Академический Документы

Профессиональный Документы

Культура Документы

1 s2.0 S0009250912004538 Main PDF

Загружено:

Leilane AndradeИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

1 s2.0 S0009250912004538 Main PDF

Загружено:

Leilane AndradeАвторское право:

Доступные форматы

Modeling of mass and heat transfer during combined processes of osmotic

dehydration and freezing (Osmo-Dehydro-Freezing)

Athanasia M. Goula

n

, Harris N. Lazarides

Department of Food Science and Technology, Faculty of Agriculture, Aristotle University of Thessaloniki, Thessaloniki, Greece

H I G H L I G H T S

c A new methodology was developed to describe Osmo-Dehydro-Freezing (ODF).

c The proposed model was not empirical but was based mainly on structural data.

c The proposed model allowed accurate prediction of temperature and phase changes.

c The proposed model allowed accurate prediction of solute and water concentrations.

c The model presents excellent prediction ability in contrast to an empirical model.

a r t i c l e i n f o

Article history:

Received 24 April 2012

Received in revised form

29 June 2012

Accepted 13 July 2012

Available online 24 July 2012

Keywords:

Drying

Food processing

Heat transfer

Mass transfer

Freezing

Osmotic dehydration

a b s t r a c t

A successive mass and heat transfer modeling approach was developed to describe the Osmo-Dehydro-

Freezing (ODF) process. The dehydration process was described by an osmotic diffusion model based on

mass transfer through cellular membranes and the diffusion of different species through intercellular

spaces. Modeling of the freezing step was carried out by means of a numerical method, which includes

the phase change phenomena in thermal balance equations through the value of enthalpy. Thus, the

equations were solved in the whole system as if it were constituted by a single phase. As a result, the

balance was transformed into a transient problem with temperature dependent properties. The

simulation of the ODF process was successfully validated with experimental results obtained on

tomato cubes (R

2

0.9970.999; RMSE0.1560.252). The predicted temperature proles almost

coincided with experimental data. This was not the case with a selected, regularly used empirical

model, which was used for comparison reasons. The prediction deviations of the tested empirical model

were not only large, but they were constantly and signicantly increasing with increased

dehydration times.

& 2012 Elsevier Ltd. All rights reserved.

1. Introduction

The increase in consumer preference for minimally processed

fruits and vegetables has prompted researchers to study combined

methods as a preservation technique. The synergistic or additive

effect of combined inhibiting factors may permit the production of

food with improved quality over that preserved by only one techni-

que, e.g. heat treatment, dehydration or freezing (Bunger et al., 2004).

Freezing is a suitable way to preserve certain quality parameters

of foods, like color, avor, and nutrients. During freezing, part of the

aqueous fraction freezes out and forms ice crystals that damage the

integrity of the cellular compartments. The cellular membranes lose

their osmotic properties and their semi-permeability (Tregunno and

Goff, 1996). The metabolic activity of the plant tissue is interrupted,

inactivation of the enzymatic system occurs and the cell loses its

turgor. Besides the change in texture, bio-chemical deterioration

reactions are probable (Talens et al., 2003). Dehydration can be

applied as a pre-treatment before freezing, to remove part of the

water in order to facilitate the freezing process. As a result, damage

of the cellular membranes is minimal and better conservation of the

food properties is achieved.

In this sense, osmotic dehydration was reported as a highly

benecial pre-treatment (Forni et al., 1987; Robbers et al., 1997).

During osmotic processing, the product is in contact with a low

water activity solution (i.e. salt and/or sugar solutions), in an

oxygen free environment, resulting in protection from oxidizing

reactions. Under these conditions a two-way mass transfer is

established: (i) water is transferred from the product to the

solution, often accompanied by limited leaching of natural sub-

stances (i.e. sugars, vitamins, pigments, avors) (Lazarides et al.,

Contents lists available at SciVerse ScienceDirect

journal homepage: www.elsevier.com/locate/ces

Chemical Engineering Science

0009-2509/$ - see front matter & 2012 Elsevier Ltd. All rights reserved.

http://dx.doi.org/10.1016/j.ces.2012.07.023

n

Corresponding author. Tel./fax: 30 2310 991658.

E-mail address: athgou@agro.auth.gr (A.M. Goula).

Chemical Engineering Science 82 (2012) 5261

1997), and (ii) osmotic solute is transferred from the solution to

the product. While solute transfer is assumed to be of the

diffusional type, the fact that water loss is greater than solid gain

is attributed to a selective osmotic transport across semipermeable

cellular membranes (Spiazzi and Mascheroni, 1997). According to

previous studies, solute penetration is conned to extracellular

spaces (Marcotte, 1988). Isse and Schubert (1991) showed that

sucrose passes through the cell wall and accumulates between the

cell wall and the cellular membrane, where it forms a hypertonic

solution leading to water outux through the cellular membrane.

Other authors have suggested that water loss is greater than solute

gain only because of differences between the diffusion coefcient

of water and solute in the product (Karel, 1975). The existence of

these simultaneous and opposite mass uxes is one of the main

difculties arising when modeling mass transfer in osmotic dehy-

dration. In addition, these uxes take place in non-equilibrium

conditions and they are accompanied by product shrinkage and

deformation, as well as interactions between the two different

ows (Biswal and Le Maguer, 1989; Floury et al., 2008).

The process of freezing osmotically dehydrated foods is known as

Osmo-Dehydro-Freezing (ODF). Depending on process conditions,

up to 50% of initial moisture can be removed in liquid form, at

ambient temperatures within a fairly short process time (i.e. 23 h).

The drastic reduction in moisture content results in major process

and product benets, including (1) better preservation of structural

and quality characteristics; (2) lower cost of packaging, distribution,

and storage; and (3) large reduction in refrigeration load and energy

demands during freezing of the remaining water. Despite these

benets, industrial exploitation of ODF is still rather limited, due to

difculties regarding osmotic solution management as well as

modeling and predicting transport phenomena, a requirement for

effective process control (Agnelli et al., 2005).

Process simulation during ODF is a difcult task, as two

different transport phenomena are involved: (1) mass transfer of

solids and water between the product and the osmotic solution

during osmotic dehydration and (2) heat transfer with phase

change during freezing. The mass exchange prole in the dehydra-

tion step naturally affects thermophysical properties, with a strong

impact on heat transfer and the phase change prole during the

subsequent freezing step. A number of studies have tried to model

mass transfer during OD and different types of models have been

proposed (Park et al., 2002; Waliszewski et al., 2002; Giraldo et al.,

2003; Moreira and Murr, 2004; Ochoa-Martnez and Ayala-Aponte,

2005). Two main approaches can be identied: mechanistic models

based on Ficks law (Crank, 1975) and empirical or semi-empirical

models, such as those suggested by Raoult-Wack et al. (1991),

Azuara et al. (1992), Palou et al. (1994) and Parjoko et al. (1996);

and polynomial ttings (i.e. Rahman et al., 2001). On the other

hand, many studies have focused on modeling of the freezing

process (e.g. Cleland et al., 1984; Califano and Zaritzky, 1997;

Delgado and Sun, 2001; Pham, 2006; Wang et al., 2007).

