Академический Документы

Профессиональный Документы

Культура Документы

0deec51eaa898f2aaf000000 PDF

Загружено:

Udaysingh PatilИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

0deec51eaa898f2aaf000000 PDF

Загружено:

Udaysingh PatilАвторское право:

Доступные форматы

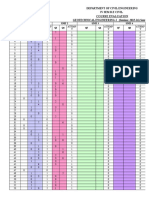

Engineering Structures 28 (2006) 18741884

www.elsevier.com/locate/engstruct

Experimental tests and analytical model of high damping

rubber dissipating devices

A. DallAsta

a,

, L. Ragni

b

a

Dipartimento di Progettazione e Costruzione dellAmbiente, Universit` a di Camerino, Ascoli Piceno, Italy

b

Dipartimento di Architettura Costruzioni e Strutture, Universit` a Politecnica delle Marche, Ancona, Italy

Received 14 November 2005; received in revised form 16 March 2006; accepted 17 March 2006

Available online 22 May 2006

Abstract

High damping rubber (HDR) consists of natural rubber to which black carbon ller is added to increase its damping properties. The use of HDR

as a dissipating device in structural systems is very promising in terms of controlling the response under live actions like wind or earthquake. The

use of HDR does however entail some problems because its dynamic behaviour is not completely understood and the few HDR models that exist

are not completely satisfactory for seismic analysis of structures equipped with HDR-base dissipation devices. Experimental tests were performed

to obtain more accurate information about the behaviour of the material under cyclic shear paths with different strain rate and strain amplitude. A

nonlinear viscoelastic damage model was proposed to describe the behaviour of rubber under cyclic loads.

c 2006 Elsevier Ltd. All rights reserved.

Keywords: High damping rubber; Mullins effect; Experimental tests; Dynamic behaviour of damper devices; Rheological model

1. Introduction

In the last few years great interest has been generated in high

damping rubber (HDR) due to its increasing use in industry, for

example in vibration isolators, earthquake bearings, dissipating

devices, but also because of its extensive use in vehicle tyres.

HDR consists of natural rubber to which black carbon ller is

added in order to improve a wide range of desirable material

properties such as the strength and damping capacities. The

addition of this ller however also has other effects, that are

not always desirable, such as the Mullins effect described

below.

The use of HDR as a dissipating device in structural systems

is very promising in terms of controlling the structural response

under live actions like wind or earthquake. This type of

dissipating device can in fact be used to realize dissipative

steel bracings which may be placed in the interior of reinforced

concrete or steel frames. The dampers may be connected

directly to the bottom of the beams and to the rigid braces

so as to endure shear strain under store drift. The result is an

Corresponding author. Tel.: +39 0736 249620; fax: +39 071 2204576.

E-mail address: andrea.dallasta@unicam.it (A. DallAsta).

increase of the frame stiffness and energy dissipation capacity

so that both the control of lateral displacements in the case of

small tremors and the reduction of damage in the case of strong

motions are ensured [1,2].

With respect to other types of damper devices, based on

elasto-plastic, viscous or shape memory materials, the HDR-

based damper seems to be a promising energy dissipating

device for a number of reasons. First, it is preferable with

respect to dissipating devices based on elasto-plastic behaviour

because the lled rubber is a fading memory material so that

no permanent strains exist even after strong seismic events.

In addition it permits dissipating energy even for the small

lateral displacements produced by wind or minor earthquakes.

Similar properties are also common to visco-elastic and viscous

devices, but their energy dissipation capacity is very sensitive

to the strain rate, contrary to HDR-based devices which show a

lower strain-rate sensitivity.

The difculty in the use of HDRmaterial is that its behaviour

is quite complex because it is strain-rate, strain-amplitude and

process dependent. The dependence on the process is known as

the Mullins effect which consists of a rapid decrease of stiffness

in the early load cycles (stress softening) due to a strain-

induced evolution of the microstructure of the material [3]. This

0141-0296/$ - see front matter c 2006 Elsevier Ltd. All rights reserved.

doi:10.1016/j.engstruct.2006.03.025

A. DallAsta, L. Ragni / Engineering Structures 28 (2006) 18741884 1875

Fig. 1. Dissipating device.

phenomenon is not completely understood and few models of

HDR exist. Additionally, the behaviour of rubber is affected by

temperature, but only marginally in the temperature range of

interest for seismic applications [4].

