Академический Документы

Профессиональный Документы

Культура Документы

RD PDF TR rd-tr-r00024-005 PDF

Загружено:

sinhleprovietИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

RD PDF TR rd-tr-r00024-005 PDF

Загружено:

sinhleprovietАвторское право:

Доступные форматы

20 Yokogawa Technical Report English Edition, No.

24 (1997)

BLENDING OPTIMIZATION SYSTEM

SASAKI Shigehiko *

1

SUGAWARA Hideaki *

1

ISHIGURI Atsuki *

1

KUBO Kenji *

1

We have developed a blending optimization system which calculates

optimum blend ratios, based on values measured in a continuous on-line analysis of

product properties, and corrects control setpoints automatically. The system is

composed of the EXABPC property control package that calculates optimum blend

ratios, a distributed control system (CENTUM CS or CENTUM-XL*

2

), and next-

generation InfraSpec near-infrared analyzers. This paper focuses on the EXABPC

and introduces its features, structure, and functions.

INTRODUCTION

T

he purpose of blending in a petroleum refinery is to mix

semi-finished products that have been rectified during

various refining processes so as to manufacture a product that

meets specification. Traditional blending operations have not

been able to avoid the following issues involving property

control:

Manual adjustment by the operator cannot control the

properties ideally and is liable to cause giveaway (an excess

in quality).

A conventional analyzer, typically a knockmeter, requires a

large amount of labor and high costs for installation and

maintenance.

The objectives of the development of this blending

optimization system are, first, to employ an optimization

calculation in the blend ratio calculation, and further, by

structuring an integrated system package including analyzers, to

reduce costs and labor drastically for users employing the system

(the troublesome testing of system connections, etc.).

OVERVIEW OF BLENDING OPTIMIZATION

SYSTEM

In this system, the properties of a product being blended are

directly measured by an InfraSpec on-line near-infrared analyzer,

and blend ratios are controlled by a closed loop. As shown in

Figure 1, this system is composed of the following modules:

1) Blend ratio control (off-site instruments in CENTUM CS or

CENTUM-XL)

2) Property control package (EXABPC)

3) On-line near-infrared analyzers (InfraSpec NR500)

1. Blend Ratio Control

Based on the prescribed blend ratios, off-site instruments in a

CENTUM CS or CENTUM-XL distributed control system

calculate the flow rate setpoint for each component and control

flow rates.

2. Property Control (Multivariable Predictive Control for

Optimum Blend Ratio Calculation)

This is the kernel module of the blending optimization

system. The purposes for the use of multivariable predictive

control in this module are to measure each property value of the

product directly on-line, and accordingly to adjust the blend ratios

so that each property value can meet specification. In

multivariable matrix control, if the degree of freedom is one or

greater, there are two or more solutions that satisfy the target

variable, in general. If the optimization coefficient is set in this

case, optimization calculations can be made. For instance, this

makes it possible to calculate optimum ratios by setting the

*1 Systems Business Division

*2 CENTUM is a registered trademark of Yokogawa Electric

Corporation.

Blending Optimization System 21

maximum allowable ratio for the component which is lowest in

terms of unit manufacturing cost as well as the minimum

allowable ratio for the component which is highest in terms of

unit manufacturing cost, to the extent that a certain property

standard (RON) permits.

In this blend optimization system, EXABPC performs

multivariable predictive control and optimum recipe calculation.

EXABPC uses an HP9000 as its hardware platform.

3. On-line Near-infrared Analyzers

This system uses InfraSpec NR500 near-infrared analyzers

for the on-line property analyses. Recently, many users have

become increasingly interested in near-infrared analyzers

because of their ability to handle on-line measurement of gasoline

octane numbers and other reasons. When used as an on-line

analyzer, a near-infrared spectrum analyzer delivers the

following merits to the user in comparison to conventional

analyzers:

Real-time measurement of multiple property values

Continuous measurement without destruction of the sample

Remote measurement using a fiber-optic cable

Simplified sampling system

Great reduction of maintenance costs and labor

4. Operation Environment of Blending Optimization System

Figure 2 shows the operation environment of the overall

blending optimization system.