However, limited research has been achieved with regard to

the process simulation during ODF (Agnelli et al., 2005). The

objective of this work was to develop a successive mass and heat

transfer modeling methodology to describe both transport phe-

nomena that are successively taking place during ODF. Such an

approach could prove useful to similar process combinations

involving heat and mass transfer.

2. Materials and methods

2.1. ODF experiments

Raw fresh tomato fruits (Cherokee variety) were purchased at

local markets and stored at 5 1C before use. Fresh tomatoes were

cut into 1.5 cm cubes. Solutions of 55 w/w% carbohydrate in

distilled water were prepared. The carbohydrates selected were

sucrose and 21 DE maltodextrin (Glucidex1, Roquette, France).

Osmotic treatment was conducted in 1 L containers placed in a

temperature controlled water bath (Memmert, Model WNE 7,

Memmert GmbH Co. KG, Schwabach FRG, Germany) at 3571 1C.

The ratio of food to osmotic medium was maintained at 1:25

(35 g of tomato sample:875 g of osmotic medium) in order to

ensure that the concentration of the osmotic solution did not

change signicantly during the experiment. During the 24 h

osmotic dehydration process, triplicate samples were taken after

0, 5, 15, 30, 60, 90, 120, 150, 180, 240, 300, 360, 480, 600, 840,

1080, and 1410 min. The samples were rinsed with distilled

water, blotted with absorbent paper and weighed. The evolution

of mass exchange was followed by monitoring water loss (WL)

and solid gain (SG)

WL

M

0

m

0

Mm

m

0

1

SG

mm

0

m

0

2

where M

0

is the initial mass of fresh tomatoes; M is the mass of

tomatoes after time t of osmotic treatment; m is the dry mass of

tomatoes after time t of osmotic treatment; and m

0

is the dry

mass of fresh tomatoes.

The dry mass of tomatoes was determined by drying in a

vacuum oven at 80 1C until consecutive weighings, made at 2-h

intervals, showed less than 0.3% variation.

After the dehydration step, the samples, suspended on a wire,

were frozen at 40 1C (Sanyo MIR 553, Sanyo Electric Co.,

Ora-Gun, Gunma, Japan). The temperature measurement was pro-

vided by a type T thermocouple (GG-TI-28, Omega Engineering,

Stamford, CT), 0.5 mm in diameter, with an accuracy of 70.1 1C.

All experiments were done in triplicate and average values

were used. Additional (parallel) samples were analyzed if a single

value deviated more than 2% from the triplicate mean.

2.2. Microstructure analysis

Samples of tomato cubes tissue, about 10 mm thick, were

obtained using a microtome. They were placed on a glass plate

and dehydrated for one day at room temperature. Samples were

poured onto microscope slides, stained with methylene blue

solution (1 w/v%), covered with glass cover slips, and observed

using an optical microscope (Axiolab A, Carl Zeiss GmbH, Jena,

Germany) with 40 and 100 objective lenses. Images of each

sample were analyzed with the public domain software Image J

v1.36b (http://rsb.info.nih.gov/ij/).

2.3. Mass transfer modeling

According to Floury et al. (2008), during osmotic treatments mass

transfer follows three different pathways: (a) transport through the

cellular volume (symplastic transport); (b) transport within the

extracellular volume (free-space transport); (c) transport across the

cell membrane (apoplastic transport). In this work, a diffusional

model was developed taking into account mass transfer through

cellular membranes and diffusion of different species through inter-

cellular spaces, based on the microstructural properties of the product

tissue. This model distinguishes between cellular, intercellular and

trans-membrane diffusion, and also taking volume changes into

proper account. Its application is not free of tting, but the number

of tted parameters was reduced to a reasonably selected minimum

A.M. Goula, H.N. Lazarides / Chemical Engineering Science 82 (2012) 5261 53

by use of structural data, correlations from the literature and well

founded estimations, wherever possible.

The mass balance for each species (i) (i w for water, i s/m for

sucrose/maltodextrin) within the product can be expressed as

@ V

c

c

i

int

_ _

@t

r V

c

D

int

ef f

rc

int

i

_ _

A

m

J

i

in the cellular volume 3

@ V

e

c

ext

i

_ _

@t

r

V

e

t

D

ext

ws=m

rc

ext

i

_ _

A

m

J

i

in the extracellular volume

4

where V

c

is the cellular volume per m

3

initial total volume; c

i

int

is

the cellular molar concentration of species (i); D

eff

int

is the effective

diffusion coefcient in the cellular volume; A

m

is the surface area

per m

3

initial total volume; J

i

is the molar ux of species (i) from

the cellular volume into the extracellular volume through the cell

membrane; V

e

is the extracellular volume per m

3

initial total

volume; c

i

ext

is the extracellular molar concentration of species (i);

t is the tortuosity factor; and D

ext

ws=m

is the binary diffusion

coefcient in the extracellular volume.

During osmotic dehydration, the cellular and extracellular

volumes change with both time and position. It was assumed

that all the cellular volume changes are due to the ux across the

membrane (Eq. (5)), whereas the extracellular volume was

considered proportional to the sum of sucrose/maltodextrin and

water volumes (Eq. (6))

@V

c

@t

A

m

v

w

J

w

v

s=m

J

s=m

_ _

5

V

e

c

ext

w

v

w

c

ext

s=m

v

s=m

c

ext

w0

v

w

c

ext

s=m0

v

s=m

V

e0

6

where v is the molar volume of water (v

w

1.810

5

m

3

mol

1

),

sucrose and maltodextrin (v

s

21.110

5

m

3

mol

1

, v

m

120.5

10

5

m

3

mol

1

).

Dimensional changes in the solid will affect concentration and

temperature gradients and this was taken into account by using a

grid based on the original position within the solid. The effect of

expansion was taken into account by dividing the gradients by a

linear expansion factor S (Floury et al., 2008):

S V

T

1=3

V

c

V

e

1=3

7

Thus, Eqs. (3) and (4) become

V

c

@c

int

i

@t

1

S

r

V

c

S

D

int

ef f

rc

int

i

_ _

A

m

J

i

c

int

i

@V

c

@t

8

V

e

@c

ext

i

@t

1

S

r

V

e

S

D

ext

ws=m

t

rc

ext

i

_ _

A

m

J

i

c

ext

i

@V

e

@t

9

The initial concentrations of species (i) in cellular and extra-

cellular volumes were assumed to be equal to

c

int

i,0

c

ext

i,0

x

i,0

r

M

i

10

where x

i

,

0

is the initial mass fraction of species (i), M

i

is the

molecular weight of species (i), and r is the initial density of the

tomato cube (1017 kg mol

1

).