It should be noted that the use of rubber with enhanced

dissipating properties is not new in the mitigation of seismic

effects although, up to now, it has almost exclusively been

adopted to produce bearings for seismic isolation of bridges or

buildings. In the case of seismic isolation the main aim was

to obtain a shift of the natural frequencies by means of very

deformable supports. The dissipative properties of the material

may be considered as a secondary effect. Very simplied

models neglecting strain-rate dependence and the Mullins effect

may be acceptable for the design [57]. These models do not

furnish an adequate description of the dynamic behaviour of

HDR devices analyzed in this paper that are usually used to

increase dissipation and stiffness. It should also be noted that

the rubber of these devices undergoes strain (homogeneous pure

shear strain) which is different from the strain experienced by

isolator rubber (simple shear and compression).

A number of experimental works on carbon lled rubber

have been published in the scientic literature and a complete

overview may be found in [8] and [9]. These works show

that the behaviour of HRD materials is mainly inuenced

by nonlinear elasticity coupled with a number of inelastic

effects: nonlinear rate dependence, the Mullins effect and

its dependence on strain amplitude. Several analytical papers

do in fact propose models for these inelastic behaviours. In

particular, in some works the quasi-static behaviour was studied

and rate independent models of the Mullins effect based on

the elasticity theory [3,10], the pseudo-elasticity theory [11]

and the continuum damage theory were proposed. Only in

work [12] is the damage theory applied to viscoelasticity

in order to obtain a rate dependent damage model. The

Mullins effect has however usually been analyzed as a

phenomenon occurring on the virgin material only whereas

further investigation is required to evaluate if the initial stiffness

may be recovered after a sufciently long period. This aspect is

particularly important in devices used for reducing the effect of

seismic events which rarely happen.

In other works, like [9,13], the dynamic behaviour of rubbers

under cyclic loads was studied by experimental tests and uni-

axial rheological models, successively extended to the three-

dimensional case, were proposed on the bases of experimental

data. In these models the nonlinear strain-rate dependence and

the small rate independent hysteresis of the stable loops are

included in order to match the energy dissipating property, but

the Mullins effect related to early cycles was not considered.

In general, these models and the experimental tests did not

aim at analyzing rubber based dissipation devices where pure

shear strain occurs, but their main aim was to characterize

the tensioncompression behaviour under loadingunloading

paths. There is thus a lack of experimental information in this

regard and the proposed relations between stress and strain

tensors are not as accurate in describing the pure shear, as

required in foreseeing the dynamic behaviour of structures.

In order to dene a model for the dynamic analysis of a

structure equipped with HDR devices, the authors carried out

a test program that aims at overcoming the previously cited

limitations of existing tests and focuses on describing the device

behaviour in the range of strain and strain rate of interest to

mitigate seismic effects.

Lastly, an analytical model is proposed. It is based on

a rheological, thermodynamically compatible, approach and

permits describing the main phenomena of relevance in the

dynamic response of structures equipped with HDR-based

dissipation devices.

2. Experimental tests

The rubber dampers used in the experimental tests (Fig. 1)

were manufactured by T.A.R.R.C. (Tun Abdul Razak Research

Center). They are based on the enhanced damping properties

of a compound of natural rubber with addition of black carbon

ller and they are designed to undergo a pure shear strain in

one direction. A single device is made by the superposition of

1876 A. DallAsta, L. Ragni / Engineering Structures 28 (2006) 18741884

Fig. 2. Cyclic strain history (a) Cyclic tests (b)

max

= 0.5 and = 1.0 s

1

, different time intervals.

two rubber layers with area A = 170 230 mm

2

and thickness

h

l

= 5 mm separated by an intermediate 2 mm thick steel shim.

