Академический Документы

Профессиональный Документы

Культура Документы

A New Type of Chitosan Hydrogel Sorbent Generated by An PDF

Загружено:

Vinh_LX_88Исходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

A New Type of Chitosan Hydrogel Sorbent Generated by An PDF

Загружено:

Vinh_LX_88Авторское право:

Доступные форматы

A new type of chitosan hydrogel sorbent generated by anionic surfactant gelation

Sudipta Chatterjee, Tania Chatterjee, Seung H. Woo

*

Department of Chemical Engineering, Hanbat National University, San 16-1, Deokmyeong-Dong, Yuseong-Gu, Daejeon 305-719, Republic of Korea

a r t i c l e i n f o

Article history:

Received 24 October 2009

Received in revised form 19 December 2009

Accepted 21 December 2009

Available online 2 February 2010

Keywords:

Adsorption

Chitosan

Hydrogel beads

Sodium dodecyl sulfate

Surfactant

a b s t r a c t

A new type of chitosan hydrogel beads (CSB) with a coreshell membrane structure was generated by

sodium dodecyl sulfate (SDS) gelation process. CSB exhibited higher mechanical strength and acid stabil-

ity than chitosan hydrogel beads (CB) formed by alkali gelation. The effect of SDS concentration variation

during gelation on the adsorption capacity of CSB for congo red (CR) as a model anionic dye showed that

CSB formed by 4 g l

1

SDS gelation had the highest adsorption capacity. The maximum adsorption capac-

ity of CSB (208.3 mg g

1

) obtained from the Sips model was found slightly higher than that of CB

(200.0 mg g

1

). Membrane materials of CSB obtained after squeezing core water from the beads showed

approximately 25 times higher volumetric adsorption capacity than CB.

2009 Elsevier Ltd. All rights reserved.

1. Introduction

The efuents discharged from textile industry contain a large

variety of dyes and it is estimated that around 1015% of the dyes

are lost in the efuent during the dyeing processes (Crini, 2006;

dos Santos et al., 2007). The discharge of dye containing efuents

to the receiving water bodies retards photosynthesis by aquatic

plants and phytoplanktons due to abnormal colouration of water

(Robinson et al., 2001). Furthermore, some dyes in the efuents

are toxic, carcinogenic or mutagenic to human beings (Crini,

2006). Azo dyes represent about 50% of all dyes and more than

53% of these commonly azo dyes are known to be highly resistant

to biological degradation process (Manu and Chaudhari, 2002).

Congo red (CR) is one of important azo dyes and it mainly occurs

in the efuents discharged from textile, paper, printing, leather

industries, etc. CR is metabolized to benzidine, a known human

carcinogen.

Various techniques such as coagulation/occulation (Hasani

et al., 2009), activated carbon adsorption (Kadirvelu et al., 2003),

oxidation (Malik and Saha, 2003), ozonation (Selcuk, 2005), elec-

trochemical oxidation (Radha et al., 2009), membrane separation

(Chiu et al., 2009), biological degradation (Gopinath et al., 2009),

etc., have been applied for the treatment of dye containing efu-

ents and most of the techniques are reported as expensive and

not environment friendly (Crini, 2006). Activated carbon is the

most widely used adsorbent for dye removal, but it is too expen-

sive and there is difculty in the regeneration process (Kadirvelu

et al., 2003). Various low-cost adsorbents such as coir pith acti-

vated carbon (Namasivayam and Kavitha, 2002), fungal and algal

biomasses (Khalaf, 2008), bacterial biomass (Vijayaraghavan

et al., 2008), neem leaf powder (Bhattacharrya and Sharma,

2004), activated desert plant (Bestani et al., 2008), palm kernel

seed coat (Oladoja and Akinlabi, 2009), etc., have been used for

the removal of dye from wastewater. However, low-adsorption

capacities of some of these adsorbents for dyes initiate further

search for new adsorbents.

Chitosan (CS) is a natural heteropolymer of glucosamine and

N-acetyl glucosamine residues, and obtained by alkaline deacety-

lation of chitin (a polymer made up of N-acetyl glucosamine

residues), the next most abundant natural polysaccharide after

cellulose (Chung and Chen, 2008; Crini and Badot, 2008).

Recently, CS hydrogel beads have generated great interest for

removal of environmentally hazardous chemicals due to their bio-

degradability, low-cost, and multiple functional groups (Crini and

Badot, 2008; Chatterjee et al., 2009a,b). CS hydrogel beads are

more extensively used than ake and powder forms of this poly-

mer because of their high surface area and porosity (Varma et al.,

2004). CS hydrogel beads have shown surprisingly high adsorp-

tion capacities for numerous dyes and heavy metals, as compared

to various adsorbents surveyed in recent review papers (Crini,

2006; Guibal, 2004; Gupta and Suhas, 2009). Nevertheless, CS

hydrogel beads formed by conventional physical or alkali gelation

face serious impediments to commercial application, such as low-

mechanical strength, low-acid stability, and a large material vol-

ume. Different methods like chemical cross-linking (Chiou et al.,

2004), carboxy alkyl substitution (Cestari et al., 2004), carbon

nanotubes impregnation (Chatterjee et al., 2009c), etc., can

0960-8524/$ - see front matter 2009 Elsevier Ltd. All rights reserved.

doi:10.1016/j.biortech.2009.12.089

* Corresponding author. Tel.: +82 42 821 1537; fax: +82 42 821 1593.

E-mail address: shwoo@hanbat.ac.kr (S.H. Woo).

Bioresource Technology 101 (2010) 38533858

Contents lists available at ScienceDirect

Bioresource Technology

j our nal homepage: www. el sevi er . com/ l ocat e/ bi or t ech

improve mechanical stability of CS hydrogel beads, but still do

not yield enough strength for use in actual situations. Moreover,

sometimes these methods cause a signicant decrease in adsorp-

tion capacity (Crini and Badot, 2008).

Recently, the study on interactions between polymeric materi-

als and anionic surfactants has been a subject of fundamental re-

search (Thongngam and McClements, 2005; Trabelsi et al., 2006).

According to literature survey, fabrication of CS hydrogel beads

by anionic surfactant gelation and its application in the adsorption

research eld have not been reported to date. In this study, a new

type of CS hydrogel beads (CSB) was generated by anionic surfac-

tant gelation process using sodium dodecyl sulfate (SDS). A de-

tailed study of the mechanical properties of these materials

together with its adsorption performance for CR as a model anionic

dye was investigated.

2. Methods

2.1. Materials

CS (>85% deacetylation), SDS, and CR were purchased from Sig-

ma Chemical Co., USA. All other analytical grade chemicals were

purchased from Sigma Chemical Co., USA.

2.2. Surfactant and alkali gelation

Formation of chitosan hydrogel beads by SDS gelation (CSB) in-

volved dropwise (drop volume 20 ll) addition of CS solution

(1 wt.% CS in 2 vol.% acetic acid) into SDS solution of various con-

centrations between 1 and 50 g l

1

through a T-1000-B pipet tip,

Axygen scientic, USA. The subsequent beads formation in the

same SDS solution depletes the amount of SDS. In order to attain

the same amount of SDS in the beads with subsequent bead forma-

tion in the solution, maximumtwenty hydrogel beads were formed

in 10 ml SDS solution of desired concentration and beads were ta-

ken from the same SDS solution after 3 h. CS hydrogel beads

formed by alkali gelation (CB) involved dropwise addition of CS

(1 wt.%) in acetic acid solution (2 vol.%) to alkali mixture

(H

2

O:MeOH:NaOH = 4:5:1, w/w). As-prepared beads were exten-

sively washed with deionized water and preserved in aqueous

environment for future use.

