Академический Документы

Профессиональный Документы

Культура Документы

Lee Pro 1000 Reloading Press Setup Guide

Загружено:

poliserpijc76170 оценок0% нашли этот документ полезным (0 голосов)

1K просмотров2 страницыUse only CCI or Remington brand primers. Other brands, espec ially Federal, can explode with sufcient force to seriously injure the user or persons nearby. When loading the primer tray, use a pencil to hold the primers in the tray while assembling it to the priming tool.

Исходное описание:

Оригинальное название

LEE PRO 1000.pdf

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документUse only CCI or Remington brand primers. Other brands, espec ially Federal, can explode with sufcient force to seriously injure the user or persons nearby. When loading the primer tray, use a pencil to hold the primers in the tray while assembling it to the priming tool.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

1K просмотров2 страницыLee Pro 1000 Reloading Press Setup Guide

Загружено:

poliserpijc7617Use only CCI or Remington brand primers. Other brands, espec ially Federal, can explode with sufcient force to seriously injure the user or persons nearby. When loading the primer tray, use a pencil to hold the primers in the tray while assembling it to the priming tool.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 2

4 3 2

INSTRUCTIONS FOR THE LEE PRO 1000

Helpful setup and operation videos available on www.leeprecision.com

FILL THE PRIMER TRAY

WARNING: Use only CCI or Remington brand

primers. Other brands, espec ially Federal, can

explode with sufcient force to seriously injure

the user or persons nearby.

ALL PRIMERS ARE DANGEROUS and it should be

anticipated that the primers in the tray could explode

through accident, misuse or spontaneously.

Should an explosion occur, our tests have demonstrat-

ed that safety glasses will normally prevent serious

injury to the user if CCI or Remington primers are used,

because the explosion is minimal. Other primers, how-

ever, can explode with sufficient force to seriously

injure the user, or persons nearby.

We do not take any position with respect to the qual-

ity of performance of primers available on the market.

However, ONLY those primers manufactured by CCI

or Remington are recommended for use in the Lee

Pro 000and when loading those primerssafety

glasses must be used. NO OTHER PRIMERS should be

used with the Lee Pro 000.

Place no more than 00

CCI or Remington brand

primers in the tray.

(Use of any other brand

exposes the operator to

unnecessary risks.) With

the cover of, shake side

to side to turn all primers

right side up.

With the cover on, use a

pencil to hold the primers

in the tray while assem-

bling it to the priming tool.

Shake the unit side to side

to ll the primer trough

LOADING A SINGLE CASE

Start with the lever in the down position (shell plate carrier up). Always

move the lever to a full stop.

Place an empty case in front of the case slider. Slowly raise the lever

and the case slider will push the case into the shell plate. Slowly lower

the lever to size and deprime the case.

Raise the leverthe case will be indexed to the next position and be

primed at the bottomof the stroke. IMPORTANT: The primer is seated

during the last inch of lever travel. Make a conscious efort to feel the

primer enter and fully seat into the case. Incomplete primer seating

will not permit the case to eject fromthe shell plate. This seems to be

the biggest problemfor rst time users.

1

2

3

YOU ARE NOW READY TO START PROGRESSIVE RELOADING

WITHOUT THE CASE FEEDER

At the bottomof each lever stroke, place a case in front of the case slider. At the top of each lever stroke,

start a bullet into the case.

A Always slowly move the lever to the positive stop.

B Priming is done on the lever upstroke. Learn to feel the primer being seated. Be sure to raise the lever

completely to fully seat the primer.

C Powder is automatically dispensed at the bottomof each stroke. Afer the powder has been added, it is

imperative that the lever be fully raised to index the case fromunder the charging die. Ashort stroke

will cause a double charge.

D Anytime the press tends to bindSTOP! Determine the reason for the binding and correct the problem.

Do not force it or something will be damaged.

ATTACH THE CASE FEEDER

Position the case feeder assembly to just clear the turret

ring and almost the thickness of a dime above a cartridge

case.

Slip the four tubes into the case feeder and ll them

with cases, head down.

OPERATING INSTRUCTIONS

1 Do not run out of primers or powder. It is easy to forget

because you will be turning out ammunition much

faster than you are accustomed to. What used to be an

evenings reloading is nowaccomplished in a fewminutes.

2 Always move the lever smoothly through its full travel. A short stroke can cause a jamor double charge.

3 Do not force it or you will break something. If it does not feel right, stop and check out the problem.

4 Keep the primer trough full. Running out of primers will cause a jam.

5 Polish the chute with steel wool and lightly oil or wax to help loaded rounds slide into your container.

SAFETY CONSIDERATIONS

1 Never place more than 00 primers in the tray.

2 Use only Remington or CCI primers. Other brands, especially Federal brand, can explode with suf-

cient force to seriously injure the user or persons nearby.