The cellular volume fraction V

c

of the material was determined

by digitally measuring the area occupied by the void phase in the

image of the plane section. The darker regions in the micrograph

were mainly the cytoplamic membrane and the cell walls,

whereas the brighter regions were holes where cell contents

had been. The surface area A

m

was estimated based on the

average diameter of the cells, d, measured from the micrographs

(d83 mm):

A

m

6V

c

d

11

The resistance to mass transfer of sucrose or maltodextrin

from cell to cell is extremely large (Spiazzi and Mascheroni,

1997); thus, its effective diffusion coefcient in the cellular space

was considered negligible. The binary diffusion coefcient can be

estimated from the StokesEinstein equation (Eq. (12)), knowing

the apparent hydrodynamic radius and the viscosity of the

osmotic solution (Saravacos, 2005):

D

ws=m

k

B

T

6pr

B

n

12

where k

B

is Boltzmanns constant (1.3810

23

J mol

1

K

1

); r

B

is

the apparent hydrodynamic radius (4.910

10

m); and n is the

solution viscosity, which is evaluated using the following empiri-

cal equation (Chenlo et al., 2002; Floury et al., 2008):

n

995:20:1284c

s=m

_ _

Un

w

r

w

10:73

c

s=m

995:20:1284c

s=m

_

exp

c

s=m

=995:20:1284c

s=m

_ _

1:10

8:345 T=273:1

_ _

7:402

_ __

13

where c

s

/

m

is the molar concentration of sucrose or maltodextrin;

n

w

is the water viscosity; and r

w

is the water density.

The effective diffusion coefcient of water was calculated as

D

int

ef f

1

D

ws=m

A

m

15 10

7

_ _

1

14

The driving force for the apoplastic transport of solutes and

water across the cell membrane is the chemical potential differ-

ence between the solutions in the cellular and extracellular

spaces:

J

i

L

m,i

UDm

i

15

The macroscopic phenomenological coefcient L

m

,

i

, which

describes the permeability characteristics of the membrane to

solute (i), and the difference in chemical potential of water and

sucrose or maltodextrin across the membrane, Dm

i

, was calcu-

lated as

L

m,i

P

m,i

U~ c

i

16

Dm

i

RTDlna

w

17

where P

m

,

i

is a macroscopic permeability coefcient for species (i),

assumed to be concentration independent; ~ c

i

is the average

concentration of solute (i) across the membrane for which a

chemical potential difference is considered (Eq. (18)); and a

w

is

the water activity estimated in both the cellular and extracellular

spaces using the Norrish equation (Eq. (19)) (Floury et al., 2008):

~ c

i

V

c

UC

int

i

V

e

UC

ext

i

18

a

w

X

w

e

kX

s=m

2

19

where X

w

and X

s/m

are the mole fractions of water and sucrose or

maltodextrin, respectively, and k is a constant (k2.6).

Since there was no data for the permeability of the membrane

to sucrose and maltodextrin, their trans-membrane ux was

assumed to be a xed ratio of the water ux across the membrane

as follows:

J

s=m

r

s=m

v

w

v

s=m

J

w

20

where r

s/m

is the volume ux ratio for sucrose or maltodextrin.

The tortuosity factor, t, was dened in terms of the effective

path length (L

e

) that a migrating molecule has to travel on average

A.M. Goula, H.N. Lazarides / Chemical Engineering Science 82 (2012) 5261 54

in the interstitium compared with the distance covered normal to

the surface (L). This path was estimated from image processing of

microscopic views of tomato cells. A ruler available in the image

processing software was used to measure L

e

from micrographs.

There are two unknown parameters in the model; the mem-

brane permeability, P

m,w

, and the volume ux ratio, r

s/m

. Their

values, ranging from 5.610

15

to 5.610

7

mol N

1

s

1

and

from 0 to1, respectively (Maourel, 1997; Floury et al., 2008), were

determined by empirical curve tting in order to improve the

agreement between predicted and experimental data of WL and

SG. They were found equal to 5.610

10

mol N

1

s

1

(P

m,w

), 0.5

(r

s

), and 0.4 (r

m

). However, using these values the model did not

describe adequately the early part of the WL/SGt curves. This

may be due to the fact that the tortuosity has not been estimated

properly. Thus, its value was adjusted and it was found that a t of

1.1 gave a better t than the t of 1.8 derived from image analysis.

2.4. Heat transfer modeling

At the end of the dehydration process, the concentration

prole of each species inside the product was successively

introduced in the heat transfer balance equation in order to solve

the successive mass and heat transfer problem. The numerical

model was developed using the enthalpy balance equation. The

thermal balance was expressed by

r

@H

@t

r krT 21

where H is the product enthalpy and k is the thermal conductivity.

This equation was solved with the enthalpy as the unknown

variable on a xed grid. Consequently, the knowledge of H allows

calculating the value of the temperature in each point of the grid.

Then, the thermal conductivity and the position of the freezing

front can be deduced. This calculation approach presents the

advantage of reducing sensitivity to the abrupt variation of the

thermal properties within the phase change regime (Agnelli and

Mascheroni, 2001).

The thermal balance was solved using an explicit scheme. The

discretization of the equation was carried out by the nite volume

method in such a way that thermal uxes are conservative (Tocci

and Mascheroni, 1995). The following initial and boundary con-

ditions were used

T T

0

for t 0 22

h T

a

T

s

krT for z L=2 23

where h is the heat transfer coefcient; T

a

is the freezing air

temperature; T

s

is the temperature of the product surface; z is the

position variable; and L is the product thickness. The temperature

dependence of enthalpy was expressed by the correlations pro-

posed by Chang and Tao (1981). Specically, for temperatures

above freezing, the specic heat capacity is a weighed average

based on the composition of the unfrozen product

Cp x

w

UCp

w

x

s

UCp

s

24

where x

w

and x

s

are the mass fractions of water and solids,

respectively, and Cp

w

and Cp

s

are the specic heat capacities of

water and solids, respectively, which are functions of temperature

(Choi and Okos, 1986):

Cp

w

41760:091UT 0:00547UT

2

25

Cp

s

15491:962UT 0:00594UT

2

26

where T is in 1C and Cp is in J kg

1

K

1

.

For temperatures below freezing, enthalpy was calculated by

the following equations (Chang and Tao, 1981):

H H

f

aUT

r

1a T

r

b

_ _

27

H

f

9792:46405096Ux

w

28

T

r

T227:6

T

f

227:6

29

a 0:3620:0498U x

w

0:73 3:465U x

w

0:73

2

30

b 27:2129:04U a0:23 481:46U a0:23

2

31

T

f

287:5649:19Ux

w

37:07Ux

w

2

32

where H

f

is the freezing enthalpy (in J kg

1

); a and b are

constants; T

r

is a ratio of temperature differences; and T

f

is the

freezing point (in K). The unfrozen water in the product was

calculated by Eq. (32) (Moore, 1972)

l

R

1

T

f w

1

T

_ _

lnX

w

33

where l is the heat of fusion per mole of pure water

(6003 J mole

1

); R is the universal gas constant (8.314 J mole

1

K),

and T

fw

is the freezing point of pure water.

The conductivity and density of the mixtures were obtained by

equations in which the contributions of water, ice, and soluble

solids were considered (Heldman, 1982)

1

r

x

w

r

w

x

s

r

s

x

I

r

I

34

k r k

w

x

w

r

w

k

s

x

s

r

s

k

I

x

I

r

I

_ _

35

where r is the density; k is the thermal conductivity; x is the mass

fraction; and the subscripts w, s, and I refer to water, solids, and

ice, respectively. The temperature dependence of components

densities and thermal conductivities was expressed by the equa-

tions proposed by Choi and Okos (1986):

r

w

9970:00314UT0:00376UT

2

36

r

s

16000:366UT 37

r

I

9170:131UT 38

k

w

0:5710:00176UT6:70U10

6

UT

2

39

k

s

0:2010:00139UT4:33U10

6

UT

2

40

k

I

2:2190:00625UT 1:01U10

4

UT

2

41

where T is in 1C, r is in kg m

3

, and k is in W m

1

K

1

.