2.3. Structure analysis

Optical micrographs of CB, and CSB by 4, 10, 20 and 50 g l

1

SDS

gelation were taken using Nikon Microscope Eclipse 80i, Japan. Ele-

mental analyses of CB, and CSB formed with various SDS concen-

trations (5, 10, 20 and 50 g l

1

) were performed using Elemental

analyzer (EA1108, Fisons). Infrared (IR) spectra of CB and CSB

formed with various SDS concentrations (5, 10, 20 and 50 g l

1

)

were characterized using a FTIR Spectrophotometer (Nicolet

6700, Thermal) with KBr pellet.

2.4. Mechanical stability

The response of the CB and CSB to ultrasonication gives an in-

sight into the mechanical stability of the beads and it was deter-

mined by measuring weight loss after ultrasonication of 1 g wet

beads in 100 ml deionized water using 750 W ultrasonic processor

(VC 750, Sonics) with a high power sonic tip operated at 20 kHz

frequency and under various power amplitudes (a) 21%, (b) 25%,

(c) 30%, and (d) 35% for 10 min. The beads obtained after ultrason-

ication were collected using 1 mmsieve and percentage dry weight

loss of beads was measured from the weight difference of the

beads before and after ultrasonication.

2.5. Acid stability

Acid stability of gel particles was characterized by determining

the mass loss due to gel dissolution in acidic solution. The swelling

experiment of beads in acid solution was performed by adding 1 g

wet beads of CB and CSB in 50 ml deionized water of various pH

levels (pH 27) and the beads were allowed to swell for 6 h at

30 C in shaking condition. The percentage dry weight loss of the

beads was determined from the difference of wet weight of the

hydrogel beads before and after swelling.

2.6. Adsorption study

The adsorption capacity of CSB formed by 4 g l

1

SDS gelation

was compared with CB for adsorption of CR from 100 mg l

1

aque-

ous solution. Here CR was selected as a model anionic dye. Mem-

brane materials of the CSB (CSM) were obtained after squeezing

core water from the beads and the adsorption performance of

CSM was also evaluated in this study. The batch adsorption exper-

iments were performed in glass vials (20 ml) containing 10 ml CR

solution of desired concentration and 0.2 g wet adsorbent materi-

als at pH 5 and 30 C under shaking condition (150 rpm) for 24 h.

The performance of CSB formed in various SDS solutions from 2

to 50 g l

1

was studied for adsorption of 100 mg l

1

CR solution.

Equilibrium isotherm studies were carried out at a xed tempera-

ture (30 C) using CB and CSB formed by 4 g l

1

SDS gelation as

adsorbent materials, and different initial concentrations of CR

(101000 mg l

1

) were prepared from a stock solution

(1000 mg l

1

). The kinetics experiments were performed to deter-

mine equilibrium time for adsorption of CR (100 mg l

1

) onto CB

and CSB, and different time intervals up to 960 min were used

for this study. The amount of CR in solution before and after

adsorption was analyzed at its absorption maximum (k

max

,

497 nm) using a DR5000 spectrophotometer (HACH, USA). All the

experiments were conducted in triplicate. The amounts of CR ad-

sorbed by the adsorbent materials were calculated using the fol-

lowing equation:

q

C

0

C

eq

V

W

1

where q (mg g

1

) is the amount of CR adsorbed by the adsorbent

materials, C

0

and C

eq

(mg l

1

) are the initial and equilibrium li-

quid-phase concentration of CR, respectively, V (l) is the initial vol-

ume of dye solution, and W (g) is the dry weight of adsorbent

materials.

2.7. Adsorption isotherm models

The non-linear forms of the Langmuir, Freundlich and Sips iso-

therm models were used to analyze the equilibrium isotherm data

and these models were evaluated by the non-linear coefcients of

determination (R

2

) and a non-linear Chi-square test (v

2

). The

expression of the Langmuir model is given as:

q

e

q

m

K

L

C

e

1 K

L

C

e

2

where C

e

is the equilibriumconcentration of CR (mg l

1

) in the solu-

tion, q

e

is the equilibrium CR concentration (mg g

1

) on the adsor-

bent, and q

m

(mg g

1

) and K

L

(l mg

1

) are Langmuir constants

related to the adsorption capacity and energy of adsorption,

respectively.

The expression of the Freundlich model is:

q

e

K

F

C

1

n

e

3

3854 S. Chatterjee et al. / Bioresource Technology 101 (2010) 38533858

K

F

is the Freundlich constant related to the sorbent capacity of sor-

bent and n is an empirical parameter representing the heterogene-

ity of site energies.

Sips model is a combination of Langmuir and Freundlich models

and it is expressed as:

q

e

q

max

K

eq

C

n

e

1 K

eq

C

n

e

4

K

eq

(l mg

1

) represents the equilibrium constant of Sips equa-

tion and q

max

(mg g

1

) is the maximum adsorption capacity. Sips

isotherm model is characterized by the heterogeneity factor, n.

2.8. Desorption studies

Desorption studies were carried out with CR loaded beads ob-

tained from an adsorption system with 10 ml of CR solution

(100 mg l

1

), and 0.2 g wet weight of beads (CB and CSB). After

adsorption for 24 h at pH 5, the beads were separated by ltration

and CR concentration in the ltrate was measured spectrophoto-

metrically. The beads were washed gently with deionized water

to remove unadsorbed CR molecules. After washing, beads were

transferred into 10 ml of deionized water adjusted to pH 1013

and CR desorbed from the beads to the solution was measured

after 24 h.

3. Results and discussion

3.1. Formation of CS hydrogel beads by alkali and SDS gelation

Formation of CB involves neutralisation of each droplet of CS

solution in alkali solution and this process generates a physical

hydrogel bead that contains only water and CS in the free amine

form. The neutralisation of NH

3

sites into NH

2

leads to the disap-

pearance of ionic repulsions between polymer chains, and the

physical hydrogel bead is formed by physical cross-linking of poly-

mer chains involving hydrogen bonds and hydrophobic interac-

tions (Ladet et al., 2008). Physical hydrogel formation of CS

simply involves the process of hydrophobic/hydrophilic balance

(Montembault et al., 2005).

Formation of CSB begins when drops of CS solution are added to

SDS solution (250 g l

1

). The mixing between the two solutions is

not instantaneous because CS solution droplets are viscous. The

oppositely charged surfactant (SDS) and polyelectrolyte (CS) come

into contact with one another by means of counter-diffusion across

the surfactant/polyelectrolyte solution interface. Unlike the deep

penetration of small OH

ion during alkali gelation into the CS

droplet, complex formation occurs only at the interface due to

the large size of the surfactant molecule, and a gel capsule is

formed around the drop. This effect results in shrinkage of the

polyelectrolyte drop, and hydrogel beads are thus formed by asso-

ciative phase separation (Lapitsky and Kaler, 2004). Such a network

is stabilised by a combination of electrostatic, iondipole, and

hydrophobic interactions (Thongngam and McClements, 2004).

After the rst soft membrane layer is rapidly formed, surfactant

molecules are still able to penetrate through the layer, and a sec-

ond membrane layer is formed by contact with chitosan molecules

that are diffused to the inner surface. Ultimately, a shell membrane

composed of thin layers is formed.