3 Be sure of proper powder and charge for bullet weight selected.

4 Wear safety glasses when reloading or shooting.

5 Be extremely careful to avoid a double charge. If in doubt, empty the case and recycle it.

6 Do not permit distractions while loading. This is a complex machine that needs your fullest attention.

7 Do not increase the capacity of the powder hopper.

More powder is many times more hazardous.

8 Oil all moving metal parts every fewthousand rounds or before use if the press has been idle two

weeks or more. Use 20 wt. motor oil or equivalent.

WHEN THINGS GO WRONG

Problems are usually caused by operator error. However, the Lee 000 is the easiest of all

progressive presses to straighten out. The cases can be removed fromeach station; rotate the shell

plate a fewdegrees by handthe case can then be pulled out without damage to the spring ngers.

If a partially seated primer holds the case in the shell plate, rotate the plate to the slot on the lef edge

and lif the case out.

The most important hazard to guard against is a double charge. It is always best to

completely remove the ofending case, dump the powder into the hopper and the case into

the case feeder if the primer is not protruding.

Afer removing the ofending case, continue loading. There is no need to have a case

in each position.

Learn to feel the primer seating when the

lever is pushed up.

Loosen allen screwand force shell plate carrier on the

ram. Retighten allen screw.

Check for primer on base or under shell plate carrier.

Carrier should contact the base with no case in the

shell holder.

Remove all oil with solvent.

Reattach case sensor to sensor clip.

Always keep primer trough full.

Reamor swage primer pocket.

Clean shell holder. Check tension nger. Straighten

or replace tension nger as required.

Adjust index. See Zero Adjustment on page 6.

See Primers not fully seated problemabove.

Move ejector pin to other side of screw.

Bend Z-bar down /8 in center to clear case feeder.

Factory tted presses have this bend.

Be sure youre using the correct case feeder for the

caliber youre loading.

( See page 6 for proper combination. )

Use hole closest to screw.

Loosen right front column bolt and swing the Z-bar

attachment as needed to hold a slight inward pres-

sure. The short end of Z-bar should enter the case

slider.

Adjust index. See Zero Adjustment on page 6.

Repair damage to slider rail with le.

Replace drive bolt. Order TR243 Drive Bolt.

Operator not pushing

hard enough

Shell plate carrier not fully

seated, or loose on ram

Obstruction to full travel

Oil in trough

Case sensor detached

Primer trough not full

Primer crimp not removed

Case not fully in shell holder

Improper index adjustment

Primers not fully seated

Cases wedge against

ejector pin

Occurs with 45 ACP

conversions because

Z-bar hits case feeder

Wrong case feeder

Z-bar in wrong case slider hole

Z-bar attachment not straight

Improper index

adjustment

Case slider binding

User damaged drive bolt

PROBLEM CAUSE REMEDY

Primers not fully

seated

Primer doesnt

feed onto

priming punch

Primer doesnt

enter case

Tipped primers

Cases dont eject

Jerky case feeding

Case feeder doesnt

work properly

Z-Bar slips out of

case slide

Case doesnt

enter shell plate

Shell plate turns

halfway

Lower the lever, and the powder measure will automatically charge the case

while expanding the case mouth to accept the bullet.

Raise the lever and the case will be positioned under the bullet seating die. Start a bullet into the case, then

lower the lever to seat the bullet and crimp it in place. If you are unable to start the bullet into the case mouth

because of insufcient are, screwthe expanding die (the die with the powder measure) /4 turn deeper. If the bullet

is not seated to the proper depth, turn the bullet seating

adjusting screwin or out to suit. Crimp is increased by

screwing the entire bullet seating die deeper. Make crimp

adjustments no more than /4 turn. See Die Instruction

Sheet for details.

CAUTION: The rear two dies should never be

adjusted so deep that they contact the shell

plate. Serious damage to the carrier can occur.

Raising the lever causes the shell plate to rotate

and eject the loaded round into the chute. This completes

one cycle.

The most important thing to remember is that once

you start moving the lever in a direction, do not reverse

directions until it comes to a complete stop at the end of

the stroke making sure that the primer is fully seated

on the lever upstroke.

The hazards of not doing this are: [A] a double

charge at the top of stroke. [B] the shell plate will

get out of time. (Should the shell plate get out of time,

disengage the ratchet by raising the shell plate carrier

/4 and advance the shell plate by hand.)

Continue loading one case at a time until you are

satised all is in order.

PRESS MOUNTING

Bolt your press to a solid bench. Use /4 nuts and bolts of suitable length. (Available at all hardware stores, 3

each required.) For convenience, a /2 hole may be drilled through the workbench to permit spent primers to pass

through. This hole may be located any place under the base of your press. Attach the lever to point up when the ram

is down.

AUTO-DISK POWDER MEASURE

The Lee Pro Auto-Disk Powder Measure is an improved ver-

sion with a positive pull back.

The bottom end of the chain should pass through the

hole in the carrier. Attach the brass pendant to the chain so the

measure is fully retracted when the ramis in the extreme down

position. Some chain should dangle below the pendant as the

weight helps the chain slide through the carrier hole on each

cycle. Fine adjustment is easiest done where the chain attaches

to the powder measure. The chain passes through two holes in

the lever and it will never move, yet it is easily adjusted. Store

the connecting link on the end of the chain. It will be available

should you need it for a repair.