FEATURES AND STRUCTURE OF EXABPC

PACKAGE

1. Features of EXABPC

This package has the following features:

Estimation of product quality in the header and the integrated

product quality in the tank

The model-based prediction formulas of the EXABPC

estimate not only the properties of the product in the blend

header (i.e., instantaneous product quality) but also the

properties of the product in the tank including heel(integrated

product quality).

Calculations of property values (FVI, cetane index, etc.)

The EXABPC not only handles values measured directly by

analyzers but also calculates other property values internally

from those values from analyzers. For instance, the FVI

value can be calculated from the RVP and E70 values.

Compatible with nonlinear property changes by using

exponential computations (compatible with blending rule)

A property that shows a nonlinear change, such as RON and

viscosity as shown in Figure 3, can be handled with

exponential computations. A user can use the equations

Off-line near-

infrared analyzer

DCS off-site

instruments

EXABPC multivariable

predictive control

Blend

library

On-line near-

infrared analyzer

Scheduler

Component A

Component B

Component N

Flowmeter

Flowmeter

Flowmeter

On-line

analyzer

Product tank

(1) (2)

(3)

Figure 1 Blending Optimization System

LAN

EXAOMC-A/B

EXABLEND

EXATIM

EXABPC

User interface

Screens

EXAOMC-A/B

EXABPC

EXABLEND

EXATIM

DCS instruments

ICS

V-net

FCS

Tank

Gauging

System Blender

NIR

Other

Systems

Laboratory

Systems

Figure 2 Operation Environment of Blending Optimization System

22 Yokogawa Technical Report English Edition, No. 24 (1997)

already contained within the EXABPC (that can be revised)

and can even write the users own equations.

Optimization using nonlinear programming

Many blend control packages from competitors use nonlinear

programming for optimization calculation, but the EXABPC

uses even more flexible nonlinear programming.

Two different optimization scenarios

The EXABPC can run two different optimization scenarios:

optimization calculations for each blending job, and

optimization calculations linked with the scheduler.

Off-line simulation on a PC

Although the EXABPCs main program runs on an HP 9000,

the EXABPC package includes an off-line simulation

program that can also run on a Windows

*3

PC. Figure 4 shows

an example of a simulation on a PC.

RON/MON Blending Rule

Blending Rules Healy

A B C D

3.205

x=1/C In((xi-A)/B)

xi=A+(B*exp(C*x))

0.279 0.031 0

I

N

D

E

X

RON/MON

35

30

25

20

15

10

5

0

50 59 68 77 86 95 104 113 122 131 140 149

Figure 3 Blending Rule (Exponential Computation for RON)

Optimum

blend ratios

Component costs

Restrictions on component inventories

Restrictions on component ratios

Target values of product

properties in tank

Component availability

management (CAM)

Restrictions on

blend ratios

Tank quality control

(TQC)

Spot property target values

Measured spot property values

Check of blend

feasibility (CBF)

Instantaneous quality

control (IQC)

Disturbance estimation

(DE)

Estimated disturbances

Tank quality estimation

(TQE)

Estimated property

values of product in tank

Figure 4 Simulation on PC

Figure 5 Blend Ratio Optimization Calculation

*3 Windows is a registered trademark of Microsoft Corporation,

USA.

Blending Optimization System 23

2. Structure and Functions of EXABPC

Blend ratio optimization calculation, the main function of the

EXABPC, is composed of the sub-functions shown in Figure 5.

(1) Disturbance estimation (DE)

To compensate the blend model, modeling difference

between the model prediction of the product quality and the

analyzer measurement is estimated as disturbances using the

following equation (see also Figure 6):

Dej(k) = EXP(-1/Tdj)*Dej(k -1) + (1- EXP(-1/Tdj)*(Pmj(k)- Ppj)

Where

De = disturbance estimation

Td = time constant of disturbance filter

Pm = property measurement index

Pp = predicted property

j = property j

k = sampling time

(2) Tank quality estimation (TQE)

The properties of a product batch (in a product tank, tank on a

ship, etc.) are estimated based on volume and properties of

remaining oil (heel), and blending volume and properties (see

also Figure 7). The index of the estimated tank property Tqj

is obtained by the following equation:

Tqj = (Qhj*Vh + qkj *V)/Vh + V

Where

V = product volume produced since the last TQE run

qk = quality of the added volume

Vh = heel volume

Qh = heel property index

j = property j

(3) Tank quality control (TQC)

Tank quality control, which is the upper level control in the

instantaneous quality control (IQC) described later,

calculates the spot property target values so that the product

property in the tank is finally on specification. The calculated

spot property target values are transmitted to instantaneous

quality control (see also Figure 8).