They are usually arranged in vertical or horizontal position

and they are disposed to connect rigid bracings to concrete or

steel frames so that the relative displacements between the steel

plates usually coincide with the inter-storey drift [1,2].

The dynamic behaviour of rubber dampers was character-

ized by performing a series of tests with a displacement feed-

back. A couple of dampers were tested in order to have a ver-

tical plane of symmetry. A 100 kN AMSLER servo-controlled

hydraulic actuator was used to assign the displacement to the

system. The actuator was mounted in such a way as not to give

eccentric loads and it was positioned in series with the load cell.

The actuator was connected to a reaction rigid frame, as shown

by Fig. 1(a). During the entire duration of the test, the total dis-

placements of the rubber devices were measured by means of

inductive displacement transducers.

The strain was measured as the ratio = /h between

the relative displacement of the plates and the total rubber

thickness h = 10 mm. The devices achieve the collapse at

a strain value of about = 4.0 and are designed to sustain

deformations up to = 2.0. The tests were performed by

limiting the maximum value of the shear strain to = 2.0 and

considering a strain rate range from 0.01 s

1

to 10 s

1

.

The rst set of cyclic tests is intended to characterize

the Mullins effect which is responsible for a softening in

the material in the initial loading path. In particular, it was

necessary to clarify whether the Mullins effect occurred in

virgin material only or if it may be observed even on a device

that has not worked for a long period of time. The rst test

was carried out on a device that had been subjected to very

numerous tests in the past and that had not successively worked

for three years so that data as to a possible aging effect of the

material could also be obtained. Further tests were carried out

after 1 week and after 1 day in order to obtain information

regarding the recovery times of the Mullins effect. The tests

consisted in applying a cyclic shear deformation where shear

strain varies with a constant rate between an amplitude of

= +0.5 and = 0.5 (Fig. 2(a)). The results reported refer

to a strain rate = 1.0 s

1

.

The forcestrain diagrams are reported in Fig. 2(b) (here

and hereafter, force F of the diagram refers to the total force

of the couple of devices). Results show that the rst loop is

very similar to the stressstrain diagram of the virgin material

(furnished by the manufacturer), thus no damage, induced

by age and previous activities, occurs in this type of rubber.

Furthermore, the test claried that the Mullins effect does not

occur on virgin material only but that it may be observed even

in non-virgin material that has not worked for a long period

of time. As a matter of fact, successive tests showed that the

softening due to the Mullins effect can be recovered in quite

a short period. A remarkable Mullins effect can be observed

even on material which has not worked for about 1 day. This

effect strongly inuences both the stiffness and the dissipating

properties of the device.

In this paper the stiffness and dissipating properties under

cyclic paths are analyzed by introducing three parameters: K

eff

,

R, and .

The rst parameter furnishes a conventional measure of the

stiffness and it can be obtained by the following ratio between

the extreme values of force F and strain :

K

eff

=

F

max

F

min

max

min

. (1)

The second parameter R furnishes information about the

dissipation capacity for cycles with different amplitudes and it

may be evaluated by the ratio

R =

W

max

(2)

where W is the external work done for every cycle and

max

is

the maximum strain attained.

Finally, the third parameter (equivalent viscous damping

coefcient) furnishes approximate information about the ratio

between the energy dissipated within a cycle and the maximum

energy stored during the strain path. It may be dened by

equating the external works done in a cycle for the considered

material and the external work done in a linear viscous system

with stiffness K

eff

at resonance condition [14]. The expression

obtained for is

=

W

2K

eff

(h

max

)

2

. (3)

A. DallAsta, L. Ragni / Engineering Structures 28 (2006) 18741884 1877

Fig. 3. K

eff

(a), R (b) and (c) of each loop for different tests.

The values of K

eff

, R and observed during the tests are

reported in Fig. 3. In the rst test (3 years) a remarkable

reduction of K

eff

, and R occurred between the rst and last

cycle; the variation with respect to the stable cycle is about

22% for K

eff

, 58% for R and 15% for . As a consequence, the

way the Mullins effect inuences the structural response cannot

be neglected when HDR is employed to control the behaviour

under live actions, like earthquakes, that rarely occur.