The heat transfer coefcient was experimentally determined

from the thermal history of an aluminum cube. The cube was

pierced at mid-height along a side in order to place a thermo-

couple in the center of the body. The h value was calculated

solving the heat transfer balance, assuming a constant tempera-

ture in the interior of the body. This is true due to the high

thermal conductivity for aluminum. Thus, the thermal ux of the

aluminum body is given by

m

al

Cp

al

dT

al

dt

hA

al

T

a

T

al

42

where m

al

is the mass of the aluminum body; Cp

al

is its heat

capacity; T

al

is its temperature; and A

al

is its surface area.

A.M. Goula, H.N. Lazarides / Chemical Engineering Science 82 (2012) 5261 55

Integrating, we obtain

ln

T

a

T

al

T

a

T

al0

lnT

n

hA

al

m

al

Cp

al

t 43

Plotting ln T* versus t and calculating the slope, the h value

was found to be equal to 47 W m

2

K

1

.

The model was implemented using a three-dimensional cubic

geometry. All the above equations are solved numerically using

the Matlab program. The mass balance was solved using an

explicit scheme. The discretization of the equation was carried

out by the nite volume method.

2.5. Empirical model

The temperature proles that were predicted by the developed

mechanistic model were compared to those obtained by separate

modeling of mass transfer during OD using a selected empirical

model. Many empirical models have been developed to describe

OD. According to Ochoa-Martinez et al. (2007), who compared

various empirical models using an extensive group of experi-

mental conditions from 25 studies, Azuaras model ts the mass

transfer kinetics data better than any other model. A similar

observation was reported by many other authors (Rahman and

Lamb, 1990; Kar and Gupta, 2001; Singh et al., 2007). According to

Azuaras model (Azuara et al., 1992), a mass balance for water is

given by

WL WL

p

M

w

m

44

where WL

p

is the water loss at equilibrium and M

w

m

is the mass of

water that is able to diffuse but remains inside the product at

time t. For constant temperature and osmotic solution concentra-

tion, the moisture loss is a function of the time and the amount of

water that can diffuse

WL s

1

UtUM

w

m

45

Substitution of Eq. (45) into Eq. (44) leads to Eq. (46), whereas,

in an analogous way, Eq. (47) is obtained for the solids gain:

WL

s

1

UtUWL

p

1s

1

Ut

46

SG

s

2

UtUSG

p

1s

2

Ut

47

where s

1

and s

2

are parameters that can be dened as relative rate

constants for water loss and solids gain, respectively. Eqs. (46)

and (47) can be linearized to yield:

t

WL

1

s

1

UWL

p

t

WL

p

48

t

SG

1

s

2

USG

p

t

SG

p

49

Eqs. (48) and (49) constitute the so-called Azuaras model.

2.6. Statistical analysis

In order to evaluate the accuracy of the proposed mechanistic

model, the predicted values of product temperature during

freezing for all ODF experiments were compared to the experi-

mental ones. Linear regression and paired t-test were applied. The

proposed model was evaluated by the correlation coefcient (R

2

)

and by the standard error of prediction (SE). However, SE was

adjusted for systematic difference (bias corrected) in RMSE, which

is the root mean square error.

3. Results and discussion

3.1. Concentration proles

Fig. 1 presents the predicted solute concentration proles

along half sample thickness (z

1/2

) for the specic process time

increments. These proles were obtained by mass balance calcu-

lations during the dehydration process. The x-axis represents

normalized distance (z/z

1/2

) from sample center. Lower solute

diffusion rates can be observed for maltodextrin solution (Fig. 1b)

compared to sucrose (Fig. 1a) for each and every process time.

This is due to higher solute size and it is in agreement with

ndings of previous studies (Lazarides et al., 1995). As it can be

seen, the external zones have higher (than average) contents of

solute; yet, within the given periods of contact, these zones did

not exactly reach equilibrium with the osmotic solution. The

solute content of inner zones increased with process time due to

diffusion from the external layers. Thus, the penetration of solutes

in the product during typically used periods of osmotic dehydra-

tion (about 34 h) is only important for the sub-surface zone.

Higher solid contents in the external zones act as a barrier

to further transport of solutes from the osmotic solution.

Thus, during the rst 3 h, the solute gain for the internal layers

0

10

20

30

40

50

60

0.0

C

o

n

c

e

n

t

r

a

t

i

o

n

(

%

)

60 min

180 min

300 min

480 min

1410 min

0

10

20

30

40

50

60

C

o

n

c

e

n

t

r

a

t

i

o

n

(

%

)

60 min

180 min

300 min

480 min

1410 min

z /z

1/2

z /z

1/2

0.2 0.4 0.6 0.8 1.0 1.2 0.0 0.2 0.4 0.6 0.8 1.0 1.2

Fig. 1. Concentration proles of sucrose (a) and maltodextrin (b) along normalized sample thickness (z/z

1/2

) as a function of dehydration time in sucrose (a)

and maltodextrin (b) solution.

A.M. Goula, H.N. Lazarides / Chemical Engineering Science 82 (2012) 5261 56

(z/z

1/2

o0.5) is practically negligible, due to the low rate of mass

transfer by diffusion in the bulk of the solid.

The above observation is similar to that reported by Chenlo

et al. (2006, 2007), who developed a logistic doseresponse model

to describe the osmotic kinetics and to obtain the pseudo-

equilibrium moisture and solute content during osmotic dehy-

dration of chestnut. In addition, the proles presented in Fig. 1

can be compared to those obtained for apple halves treated in 50%

sucrose solutions (Monnerat et al., 2006). In that case, the data

analysis showed a quickly equilibrated layer close to the surface

and a constantly advancing disturbance front, dened by the

authors as an imaginary plane located between the outer zone,

which is affected by the mass transfer, and the inner zone,

without substantial concentration changes. Yao and Le Maguer

(1997) also observed the sucrose front moving as a sharp

concentration ridge, which was more pronounced in proles

encountered with high solute concentrations (50%). It is possi-

ble that the high concentrations caused additional structural

changes due to the shrinking tissue. The conjunction of these

factors leads to higher effective diffusion coefcients in the

surface region and lower coefcients in the inner region, an

inverse behavior when compared to that occurring in the diffu-

sivity in pure sucrosewater solutions (Henrion, 1964).

The experimental (means of three replicates) and calculated

values of water loss and solid gain during osmotic dehydration of

tomato cubes are given in Figs. 2 and 3. The repeatability for the

WL and SG measurements, expressed as the average standard

deviation of all triplicate calculations, were 0.67% and 0.28% for

WL and SG, respectively. The WL and SG considerably increased

with increasing contact time. High rates of water removal and

solids uptake during the rst hours were followed by slower rates

in later stages. This may be due to the progressive decrease in the

driving potentials for moisture and solute transfer as a result of

extensive mass exchange within the rst hours. In addition,

progressive solids uptake may result in the formation of a high

solids sub-surface layer, which interferes with the concentration

gradient across the productsolution interface, acting as a barrier

against further removal of water and uptake of solids. The water

loss in the rst six hours was 37% and 46% for solutions of sucrose

and maltodextrin, respectively; these values are much lower than

the ones reported by other researchers (Andrade et al., 2007).