3.2. Structure of hydrogel beads

Optical microscope images of hydrogel beads (gure not

shown) illustrate that CB consist purely of CS molecules, whereas

CSB formed by 4 g l

1

SDS gelation consist of a sparsely gelled core

encapsulated by a dense shell, indicating a coreshell structure.

The images of CSB at different stages of gelation (gure not shown)

clearly indicate that SDS complexation continues in SDS solution

even after bead formation, and structural organisation of the beads

changes with time after formation in the same solution. Cross-sec-

tions of CSB exhibit a multi-membrane structure. As SDS concen-

tration is increased in the gelling solution, stronger and denser

hydrogel beads are formed. Additionally, shrinkage is observed

from osmotic action of the shell membrane, by which more water

molecules in the shell are released at high concentrations of SDS in

the gelling solution.

The results of elemental analysis of CSB formed by various SDS

concentrations are listed in Table 1. The sulfur (S) content of CSB is

close to the stoichiometric molar ratio, but this value slightly in-

creases with an increase in SDS concentration in the gelling solu-

tion. The determination of SDS content of CSB is purely based on

S (%) obtained by elemental analysis because the amount of S in

CSB is solely contributed by SDS molecules. Thereby, the increase

in SDS concentration during gelation increases SDS content in

CSB (Table 2).

FTIR spectra of CB (gure not shown) show characteristic peaks

assignment of CB: 3442 cm

1

(wide peak of OH stretching over-

lapped with NH stretching), 2878 cm

1

(CH stretching),

1651 cm

1

(amide II band, NH bending and C@O stretching of

acetyl groups), 1382 cm

1

(OH bending and CN stretching) and

1071 cm

1

(bridge COC stretching and CO stretching). Charac-

teristic peaks obtained for CSB (gure not shown) with various

SDS concentrations during gelation (5, 10, 20, 50 g l

1

) are:

3441 cm

1

(wide peak of OH stretching overlapped with NH

stretching), 2923 and 2853 cm

1

(CH stretching), 1635 cm

1

(amide II band, NH bending and C@O stretching of acetyl groups),

1467 cm

1

(asymmetric CH bending of CH

2

group), 1379 cm

1

(OH bending and CN stretching) and 1061 cm

1

(bridge COC

stretching and CO stretching). The appearance of new spectral

Table 1

Elemental analysis of CSBs with various concentrations of SDS.

Element (%) SDS concentration (g l

1

)

5 10 20 50

N 3.36 0.03 3.40 0.02 3.41 0.03 3.37 0.01

C 47.52 0.31 47.50 0.34 47.42 0.08 48.14 1.98

H 8.46 0.07 8.46 0.11 8.38 0.05 8.49 0.30

S 6.14 0.32 6.52 0.16 6.71 0.04 6.77 0.01

Data represents average of three replicates with standard deviations.

SDS (g l

-1

)

0 5 10 15 20 25

D

r

y

w

e

i

g

h

t

l

o

s

s

(

%

)

0

20

40

60

80

100

120

CB (21%)

CB (25%)

CB (30%)

CB (35%)

CSB (21%)

CSB (25%)

CSB (30%)

CSB (35%)

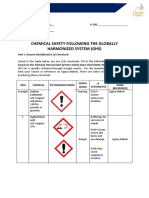

Fig. 1. Mechanical stability test of CB and CSB formed at various SDS concentrations

(5, 10 and 20 g l

1

). The value in the parenthesis of the legend represents power

amplitude during ultrasonic operation.

S. Chatterjee et al. / Bioresource Technology 101 (2010) 38533858 3855

peaks especially in the region of 16501550 cm

1

, and at

2923 cm

1

indicates binding of dodecyl sulfate with the amine

group of CS molecules during SDS gelation. Thereby, FTIR results

clearly suggest that the interactions between CS and oppositely

charged SDS molecules lead to complex formation, in which gluco-

samine units of CS form salt bonds with SDS. The nal bead struc-

ture forms via hydrophobic interactions between non-polar

segments of SDS in aqueous solution.

3.3. Mechanical stability of hydrogel beads

Mechanical stability testing of the beads is given as mass loss

under ultrasonication. Fig. 1 shows that CSB showed much less

mass loss than CB after ultrasonication, indicating that beads

formed by SDS gelation are mechanically more stable than physical

hydrogel beads of CS. The percentage dry weight loss of CSB after

ultrasonication decreased with an increase in SDS concentration

during gelation. It has been reported in earlier publication (Chat-

terjee et al., 2009c) that mechanical stability of CB was greatly en-

hanced by carbon nanotube (CNT) impregnation. The weight loss of

CNT impregnated CB was 2.02% after ultrasonication under 25%

power amplitude for 10 min, whereas, that for CB and CB cross-

linked with epichlorohydrin (ECH) was 51.61% and 40.21%, respec-

tively. In this study, CSB formed by 5, 10 and 20 g l

1

SDS gelation

exhibited 1.14%, 0.42% and 0% weight loss, respectively, after ultra-

sonication under 25% power amplitude for 10 min. The less mass

loss of CSB than CNT impregnated CB or cross-linked CB indicates

the effectiveness of SDS gelation method for enhancing mechanical

stability of CB.

3.4. Acid stability of hydrogel beads

Acid stability test of hydrogel beads indicated that the mass loss

of CB was found to increase with a decrease in pH of the solution

(gure not shown). Complete solubilisation of CB at pH 2 indicates

poor acid stability because free positive charges develop in beads

due to protonation of the amine groups of CS and the resulting mu-

tual repulsion causes swelling. CSB formed by 5 g l

1

SDS gelation

did not show any mass loss or pH-sensitive swelling under acidic

conditions, even in a pH 2 solution. In the previous study (Chatter-

jee et al., 2009c), CB after CNT impregnation did not show any

additional acid stability. The acid stability of CB was only enhanced

after ECH cross-linking, and interestingly, the weight loss of CSB

(0.4%) was obtained much less than CB cross-linked with ECH

(24.8%) in a pH 2 solution. Therefore, SDS gelation could provide

a good acid stability of CS hydrogel beads without additional

cross-linking treatment.

3.5. Effect of SDS concentration on CR adsorption

SDS concentration variation (250 g l

1

) during gelation exhib-

ited effects on the adsorption capacity of CSB (mg g

1

) for CR

(100 mg l

1

). The maximum adsorption capacity of CSB was ob-

served with 4 g l

1

SDS gelation and at concentrations of SDS great-

er than 4 g l

1

, CSB showed a decrease in adsorption capacities. The

increase of adsorption capacity up to 4 g l

1

SDS gelation is attrib-

uted to hydrophobic interactions between CR and SDS molecules

dominating over the charge repulsions by the same molecules dur-

ing adsorption. The increase in SDS concentration during gelation

increases the SDS content in CSB (Table 2) and makes the beads

denser; this may cause increased charge repulsion between CR

and negatively charged groups of free SDS molecules and obstruct

mass transfer of CR into the interior adsorption site during

adsorption.

3.6. Volumetric adsorption capacity

Table 3 shows that CSB formed by 4 g l

1

SDS gelation exhibited

better adsorption capacity (115.8 mg CR g

1

dry weight of beads)

than CB (83.1 mg CR g

1

dry weight of beads) for adsorption from

a 100 mg l

1

CR solution, and that was most likely due to increased

hydrophobic interactions between SDS and CR. The volumetric

adsorption capacity of beads (mg CR ml

1

material volume) was

obtained by multiplying q

e

(mg g

1

) of adsorbent materials with

the g dry weight ml

1

of materials, which was increased from

0.023 g ml

1

for CB to 0.45 g ml

1

for CSM. The volumetric adsorp-

tion capacity (47.0 mg ml

1

) for CSM was signicantly enhanced

compared to that for CB (1.9 mg ml

1

), which represents a 25 in-

crease. Therefore, signicant enhancement of the volumetric

adsorption capacity of CSM could enhance applicability in real

wastewater treatment.