A second aspect that also requires investigations is the

dependence of the response on the strain amplitude. This aspect

has already been observed in the uni-axial stretch test [9,13].

In order to investigate the phenomenon, a number of cyclic

tests at a constant strain rate = 1.0 s

1

were carried out by

increasing amplitude, and allowing 1 day of rest between two

subsequent tests.

The results reported in Fig. 4 show that after 68 cycles,

once that transient contribution due to the Mullins effect has

vanished, the response always attains a stable loop which has a

typical buttery shape. Furthermore, stable loops attained for

different maximum strains differ from each other both in terms

of stiffness and shape. More specically, loops corresponding

to lower strain exhibit a lower dissipation and a higher stiffness.

A comparison between these and loops is reported in Fig. 5.

Fig. 6 reports the values of K

eff

, R and for each cycle

amplitude. The diagrams show that K

eff

decreases remarkably

when the amplitude increases, while the ratio between the

energy dissipated and the maximum strain increases with rising

values of amplitude. As a result, the devices are less rigid and

more efcient in dissipating energy for larger strain values.

The change of dissipation properties that occurs when the

strain amplitude is varied, is between the behaviour of elasto-

plastic materials, where R tends to a constant value, and linear

viscoelastic materials, for which R linearly increases. Despite

the stiffness and the energy dissipated strongly varying by

varying the cycle amplitude, the equivalent damping coefcient

is approximately constant and the average value is about 0.135

for the rst cycles and 0.11 for stable cycles.

The difference between the stable loops reveals that the

change of material behaviour related to the Mullins effect is

inuenced by the maximum strain. This is also conrmed by a

further test where a loop with amplitude of about = 0.5 is

carried out after that larger strain has been applied by means of

a test with amplitude = 2.0. In both the cases, before and

after the test at = 2.0 the response attains a stable loop but

cycle stiffness is different as shown by Fig. 7.

In order to investigate the dependence of the response on

the strain rate a number of cyclic tests with different rates were

conducted. Results concerning a similar amplitude of around

= 2.0 and different strain rate spanning from 0.01 s

1

to 10 s

1

are reported in Fig. 8. In general, a remarkable

increase in stiffness and dissipating properties was observed

when the rate exceeds the value of 1.0 s

1

that is usual in

structural systems undergoing earthquake or wind tremors. It

is interesting to observe that the strain rate affects both the

transient response and the stable loops: the Mullins effect is

very small for strain rates below 1.0 s

1

and becomes more

and more remarkable when strain rate increases. The stable

loops, compared in Fig. 9, are also different: the stiffness

increases and the buttery shape becomes more evident for

high values of strain rate. As previously, the values of K

eff

,

R and are reported in Fig. 10. In the range considered both

K

eff

and R increase from slow cycles to fast cycles. A limit

1878 A. DallAsta, L. Ragni / Engineering Structures 28 (2006) 18741884

Fig. 4. Cyclic tests at different amplitudes.

Fig. 5. Stable loop at different strain amplitudes.

value of the energy dissipated seems to be achieved however,

for = 5.0 s

1

. The cycle with the maximum strain rate

shows a remarkable increase of K

eff

and R, of about 37% and

40% respectively, with respect to the cycle with the minimum

strain rate. Regarding the equivalent damping coefcient ,

from Fig. 10(c) it can be observed that it remains about constant

around the value 0.14 for strain rate up to 5.0 s

1

while it

strongly increases up to 0.19 for larger strain rate values.

Finally in order to verify that no permanent strain occurs and

in order to separate the elastic response from the time relaxing

overstress, relaxation tests were carried out with different strain

values through to = 2.0. The forcestrain diagrams are

reported in Fig. 11(a). The overstress contribution vanishes in a

very long period and, in order to obtain an upper and lower

bound of the elastic contribution, the stress evolution at the

same constant strain was measured by applying two different

time histories (type a and b of Fig. 11(b)) in which the

equilibrium stress is obtained from lower and higher values of

stress.