Equilibrium was practically reached after 10 and 18 h of osmotic

processing for sucrose and maltodextrin, respectively. Beyond

equilibrium, water loss and solids gain remained literally con-

stant. Askar et al. (1996) and Panagiotou et al. (1999) reported

shorter equilibrium times (4 h) in osmotic dehydration of

several fruits and vegetables. This difference may be due to the

type of tomato membrane, which is characterized as differentially

permeable and not semipermeable (Andrade et al., 2007). In

addition, the osmotic dehydration in sucrose, which has a lower

molecular weight, caused higher solids gain and lower water loss

compared to OD in maltodextrin. This observation may be

attributed to the fact that solutes of low molecular weight favor

solute impregnation rather than water loss (Lazarides et al., 1995;

Dermesonlouoglu et al., 2007).

0

10

20

30

40

50

60

0

Osmotic dehydration time (min)

sucrose

maltodextrin

mechanistic model

empirical model

W

L

(

%

)

300 600 900 1200 1500

Fig. 2. Water loss (WL) as a function of dehydration time in sucrose and

maltodextrin solution; square symbols correspond to experimental values, while

lines correspond to predicted values using two different models (a proposed

mechanistic and a selected empirical).

0

2

4

6

8

10

12

0

Osmotic dehydration time (min)

sucrose

maltodextrin

mechanistic model

empirical model

S

G

(

%

)

300 600 900 1200 1500

Fig. 3. Solids gain (SG) as a function of dehydration time in sucrose and

maltodextrin solution; square symbols correspond to experimental values, while

lines correspond to predicted values using two different models (a proposed

mechanistic and a selected empirical).

0

20

40

60

80

100

120

140

160

0

WL -sucrose

WL -maltodextrin

SG -sucrose

SG -maltodextrin

t

/

W

L

o

r

t

/

S

G

Osmotic dehydration time, t (min)

300 600 900 1200 1500

Fig. 4. Linear plots of Azuaras model during osmotic dehydration in sucrose and

maltodextrin solutions.

A.M. Goula, H.N. Lazarides / Chemical Engineering Science 82 (2012) 5261 57

Figs. 2 and 3 show that there is a close agreement between

experimental and predicted values of WL and SG by both the

proposed mechanistic and the selected empirical model. The

determination coefcient values were in the range of 0.976

0.997 showing a good t of both models to the experimental

data. The lack of t test applied to the replicated data showed that

the models adequately described the moisture loss and solid gain

in the tomato cubes. The L-values, which were calculated from

independent and dependent estimators of residual standard

deviations for both moisture loss and solid gain, were less than

the upper tail cut-off value obtained from F-distribution, con-

rming the validity of the proposed models for an osmotic

dehydration process.

The values of t/WL and t/SG as calculated from the moisture

loss and solid gain data for the two different carbohydrate

solutions were plotted against time (Fig. 4). A linear trend was

observed in all cases. Straight lines were, therefore, tted by

performing linear regression and the parameter values were

determined. The values of s

1

and WL

N

for moisture loss kinetics

and of s

2

and SG

N

for solid gain kinetics are given in Table 1.

The residual analysis presented in Fig. 5 clearly shows that, for

most of the investigated processing times, much smaller differ-

ences between predicted and experimental values were observed

for the proposed mechanistic model compared to the empirical

one. This can also be veried through the statistical parameters R

2

and RMSE presented in Table 1. Generally speaking, the selected

empirical model seems to be quite accurate for certain processing

times, but it is not accurate enough over the entire range of

processing times. This may be the case because the empirical

model does not take into account the size, shape, and structure of

the material and it does not consider crucial process variables,

such as temperature, concentration, solution-to-fruit mass ratio

or agitation.

3.2. Temperature proles

As mentioned earlier, the concentration prole of each species

inside the product was successively introduced into the heat

transfer balance equation. Fig. 6 presents the experimental

(means of three replicates) and predicted temperature proles

of the product center during freezing of osmo-dehydrated tomato

cubes for specic dehydration times. The repeatability for the

temperature measurement, expressed as the average standard

deviation of all triplicate calculations, was 0.7 1C. As it can be

seen, each temperature curve presented three stages. The rst

stage corresponds to a rapid temperature decrease due to the

removal of sensible heat. This was followed by a period of much

slower temperature decrease, attributed to prevailing latent heat

removal for water crystallization. According to Wang et al. (2007),

the heat transfer effect mainly contributes to ice formation with a

minor simultaneous impact on temperature change. After the

center is frozen, there is no more latent heat to be released, the

apparent specic heat decreases, the coefcient of heat conduc-

tivity increases, and the center temperature decreases rapidly,

due to the removal of sensible heat once again.

The kinetic curves of the temperature change in the product

center predicted by the specic mechanistic model are in good

agreement with the experimental results. R

2

and RMSE ranged

from 0.997 to 0.999 and from 0.156 to 0.252, respectively. In

addition, the proposed model predicts the freezing times more

accurately than the approximate solution methods usually used

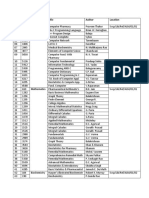

Table 1

Parameters of the proposed mechanistic and the selected empirical model tted to experimental data of osmotic dehydration in sucrose and maltodextrin solutions.

Parameter Sucrose solution Maltodextrin solution

Water loss Solid gain Water loss Solid gain

Mechanistic Empirical Mechanistic Empirical Mechanistic Empirical Mechanistic Empirical

R

2

0.996 0.985 0.995 0.991 0.999 0.994 0.997 0.992

RMSE 0.313 0.489 0.086 0.091 0.102 0.372 0.048 0.072

WL

N

or SG

N

(%) 48.077 11.947 57.804 10.152

s

1

or s

2

(min

1

) 0.0084 0.0085 0.0092 0.0086

-3

-2

-1

0

1

2

0

R

e

s

i

d

u

a

l

(

%

)

Osmotic dehydration time (min)

WL -mechanistic model

WL -empirical model

SG -mechanistic model

SG -empirical model

-3

-2

-1

0

1

2

0

R

e

s

i

d

u

a

l

(

%

)

Osmotic dehydration time (min)

WL -mechanistic model

WL -empirical model

SG -mechanistic model

SG -empirical model

300 600 900 1200 1500

300 600 900 1200 1500

Fig. 5. Residuals between predicted (by the proposed mechanistic and the

selected empirical model) and experimental values of water loss (WL) and solids

gain (SG) during osmotic dehydration in sucrose (a) and maltodextrin (b) solution.

A.M. Goula, H.N. Lazarides / Chemical Engineering Science 82 (2012) 5261 58

to simulate freezing processes (Pham, 1996; Sanz et al., 1996,

1999; Lopez-Leiva and Hallstrom, 2003). This can be attributed to

the fact that approximate methods are based on revised Plank

equations; therefore they present three main disadvantages.

Firstly, they assume the existence of a two-phase interface, which

is, time-dependent and can be characterized as a moving

boundary zone. Secondly, the temperatures in approximate

solution methods are often average values; and thirdly, these

methods do not consider that freezing mainly occurs within a

short time-zone below the ice point and latent heat is mostly

released during this period.