3.7. Adsorption isotherm

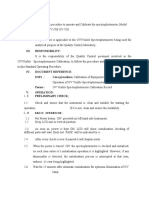

Fig. 2 exhibits the tting of equilibrium adsorption isotherm

data for CB and CSB by 4 g l

1

SDS gelation to the non-linear form

of Langmuir, Freundlich and Sips isotherm models. The results of

non-linear R

2

and v

2

for three adsorption isotherms are shown in

Table 4. The Sips isotherm model appeared to be the best tting

model for CR adsorption onto CB because of highest R

2

(0.993)

and lowest Chi-square, v

2

(2.69) values. The results of non-linear

R

2

(0.997) and v

2

(1.60) of Langmuir model, and R

2

(0.997) and

v

2

(1.70) of Sips model for adsorption of CR onto CSB indicated that

adsorption isotherm data for CSB exhibited good t with both

models. The value of n for CR adsorption onto CSB was close to

Table 2

CS and SDS contents of CSBs with various SDS concentrations.

Adsorption SDS concentration (g l

1

)

5 10 20 50

Sulfur (S) content (g) g

1

dry weight of beads

a

0.061 0.003 0.065 0.002 0.067 0.000 0.068 0.000

SDS content (g) g

1

dry weight of beads 0.553 0.028 0.587 0.014 0.605 0.003 0.610 0.001

CS content (g) g

1

dry weight of beads 0.447 0.028 0.413 0.014 0.395 0.003 0.390 0.000

mol NH

2

of CS g

1

dry weight of beads 0.0024 0.0002 0.0022 0.0001 0.0021 0.0000 0.0021 0.0000

mol SDS mol

1

NH

2

of CS 0.818 0.094 0.936 0.054 1.005 0.008 1.030 0.002

Data represents average of three replicates with standard deviations.

a

S content of CSB obtained by elemental analysis.

Table 3

Adsorption capacities of different type adsorbent materials

a

.

Type q

e

(mg CR g

1

) q

e,v

(mg CR ml

1

)

CB 83.1 1.14 1.87 0.03

CSB

b

115.8 0.96 2.66 0.03

CSM

b

103.5 1.01 47.0 0.12

a

Initial CR concentration was 100 mg l

1

.

b

The materials were produced by the gelation with 4 g l

1

SDS solution

3856 S. Chatterjee et al. / Bioresource Technology 101 (2010) 38533858

unity (n = 1.02), indicating that adsorption onto CSB is homoge-

neous. The close similarity between maximum adsorption capacity

values obtained from Langmuir (208.1 mg g

1

) and Sips

(208.3 mg g

1

) isotherm models for CSB beads indicated homoge-

neous adsorption process. The maximum adsorption capacity of

CSB (208.3 mg g

1

) and CB (200.0 mg g

1

) obtained from the Sips

isotherm model was similar, whereas maximum adsorption capac-

ity of CSB (208.1 mg g

1

) obtained from the Langmuir isotherm

model was higher than that of CB (179.2 mg g

1

). Thereby,

mechanically improved CSB exhibited similar (Sips isotherm) or

higher (Langmuir isotherm) maximum adsorption capacity than

CB.

The comparison of maximum adsorption capacity of CSB

(208.3 mg g

1

) with that of other adsorbents used for adsorption

of CR such as 6.70 mg g

1

of activated carbon prepared from coir

pith (Namasivayam and Kavitha, 2002), 41.20 mg g

1

of neem leaf

powder (Bhattacharrya and Sharma, 2004), 66.23 mg g

1

of palm

kernel seed coat (Oladoja and Akinlabi, 2009), and 330.62 mg g

1

of N,O-carboxymethyl CS (Wang and Wang, 2008) indicated that

CSB could be used as an effective adsorbent for adsorption of CR

from aqueous solutions. Moreover, adsorption performance of this

sorbent could be further improved by surface modication or

impregnation with various chemicals and materials as CR adsorp-

tion capacity increased by cetyl trimethyl ammonium bromide

impregnation (Chatterjee et al., 2010) or carbon nanotubes impreg-

nation (Chatterjee et al., 2009d).

3.8. Kinetic study

Experimental kinetic data for adsorption of CR onto CB and CSB

from a 100 mg l

1

solution have been illustrated in Fig. 3 and equi-

librium adsorption time for both adsorption systems was 420 min.

Two simplied kinetic models including pseudo-rst-order and

pseudo-second-order equations, and intra-particle diffusion mod-

el, were used in this study.

The non-linear form of the pseudo-rst-order rate equation is

given as:

q

t

q

e

1 e

k

1

t

5

where q

e

and q

t

are the amounts of CR adsorbed (mg g

1

) at equilib-

rium and at a predetermined time (t), respectively, and k

1

(min

1

) is

the rate constant of this equation. The constants, k

1

and q

e

values

obtained from this rate model are given in Table 5.

The non-linear form of pseudo-second-order rate equation is

expressed as:

q

t

q

2

e

k

2

t

1 q

e

k

2

t

and h k

2

q

2

e

6

where h represents the initial adsorption rate (mg g

1

min

1

) and k

2

(g mg

1

min

1

) is the pseudo-second-order rate constant. The val-

ues of q

e

, k

2

and h obtained from rate model are presented in Table

5.

The correlation coefcient (R

2

) values of the pseudo-rst-order

equation were 0.998 and 0.994 for CB and CSB, respectively. For the

pseudo-second-order model, the correlation coefcient (R

2

) values

were 0.988 and 0.991 for CB and CSB, respectively. The R

2

values of

both rate models for each adsorption system indicated that CR

adsorption onto CB and CSB could be better explained by pseu-

do-rst-order rate model than pseudo-second-order rate model.

As shown in Table 5, the q

e

values of CB (83.34 mg g

1

) and CSB

(116.92 mg g

1

) obtained from pseudo-rst-order rate model were

in better agreement with q

e (exp)

value of CB (83.19 mg g

1

) and

CSB (115.90 mg g

1

), respectively, than q

e

values of CB

(96.59 mg g

1

) and CSB (140.15 mg g

1

) obtained from pseudo-

second-order rate model.

C

e

(mg l

-1

)

0 200 400 600 800 1000

q

e

(

m

g

g

-

1

)

-50

0

50

100

150

200

250

Experimental data (CB)

Langmuir non-linear (CB)

Freundlich non-linear (CB)

Sips non-linear (CB)

Experimental data (CSB)

Langmuir non-linear (CSB)

Freundlich non-linear fit (CSB)

Sips non-linear fit (CSB)

4 g l

-1

SDS gelation,

pH 5, 30

0

C

Fig. 2. Plot of q

e

vs. C

e

for adsorption of CR onto CB and CSB formed by 4 g l

1

SDS

gelation; pH 5 and 30 C.

Table 4

Constants for equilibrium isotherm models with error analysis values.

