock Slope ReinforcementДокумент24 страницыDesign of Rock Slope Reinforcementdeepaknhpc_21Оценок пока нет

- On Estimating Slope Stability Reduction Due To Rain Infiltration MoundingДокумент36 страницOn Estimating Slope Stability Reduction Due To Rain Infiltration MoundingSuvadeep DalalОценок пока нет

- Tensar PPT Biaxial GridsДокумент20 страницTensar PPT Biaxial GridsPasc Oana JianinaОценок пока нет

- FHWA-shallow FoundationДокумент297 страницFHWA-shallow FoundationENGIDA100% (1)

- FLAC DynamicДокумент294 страницыFLAC DynamicMaximillian KrisnadiОценок пока нет

- Laterally Loaded Rock Socket Design - A Review of The P-Y Curve Design ApproachДокумент9 страницLaterally Loaded Rock Socket Design - A Review of The P-Y Curve Design ApproachmyplaxisОценок пока нет

- Johnston - Revisiting Methods For Design of Rock Socketed Piles (2020)Документ13 страницJohnston - Revisiting Methods For Design of Rock Socketed Piles (2020)Erik SkulstadОценок пока нет

- Soil Nailing PDFДокумент123 страницыSoil Nailing PDFAnonymous fE2l3Dzl83% (6)

- Cat Engine 3512bДокумент9 страницCat Engine 3512bPrasanna BhattacharyaОценок пока нет

- Reinforced Soil Retaining Wall: A Feasible Eurocode 7 Design Approach Derived From Bs 8006Документ78 страницReinforced Soil Retaining Wall: A Feasible Eurocode 7 Design Approach Derived From Bs 8006ajlaОценок пока нет

- Rock Bolts - Improved Design and Possibilities by Capucine Thomas-Lepine PDFДокумент105 страницRock Bolts - Improved Design and Possibilities by Capucine Thomas-Lepine PDFSaphal LamichhaneОценок пока нет

- Chapter 16 PDFДокумент212 страницChapter 16 PDFGabriela Sequeira60% (5)

- Drilled Shaft in Rock Analysis and Design - Part1Документ109 страницDrilled Shaft in Rock Analysis and Design - Part1rshaghayan100% (3)

- Fellenius - The Analysis of Results From Pile Load TestsДокумент10 страницFellenius - The Analysis of Results From Pile Load TestsFederico MontesverdesОценок пока нет

- Soil Nailing - Where When and WhyДокумент27 страницSoil Nailing - Where When and WhyarshashajiОценок пока нет

- Piston, Connecting Rod and Cylinder Liner L28/32H: DescriptionДокумент57 страницPiston, Connecting Rod and Cylinder Liner L28/32H: DescriptionERepublikPolskaОценок пока нет

- CHP 4 - Rock Slope Stability AnalysisДокумент109 страницCHP 4 - Rock Slope Stability AnalysisKoh Jia JieОценок пока нет

- Soil Nail - GNP - GoodДокумент19 страницSoil Nail - GNP - GoodgahsoonОценок пока нет

- Shovel Vs Wheel LoaderДокумент22 страницыShovel Vs Wheel LoadermanamohanroutОценок пока нет

- Rock Bolting IntroductionДокумент22 страницыRock Bolting IntroductionrvmuruganОценок пока нет

- Design of Micro Piles For Slope StabilizationДокумент70 страницDesign of Micro Piles For Slope StabilizationedguortОценок пока нет

- Self Drilling Hollow Bars - Ground Anchor, Tension Pile or Soil NailДокумент16 страницSelf Drilling Hollow Bars - Ground Anchor, Tension Pile or Soil NailShiela Mae Intia MagalonaОценок пока нет

- Rock MechanicsДокумент20 страницRock MechanicsgizeaОценок пока нет

- Vsip - Info - Fhwa Design For Soil Nail Walls SLD Method 4 PDF FreeДокумент5 страницVsip - Info - Fhwa Design For Soil Nail Walls SLD Method 4 PDF FreeSri RamprasathОценок пока нет

- The Use of Field Geophysical Techniques To Determine Geotechnical Stiffness ParametersДокумент12 страницThe Use of Field Geophysical Techniques To Determine Geotechnical Stiffness ParametersoldinaОценок пока нет

- CM P1 11604 en SKF Vibration Sensors CatalogДокумент140 страницCM P1 11604 en SKF Vibration Sensors CatalogMarcelo MallmannОценок пока нет

- UK Designers Handbook SteelgridHR Rev2 - 2Документ55 страницUK Designers Handbook SteelgridHR Rev2 - 2Kenneth Knox100% (1)