The heel correction speed (SPEED FACTOR) is provided as

a coefficient to decide to finish heel correction on the basis of

total blending volume. The spot property target values are

calculated by the following equations:

Qspt_highj = {Qspec_highj*(Vh + Vc) - (Qcj*Vh)}/Vc

Qspt_lowj = {Qspec_lowj*(Vh + Vc) - (Qcj*Vh)}/Vc

Vc = (Vb + Vhl)*Kc

Where

Qspt_high = upper limit of spot property target

Qspt_low = lower limit of spot property target

Qspec_high = upper limit of product specification for product tank

Qspec_low = lower limit of product specification for product tank

Vh = heel volume at this period

Qc = estimated properties of a product tank at this period

Vc = heel correction volume

Vb = total blending volume

Vhl = heel volume at blending start

Kc = heel correction speed factor

j = property j

(4) Component availability management (CAM)

From the highest constraint among the following, the upper

and lower limits of each component ratio is calculated.

Limit of component ratio

Limited to the maximum and minimum component (oil)

ratios set by the operator.

Limit of component volume

Limited to the maximum and minimum component (oil)

volumes set by the operator.

Limit of flow rate

Limited to the maximum and minimum allowable flow rates

set by the operator.

Rate-of-change limit of component ratio

Limited to the maximum change rates of component (oil)

ratios set by the operator.

Blend

ratio

Process

(Blender BRC

FRC QMI)

Steady-state

model

Dynamic

model

Disturbance

filter

Disturbance

estimation

Blender model

Figure 6 Disturbance Estimation (DE)

V, qk(j)

Vh, Qh(j)

Vb: total

blending

volume

Vhl: heel

volume at

blending start

Vh: heel volume

at this period

Vc: heel

correction

volume

Figure 7 Tank Quality Estimation (TQE) Figure 8 Tank Quality Control (TQC)

24 Yokogawa Technical Report English Edition, No. 24 (1997)

(5) Instantaneous quality control (IQC)

Instantaneous quality control decides the optimum blend

ratios for the spot property target values (see also Figure 9),

lower level controller in tank quality control controls the

properties in the blend header. To do so, it calculates the

optimum blending recipe and ensures that it is within

constraints.

IQC mode

There are two modes for the IQC. Either one is selected for

use according to the economic and control purposes within

the petroleum refinery.

(a) Minimum cost

In the minimum cost mode, the IQC calculates the component

ratios (Ri) that can minimize the result of the following

equation:

i{Ci* Ri }**2 + i{Ri - Ri}**2*Pi**2

Where

Ci = component (oil) cost

Ri = optimum ratio of component i

Ri= optimum ratio of component i in the last period

Pi = optimization continuity factor of component i

Constraints

Hjmin i(Pji*Ri + Dj) Hjmax

Where

Hjmax = spot property target upper limit of property j

Hjmin = spot property target lower limit of property j

Pji = property j of component i

Dj = estimated disturbance of property j

Lower limit of ratio Ri upper limit of ratio

Total of Ri = 1 (= 100%)

(b) Minimum distance

In the minimum distance mode, the IQC calculates the

component (oil) ratios (Ri) that can minimize the result of the

following equation:

i{Ci*(Ri -Ropt)}**2 +{Ri - Ri}**2*Pi**2

Where

Ropt = component optimization mode

Depending on the value of Ropt(i), one of the following ratios

is calculated:

When Ropt(i) = 1, then the minimum ratio calculated by the

component availability management (CAM);

When Ropt(i) = 2, then the off-line optimum ratio recipe*

4

;

and

When Ropt(i) = 3, then the maximum ratio calculated by the

component availability management (CAM).