Langmuir isotherm model

Adsorbent K

L

(l mg

1

) q

m

(mg g

1

) Error analysis

R

2

v

2

CB 0.026 179.2 0.980 12.86

CSB 0.046 208.1 0.997 1.60

Freundlich isotherm model

Adsorbent K

F

(l g

1

) 1/n Error analysis

R

2

v

2

CB 26.91 0.291 0.938 23.00

CSB 39.17 0.262 0.893 51.09

Sips isotherm model

Adsorbent q

max

(mg g

1

) K

eq

(l mg

1

) n Error analysis

R

2

v

2

CB 200.0 0.054 0.72 0.993 2.69

CSB 208.3 0.044 1.02 0.997 1.70

t (min)

0 200 400 600 800 1000 1200

q

t

(

m

g

g

-

1

)

0

20

40

60

80

100

120

Experimental data (CB)

Pseudo-first-order (CB)

Pseudo-second-order (CB)

Intra particle diffusion (CB)

Experimental data (CSB)

Pseudo-first-order (CSB)

Pseudo-second-order (CSB)

Intra particle diffusion (CSB)

4 g l

-1

SDS gelation

C

0

= 100 mg l

-1

, pH 5

Fig. 3. Plot of q

t

vs. t for adsorption of CR onto CB and CSB formed by 4 g l

1

SDS

gelation; initial CR concentration, 100 mg l

1

; pH 5.

S. Chatterjee et al. / Bioresource Technology 101 (2010) 38533858 3857

The intra-particle diffusion equation is given as:

q

t

k

p

t

0:5

7

k

p

is the intra-particle diffusion rate constant (mg g

1

min

0.5

) and

the values of k

p

for CB and CSB were 4.96 and 5.76 mg g

1

min

0.5

,

respectively (Table 5). The correlation coefcients (R

2

) values for CB

(0.947) and CSB (0.953) indicated that intra-particle diffusion has a

signicant role in initial stage of adsorption in the study.

3.9. Desorption study

Desorption studies help to understand the mechanism of

adsorption and also help in the recovery of CB and CSB. The results

indicated that CSB exhibited less increase in desorption (from

16.18% 0.89 to 25.06% 1.72) than CB (from 25.92% 1.01 to

36.84% 2.060) with pH change from 10 to 13. CB showed very

low-desorption for CR with pH change because of strong bond for-

mation between CR and CS molecules and involvement of some

interactions other than electrostatic interactions. Moreover, the

less desorption for CSB than CB with pH change suggests strong

hydrophobic interactions between CSB and CR molecules.

4. Conclusions

CS hydrogel bead formed by SDS gelation (CSB) produced dense

coreshell membrane structure, and it showed higher mechanical

strength and acid stability than conventional CS hydrogel bead

formed by alkali gelation (CB). CSB formed by 4 g l

1

SDS gelation

exhibited slightly higher adsorption capacity than CB for congo red

(CR). Membrane materials of CSB (CSM) generated by removing

core water had approximately 25 times higher volumetric adsorp-

tion capacity than CB for CR. Thus, generation of CSM from CSB

could enhance the technical and commercial importance of con-

ventional CB in the eld of wastewater treatment by solving its

major limitations.

Acknowledgement

This research was supported by Basic Science Research Program

through the National Research Foundation of Korea (NRF) funded

by the Ministry of Education, Science and Technology (grant num-

ber 2009-0079636).

References

Bestani, B., Benderdouche, N., Benstaali, B., Belhakem, M., Addou, A., 2008.

Methylene blue and iodine adsorption onto an activated desert plant.

Bioresour. Technol. 99, 84418444.

Bhattacharrya, K.G., Sharma, A., 2004. Azadirachta indica leaf powder as an effective

biosorbent for dyes: a case study with aqueous congo red solutions. J. Environ.

Manage. 71, 217229.

Cestari, A.R., Vieira, E.F.S., dos Santos, A.G.P., Mota, J.A., de Almeida, V.P., 2004.

Adsorption of anionic dyes on chitosan beads. 1. The inuence of the chemical

structures of dyes and temperature on the adsorption kinetics. J. Colloid

Interface Sci. 280, 380386.

Chatterjee, S., Lee, D.S., Lee, M.W., Woo, S.H., 2009a. Nitrate removal from aqueous

solutions by cross-linked chitosan beads conditioned with sodium bisulfate. J.

Hazard. Mater. 166, 508513.

Chatterjee, S., Lee, D.S., Lee, M.W., Woo, S.H., 2009b. Enhanced adsorption of congo

red from aqueous solutions by chitosan hydrogel beads impregnated with cetyl

trimethyl ammonium bromide. Bioresour. Technol. 100, 28032809.

Chatterjee, S., Lee, M.W., Woo, S.H., 2009c. Enhanced mechanical strength of

chitosan hydrogel beads by impregnation with carbon nanotubes. Carbon 47,

29332936.

Chatterjee, S., Lee, M.W., Woo, S.H., 2010. Adsorption of congo red by chitosan

hydrogel beads impregnated with carbon nanotubes. Bioresour. Technol. 101,

18001806.

Chiou, M.S., Ho, P.Y., Li, H.Y., 2004. Adsorption of anionic dyes in acid solutions using

chemically cross-linked chitosan beads. Dyes Pigm. 60, 6984.

Chiu, H.C., Liu, C.H., Chen, S.C., Suen, S.Y., 2009. Adsorption removal of anionic dye

by inorganicorganic hybrid anion-exchange membranes. J. Membr. Sci. 337,

282290.

Chung, Y.-C., Chen, C.-Y., 2008. Antibacterial characteristics and activity of acid-

soluble chitosan. Bioresour. Technol. 99, 28062814.

Crini, G., 2006. Non-conventional low-cost adsorbents for dye removal: a review.

Bioresour. Technol. 97, 10611085.

Crini, G., Badot, P.M., 2008. Application of chitosan, a natural aminopolysaccharide,

for dye removal from aqueous solutions by adsorption processes using batch

studies: a review of recent literature. Prog. Polym. Sci. 33, 399447.

dos Santos, A.B., Cervantes, F.J., van Lier, J.B., 2007. Review paper on current

technologies for decolourisation of textile wastewaters: perspectives for

anaerobic biotechnology. Bioresour. Technol. 98, 23692385.

Gopinath, K.P., Murugesan, S., Abraham, J., Muthukumar, K., 2009. Bacillus sp.

mutant for improved biodegradation of congo red: random mutagenesis

approach. Bioresour. Technol. 100, 62956300.

Guibal, E., 2004. Interactions of metal ions with chitosan-based sorbents: a review.

Sep. Purif. Technol. 38, 4374.

Gupta, V.K., Suhas, 2009. Application of low-cost adsorbents for dye removal a

review. J. Environ. Manage. 90, 23132342.

Hasani, Z.M., Alavi, M.M.R., Arami, M., 2009. Coagulation/occulation of dye-

containing solutions using polyaluminium chloride and alum. Water Sci.

Technol. 59, 13431351.

Kadirvelu, K., Kavipriya, M., Karthika, C., Radhika, M., Vennilamani, N., Pattabhi, S.,

2003. Utilization of various agricultural wastes for activated carbon preparation

and application for the removal of dyes and metal ions from aqueous solutions.

Bioresour. Technol. 87, 129132.

Khalaf, M.A., 2008. Biosorption of reactive dye from textile wastewater by non-

viable biomass of Aspergillus niger and Spirogyra sp.. Bioresour. Technol. 99,

66316634.

Ladet, S., David, L., Domard, A., 2008. Multi-membrane hydrogels. Nature 452, 76

79.

Lapitsky, Y., Kaler, E.W., 2004. Formation of surfactant and polyelectrolyte gel

particles in aqueous solutions. Colloid Surf. A 250, 179187.

Malik, P.K., Saha, S.K., 2003. Oxidation of direct dyes with hydrogen peroxide using

ferrous ion as catalyst. Sep. Purif. Technol. 31, 241250.