In addition, as it can be seen in Fig. 6, the differences between

predicted and experimental data were much smaller when

modeling was based on the proposed mechanistic model, com-

pared to the empirical Azuaras model. This can also be veried

through the statistical parameters R

2

and RMSE, which ranged

from 0.997 to 0.999 and from 0.156 to 0.252, respectively, for the

mechanistic model, and from 0.875 to 0.952 and from 1.197 to

2.066, respectively, for the empirical model. As it follows from

Fig. 6(a)(c), the deviation between predicted and experimental

values for Azuaras model not only large, but it is constantly and

signicantly increasing with increased dehydration times. Thus,

the predictions of Azuaras model for WL and SG cannot be used to

accurately describe the freezing process following the osmotic

drying step.

According to Ispir and Togrul (2009), the empirical and semi-

empirical models may give a reasonable t to the experimental

data, but their use is quite limited, because they are strongly

dependent on the specic experimental conditions under which

they were produced. On the other hand, mechanistic models that

are strictly based on the diffusion approach use a number of

assumptions, which are difcult to fulll (Kaymak-Ertekin and

Sultanoglu, 2000), and effective diffusivity becomes an adjustable

kinetic parameter that strongly depends on the experimental

conditions and the physical properties of the product (Salvatori

et al., 1999). In addition, during osmotic dehydration, the cellular

and extracellular volumes change with both time and position

and these dimensional changes affect signicantly both concen-

tration and temperature gradients (Spiazzi and Mascheroni, 1997;

Li, 2006). In order to overcome these limitations, the proposed

mechanistic model is based on a cellular physiology approach

calculating the evolution of cellular and extracellular volumes and

the resulting (different) concentration values for the two volumes

(cellular and extracellular). For example, during dehydration in

sucrose solution for 60 min, in a region close to product/solution

interface, the cellular volume decreased to 54% its initial value,

while the extracellular volume increased by 32%. After 240 min,

these values were 16% and 67%, respectively, while in a region

closer to the center the respective values were 30% and 58%. After

about 600 min, conditions close to equilibrium were obtained; in

almost all regions of the cube, the cellular volume reaches a

minimum value (9% of the initial), while the extracellular volume

doubles. As a result the percentage of cellular volume with

respect to the total volume reduces to 29%, from an initial value

of 80% in the fresh product. The accurate calculation of volume

and concentration changes for both cellular and extracellular

volumes naturally leads to an accurate prediction of temperature

gradients (Floury et al., 2008). On the contrary, using Azuaras

model, a at concentration prole for water and solids is assumed

and the difference between cellular and extracellular volumes is

not considered. Due to these limitations, despite its accurate WL

and SG predictions, Azuaras model seems unsuitable for simulat-

ing transport phenomena in a successive mass and heat transfer

methodology.

-40

-30

-20

-10

0

10

20

30

0

Freezing time (min)

sucrose

maltodextrin

mechanistic model

empirical model

sucrose

maltodextrin

mechanistic model

empirical model

sucrose

maltodextrin

mechanistic model

empirical model

T

(

C

)

-40

-30

-20

-10

0

10

20

30

T

(

C

)

-40

-30

-20

-10

10

0

20

30

2 4 6 8 10 12 14 16 0

Freezing time (min)

2 4 6 8 10 12 14 16

0

Freezing time (min)

2 4 6 8 10 12 14 16

T

(

C

)

Fig. 6. Experimental (symbols) and model predicted (lines) center temperature proles during freezing of tomato cubes after osmotic dehydration for 60 min (a), 300 min

(b), and 1410 min (c) in sucrose and maltodextrin solutions.

A.M. Goula, H.N. Lazarides / Chemical Engineering Science 82 (2012) 5261 59

Linear regression and paired t-test were applied in order to

compare the experimental and simulated (by the proposed

mechanistic model) values of product temperature during freez-

ing for all ODF experiments. When calculating the slope and

intercept of simulated versus experimental values, no statistical

differences were found from the respective theoretical values of

1.00 and 0.00 (p0.05). In addition, the calculated t-values were

lower than the theoretical t-values (p0.05). Therefore the null

hypothesis was retained: the simulation data on product tem-

perature agreed well with the experimental data conrming the

validity of the proposed model for the ODF process.

4. Conclusions

A new modeling methodology has been developed to describe

the ODF process based on the successive mass and heat

transfer.

The proposed mechanistic model is based on a cellular

physiology approach, thus overcoming major limitations asso-

ciated with both empirical models and mechanistic models

strictly based on diffusion.

The proposed model allowed accurate prediction of tempera-

ture and phase changes as well as solute and water concen-

trations as a function of processing (dehydration or

freezing) time.

The prediction capacity of the proposed model was compared

to that of a selected, regularly used empirical model (Azuaras

model). The latter gave large deviations between predicted

and experimental values, which were signicantly increasing

with increased dehydration times; thus, the tested empirical

model does not appear to be suitable for modeling ODF

processes.

Accurate, successive mass and heat transfer simulation of the

ODF process allows for effective process control, an absolute

requirement for industrial exploitation in the production of

high quality, low cost dehydrofrozen food products.

References

Andrade, S.A.C., Neto, B.B., Nobrega, A.C., Azoubel, P.M., Guerra, N.B., 2007.

Evaluation of water and sucrose diffusion coefcients during osmotic dehy-

dration of Jenipapo (Genipa americana L.). J. Food Eng. 78, 551555.

Agnelli, M.E., Marani, C.M., Mascheroni, R.H., 2005. Modelling of heat and mass

transfer during (osmo) dehydrofreezing of fruits. J. Food Eng. 69, 415424.

Agnelli, M.E., Mascheroni, R.H., 2001. Cryomechanical freezing. A model for the

heat transfer process. J. Food Eng. 47, 263270.

Askar, A., Abdel-Fadeel, M.G., Ghonaim, S.M., AbdeL-Gaid, I.O., Ali, A.M., 1996.

Osmotic and solar dehydration of peach fruits. Fruit Process. 9 (1), 258262.

Azuara, E., Beristain, C.I., Garcia, H.S., 1992. Development of a mathematical model

to predict kinetics of osmotic dehydration. J. Food Sci. Technol. 29, 239242.

Biswal, R.N., Le Maguer, M., 1989. Mass transfer in plant material in contact with

aqueous solutions of ethanol and sodium chloride equilibrium data. J. Food

Process. Eng. 11, 159176.

Bunger, A., Moyano, P.C., Vega, R.E., Guerrero, P., Osorio, F., 2004. Osmotic

dehydration and freezing as combined processes on apple preservation. Food

Sci. Technol. Int. 10 (3), 163170.

Califano, A.N., Zaritzky, N.E., 1997. Simulation of freezing or thawing heat

conduction in irregular two dimensional domains by a boundary tted grid

method. Lebens. Wiss. Technol. 30, 7076.

Chang, H.D., Tao, L.C., 1981. Correlations of enthalpies of food systems. J. Food Sci.

46, 14931497.

Chenlo, F., Moreira, R., Pereira, G., Ampudia, A., 2002. Viscosities of aqueous

solutions of sucrose and sodium chloride of interest in osmotic dehydration

processes. J. Food Eng. 54, 347352.