Install the proper disk into the Auto-Disk Powder Measure.

See Auto-Disk Powder Measure Instruction Sheet for details.

Select load fromdata supplied with your Lee Dies of fromany reliable source. Fill the hopper with the correct

powder.

SETTING UP

Slip the turret into the press with the sizing die (the one with the decapping pin) up front. The dies

have been factory adjusted, but will require bullet depth adjustment, minor crimp adjustment and minor are

adjustment. See Die Instruction Sheet for details.

LEE PRECISION, INC. 4275 HWY. U HARTFORDWISCONSIN53027

Ammunition reloading can be dangerous if done im properly and should not

be attempted by persons not willing and able to read and fol low instructions

exactly. Children should not be permitted to reload ammunition without strict

parental supervision. Always wear safety glasses when reloading and shoot-

ing. Ammunition loaded with these tools and data should only be used in modern guns in good

condition. We do not accept responsibility for ammunition loaded with these tools or data as we

have no control over the manufacture and storage of components or the loading procedure and

techniques. Primers and gun powders, like gasoline and matches, can be dangerous if improperly

handled or misused.

Guarantee

ss xsoAoo vxooucis are guar-

anteed not to wear out or break from

normal use for two full years or they will

be re paired or replaced at no charge if

returned to the factory. Any Lee product

of current manufacture, regardless of age

orcondition, will bereconditionedtonew,

including a newguarantee, if returned to

thefactorywithpayment equal tohalf the

current retail price.

COMPLETE INSTRUCTIONS FOR THE

LEE PRO 1000

CAUTION

ZERO ADJUSTMENT FOR

SHELL PLATE INDEXING

With the turret installed, raise and lower the shell plate carrier. If the

shell plate does not index to the proper spot, turn the adjusting screw

clockwise; the shell plate should move. If notraise and lower the ram

again to engage the ratchet. Keep turning until the shell plate snaps

into place; then turn an additional /2 to 3/4 turn.

Conrmthe zero adjust is set properly. With the carrier in the

down position, try turning the shell plate clockwise; there should be no

movement. If there is, rotate the zero adjust screwa fraction of a turn

clockwise to remove all free play.

This need only be done once. If the shell plate gets out of adjust-

ment because of a short stroke or jam, simply advance the shell plate

by hand, not the adjusting screw.

KEEP YOUR PRESS WELL OILED AND IT WILL LAST A LIFETIME

SHELL PLATE PARTS LIST

When changing calibers that use a diferent primer

size, we recommend changing the entire shell plate

carrier. If caliber uses the same primer size,

you can easily change just the shell plate.

TR2139 1/4 2Ux1+ Bo|t

FO177U #8 - 32 x 5crew

FT1781

#8-32 x 5crew

TR2439 Gear P|ate

TR2433 Detent Ball

TR2434 Detent Spring

TR2431 Drive Bo|t

TR2442 E[ector Pin

TR255U 5ensor Bushing 1.UU

TR194U 5ensor 5crew

TR2549 5ensor C|ip

TR2548 Case 5ensor

TR2435 x2Ux5ocket

H.D. 5crew

9U1U8 Hex Ratchets

(3 Pack}

TR2432 Ratchet Gear

TR2443 Tension Fingers

TR2429 Carrier

TR2164B Primer Trough,

Large

TR2164C Primer Trough,

5ma||

PT1UU4 Primer Tray

Cover

TR2164A Primer Tray

TR2436 Primer Pin, Large

TR2437 Primer Pin,5ma||

TR2479 Primer 5pring

CASE FEEDER TUBES

PROAUTO-DISK

POWDER MEASURE

PRIMER TRAY

AND COVER

TURRET

TURRET RING

PRIMER TROUGH

COLUMN

SHELL PLATE CARRIER

ADJUSTING SCREW

RAM

SHOULDER BOLTS

CONNECTING

LINK

LINK

BOLT

TOGGLE ( 2 )

PRESS SHOWN MOUNTED ON LEE RELOADING STAND (OPTIONAL)