There is a certain gap between the termination points of

relaxation and this seems to indicate a very small equilibrium

hysteresis. As shown in the forcetime diagram however, the

relaxation process may not be completed within the time

interval observed. These observations lead to the conclusion

that there are relaxation processes leading to equilibrium

with different (very short and very long) relaxation times.

Consequently, after a sufciently long period of time from

the application of the strain history, the device returns to its

natural state (zero stress and zero strain) and the material can

be classied as a fading memory material.

In conclusion, experimental tests showed that the material

behaviour is characterized by a transient contribution, usually

called the Mullins effect, which vanishes for a repeated cyclic

strain path and depends both on the strain rate and the

maximum strain experienced. Furthermore, once the transient

response disappears, the material exhibits stable loops which

are strain-rate dependent and have a typical buttery shape

that becomes more evident when the strain amplitude increases.

After the application of a strain history, the material relaxes to

its initial natural state in just a few hours and recovers its

initial characteristics, i.e. it shows a similar transient response

for similar strain histories, in just a few days. The variation

A. DallAsta, L. Ragni / Engineering Structures 28 (2006) 18741884 1879

Fig. 6. K

eff

(a), R (b) and (c) for different strain amplitudes.

of the properties in terms of effective stiffness and lost energy

related to the Mullins effect and the strain-rate and amplitude

dependence, can be quite remarkable even if the equivalent

viscous coefcient exhibits less signicant variations.

3. Constitutive model

The aim of this section is to formulate a constitutive model

for the devices tested, to describe the transient and stable

responses, in the range of strain rate and strain amplitude

of interest for practical applications. The proposed model

furnishes a relation between the strain (previously dened)

and the shear force in the dissipating devices which is expressed

by the ratio between the force and the area of the rubber.

1

The response of the material has been decomposed as the

sum of two contributions: the former exists for every strain

history and the latter describes a transient response (Mullins

effect) which vanishes as the strain history progresses.

The former component of the stress

0

has been described

by assuming a rheological model consisting of a nonlinear

elastic spring acting in parallel with two generalized Maxwell

elements with linear springs. This approach has the advantage

of furnishing models whose thermodynamic compatibility may

be easily checked [15]. The total stress can consequently be

expressed in the form:

0

=

e

+

v1

+

v2

(4)

1

The pure shear strain of the rubber also produces a reactive traction on the

steel plates. It may be of interest to design the devicestructure connection. This

force is usually small and was not considered in this paper.

Fig. 7. Cyclic tests before (a) and after (b) test at = 2.0.

where

e

= f

e

( ) (5a)

v1

= E

v1

[

v1

] (5b)

v2

= E

v2

[

v2

] . (5c)

The rst term represents an elastic contribution and the other

two terms are overstresses relaxing in time. At least two terms

are required to describe different material behaviours related to

long-time (Eq. (5b)) and short-time relaxation (Eq. (5c)).

1880 A. DallAsta, L. Ragni / Engineering Structures 28 (2006) 18741884

Fig. 8. Cyclic tests at different strain rates.

The internal variables

v1

and

v2

describe inelastic strains

and their evolution is controlled by the two different laws

v1

=

| |

1

( )

+

1

v1

(6a)

v2

=

H ( )

2

| | +

2

v2

(6b)

where

1

( ) =

0

+

1

| | and H is the Heaviside function

(H (x) = 1 if x > 0 and H (x) = 0 if x 0). The constant

parameters

1

and

2

control the rate of relaxation in time while

the other terms control the shape of the diagram.

This partial model can describe the limit loops experimen-

tally observed for strain cycles ranging from = 2.0 to

= 2.0 and involving different strain rates. The comparison

between model and experimental data is reported in Fig. 12 for

= 2.0 and strain rate ranging from 0.1 s

1

to 10 s

1

.

The approach proposed with internal variables is similar to

that presented by [13] but the evolution laws proposed in this

paper are different and permit describing the particular shape

of the stable loops and the change observed for different strain

rates.