Chenlo, F., Moreira, R., Fernandez-Herrero, C., Vazquez, G., 2006. Experimental

results and modeling of the osmotic dehydration kinetics of chestnut with

glucose solutions. J. Food Eng. 74, 324334.

Chenlo, F., Moreira, R., Fernandez-Herrero, C., Vazquez, G., 2007. Osmotic dehy-

dration of chestnut with sucrose: mass transfer processes and global kinetics

modelling. J. Food Eng. 78, 765774.

Choi, Y., Okos, M.R., 1986. Effect of temperature and composition on thermal

properties of foods. In: Le Maguer, M., Jelen, P. (Eds.), Food Engineering and

Process Applications. Transport Phenomena. Elsevier, New York.

Cleland, D.J., Cleland, A.C., Earle, R.W., Byrne, S.J., 1984. Prediction of rates of

freezing, thawing and cooling in solids of arbitrary shape using the nite

element method. Int. J. Refrig. 7, 613.

Crank, J., 1975. The Mathematics of Diffusion. Clarendon Press, Oxford.

Delgado, A.E., Sun, D.W., 2001. Heat and mass transfer models for predicting

freezing processesa review. J. Food Eng. 47, 157174.

Dermesonlouoglu, E.K., Giannakourou, M.C., Taoukis, P., 2007. Stability of dehy-

drofrozen tomatoes pretreated with alternatives osmotic solutes. J. Food Eng.

78, 272280.

Floury, J., Le Bail, A., Pham, Q.T., 2008. A three-dimensional numerical simulation

of the osmotic dehydration of mango and effect of freezing on the mass

transfer rates. J. Food Eng. 85, 111.

Forni, E., Torreggiani, K., Crivelli, G., Maestrelle, A., Bertolo, G., Santelli, F., 1987.

Inuence of osmosis time on the quality of dehydrofrozen Kiwi fruit. Acta

Hortic. 282, 425434.

Giraldo, G., Talens, P., Fito, P., Chiralt, A., 2003. Inuence of sucrose solution

concentration on kinetics and yield during osmotic dehydration of mango. J.

Food Eng. 58, 3343.

Heldman, D.R., 1982. Food properties during freezing. Food Technol. 36 (2), 92.

Henrion, P.N., 1964. Diffusion in the sucrosewater system. Trans. Faraday Soc.

60, 7274.

Ispir, A., Togrul, I.T., 2009. Osmotic dehydration of apricot: kinetics and the effect

of process parameters. Chem. Eng. Res. Des. 87, 166180.

Isse, M.G., & Schubert, H. (1991). Osmotic dehydration of mango: mass transfer

between mango and syrup. In: Fourth World Congress of Chemical Engineer-

ing, Karlsruhe, Germany.

Kar, A., Gupta, D.K., 2001. Osmotic dehydration characteristics of button mush-

rooms. J. Food Sci. Technol. 38, 352357.

Karel, M., 1975. Osmotic drying. In: Fennema, O. (Ed.), Principles of Food Science,

Part II. Marcel Dekker, New York and Basel.

Kaymak-Ertekin, F., Sultanoglu, M., 2000. Modelling of mass transfer during

osmotic dehydration of apples. J. Food Eng. 46, 243250.

Lazarides, H.N., Katsanidis, E., Nicolaidis, A., 1995. Mass transfer kinetics during

osmotic preconcentration aiming at minimal solid uptake. J. Food Eng. 25,

151166.

Lazarides, H.N., Gekas, V., Mavroudis, N., 1997. Apparent mass diffusivities in fruit

and vegetable tissues undergoing osmotic processing. J. Food Eng. 31,

315324.

Li, L., 2006. Numerical simulation of mass transfer during the osmotic dehydration

of biological tissues. Comput. Mater. Sci. 35, 7583.

Lopez-Leiva, M., Hallstrom, B., 2003. The original Plank equation and its use in the

development of food freezing rate predictions. J. Food Eng. 58, 267275.

Maourel, C., 1997. Aquaporins and water permeability of plant membranes. Annu.

Rev. Plant Physiol. Plant Mol. Biol. 48, 399429.

Marcotte, M., 1988. Mass Transfer Phenomena in Osmotic Processes. Experimental

Measurements and Theoretical Considerations. Ph.D. Thesis, University of Alberta.

Monnerat, S.M., Pizzi, T.R.M., Mauro, M.A., Menegalli, F.C., 2006. Concentration

proles and effective diffusion coefcients of sucrose and water in osmo-

dehydrated apples. Food Res. Int. 39, 739748.

Moore, W.J., 1972. Physical Chemistry. Prentice-Hall, Englewood Cliffs, NJ.

Moreira, P., Murr, F., 2004. Mass transfer kinetics of osmotic dehydration of cherry

tomato. J. Food Eng. 61, 291295.

Ochoa-Martnez, C.I., Ayala-Aponte, A.A., 2005. Modelos matematicos de transfer-

encia de masa en deshidratacion osmotica. Cienc. Tecnol. Aliment. 4 (5),

330342.

Ochoa-Martinez, C.I., Ramaswamy, H.S., Ayala-Aponte, A.A., 2007. A comparison of

some mathematical models used for the prediction of mass transfer kinetics in

osmotic dehydration of fruits. Dry Technol. 25, 16131620.

Palou, E., Lopez-Malo, A., Argaiz, A., Welti, J., 1994. The use of Pelegs equation to

model osmotic concentration of papaya. Dry Technol. 12, 965978.

Panagiotou, N.M., Karathanos, V.T., Maroulis, Z.B., 1999. Effect of osmotic agent on

osmotic dehydration of fruits. Dry Technol. 17 (1/2), 175189.

Parjoko, K.A., Rahman, M.S., Buckle, K.A., Perera, C.O., 1996. Osmotic dehydration

kinetics of pineapple wedges using palm sugar. Lebens. Wiss. Technol. 29,

452459.

Park, K.J., Bin, A., Brod, F.P.R., Park, T.H.K.B., 2002. Osmotic dehydration kinetics of

pear Danjou. J. Food Eng. 52, 293298.

Pham, Q.T., 1996. Prediction of calorimetric properties and freezing time of foods

form composition data. J. Food Eng. 30 (12), 267275.

Pham, Q.T., 2006. Modelling heat and mass transfer in frozen foods: a review. Int.

J. Refrig. 29, 876888.

Rahman, M.S., Lamb, J., 1990. Osmotic dehydration of pineapple. J. Food Sci.

Technol. 27, 150152.

Rahman, M.S., Sablani, S.S., Al-Ibrahin, M.A., 2001. Osmotic dehydration of potato:

equilibrium kinetics. Dry Technol. 19, 11631176.

Raoult-Wack, A., Guilbert, S., Le Maguer, M., Rios, G., 1991. Simultaneous water

and solute transport in shrinking media. Part 1. Application to dewatering and

impregnation soaking process analysis. Dry Technol. 9, 589612.

Robbers, M., Singh, R.P., Cunha, L.M., 1997. Osmotic-convective dehydrofreezing

process for drying Kiwifruit. J. Food Sci. 62 (5), 10391047.