Manu, B., Chaudhari, S., 2002. Anaerobic decolorisation of simulated textile

wastewater containing azo dyes. Bioresour. Technol. 82, 225231.

Montembault, A., Viton, C., Domard, A., 2005. Physicochemical studies of the

gelation of chitosan in a hydroalcoholic medium. Biomaterials 26, 933943.

Namasivayam, C., Kavitha, D., 2002. Removal of congo red from water by adsorption

onto activated carbon prepared from coir pith, an agricultural solid waste. Dyes

Pigm. 54, 4758.

Oladoja, N.A., Akinlabi, A.K., 2009. Congo red biosorption on palm kernel seed coat.

Ind. Eng. Chem. Res. 48, 61886196.

Radha, K.V., Sridevi, V., Kalaivani, K., 2009. Electrochemical oxidation for the

treatment of textile industry wastewater. Bioresour. Technol. 100, 987990.

Robinson, T., McMullan, G., Marchant, R., Nigam, P., 2001. Remediation of dyes in

textile efuent: a critical review on current treatment technologies with a

proposed alternative. Bioresour. Technol. 77, 247255.

Selcuk, H., 2005. Decolourization and detoxication of textile wastewater by

ozonation and coagulation processes. Dyes Pigm. 64, 217222.

Thongngam, M., McClements, D.J., 2004. Characterization of interactions between

chitosan and an anionic surfactant. J. Agric. Food Chem. 52, 987991.

Thongngam, M., McClements, D.J., 2005. Inuence of pH, ionic strength, and

temperature on self-association and interactions of sodium dodecyl sulfate in

the absence and presence of chitosan. Langmuir 21, 7986.

Trabelsi, S., Guillot, S., Raspaud, E., Delsanti, M., Langevin, D., Bou, F., 2006. New

nano- and microparticles with a liquid-crystal-like interior. Adv. Mater. 18,

24032406.

Varma, A.J., Deshpande, S.V., Kennedy, J.F., 2004. Metal complexation by chitosan

and its derivatives: a review. Carbohydr. Polym. 55, 7793.

Vijayaraghavan, K., Lee, M.W., Yun, Y.S., 2008. A new approach to study the

decolorization of complex reactive dye bath efuent by biosorption technique.

Bioresour. Technol. 99, 57785785.

Wang, L., Wang, A., 2008. Adsorption properties of congo red from aqueous solution

onto N,O-carboxymethly-chitosan. Bioresour. Technol. 99, 14031408.

Table 5

Constants of different rate models for CB and CSB

a

.

Adsorbent q

e (exp)

Pseudo-rst-order equation Pseudo-second-order equation Intra-particle diffusion

(mg g

1

) q

e (cal)

(mg g

1

) k

1

(min

1

) q

e (cal)

(mg g

1

) k

2

(g mg

1

min

1

) h (mg g

1

min

1

) k

p

(mg g

1

min

0.5

)

CB 83.19 83.34 0.010 96.59 1.24 10

4

1.16 4.96

CSB 115.90 116.92 0.007 140.15 5.61 10

5

1.10 5.76

a

Initial CR concentration was 100 mg l

1

.

3858 S. Chatterjee et al. / Bioresource Technology 101 (2010) 38533858

Вам также может понравиться

- Extracción CromoДокумент5 страницExtracción CromoFernanda ReveloОценок пока нет

- Cadmium removal from wastewater using sunflower waste calcium–alginate beadsДокумент7 страницCadmium removal from wastewater using sunflower waste calcium–alginate beadsDerejeОценок пока нет

- Bioresource Technology Reports: A B B C BДокумент5 страницBioresource Technology Reports: A B B C BPedroLHernandezОценок пока нет

- Bioresource Technology: A B C A B A B A B D A B A BДокумент7 страницBioresource Technology: A B C A B A B A B D A B A BSoumav SarkarОценок пока нет

- Infrared ArticleДокумент23 страницыInfrared ArticleTadeu MaTASОценок пока нет

- Water: Crayfish Carapace Micro-Powder (CCM) : A Novel and Efficient Adsorbent For Heavy Metal Ion Removal From WastewaterДокумент16 страницWater: Crayfish Carapace Micro-Powder (CCM) : A Novel and Efficient Adsorbent For Heavy Metal Ion Removal From Wastewatergabriela lehutuОценок пока нет

- Gui Bal 1998Документ10 страницGui Bal 1998DanielRiosMirandaОценок пока нет

- Removal of Cadmium and Hexavalent Chromium From Electroplating Waste Water Using Thiocarbamoyl ChitosanДокумент6 страницRemoval of Cadmium and Hexavalent Chromium From Electroplating Waste Water Using Thiocarbamoyl ChitosanSabiho GinoОценок пока нет

- Preparation of Cationic Surfactant Modified Kaolin For Enhanced Adsorption of Hexavalent Chromium From Aqueous SolutionДокумент8 страницPreparation of Cationic Surfactant Modified Kaolin For Enhanced Adsorption of Hexavalent Chromium From Aqueous SolutionSaddam HusienОценок пока нет

- Remocion de Azul de Metileno Por Adsorcion de Caolin PDFДокумент8 страницRemocion de Azul de Metileno Por Adsorcion de Caolin PDFbetancur970929Оценок пока нет

- Food Hydrocolloids: Mei Liu, Yibin Zhou, Yang Zhang, Chen Yu, Shengnan CaoДокумент6 страницFood Hydrocolloids: Mei Liu, Yibin Zhou, Yang Zhang, Chen Yu, Shengnan CaoCamiloSilvaОценок пока нет

- DesalinizationДокумент14 страницDesalinizationmarcofriuli2Оценок пока нет

- Li2019 (Q2)Документ10 страницLi2019 (Q2)septian dewantaОценок пока нет

- Application of Chitosan-Clay Biocomposite Beads For Removal of Heavy Metal and Dye From Industrial EffluentДокумент14 страницApplication of Chitosan-Clay Biocomposite Beads For Removal of Heavy Metal and Dye From Industrial EffluentVojislavJovanovićОценок пока нет

- 147-Article Text-251-1-10-20180619Документ6 страниц147-Article Text-251-1-10-20180619Asrel05Оценок пока нет

- Adsorption of Chromium (VI) On Low Cost Adsorbents Derived From Agricultural Waste Material - A Comparative StudyДокумент6 страницAdsorption of Chromium (VI) On Low Cost Adsorbents Derived From Agricultural Waste Material - A Comparative StudyClaoston NardonОценок пока нет

- 1 s2.0 S0304389421017453 MainДокумент13 страниц1 s2.0 S0304389421017453 MainHaris NadeemОценок пока нет

- (664-673) V10N5CT-Hydro Dynamics PaperДокумент10 страниц(664-673) V10N5CT-Hydro Dynamics Paperleelabhanu12Оценок пока нет

- Scale Inhibition in Industrial Water Systems UsingДокумент11 страницScale Inhibition in Industrial Water Systems Usingahmedsadeq2014Оценок пока нет

- Duan 2013Документ12 страницDuan 2013tylerОценок пока нет

- Improved Biosorption For CR (VI) Reduction and Removal by Arthrobacter Viscosus Using ZeoliteДокумент8 страницImproved Biosorption For CR (VI) Reduction and Removal by Arthrobacter Viscosus Using ZeoliteEdilberto Murrieta LunaОценок пока нет