The other contribution due to the Mullins effect is modelled

hereafter. The experimental tests show that the material tends

to different stable loops when strain cycles involve different

maximum strains and this phenomenon may be described by

means of a damage parameter q

e

which tends to a limit value

depending on the maximum strain experienced. Its evolution

law may be posed in the following form:

q

e

=

e

| | (0.5| | q

e

) if q

e

< 0.5| | (7a)

Fig. 9. Stable loop at different strain rates.

q

e

= 0 if 0.5| | q

e

1. (7b)

The experimental tests also showed that a strain-rate dependent

contribution to stress exists in the transient response. This

completely vanishes as the strain history progresses and can

be described by a second damage parameter q

v

with a simpler

evolution law:

q

v

=

v

| | (1 q

v

) . (8)

The total contribution to stress

m

from the Mullins effect,

controlled by the two damage parameters, can now be described

as the sum of the two contributions

m

=

me

+

mv

(9)

A. DallAsta, L. Ragni / Engineering Structures 28 (2006) 18741884 1881

Fig. 10. K

eff

(a), R (b) and (c) at different strain rates.

Fig. 11. Relaxation tests at different strain values (a). Time history a and b (b).

where

me

=

m

(1 q

e

) f

e

( ) (10a)

mv

= E

v3

(1 q

v

) [

v3

] . (10b)

The former is elastic and describes a stiffness increment which

tends to a strain dependent value and the latter is a strain-

rate dependent contribution similar to

v2

which requires the

denition of the related evolution law

v3

=

H ( )

(1 q

v

)

| |

3

+

3

mv

. (11)

It should be observed that q

e

also affects the parameter

1

, previously introduced, whose complete expression is

1

(, q

e

) =

01

+

02

(1 q

e

)

2

+

1

| |. The total stress is

consequently the sum of

0

(Eq. (4)) and

m

(Eq. (9)). Fig. 13

gives a comparison between the experimental data and the

analytical model with different maximum strains to test the

ability of q

e

to describe the asymptotic behaviour. In Fig. 14

experimental data and the analytical model for different strain

rates are compared to test the other damage parameter q

v

.

In describing the Mullins effect, the authors followed

the basic idea of introducing a growing damage, already

1882 A. DallAsta, L. Ragni / Engineering Structures 28 (2006) 18741884

Fig. 12. Stable loops at different strain rates: comparison between experimental data and analytical model.

Fig. 13. Transient response at different strain amplitudes: comparison between experimental data and analytical model.

proposed by [12] but, in the model proposed in this paper,

two different damage parameters, with different evolution

laws, were introduced to describe both the dependence on the

maximum strain and the strain rate.

The constitutive behaviour is completely dened once the

strain and ve internal variables, which may be collected in

a vector y = [

v1

,

v2

v3

, q

e

q

v

], are known. The specic free

energy per unit volume has the following form

(, y) = [1 +

m

(1 q

e

)]

e

( ) +

E

v1

2

(

v1

)

2

+

E

v2

2

(

v2

)

2

+(1 q

v

)

E

v3

2

(

v3

)

2

(12)

where

e

( ) is the strain energy of the elastic component,

such that f

e

= d

e

/d (see Eqs. (5a) and (10a)), and the

other terms describe the strain-rate dependent contributions.

Thermodynamic compatibility requires that (repeated index

denotes summation).

=

y

k

y

k

0 (13)

and is ensured once E

vi

0,

i

> 0,

i

0,

e

0,

v

0, (i = 1, 2, 3). In this work no attempt to describe the

recovery of the initial stiffness of the material in time was made

because it is not of particular interest in studying the response

A. DallAsta, L. Ragni / Engineering Structures 28 (2006) 18741884 1883

Fig. 14. Transient response at different strain rates: comparison between experimental data and analytical model.