WITH OPTIONAL BINAND BRACKET

LEVER

NEWERGO HANDLE

Z-BAR

CYLINDER

AND PLATE

CASE

SLIDER

CARTRIDGE Z-BAR

SHELL PLATE SHELL PLATE SHELL PLATE SHELL COMPLETE

NUMBER ONLY WITH CARRIER SLIDER CASE FEEDER

32 5W Long & 32 HR

38U Auto 4 9U653 9U646 sma|| 9U659

38 5PC & 357 MAG

357 MAG & 357 MAX 1 9U651 9U644 std. 9U658

45 ACP & 45 HP Ita|ian 2 9U652 9U645 std. 9U658 bent

9mm Luger 19 9U669 9U683 sma|| 9U659

4U 5&W 19 9U669 9U683 sma|| 9U658* bent

1Umm Auto 19 9U669 9U662 std. 9U658

41 Mag 9 9U656 9U649 std. 9U658

44 5P, 44 Mag, 45 Co|t 11 9U657 9U65U std. 9U658

223, 222 REM & 7mm TCU 4 9U653 9U646 std. 9U663

7.62 x 39 12 9U666 5.O. Lg. Prim. std. 9U658

3UM1 7 9U655 9U648 std. 9U663

7mm BR 2 9U652 5.O. 5m. Prim. std. 9U658

32 Auto (ACP} 7B 9U668 5.O. 5m. Prim. std. 9U659

41 AE 19 9U669 9U683 std. None avai|.

45 Auto Rim 13 9U665 5.O. Lg. Prim. std. 9U658 bent

22U Russ, PPC 12 9U666 5.O. 5m. Prim. std. 9U658

S.O. = Special Order *Requires Purchase of Small Slider

Insert the assembly fromthe

front of the press until it con-

tacts the press in three places

as shown.

Push the action rod up

through the top of the press

and continue rotation to level

position. Be sure to keep the

primer trough pin behind the

right rear column.

Push the assembly onto the

rams end. Tighten the clamp

screwwith a hex wrench.

DONOTOVERTIGHTEN.

CHANGING THE SHELL PLATE CARRIER

v

INSTALLING THE SHELL PLATE CARRIER

The carrier is attached to the ramwith a single socket head screw. This makes it very easy

to change the entire carrier for caliber changing.

Push the action rod through the carrier fromthe bottomside until the end slightly protrudes through the

top. Be sure the twisted end is down.

CHANGING SHELL PLATE ONLY

With the shell holder carrier free of the press, loosen the screwthat holds the ejector and

remove the ejector. DO NOT LOSE IT!

Using a /4 hex wrench, turn the drive bolt clockwise to thread it out of the shell plate.

You must hold the shell plate fromturning while doing this. A 3/6 hex wrench or

small screwdriver through the plate in the depriming position works well.

If changing primer size, be sure to change the primer trough and primer punch before

installing a newshell plate.

Be careful to not lose the 3/8

steel detent ball and spring. Also,

be careful not to bend the spring

ngers that hold the cases in the

shell plate.

Reassemble the unit and readjust

the zero index as explained under

Zero Adjustment on next page.

DONOTOVERTIGHTENTHE DRIVE BOLT.

Turn until snug, using a single nger.

DRIVE BOLTis easily user damaged by

overtightening or turning in wrong direction.

2

1

2

3

4

5

3 4

1

2

3

4

1

CONTACT

CONTACT

CONTACT

5 6

Remove turret, primer tray

and z-bar

Loosen allen screw

clamp

Place wood block

under carrier

Use lever to pull ram

out of carrier

LOOSEN

Z-BAR ATTACH

Z-BAR

CASE SENSOR

PRIMER GATE (NOT ONALL MODELS)

Z-BAR ATTACH SPRING

ACTION

ROD

T

R

2

4

4

1

LEE BULLET FEEDER OPTIONAL

The bullet feeder designed to directly t the Pro

000. Automatically feeds bullets into the mouth

of the seating die.

Aligns bullets more accurately than possible by

hand. Increases cyclic rate 50 to 00%.

10.20.11 Lee Precision, Inc. 7050

CHECKED BY

TR2441 Pro 1000 Instructions mjh

PARTS LIST

UI3609 1:s wAShLk

IU2113 :s 18 X 1+ 8U|J

UI3221 kAH|N SJL

UI3613 |LvLk C|AH

UI2853 JU66|L (2 kLUU|kL0j

J2129 CUNNLCJ|N6 ||Nk

J2111 ||nk 8o|t s 24

I81181 s x 24 NUJ

J2111 :s18 NUJ

IJ2991 :s18 x 1: 8U|J (2 kLUU|kL0j

J2116 kAH|N

J2118 ShUU|0Lk 8U|J

J2125 8ASL CASJ|N6

J2126 JUkkLJ k|N6 w|Jh 0LJLNJ 8A||

90491 JUkkLJ

Jk2441 |NSJkUCJ|UNS

Jk2444 kAH

Jk2460 |LIJ kLAk CU|UHN

Jk2461 k|6hJ kLAk CU|UHN

Jk2361 IkUNJ CU|UHN

Jk2462 IkUNJ CU|UHN SACLk

IJ2463 :s18 X 2+ 8U|J

Jk2452A I-8Ak

Jk24528 I-8Ak 8LNJ

Jk2454 I-8Ak AJJACh

Jk2455 I-8Ak AJJACh Sk|N6

Jk2449A CASL ILL0Lk C||N0Lk

& |AJL |Ak6L

Jk24498 CASL S||0Lk |Ak6L

Jk2449C CASL S||0Lk SHA||

Jk24490 CASL ILL0Lk C||N0Lk

& |AJL SHA||

Jk2449L CASL ILL0Lk C||N0Lk

& |AJL k|I|L

90661 CASL ILL0Lk JU8LS (1 ACkj

Jk2438 ACJ|UN kU0

Вам также может понравиться

- Churchills Mauser C96: Notes on -The blow-up in Sydney Street- from the London DecameroneОт EverandChurchills Mauser C96: Notes on -The blow-up in Sydney Street- from the London DecameroneОценок пока нет