- Mixed Sulfate-Reducing Bacteria-Enriched Microbial Fuel Cells For TheДокумент9 страницMixed Sulfate-Reducing Bacteria-Enriched Microbial Fuel Cells For TheKhushboo ZahraОценок пока нет

- Uv Radiation GO in WaterДокумент10 страницUv Radiation GO in Waterreza zeinОценок пока нет

- Treatment of Dye Wastewater Using Granular Activated Carbon and Zeolite FilterДокумент15 страницTreatment of Dye Wastewater Using Granular Activated Carbon and Zeolite FilterPuneet SharmaОценок пока нет

- In Situ CD Bioremediation With BiocharДокумент10 страницIn Situ CD Bioremediation With BiocharValentin dutillieuxОценок пока нет

- Reactor Systems For The Degradation of Textile Dyes: Research Article ISSN 0976 - 4402Документ6 страницReactor Systems For The Degradation of Textile Dyes: Research Article ISSN 0976 - 4402Diana CabezasОценок пока нет

- Algas Absorventes Aceites PDFДокумент10 страницAlgas Absorventes Aceites PDFarmandeinОценок пока нет

- Nanocellulose spheroids remove up to 95% of Cr VIДокумент12 страницNanocellulose spheroids remove up to 95% of Cr VIJavier CarvajalОценок пока нет

- Production of A Water Disinfectant by Membrane EleДокумент14 страницProduction of A Water Disinfectant by Membrane EleNgo TuyenОценок пока нет

- Synthesis and Evaluation Catalytic Efficiency of Perovskite-Type Oxide Nanopowders in Removal of Bromocresol Purple From Aqueous SolutionДокумент12 страницSynthesis and Evaluation Catalytic Efficiency of Perovskite-Type Oxide Nanopowders in Removal of Bromocresol Purple From Aqueous SolutionAmin MojiriОценок пока нет

- Dried Activated Sludge As An Appropriate Biosorbent For Removal of Copper (II) IonsДокумент7 страницDried Activated Sludge As An Appropriate Biosorbent For Removal of Copper (II) IonsNataliakusumaDewiОценок пока нет

- Manuscript 1 PDFДокумент8 страницManuscript 1 PDFParaneeiswaranОценок пока нет

- Chromium Removal From Solution by Five PhotosyntheticДокумент13 страницChromium Removal From Solution by Five Photosyntheticdaniela.aparecidaОценок пока нет

- Characterization of Hydroxybenzoic Acid Chelating Resins: Equilibrium, Kinetics, and Isotherm Profiles For CD (II) and PB (II)Документ32 страницыCharacterization of Hydroxybenzoic Acid Chelating Resins: Equilibrium, Kinetics, and Isotherm Profiles For CD (II) and PB (II)TailorriteshОценок пока нет

- Kavianinia 2012Документ12 страницKavianinia 2012Lyka NievesОценок пока нет

- Zhang2019 (Q1)Документ9 страницZhang2019 (Q1)septian dewantaОценок пока нет

- Carboxymethyl Chitosan Phytic AcidДокумент8 страницCarboxymethyl Chitosan Phytic AciduthraОценок пока нет

- Journal of Molecular Structure: 3 3 Asia A. Taha, Sherif Kandil, Laila A. Mohamed, M.G. Sallam, Hany Fathy HeibaДокумент15 страницJournal of Molecular Structure: 3 3 Asia A. Taha, Sherif Kandil, Laila A. Mohamed, M.G. Sallam, Hany Fathy HeibaHany HeibaОценок пока нет

- Chitosan Effect of The Type of Solvent AcidДокумент6 страницChitosan Effect of The Type of Solvent AcidOscar Rendón H.Оценок пока нет

- Lenox Institute PressДокумент59 страницLenox Institute PressLenox InstituteОценок пока нет

- Pradhan 2019Документ40 страницPradhan 2019Isna NurhidayatiОценок пока нет

- Bagasse Fly Ash Removes Copper & CadmiumДокумент25 страницBagasse Fly Ash Removes Copper & CadmiumSatyamGuptaОценок пока нет

- The Effective Removal of Heavy Metals From Water by Activated Carbon Adsorbents of Albizia Lebbeck and Melia Azedarach Seed ShellsДокумент8 страницThe Effective Removal of Heavy Metals From Water by Activated Carbon Adsorbents of Albizia Lebbeck and Melia Azedarach Seed ShellsPortia DubeОценок пока нет

- Adsorptive Removal of CR (VI) by Chitosan-SiO2-TiO2 NanocompositeДокумент10 страницAdsorptive Removal of CR (VI) by Chitosan-SiO2-TiO2 NanocompositeShimelis KebedeОценок пока нет

- K. BOUAOUINA-ChemosphereДокумент10 страницK. BOUAOUINA-Chemospherekenza.bouaouinaОценок пока нет

- Synthesis and Characterization of Porous Silica Gels For Biomedical ApplicationsДокумент5 страницSynthesis and Characterization of Porous Silica Gels For Biomedical ApplicationsPham Thi Thu HongОценок пока нет

- Bioresource Technology: Yaolan Niu, Kan Li, Diwen Ying, Yalin Wang, Jinping JiaДокумент6 страницBioresource Technology: Yaolan Niu, Kan Li, Diwen Ying, Yalin Wang, Jinping JiaArinjayKumarОценок пока нет

- Lyocell ProcessingДокумент9 страницLyocell ProcessingmusmanazeemОценок пока нет

- Environmental Advances: Leal-Casta Neda E. J, Mel Endez-Estrada J, Toscano-Flores L. GДокумент7 страницEnvironmental Advances: Leal-Casta Neda E. J, Mel Endez-Estrada J, Toscano-Flores L. GIris RibeiroОценок пока нет

- Bioresource Technology: Jai Prakash Kushwaha, Vimal Chandra Srivastava, Indra Deo MallДокумент10 страницBioresource Technology: Jai Prakash Kushwaha, Vimal Chandra Srivastava, Indra Deo MallAAmitava ChakrabortyОценок пока нет

- Haroon2016 PDFДокумент10 страницHaroon2016 PDFNórida Pájaro GómezОценок пока нет

- Pervaporation Separation of Isopropanol-Water Mixtures Through Crosslinked Chitosan MembranesДокумент9 страницPervaporation Separation of Isopropanol-Water Mixtures Through Crosslinked Chitosan MembranesVĩnh LêОценок пока нет

- Removal of Methyl Orange Dye From Textile Effluent Using Adsorption On Chitosan Hydrogel BeadsДокумент8 страницRemoval of Methyl Orange Dye From Textile Effluent Using Adsorption On Chitosan Hydrogel BeadsESSENCE - International Journal for Environmental Rehabilitation and ConservaionОценок пока нет

- The Use of Ionic Liquids Based On Choline Chloride For MetalДокумент8 страницThe Use of Ionic Liquids Based On Choline Chloride For Metaljro84Оценок пока нет

- 1 s2.0 S004565352201801X MainДокумент9 страниц1 s2.0 S004565352201801X MainArnab GhoshОценок пока нет

- 1-S2.0-S2212982021001554-Main CuO CompleteДокумент9 страниц1-S2.0-S2212982021001554-Main CuO Completezmaxprom5Оценок пока нет

- 1051-Article Text-3401-1-10-20200311Документ17 страниц1051-Article Text-3401-1-10-20200311Kulet GuazonОценок пока нет

- Fuels, Chemicals and Materials from the Oceans and Aquatic SourcesОт EverandFuels, Chemicals and Materials from the Oceans and Aquatic SourcesFrancesca M. KertonОценок пока нет