(c) Secondary solution method

The EXABPC has a function to decide ratios by loosening the

constraints partially when the aforementioned optimization

problem cannot be resolved.

(6) Feasibility check (CBF)

The check for blend feasibility (CBF) checks whether or not

the product tank properties are within the range of product

specification when the blend operation ends.

BENEFITS OF SYSTEM

The blending optimization system delivers the following

benefits to the user:

User-friendly operations

The system can be operated via an ICS of a CENTUM CS

system, allowing single-window and user-friendly operations

with high operability.

Prevention of quality giveaways

Properties such as the octane number in a gasoline blender or

the viscosity and sulfur rating in a fuel oil blender can be

within the range of target values of the specifications. This

minimizes costs caused by quality giveaway, and can make a

big benefit for the user.

Component

ratio

constraints

Optimum ratio

calculation

Blend

ratio Process

(Blender BRC

FRC QMI)

Blender model

Control

filter

Disturbance

filter

Disturbance

estimate

Figure 9 Instantaneous Quality Control (IQC)

*4 The off-line optimum ratios are decided by the scheduler in

consideration of the economy of the entire petroleum refinery.

For instance, a component which was produced excessively

should be used a lot even if it is a costly component, and using

a lot of an inexpensive component is not allowed if there is

little inventory of that component on hand. An off-line

optimum recipe is provided by the off-line scheduler and

optimizer. Normally a blend recipe is determined by the

scheduler in consideration of the optimum consumption of

components. A single blend optimization does not always

mean using an optimum component. The optimum

consumption of blend components depends on the availability

of each component and storage capacity of component tanks.

Blending Optimization System 25

Reduction of product tanks and product stock

Direct loading from blender to a ship is possible because

qualities of the product by blender are assured. This can

reduces not only product stock tanks but also greatly reduces

the product stock on hand.

Minimization of re-blending operation

Re-blending can be minimized by improving the qualities of

blends. This results in great reductions in product stock and

manpower.

Implementation of integrated system

By the adoption of relational databases (RDB), the integrated

system can be implemented by easily connecting other

systems such as the laboratory system.

Reduction of product loss

Oil remaining in the pipe line from a blender to a wharf and

that remaining in a product tank after tank blending is handled

as heels and automatically compensated. This prevents slop

processing and product downgrading, and leads to a greater

reduction of product loss.

Figure 10 shows a quality control monitor screen and figure

11 shows a quality trend screen.

FUTURE IMPROVEMENTS

Multi-platform

The current version of the EXABPC can run on an HP-UNIX-

based computer (HP 9000/E series or compatibles). By

developing a version that runs under a Windows NT

Figure 10 Quality Control Monitor Screen Figure 11 Quality Control Trend Screen

Workstation, we are enabling further reduction in the initial

costs to employ the system.

Multiblending

The current version of the EXABPC optimizes each blending

job. We are studying a mechanism to optimize multiple

blending jobs in a specified time period.

CONCLUSIONS

The blending optimization system introduced in this report

was developed as a package through our expertise in two systems

delivered to Japanese users and three systems for overseas users.

Featuring a variety of original Yokogawa functions dedicated to

blending control, this package is a great interest to customers.

From another aspect, it is meaningful that it is possible to

develop an integrated system with high added value by

integrating the application technology of our systems with our

other measurement and control systems.

REFERENCES

(1) TANAAMI T. et al., "High speed and High SNR Fourier

Transform Spectroscopy" Yokogawa Technical Report

English Edition No. 22 (1996) pp. 1 to 4

(2) "Ethyl Research Develops New Octane Blending Scale." The

Oil and Gas Journal, Vol. 58, No. 6, February 8, 1960

(3) "Flash Points of Blends Correlated," Hydrocarbon Processing

& Petroleum Refinery

(4) "Equation Predicts Diesel Cloud Points," Technology, May

28, 1986

Вам также может понравиться

- Basicsoflubricantadditives 100423231951 Phpapp02Документ40 страницBasicsoflubricantadditives 100423231951 Phpapp02Jako MishyОценок пока нет