- Lee Turret PressДокумент2 страницыLee Turret Pressa928315100% (1)

- Punching Holes: Buying Ammunition, Gun Accessories, Knives and Tactical Gear at Wholesale PricesОт EverandPunching Holes: Buying Ammunition, Gun Accessories, Knives and Tactical Gear at Wholesale PricesОценок пока нет

- Crane JigДокумент2 страницыCrane Jigradio-chaserОценок пока нет

- Lee Powder Measure PDFДокумент2 страницыLee Powder Measure PDFwcp4570Оценок пока нет

- Functional Composite Materials: Manufacturing Technology and Experimental ApplicationОт EverandFunctional Composite Materials: Manufacturing Technology and Experimental ApplicationОценок пока нет

- Old Model B392-OM1Документ9 страницOld Model B392-OM1Just4HimОценок пока нет

- Winchester Model 1885Документ0 страницWinchester Model 1885carlosfanjul1Оценок пока нет

- M1 Garand New Barrel InstallationДокумент35 страницM1 Garand New Barrel InstallationToschanoОценок пока нет

- Us 5596162Документ9 страницUs 5596162Stanley PinesОценок пока нет

- Thompson Center R 55 RifleДокумент36 страницThompson Center R 55 RifleJon MorenoОценок пока нет

- Homebuilt Reloading Stand by Erik PrestmoДокумент18 страницHomebuilt Reloading Stand by Erik Prestmopeter.gomes20087216Оценок пока нет

- High Standard-MagazinesДокумент3 страницыHigh Standard-MagazinesBob WilliamsОценок пока нет

- BT-99 Trap Shotgun: Owner'S ManualДокумент33 страницыBT-99 Trap Shotgun: Owner'S ManualbjmooseОценок пока нет

- GLOCK Parts Order Form SEOДокумент7 страницGLOCK Parts Order Form SEODante DeAngelisОценок пока нет

- AR15 Roller Cam Pin Reduces Friction and Wear vs. ConventionalДокумент10 страницAR15 Roller Cam Pin Reduces Friction and Wear vs. ConventionalRob ZelОценок пока нет

- Brownells-2 5LB1911TriggerPullДокумент4 страницыBrownells-2 5LB1911TriggerPullRyan ShanksОценок пока нет

- Product Instructions - Trigger Guard Rivet Drilling Jig Instructions PDFДокумент3 страницыProduct Instructions - Trigger Guard Rivet Drilling Jig Instructions PDFFrank MeekerОценок пока нет

- Crosman Model Series 761XLДокумент6 страницCrosman Model Series 761XLjayОценок пока нет

- 30-06-Spfld-110gr Reloading GuideДокумент1 страница30-06-Spfld-110gr Reloading Guidevihkr9506Оценок пока нет

- Savage MKII Bolt Action RimfireДокумент38 страницSavage MKII Bolt Action RimfireCarl J. Wilkey100% (1)

- M1 Jig Instructions PDFДокумент8 страницM1 Jig Instructions PDFAnonymous nMXXPvg1R2100% (1)

- 870 Detent Staking PunchДокумент1 страница870 Detent Staking PunchZardoz1090Оценок пока нет

- Thompson/Center Arms Co., Inc. P.O. Box 5002 Rochester, New Hampshire 03866Документ28 страницThompson/Center Arms Co., Inc. P.O. Box 5002 Rochester, New Hampshire 03866johndoneОценок пока нет

- North American Arms, Inc. Owner & Instruction Manual: .22 Magnum, .22 Long Rifle, .22 Short Mini-Master & Black WidowДокумент5 страницNorth American Arms, Inc. Owner & Instruction Manual: .22 Magnum, .22 Long Rifle, .22 Short Mini-Master & Black WidowpreceptiveinquirerОценок пока нет

- Ada 006146Документ98 страницAda 006146Oskar DirlewangerОценок пока нет

- 2015 Standard BallisticsДокумент7 страниц2015 Standard BallisticsharrisburrrgОценок пока нет

- User ManualДокумент22 страницыUser Manualliwei0% (1)

- About BuckshotДокумент12 страницAbout BuckshotpitasignupОценок пока нет

- Miscellaneo - .,S: Shgi Stze / Pellet Count R Tolerances Ob/03/200Документ1 страницаMiscellaneo - .,S: Shgi Stze / Pellet Count R Tolerances Ob/03/200angelines123Оценок пока нет

- Grafs Powder Burn Rate ChartДокумент2 страницыGrafs Powder Burn Rate ChartcolasОценок пока нет