- Design of Piles Under Cyclic Loading: SOLCYP RecommendationsОт EverandDesign of Piles Under Cyclic Loading: SOLCYP RecommendationsAlain PuechОценок пока нет

- Design Guidelines For Construction of Gabion WallДокумент48 страницDesign Guidelines For Construction of Gabion Walljanhvi muleОценок пока нет

- 1 - Rockfall Barrier Design - Maccaferri - Con Ejemplos PDFДокумент45 страниц1 - Rockfall Barrier Design - Maccaferri - Con Ejemplos PDFShawn HopperОценок пока нет

- 4 Laws of MotionДокумент15 страниц4 Laws of MotionHimanshu Gupta100% (1)

- Steelgrid Technical Paper Rock Soil Slope ProtectionДокумент12 страницSteelgrid Technical Paper Rock Soil Slope ProtectionGema FajriОценок пока нет

- Rock Socketed PilesДокумент7 страницRock Socketed PilesMohamedRaahimОценок пока нет

- Design Methods Forthe Reinforcement of Highway Slopes by Reinforced Soil and Soil Nailing TechniquesДокумент108 страницDesign Methods Forthe Reinforcement of Highway Slopes by Reinforced Soil and Soil Nailing TechniquesNita BogdanОценок пока нет

- ZHAO, XXX, Rock Mechanics For Civil Engineers PDFДокумент196 страницZHAO, XXX, Rock Mechanics For Civil Engineers PDFMarcial JaraОценок пока нет

- Mechanisms of Shotcrete Roof Support: C. Banton, M.S. Diederichs, D.J. Hutchinson S. EspleyДокумент6 страницMechanisms of Shotcrete Roof Support: C. Banton, M.S. Diederichs, D.J. Hutchinson S. EspleyAlexandre GomesОценок пока нет

- Handbook No 2Документ266 страницHandbook No 2Z AОценок пока нет

- RH - Em9seДокумент6 страницRH - Em9seJefa DanarОценок пока нет

- NR467 - C1 - 2018-07 BV RulesДокумент568 страницNR467 - C1 - 2018-07 BV Rulesmlaouhi majedОценок пока нет

- Draft Guidelines For Engineering of Natural Slopes (H-4) - CompressedДокумент224 страницыDraft Guidelines For Engineering of Natural Slopes (H-4) - CompressedSanthoshkumar Rayavarapu100% (1)

- Spang - Egger - Action of Fully Grouted Rock Bolts in Jointed Rock and Factors of InfluenceДокумент29 страницSpang - Egger - Action of Fully Grouted Rock Bolts in Jointed Rock and Factors of InfluencegianniorlatiОценок пока нет

- Design of Simple Drapery Systems For Rock Cuts and Natural SlopesДокумент8 страницDesign of Simple Drapery Systems For Rock Cuts and Natural SlopesmatteoОценок пока нет

- Shotcrete Design GuidelinesДокумент36 страницShotcrete Design GuidelinesJose MartinezОценок пока нет

- CHAPTER 2 - Part 1 Air Conditioning System PDFДокумент77 страницCHAPTER 2 - Part 1 Air Conditioning System PDFazmie100% (1)

- Seismic Slope Stability (CruzLaconsayTamayo)Документ43 страницыSeismic Slope Stability (CruzLaconsayTamayo)Glenn Gil TamayoОценок пока нет

- Proceedings Rockfall PDFДокумент131 страницаProceedings Rockfall PDFChin Thau WuiОценок пока нет

- RS2 Stress Analysis Verification Manual - Part 1Документ166 страницRS2 Stress Analysis Verification Manual - Part 1Jordana Furman100% (1)

- Brunet Giacchetti - Secured DraperyДокумент20 страницBrunet Giacchetti - Secured DraperymaccaferriasiaОценок пока нет

- Design Software For Secured Drapery - Brunet, GiacchettiДокумент22 страницыDesign Software For Secured Drapery - Brunet, GiacchettiKYLEОценок пока нет

- Calculation Spreadsheet Hexagonal Mesh - MaccaferriДокумент4 страницыCalculation Spreadsheet Hexagonal Mesh - MaccaferrianggaxkusumaОценок пока нет

- Steelgrid HR Installation Manual NZДокумент28 страницSteelgrid HR Installation Manual NZoscar rodriguezОценок пока нет

- Soil Nailing With Flexible Structural Facing - Design and ExpДокумент6 страницSoil Nailing With Flexible Structural Facing - Design and ExptehОценок пока нет

- Soil Nailing For Stabilization of Steep Slopes NeaДокумент216 страницSoil Nailing For Stabilization of Steep Slopes NeanidhisasidharanОценок пока нет