- WG DA SYN Blower OilДокумент1 страницаWG DA SYN Blower OilsinhleprovietОценок пока нет

- English Speaking Club Tet Holiday2Документ32 страницыEnglish Speaking Club Tet Holiday2sinhleprovietОценок пока нет

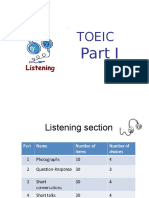

- Toeic Listening Part 1Документ10 страницToeic Listening Part 1sinhleprovietОценок пока нет

- Aeon PD PDFДокумент4 страницыAeon PD PDFAlex NavarreteОценок пока нет

- Shell Gadus S2 V220 2 High Performance GreaseДокумент2 страницыShell Gadus S2 V220 2 High Performance Greasekevin_lim90Оценок пока нет

- Hydraulic Fluid Care GuideДокумент16 страницHydraulic Fluid Care GuidegabrieljuarezgОценок пока нет

- API Oil Engine Classifications 2013Документ10 страницAPI Oil Engine Classifications 2013sinhleprovietОценок пока нет

- 2012 Paper Screw CompressorsДокумент24 страницы2012 Paper Screw CompressorsbracioОценок пока нет

- AeroShell Turbine Oil 560 (En) TDSДокумент3 страницыAeroShell Turbine Oil 560 (En) TDSsinhleprovietОценок пока нет

- Nano Particle Technology For Drug Delivery (2006)Документ427 страницNano Particle Technology For Drug Delivery (2006)prishly7108100% (3)

- TechBrief10 - Oil Base StocksДокумент9 страницTechBrief10 - Oil Base StockssinhleprovietОценок пока нет

- Lubricants & Greases: A.Antony PeterДокумент112 страницLubricants & Greases: A.Antony PetersinhleprovietОценок пока нет

- How To Write A Report - Explorer Junior Library How To WriteДокумент25 страницHow To Write A Report - Explorer Junior Library How To Writesinhleproviet100% (2)

- Cincinnati HydraulicДокумент1 страницаCincinnati HydraulicsinhleprovietОценок пока нет

- Cincinnati GearДокумент1 страницаCincinnati GearsinhleprovietОценок пока нет

- D71Документ2 страницыD71rpajaro75Оценок пока нет

- Roots Blower OilДокумент2 страницыRoots Blower OilsinhleprovietОценок пока нет

- WG DA SYN Blower OilДокумент1 страницаWG DA SYN Blower OilsinhleprovietОценок пока нет

- D61Документ3 страницыD61rpajaro75Оценок пока нет

- API Engine Oil Classifications 2010Документ8 страницAPI Engine Oil Classifications 2010Stefan BurbuleaОценок пока нет

- Lubricant Base OilsДокумент3 страницыLubricant Base OilssinhleprovietОценок пока нет

- Souther Training Metal WorkingДокумент31 страницаSouther Training Metal Workingsurajit7guptaОценок пока нет

- LubricationДокумент21 страницаLubricationmojiryhamid100% (1)

- Engine Cooling SystemДокумент22 страницыEngine Cooling SystembachayadavОценок пока нет

- United States Patent n91: Newingham Et AlДокумент7 страницUnited States Patent n91: Newingham Et AlsinhleprovietОценок пока нет

- D 3306 - 00 - RdmzmdytmdbbДокумент5 страницD 3306 - 00 - Rdmzmdytmdbbjamaljamal20100% (1)

- 06 Lubricating OilsДокумент32 страницы06 Lubricating Oilsfarhan2ansariОценок пока нет

- S - Mpo BearingthermДокумент1 страницаS - Mpo BearingthermsinhleprovietОценок пока нет

- SAEДокумент1 страницаSAEsinhleprovietОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Phronesis Volume 7 Issue 1 1962 (Doi 10.2307/4181698) John Malcolm - The Line and The CaveДокумент9 страницPhronesis Volume 7 Issue 1 1962 (Doi 10.2307/4181698) John Malcolm - The Line and The CaveNițceValiОценок пока нет

- Function Point and Cocomo ModelДокумент31 страницаFunction Point and Cocomo ModelParinyas SinghОценок пока нет