- Banzai! by Parabellum by Grautoff, Ferdinand Heinrich, 1871-1935Документ155 страницBanzai! by Parabellum by Grautoff, Ferdinand Heinrich, 1871-1935Gutenberg.orgОценок пока нет

- American 180 Rifle PDFДокумент25 страницAmerican 180 Rifle PDFValeriy ZadorozhnyiОценок пока нет

- IAI Automag III PDFДокумент11 страницIAI Automag III PDFab212amisarОценок пока нет

- 2004 AlliantPowderSMДокумент64 страницы2004 AlliantPowderSMscottperkinsusaОценок пока нет

- Awc CatalogДокумент23 страницыAwc CatalognachosuaveОценок пока нет

- Reloading The 50Документ22 страницыReloading The 50militia mitch100% (1)

- m14 Maintenance 1 PDFДокумент4 страницыm14 Maintenance 1 PDFentomophileОценок пока нет

- The GOLD MEDAL TRIGGER The Field Target Trigger For The Rapid RangeДокумент1 страницаThe GOLD MEDAL TRIGGER The Field Target Trigger For The Rapid Rangegraham4877Оценок пока нет

- M193 55gr & SS109 62gr 5.56 Ballistics ComparisonДокумент1 страницаM193 55gr & SS109 62gr 5.56 Ballistics ComparisonLilo StitchОценок пока нет

- Remington 572Документ6 страницRemington 572Tuna's Firearm SalesОценок пока нет

- ChicopeerfДокумент15 страницChicopeerfRomG78Оценок пока нет

- Uzi Carbine Fixed Stock InstallationДокумент4 страницыUzi Carbine Fixed Stock Installationelvergonzalez1Оценок пока нет

- Tubing Sizes For Improvised Firearm Barrels FromДокумент1 страницаTubing Sizes For Improvised Firearm Barrels Frommatko_matićОценок пока нет

- 41 Avenger: A SSKДокумент7 страниц41 Avenger: A SSKPatrick BodartОценок пока нет

- Chambering The Next Round - Emergent Small-Calibre Cartridge Technologies - by N.R. Jenzen-Jones PDFДокумент80 страницChambering The Next Round - Emergent Small-Calibre Cartridge Technologies - by N.R. Jenzen-Jones PDFanonОценок пока нет

- 264 Winchester Magnum load data from Hodgdon Powder CompanyДокумент2 страницы264 Winchester Magnum load data from Hodgdon Powder Companyengine33rОценок пока нет

- Bolens Snowmobile Technical Specifications and Service ManualДокумент3 страницыBolens Snowmobile Technical Specifications and Service ManualPaul MartinОценок пока нет

- Steyr AUG Barrel 14Документ3 страницыSteyr AUG Barrel 14ouraltn2001Оценок пока нет

- Checkmate TM 2013 .22lr Manual.Документ2 страницыCheckmate TM 2013 .22lr Manual.Griffin Armament SuppressorsОценок пока нет

- M17a3 PDFДокумент14 страницM17a3 PDFErika Lorena Gonzalez PeñaОценок пока нет

- 192 Office/Tech:: Shotgun IndexДокумент16 страниц192 Office/Tech:: Shotgun IndexStan BrittsanОценок пока нет

- SHTF 50Документ6 страницSHTF 50Tonyf6188Оценок пока нет

- Basic BallisticsДокумент18 страницBasic BallisticsDarrell HughesОценок пока нет

- Marlin 1894 & 1895Документ9 страницMarlin 1894 & 1895gretalu2100% (1)

- Schematic: Click On Your ComponentДокумент1 страницаSchematic: Click On Your ComponentDean MillerОценок пока нет

- Top .38 Caliber RevolversДокумент8 страницTop .38 Caliber RevolverssgtmonroeОценок пока нет

- Powder Bushing: ChartДокумент2 страницыPowder Bushing: Chartmikeabramson316Оценок пока нет

- HK Mp5 Armorers ManualДокумент90 страницHK Mp5 Armorers Manualjustin_j_gaudet100% (5)

- Adirondack ChairДокумент12 страницAdirondack Chairpoliserpijc7617Оценок пока нет

- Crisis - Hostage - Negotiation - Current Strategies and Issues in High Rish Conflict ResolutionДокумент19 страницCrisis - Hostage - Negotiation - Current Strategies and Issues in High Rish Conflict ResolutionRobers ArmandОценок пока нет

- Dillon Alignment Tool InstructionsДокумент4 страницыDillon Alignment Tool Instructionspoliserpijc7617Оценок пока нет

- Comment: An Introduction To The Study of Epidemiology PublishedДокумент4 страницыComment: An Introduction To The Study of Epidemiology Publishedpoliserpijc7617Оценок пока нет

- Planting Bench With Protected Growing StationДокумент26 страницPlanting Bench With Protected Growing Stationpoliserpijc7617Оценок пока нет

- Ebola Evaluation AlgorithmДокумент1 страницаEbola Evaluation Algorithmpoliserpijc7617Оценок пока нет