Table 1

Constant values

f

e

( ) E

v1

1

1

(, q

e

) E

v2

2

2

N

mm

2

N

mm

2

mm

2

N s

N

mm

2

N

mm

2

mm

2

N s

N

mm

2

0.029

5

0.082

3

+0.29 2.56 0.078 0.179 0.127(1 q

e

)

2

+0.047| | 0.447 26 0.025

m

E

3v

3

3

e

v

N

mm

2

N

mm

2

mm

2

N s

N

mm

2

1.5 0.256 2.23 0.025 1.0 0.2

under seismic actions which act rarely and for a short period of

time so that a complete recovery of the initial stiffness usually

occurs between two subsequent events. The results reported in

the diagrams were obtained by adopting the parameter values

reported in Table 1.

4. Conclusions

An experimental test program was performed in order to

characterize the cyclic behaviour of high damping rubber under

pure shear strain and investigate some aspects not previously

completely understood more thoroughly.

Experimental tests demonstrated that material behaviour is

characterized by a transient contribution. Once the transient

response has disappeared, the material exhibits stable loops

which are strain-rate dependent and have a typical buttery

shape. After applying a strain history, the material relaxes to its

initial natural state and recovers its initial characteristics.

On the basis of experimental results, an analytical model,

able to describe the material behaviour in the range of interest

for seismic applications, was developed. The constitutive

behaviour was described by means of a thermodynamically

compatible rheological model, in which internal variables were

introduced to describe inelastic phenomena. The results are

quite accurate and permit overcoming the limitations of models

previously adopted in seismic analysis, that were generally

based on hysteretic laws neglecting the dependence on the

strain rate and the Mullins effect.

References

[1] DallAsta A, Dezi L, Giacchetti R, Leoni G, Ragni L. Dynamic response

of composite frames with rubber-based dissipating devices: experimental

tests. In: Proceedings of ICASS, fourth international conference on

advances in steel structures. 2005.

[2] Bartera F, Giacchetti R. Steel dissipating braces for upgrading existing

building frames. J Construct Steel Res 2004;60(3):75169.

1884 A. DallAsta, L. Ragni / Engineering Structures 28 (2006) 18741884

[3] Govindjee S, Simo JC. Transition from micro-mechanics to computation-

ally efcient phenomenology: carbon black lled rubbers incorporating

Mullins effect. J Mech Phys Solids 1992;40:21333.

[4] Lion A. On large deformation behaviour of reinforced rubber at different

temperatures. J Mech Phys Solids 1997;45:180534.

[5] FEMA450: NEHRP Recommended provisions for seismic regulations for

new buildings and other structures. Part 1: Provisions. Washington D.C.:

Federal Emergency Management Agency; 2003.

[6] FEMA 356: Prestandard and commentary for the seismic rehabilitation of

buildings. Washington D.C.: Federal Emergency Management Agency;

2000.

[7] PrEN 1998-2. Eurocode 8: design of structures for earthquake resistance.

Part 2: Bridges. Brussels (Belgium): CECN, European Committee for

standardization, 2003.

[8] Dorfmann A, Ogden RW. A constitutive model for the Mullins effect with

permanent set in particle-reinforced rubber. Int J Solids Struct 2004;41:

185578.

[9] Lion A. A physically based method to represent the thermomechanical

behaviour of elastomers. Acta Mech 1997;123:125.

[10] Govindjee S, Simo JC. A micro-mechanically based continuum damage

model for carbon black lled-rubber incorporating the Mullins effect.

J Mech Phys Solids 1991;39:87112.

[11] Dorfmann A, Ogden RW. A pseudo-elastic model for loading, partial

unloading and reloading of particle-reinforced rubber. Int J Solids Struct

2003;40:2699714.

[12] Govindjee S, Simo JC. Mullins effect and the strain amplitude dependence

of the storage modulus. Int J Solids Struct 1992;29:173751.

[13] Haupt P, Sedlan H. Viscoplasticity of elastomeric materials: experimental

facts and constitutive modelling. Arch Appl Mech 2001;71:89109.

[14] Chopra AK. Dynamics of structures: theory and applications to

earthquake engineering. 2nd ed. Upper Saddle River (NJ): Prentice-Hall;

2000.