- RockfallДокумент6 страницRockfallkaustubhОценок пока нет

- 16 BARRIERS Grimod Giacchetti - GeoHaz6Paper116 - 2014 - enДокумент11 страниц16 BARRIERS Grimod Giacchetti - GeoHaz6Paper116 - 2014 - enmaccaferriasiaОценок пока нет

- 1999 Stability of Large Excavations in Laminated Hard Rock Masses The Voussoir Analogue Revisited PDFДокумент21 страница1999 Stability of Large Excavations in Laminated Hard Rock Masses The Voussoir Analogue Revisited PDFSumanОценок пока нет

- Bentomat Installation GuidelinesДокумент16 страницBentomat Installation GuidelinesAlessandraDaRochaFonsecaОценок пока нет

- Notes - Eng Geol of MelbourneДокумент6 страницNotes - Eng Geol of MelbourneRagha VendraОценок пока нет

- Superficial Consolidation of Rock SlopeДокумент7 страницSuperficial Consolidation of Rock SlopevictorОценок пока нет

- 82 Some Aspects Design Surface Tunnel PDFДокумент10 страниц82 Some Aspects Design Surface Tunnel PDFAjay SinghОценок пока нет

- Example of Hitched Plug DesignДокумент9 страницExample of Hitched Plug DesignRosalyMullisacaValenciaОценок пока нет

- Hydraulic Stability of Antifer Block Armour Layers Physical Model StudyДокумент10 страницHydraulic Stability of Antifer Block Armour Layers Physical Model Studyr_anzarОценок пока нет

- Structural Analysis Is A: Science, Having Definite ValueДокумент34 страницыStructural Analysis Is A: Science, Having Definite ValueRamanathan SenthilОценок пока нет

- Physics Problem Solving ExampleДокумент3 страницыPhysics Problem Solving Examplenathaniel borlazaОценок пока нет

- Metalworking 24479 Metaalbewerking UKДокумент21 страницаMetalworking 24479 Metaalbewerking UKOmkec DelalićОценок пока нет

- Laboratory Study On Pore Pressure Generation and Liquefaction of Low-Plasticity Silty Sandy Soils During The 2012 Earthquake in ItalyДокумент10 страницLaboratory Study On Pore Pressure Generation and Liquefaction of Low-Plasticity Silty Sandy Soils During The 2012 Earthquake in ItalyPinak RayОценок пока нет

- Mechanical Properties of FluidsДокумент66 страницMechanical Properties of FluidsAsian THUGОценок пока нет

- ASTM A1034 A1034M 2010a (Reapproved 2015)Документ5 страницASTM A1034 A1034M 2010a (Reapproved 2015)Mukesh kumarОценок пока нет

- FE700 Installation Manual Echo SounderДокумент58 страницFE700 Installation Manual Echo SounderNidhin.c.prakashОценок пока нет

- Blasius TheoremДокумент9 страницBlasius TheoremAhmed Assaf100% (1)

- Pipeliner® NR®-208-XP: (Applies Only To U.S. Products)Документ2 страницыPipeliner® NR®-208-XP: (Applies Only To U.S. Products)Pablo PazОценок пока нет

- Busch Scroll Vacuum Pump Fossa CatalogueДокумент2 страницыBusch Scroll Vacuum Pump Fossa CatalogueargpОценок пока нет

- Problems Solutions ReichlДокумент141 страницаProblems Solutions ReichlAndre0% (1)

- DENSO Robotics Datasheet VS-G Series PDFДокумент2 страницыDENSO Robotics Datasheet VS-G Series PDFjohnОценок пока нет

- G10 Ch03 Test 2024 01 AnsДокумент2 страницыG10 Ch03 Test 2024 01 AnsmethaethkОценок пока нет

- Scale Up of HSM GranulatorsДокумент15 страницScale Up of HSM Granulatorshicham1963Оценок пока нет

- 96463Документ45 страниц96463Paulo César Daqui LoureiroОценок пока нет

- 5.3 Code, Standard and RegulationДокумент7 страниц5.3 Code, Standard and Regulationandrieysyah2525Оценок пока нет

- CONTINUOUS CASTING ColloquiumДокумент18 страницCONTINUOUS CASTING ColloquiumakritiОценок пока нет

- Lecture 7. HumidificationДокумент29 страницLecture 7. HumidificationNOBLEMAN100% (1)

- Lesson Learned: Solution of The ProblemДокумент1 страницаLesson Learned: Solution of The ProblemRadovanZivanovicRashaОценок пока нет

- Enerpac PullerДокумент14 страницEnerpac PullerantonioОценок пока нет

- Black Holes, Singularities and Information Loss - Richard P DolanДокумент5 страницBlack Holes, Singularities and Information Loss - Richard P DolancolordiamondsОценок пока нет