- Pdbook TrichinellaДокумент9 страницPdbook Trichinellapoliserpijc7617Оценок пока нет

- 2012 Burris CatalogДокумент48 страниц2012 Burris Catalogpoliserpijc7617Оценок пока нет

- Disaster HandbookДокумент40 страницDisaster Handbookpoliserpijc7617Оценок пока нет

- Bacterial Meningitis PDFДокумент18 страницBacterial Meningitis PDFZulaicha MumarridzohОценок пока нет

- Disaster Management Training Program Preparedness UNDPДокумент64 страницыDisaster Management Training Program Preparedness UNDPTAKI - TAKI100% (1)

- Active Shooter 2012 EditionДокумент210 страницActive Shooter 2012 EditionNew York PostОценок пока нет

- Silla PlegableДокумент1 страницаSilla Plegablepoliserpijc7617Оценок пока нет

- Shale Oil StudyДокумент65 страницShale Oil Studypoliserpijc7617Оценок пока нет

- Pallet Adirondack ChairДокумент29 страницPallet Adirondack Chairpoliserpijc7617Оценок пока нет

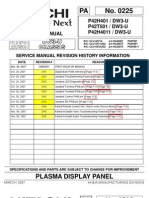

- P42H401Документ124 страницыP42H401jangel332045Оценок пока нет

- Continuum Plain English ReferenceДокумент710 страницContinuum Plain English Referencedontinuum100% (3)

- Best Practices in ElasticsearchДокумент5 страницBest Practices in ElasticsearchGangadhar AmbatiОценок пока нет

- Info AgeДокумент21 страницаInfo Ageroland uadan jrОценок пока нет

- BOM Registraton ManagementДокумент11 страницBOM Registraton ManagementNguyễn Hoàng SơnОценок пока нет

- Inmotion M812Документ12 страницInmotion M812Luis GilОценок пока нет

- ANSI device numbersДокумент5 страницANSI device numbersGerman SchwabОценок пока нет

- Debug 1214Документ3 страницыDebug 1214emancypantka_Оценок пока нет

- LF351 PDFДокумент9 страницLF351 PDFIsaac SosaОценок пока нет

- EtrxДокумент10 страницEtrxapi-236544093Оценок пока нет

- Canon Ip5200 Service ManualДокумент64 страницыCanon Ip5200 Service ManualCharles Doud100% (1)

- Differential EvolutionДокумент11 страницDifferential EvolutionDuško TovilovićОценок пока нет

- Manual Roller 20 PNДокумент33 страницыManual Roller 20 PNSilvio Luiz SalotiОценок пока нет

- Convert Seismological Data and Analyze WaveformsДокумент72 страницыConvert Seismological Data and Analyze WaveformsYayanMi'rojulHusniОценок пока нет

- Philips AmpLightДокумент5 страницPhilips AmpLighthusnikhalilОценок пока нет

- 3ft SMA-WK-3 Wind Kit 250kmh (NMT266-06)Документ2 страницы3ft SMA-WK-3 Wind Kit 250kmh (NMT266-06)guns1976Оценок пока нет

- 15 3 Introduction To ISA (Instruction Set Architecture) 25-08-2021 (25 Aug 2021) Material - I - 25 Aug 2021 - InstructiДокумент10 страниц15 3 Introduction To ISA (Instruction Set Architecture) 25-08-2021 (25 Aug 2021) Material - I - 25 Aug 2021 - InstructiMudit JainОценок пока нет

- Terminales y ConectoresДокумент64 страницыTerminales y Conectoreswaltico2812100% (3)

- 01 Laboratory Exercise Lorejo JomreyДокумент3 страницы01 Laboratory Exercise Lorejo JomreyJimboy LorejoОценок пока нет

- VariCAD 2D 3D Light Industrial and Mechanical CAD SystemДокумент178 страницVariCAD 2D 3D Light Industrial and Mechanical CAD Systemicad100% (4)

- CSE101 - Basics of ComputerДокумент41 страницаCSE101 - Basics of Computer2019-3-30-034Оценок пока нет

- 2757548Документ55 страниц2757548NetkomОценок пока нет

- (2013) Package Relaimpo PDFДокумент36 страниц(2013) Package Relaimpo PDFLyly MagnanОценок пока нет

- Ec501 Practical Work 4 PDFДокумент25 страницEc501 Practical Work 4 PDFAdam DmcОценок пока нет

- Fig: Superscalar Architecture of PentiumДокумент19 страницFig: Superscalar Architecture of PentiumRathan NОценок пока нет

- AWS LambdaДокумент6 страницAWS LambdaVishakha SinghОценок пока нет

- PJ2500M 3500M C - 4000u K - 0309Документ4 страницыPJ2500M 3500M C - 4000u K - 0309julio castroОценок пока нет

- Flexi EDGE BTSДокумент67 страницFlexi EDGE BTSDel CamachoОценок пока нет

- Optiplex 330 Into HackintoshДокумент3 страницыOptiplex 330 Into HackintoshorangotaОценок пока нет