- Fraud under Indian Contract Act - Essentials and Exceptions to Mere SilenceДокумент6 страницFraud under Indian Contract Act - Essentials and Exceptions to Mere SilenceabhilashОценок пока нет

- How To Download Cosmetic Injection Techniques A Text and Video Guide To Neurotoxins Fillers Ebook PDF Docx Kindle Full ChapterДокумент36 страницHow To Download Cosmetic Injection Techniques A Text and Video Guide To Neurotoxins Fillers Ebook PDF Docx Kindle Full Chapterkerri.kite140100% (23)

- Human Rights Project, 2018Документ25 страницHuman Rights Project, 2018Vishal Jain100% (3)

- Chronology of TLM Event in The PhilippinesДокумент3 страницыChronology of TLM Event in The PhilippinesTheus LineusОценок пока нет

- 800m Training Plan For Mando EmployeДокумент7 страниц800m Training Plan For Mando EmployeSunder Veera Karthikeyan100% (1)

- Atmakaraka PDFДокумент46 страницAtmakaraka PDFrohitsingh_8150% (4)

- Alpha To Omega PPT (David & Krishna)Документ11 страницAlpha To Omega PPT (David & Krishna)gsdrfwpfd2Оценок пока нет

- Tanada, Et Al. Vs Angara, Et Al., 272 SCRA 18, GR 118295 (May 2, 1997)Документ3 страницыTanada, Et Al. Vs Angara, Et Al., 272 SCRA 18, GR 118295 (May 2, 1997)Lu CasОценок пока нет

- Ethics Module 1-7Документ57 страницEthics Module 1-7Maey RoledaОценок пока нет

- R209292y@students Msu Ac ZWДокумент7 страницR209292y@students Msu Ac ZWColias DubeОценок пока нет

- (13-14) - Modeling of Thermal SystemsДокумент33 страницы(13-14) - Modeling of Thermal SystemsmawooaОценок пока нет

- Minimizing Dose Is DR PDFДокумент4 страницыMinimizing Dose Is DR PDFYamuna GovindarajОценок пока нет

- Mugunthan ResumeДокумент4 страницыMugunthan Resumeapi-20007381Оценок пока нет

- Mathematics Course Alagappa UniversityДокумент10 страницMathematics Course Alagappa UniversityTirthajit SinhaОценок пока нет

- Contact Resistance Between Gas Diffusion Layer and CatalystДокумент5 страницContact Resistance Between Gas Diffusion Layer and Catalystp.designОценок пока нет

- 7 Basic Control ActionsДокумент27 страниц7 Basic Control ActionsAhmad ElsheemyОценок пока нет

- Bobby Joe Public NoticeДокумент3 страницыBobby Joe Public NoticeUpscale International InvestmentsОценок пока нет

- A Summer's Reading - Sample Questions With AnswersДокумент11 страницA Summer's Reading - Sample Questions With AnswersRoy SchwartzОценок пока нет

- Property Management Agreement TemplateДокумент2 страницыProperty Management Agreement TemplatemarcelОценок пока нет

- (PC) Brian Barlow v. California Dept. of Corrections Et Al - Document No. 4Документ2 страницы(PC) Brian Barlow v. California Dept. of Corrections Et Al - Document No. 4Justia.comОценок пока нет

- Webquest Biotechnology RubricДокумент2 страницыWebquest Biotechnology Rubricapi-556285637Оценок пока нет

- KARG - (Ravenloft) Quoth The Raven #10Документ179 страницKARG - (Ravenloft) Quoth The Raven #10David CullifordОценок пока нет

- Lesson PlanДокумент8 страницLesson PlanNunette SenilloОценок пока нет

- Health Grade 9 1st QuarterДокумент1 страницаHealth Grade 9 1st QuarterCapila Ron100% (1)

- Ch5 Multivariate MethodsДокумент26 страницCh5 Multivariate MethodsRikiОценок пока нет

- Demand for Money Theory ExplainedДокумент31 страницаDemand for Money Theory Explainedrichard kapimpaОценок пока нет

- Anatomy One LinersДокумент10 страницAnatomy One Linersridin007100% (2)