- Reactive Transport Modeling: Applications in Subsurface Energy and Environmental ProblemsОт EverandReactive Transport Modeling: Applications in Subsurface Energy and Environmental ProblemsYitian XiaoОценок пока нет

- Atmospheric Sampling Glow Discharge Ionization Source For The Determination of Trace Organic Compounds in Ambient Air.Документ8 страницAtmospheric Sampling Glow Discharge Ionization Source For The Determination of Trace Organic Compounds in Ambient Air.Vinh_LX_88Оценок пока нет

- Effect of Nitrate On The Degradation of Bisphenol AДокумент9 страницEffect of Nitrate On The Degradation of Bisphenol AVinh_LX_88Оценок пока нет

- S2O8 UVC and H2O2 UV-C Treatment of Bisphenol A Assessment of Toxicity Estrogenic Activity Degradation Products and Results in Real WaterДокумент9 страницS2O8 UVC and H2O2 UV-C Treatment of Bisphenol A Assessment of Toxicity Estrogenic Activity Degradation Products and Results in Real WaterVinh_LX_88Оценок пока нет

- Effect of Nitrate On The Degradation of Bisphenol AДокумент9 страницEffect of Nitrate On The Degradation of Bisphenol AVinh_LX_88Оценок пока нет

- Application of Low-Cost Adsorbents For Dye Removal - A Review PDFДокумент30 страницApplication of Low-Cost Adsorbents For Dye Removal - A Review PDFVinh_LX_88Оценок пока нет

- Adsorption of Bisphenol A On Sediments in The YellowДокумент12 страницAdsorption of Bisphenol A On Sediments in The YellowVinh_LX_88Оценок пока нет

- Efficiency of Different Solar Advanced Oxidation Processes On The Oxidation of Bisphenol A in WaterДокумент10 страницEfficiency of Different Solar Advanced Oxidation Processes On The Oxidation of Bisphenol A in WaterVinh_LX_88Оценок пока нет

- Oxidation of Bisphenol A by UVS 2 O - Comparison With UVH 2 OДокумент7 страницOxidation of Bisphenol A by UVS 2 O - Comparison With UVH 2 OVinh_LX_88Оценок пока нет

- Application of Magnetic Chitosan Composites For The Removal of Toxic Metal and Dyes From Aqueous Solutions PDFДокумент26 страницApplication of Magnetic Chitosan Composites For The Removal of Toxic Metal and Dyes From Aqueous Solutions PDFVinh_LX_88Оценок пока нет

- Adsorptive Removal of Congo Red, A Carcinogenic Textile Dye by Chitosan Hydrobeads - Binding Mechanism, Equilibrium and Kinetics PDFДокумент7 страницAdsorptive Removal of Congo Red, A Carcinogenic Textile Dye by Chitosan Hydrobeads - Binding Mechanism, Equilibrium and Kinetics PDFVinh_LX_88Оценок пока нет

- Kelm 206Документ14 страницKelm 206Soumik MukhopadhyayОценок пока нет

- Activity 1 - Lab ExerciseДокумент7 страницActivity 1 - Lab ExerciseAL Jhon Bautista100% (2)

- 3944 1982 Reff2020Документ13 страниц3944 1982 Reff2020Ashish DubeyОценок пока нет

- Non Woven StandardsДокумент13 страницNon Woven StandardsAnonymous LEVNDh4100% (2)

- 13.2 Characteristic Organic ReactionsДокумент45 страниц13.2 Characteristic Organic Reactionssafiya_91Оценок пока нет

- 1339777312jasr 1710111Документ8 страниц1339777312jasr 1710111Harry CortezОценок пока нет

- Engineering Applications in Sustainable Design and Development 1st Edition by Striebig Ogundipe and Papadakis ISBN Solution ManualДокумент51 страницаEngineering Applications in Sustainable Design and Development 1st Edition by Striebig Ogundipe and Papadakis ISBN Solution Manualann100% (20)

- Chapter 3 DHДокумент53 страницыChapter 3 DHVlad KaneОценок пока нет

- Determination of Vitamin CДокумент2 страницыDetermination of Vitamin CWalwin HareОценок пока нет

- Deutschmann NatGasCS01Документ8 страницDeutschmann NatGasCS01vazzoleralex6884Оценок пока нет

- Predicting The Earthquake Response of Buildings Using Equivalent Single Degree of Freedom SystemДокумент9 страницPredicting The Earthquake Response of Buildings Using Equivalent Single Degree of Freedom SystemElvis GuizadoОценок пока нет

- Quartz CTP 2000Документ60 страницQuartz CTP 2000Angel Vargas REОценок пока нет

- Fusabond Vs Graftabond PP Gf30Документ2 страницыFusabond Vs Graftabond PP Gf30李万福Оценок пока нет

- 3PS Gaw 001 - 03Документ15 страниц3PS Gaw 001 - 03Viveck VivekОценок пока нет

- Chemistry Standard Level Paper 1: Instructions To CandidatesДокумент11 страницChemistry Standard Level Paper 1: Instructions To Candidatesdaniel toboso ferreОценок пока нет

- Aflatoxin B1 ELISA Test Kit Manual: Bioo Food and Feed SafetyДокумент11 страницAflatoxin B1 ELISA Test Kit Manual: Bioo Food and Feed SafetyComan GigiОценок пока нет

- PCTT60146Документ1 страницаPCTT60146LIM YE HENGОценок пока нет

- Class X Science - Subject Enrichment MaterialДокумент97 страницClass X Science - Subject Enrichment Materialkishor kumarОценок пока нет

- Econ2524 5526Документ4 страницыEcon2524 5526Shilla Mae BalanceОценок пока нет

- Federal Praktis Orientasi Topikal STPM Chemistry Sem 2 InorganicДокумент86 страницFederal Praktis Orientasi Topikal STPM Chemistry Sem 2 InorganicSharon RamaiahОценок пока нет

- Chapter 11: Reactions of Alkyl HalidesДокумент34 страницыChapter 11: Reactions of Alkyl HalidesHeena DuaОценок пока нет

- 41 Topics in Organometallic ChemistryДокумент11 страниц41 Topics in Organometallic ChemistrySaurav PaulОценок пока нет

- 31-6-2 ScienceДокумент15 страниц31-6-2 ScienceGsgshsjОценок пока нет

- Peek Short-Term Mechanical PropertiesДокумент15 страницPeek Short-Term Mechanical PropertiesSh.nasirpurОценок пока нет

- DEVELOPMENT OF GFRP IRRIGATION WATER GATESДокумент11 страницDEVELOPMENT OF GFRP IRRIGATION WATER GATESHanhan Ahmad SОценок пока нет

- Reinforcement Steel SpecificationsДокумент1 страницаReinforcement Steel SpecificationsSureshKumarОценок пока нет

- All India Aakash Test Series For JEE (Advanced) - 2022: TEST - 2A (Paper-1) - Code-EДокумент10 страницAll India Aakash Test Series For JEE (Advanced) - 2022: TEST - 2A (Paper-1) - Code-EManjit PandaОценок пока нет

- Flexible Coating For Manhole Tapers GAAДокумент2 страницыFlexible Coating For Manhole Tapers GAASlagalicaSlagalicaОценок пока нет

- Operation and Calibration of UV-VIS SpectrophotometerДокумент8 страницOperation and Calibration of UV-VIS SpectrophotometerMaruthi K100% (1)

- Dilution Tutorial and ProblemsДокумент4 страницыDilution Tutorial and Problemsapi-285970484Оценок пока нет