- 8085 Microprocessor Architecture, Registers, Buses and Pin DescriptionДокумент43 страницы8085 Microprocessor Architecture, Registers, Buses and Pin DescriptionElisha NdhlovuОценок пока нет

- Becky Lynch: The Man: Not Your Average Average GirlОт EverandBecky Lynch: The Man: Not Your Average Average GirlРейтинг: 4.5 из 5 звезд4.5/5 (12)

- Horse Training 101: Key Techniques for Every Horse OwnerОт EverandHorse Training 101: Key Techniques for Every Horse OwnerРейтинг: 4.5 из 5 звезд4.5/5 (27)

- Crazy for the Storm: A Memoir of SurvivalОт EverandCrazy for the Storm: A Memoir of SurvivalРейтинг: 3.5 из 5 звезд3.5/5 (217)

- The Teen’s Living Guide: Unlocking Your Potential for a Remarkable JourneyОт EverandThe Teen’s Living Guide: Unlocking Your Potential for a Remarkable JourneyРейтинг: 5 из 5 звезд5/5 (76)

- The Arm: Inside the Billion-Dollar Mystery of the Most Valuable Commodity in SportsОт EverandThe Arm: Inside the Billion-Dollar Mystery of the Most Valuable Commodity in SportsРейтинг: 4 из 5 звезд4/5 (49)

- Elevate and Dominate: 21 Ways to Win On and Off the FieldОт EverandElevate and Dominate: 21 Ways to Win On and Off the FieldРейтинг: 5 из 5 звезд5/5 (4)

- Life Is Not an Accident: A Memoir of ReinventionОт EverandLife Is Not an Accident: A Memoir of ReinventionРейтинг: 3.5 из 5 звезд3.5/5 (7)

- What Winners Won't Tell You: Lessons from a Legendary DefenderОт EverandWhat Winners Won't Tell You: Lessons from a Legendary DefenderРейтинг: 4.5 из 5 звезд4.5/5 (7)

- Endure: How to Work Hard, Outlast, and Keep HammeringОт EverandEndure: How to Work Hard, Outlast, and Keep HammeringРейтинг: 4.5 из 5 звезд4.5/5 (283)

- The Perfect Mile: Three Athletes, One Goal, and Less Than Four Minutes to Achieve ItОт EverandThe Perfect Mile: Three Athletes, One Goal, and Less Than Four Minutes to Achieve ItОценок пока нет

- Bloodlines: The True Story of a Drug Cartel, the FBI, and the Battle for a Horse-Racing DynastyОт EverandBloodlines: The True Story of a Drug Cartel, the FBI, and the Battle for a Horse-Racing DynastyРейтинг: 4 из 5 звезд4/5 (8)

- Sprawlball: A Visual Tour of the New Era of the NBAОт EverandSprawlball: A Visual Tour of the New Era of the NBAРейтинг: 4 из 5 звезд4/5 (11)

- The Truth About Aaron: My Journey to Understand My BrotherОт EverandThe Truth About Aaron: My Journey to Understand My BrotherОценок пока нет

- Last Child in the Woods: Saving Our Children From Nature-Deficit DisorderОт EverandLast Child in the Woods: Saving Our Children From Nature-Deficit DisorderРейтинг: 4 из 5 звезд4/5 (283)

- Bulletproof Seduction: How to Be the Man That Women Really WantОт EverandBulletproof Seduction: How to Be the Man That Women Really WantРейтинг: 4.5 из 5 звезд4.5/5 (168)

- The Last Dive: A Father and Son's Fatal Descent into the Ocean's DepthsОт EverandThe Last Dive: A Father and Son's Fatal Descent into the Ocean's DepthsОценок пока нет

- Summary: Range: Why Generalists Triumph in a Specialized World by David Epstein: Key Takeaways, Summary & Analysis IncludedОт EverandSummary: Range: Why Generalists Triumph in a Specialized World by David Epstein: Key Takeaways, Summary & Analysis IncludedРейтинг: 4.5 из 5 звезд4.5/5 (6)

- Strong Is the New Beautiful: Embrace Your Natural Beauty, Eat Clean, and Harness Your PowerОт EverandStrong Is the New Beautiful: Embrace Your Natural Beauty, Eat Clean, and Harness Your PowerРейтинг: 4 из 5 звезд4/5 (5)

- The Inside Game: Bad Calls, Strange Moves, and What Baseball Behavior Teaches Us About OurselvesОт EverandThe Inside Game: Bad Calls, Strange Moves, and What Baseball Behavior Teaches Us About OurselvesРейтинг: 4 из 5 звезд4/5 (7)

- Patriot Reign: Bill Belichick, the Coaches, and the Players Who Built a ChampionОт EverandPatriot Reign: Bill Belichick, the Coaches, and the Players Who Built a ChampionРейтинг: 3.5 из 5 звезд3.5/5 (30)