Salvatori, D., Andre s, A., Chiralt, A., Fito, P., 1999. Osmotic dehydration progression

in apple tissue I: spatial distribution of solutes and moisture content. J. Food

Eng. 42 (3), 125132.

A.M. Goula, H.N. Lazarides / Chemical Engineering Science 82 (2012) 5261 60

Sanz, P.D., Ramos, M., Mascheroni, R.H., 1996. Using equivalent volumetric

enthalpy variation to determine the freezing time in foods. J. Food Eng. 27

(2), 177190.

Sanz, P.D., Ramos, M., Aguirre-Puente, J., 1999. One-stage model of foods freezing.

J. Food Eng. 40 (4), 233239.

Saravacos, G.D., 2005. Mass transfer properties of foods. In: Rao, M.A., Rizvi, S.S.H.,

Datta, A.K. (Eds.), Engineering Properties of Foods, 3rd ed. CRC Press, Taylor

and Francis Group.

Singh, B., Kumar, A., Gupta, A.K., 2007. Study of mass transfer kinetics and effective

diffusivity during osmotic dehydration of carrot cubes. J. Food Eng. 79,

471480.

Spiazzi, E., Mascheroni, R., 1997. Mass transfer model for osmotic dehydration of

fruits and vegetablesI. Development of the simulation model. J. Food Eng. 34,

387410.

Talens, P., Escriche, I., Martnez-Navarrete, N., Chiralt, A., 2003. Inuence of

osmotic dehydration and freezing on the volatile prole of Kiwi fruit. Food

Res. Int. 36, 635642.

Tocci, A.M., Mascheroni, R.H., 1995. Numerical models for the simulation of the

simultaneous heat and mass transfer during food freezing and storage. Int.

Commun. Heat Mass Transfer 22 (2), 251260.

Tregunno, N.B., Goff, H.D., 1996. Osmodehydrofreezing of apples: structural and

textural effects. Food Res. Int. 29, 471479.

Waliszewski, K.N., Delgado, J.L., Garca, M.A., 2002. Equilibrium concentration and

water and sucrose diffusivity in osmotic dehydration of pineapple slabs. Dry

Technol. 20 (2), 527538.

Wang, Z., Wu, H., Zhao, G., Liao, X., Chen, F., Wu, J., Hu, X., 2007. One-dimensional

nite difference modeling on temperature history and freezing time of

individual food. J. Food Eng. 79, 502510.

Yao, Z., Le Maguer, M., 1997. Mathematical modelling and simulation of mass

transfer in osmotic dehydration processes. Part II: simulation and model

verication. J. Food Eng. 32, 2132.

A.M. Goula, H.N. Lazarides / Chemical Engineering Science 82 (2012) 5261 61

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Sensors 3Документ59 страницSensors 3zubairawОценок пока нет

- HDK Hydrophobic and Hydrophilic Fumed SilicaДокумент6 страницHDK Hydrophobic and Hydrophilic Fumed SilicaDidar YazhanovОценок пока нет

- Design Basis Report-Nh208Документ19 страницDesign Basis Report-Nh208Atanu AdhiakryОценок пока нет

- SJPO General Round 2010 PDFДокумент19 страницSJPO General Round 2010 PDFziwei_from_chinaОценок пока нет

- Relativity: The Special and General TheoryДокумент11 страницRelativity: The Special and General TheoryKhamsah Al-FarhanОценок пока нет

- Advanced materials processing techniques for automotive, aerospace and energy applicationsДокумент3 страницыAdvanced materials processing techniques for automotive, aerospace and energy applicationsvinothksОценок пока нет

- GUI PWR Sim Using Python DTU ThesisДокумент56 страницGUI PWR Sim Using Python DTU ThesisAnkit RajОценок пока нет

- JIS G3466 - Thailand - CONTENT1011579693989745Документ1 страницаJIS G3466 - Thailand - CONTENT1011579693989745Nguyễn Tiến TùngОценок пока нет

- Homework 3 data analysis and interpretationДокумент111 страницHomework 3 data analysis and interpretationFebriОценок пока нет

- On Scalable Analytical Models For Heap Leaching PDFДокумент6 страницOn Scalable Analytical Models For Heap Leaching PDFInfernuzОценок пока нет

- Math3104 Part1 2023 Lecture2 SlidesДокумент23 страницыMath3104 Part1 2023 Lecture2 SlidesWriter CourseОценок пока нет

- Austenitic Cast Iron Welding Detailsfrequently Aske-WPS OfficeДокумент17 страницAustenitic Cast Iron Welding Detailsfrequently Aske-WPS Officearjun prajapatiОценок пока нет

- 06-11-2021 - SR Iit Co Sc-n120 - Jee Main Model - ptm-1 - QP FinalДокумент14 страниц06-11-2021 - SR Iit Co Sc-n120 - Jee Main Model - ptm-1 - QP FinalDeeip DОценок пока нет

- Physical Science ReportДокумент9 страницPhysical Science ReportRoschelle ValleОценок пока нет

- Topic 4 - EnergeticsДокумент2 страницыTopic 4 - EnergeticsKajaОценок пока нет

- Starting With Zero: Create Your Own Topographic Map ProjectДокумент4 страницыStarting With Zero: Create Your Own Topographic Map ProjectVinujah SukumaranОценок пока нет

- Formulation and evaluation of floating microspheres of ranolazineДокумент8 страницFormulation and evaluation of floating microspheres of ranolazineIkhsan SoesiloОценок пока нет

- BS en 12449 2016Документ46 страницBS en 12449 2016engr.sshoaibrazaОценок пока нет

- Isotech Journal OF Thermometry: Published by Isothermal Technology LTDДокумент57 страницIsotech Journal OF Thermometry: Published by Isothermal Technology LTDlizarazojavierОценок пока нет

- RIFRATTOMETRIAДокумент14 страницRIFRATTOMETRIAAlessandro CaiazzoОценок пока нет

- D ILIPДокумент30 страницD ILIPAnonymous YloEbh0% (1)

- Copernican PrincipleДокумент7 страницCopernican Principlemaddy555Оценок пока нет

- Alternadores GPW Gpa GPF GSW Gsa GSF en 02Документ39 страницAlternadores GPW Gpa GPF GSW Gsa GSF en 02Gesiel SoaresОценок пока нет

- Thermal AnalysisДокумент40 страницThermal AnalysisGarima UppadhyayОценок пока нет

- Carbon Dioxide: Pressure - Enthalpy Diagram: R 90 0 Sity 7 00 KG/MДокумент1 страницаCarbon Dioxide: Pressure - Enthalpy Diagram: R 90 0 Sity 7 00 KG/MJackОценок пока нет

- Approximate Design of Multiple Feed Side Stream Distillation Systems 1987 Industrial and Engineering Chemistry ResearchДокумент7 страницApproximate Design of Multiple Feed Side Stream Distillation Systems 1987 Industrial and Engineering Chemistry ResearchDevaucayОценок пока нет

- Ionic EquilibriumДокумент91 страницаIonic EquilibriumGabrielОценок пока нет

- Asam Mefenamat EmulgelДокумент5 страницAsam Mefenamat EmulgelVi Vian HiuОценок пока нет

- Lightening ArresterДокумент13 страницLightening Arresterrohanlagad10Оценок пока нет