[15] Fabrizio M, Morro A. Mathematical problems in linear viscoelasticity,

Philadelphia: SIAMStudies In Applied Mathematics; 1992.

Вам также может понравиться

- Dall'Asta 2008 Engineering-StructuresДокумент9 страницDall'Asta 2008 Engineering-StructuresAndreea NanОценок пока нет

- Luo 2016Документ17 страницLuo 2016HİLMİKISAОценок пока нет

- $RRF3YLEДокумент17 страниц$RRF3YLESebastian ChavezОценок пока нет

- Finite Element Analysis of Base Isolated Buildings Subjected To Earthquake LoadsДокумент21 страницаFinite Element Analysis of Base Isolated Buildings Subjected To Earthquake LoadsasdОценок пока нет

- Deformation and Stability of Compressible Rubber O-Rings: Originalarticle Open AccessДокумент13 страницDeformation and Stability of Compressible Rubber O-Rings: Originalarticle Open Access2007rlwjdtnОценок пока нет

- Damage Initiation Mechanism in Rubber Sheet Composites During The Static LoadingДокумент8 страницDamage Initiation Mechanism in Rubber Sheet Composites During The Static LoadingMa RcoОценок пока нет

- Polymer Testing: Per-Erik Austrell, Anders K. OlssonДокумент7 страницPolymer Testing: Per-Erik Austrell, Anders K. OlssonLester LiewОценок пока нет

- LECTURA 2 Bortoleto2013Документ8 страницLECTURA 2 Bortoleto2013Victor Manuel CastañedaОценок пока нет

- University of Engineering and Technology: SubjectДокумент5 страницUniversity of Engineering and Technology: SubjectZainОценок пока нет

- EBP 420 - Nota 1Документ29 страницEBP 420 - Nota 1James OoiОценок пока нет

- HDRB 1Документ24 страницыHDRB 1Shritej nirmalОценок пока нет

- Bridge Isolation With High-Damping Rubber BearingsДокумент15 страницBridge Isolation With High-Damping Rubber Bearingslucassn14Оценок пока нет

- Materials 13 04032Документ14 страницMaterials 13 04032Schmiernippel OskarОценок пока нет

- Ranaei-Aghakouchak2021 Article ExperimentalAndNumericalStudyOДокумент23 страницыRanaei-Aghakouchak2021 Article ExperimentalAndNumericalStudyOsunali jaishОценок пока нет

- Hypervelocity Impact Damage in Composites PDFДокумент24 страницыHypervelocity Impact Damage in Composites PDFbedo39Оценок пока нет

- 99-s38 - On Evaluation of Rotation Capacity For Reinforced Concrete BeamsДокумент9 страниц99-s38 - On Evaluation of Rotation Capacity For Reinforced Concrete BeamsbllldОценок пока нет

- Effect of Viscoelastic Material Thickness of Damping Treatment Behavior On GearboxДокумент7 страницEffect of Viscoelastic Material Thickness of Damping Treatment Behavior On GearboxPierin Arevalo TuestaОценок пока нет

- WCEE - Paper - N°4237Документ16 страницWCEE - Paper - N°4237Vincenzo PilusoОценок пока нет

- Santos 2014Документ5 страницSantos 2014Gordei SilviuОценок пока нет

- Ghelli 2011Документ13 страницGhelli 2011Sourabh GaikwadОценок пока нет

- IntroductionДокумент9 страницIntroductionLeonardo FurlanОценок пока нет

- Construction and Building Materials: M. Latour, V. Piluso, G. RizzanoДокумент18 страницConstruction and Building Materials: M. Latour, V. Piluso, G. RizzanoMassimo LatourОценок пока нет

- Rubber Isolator 1921Документ10 страницRubber Isolator 1921Mario Daniel MLОценок пока нет

- Engineering Structures: Chang-Hwan Lee, Jinkyu Kim, Do-Hyun Kim, Jaeho Ryu, Young K. JuДокумент18 страницEngineering Structures: Chang-Hwan Lee, Jinkyu Kim, Do-Hyun Kim, Jaeho Ryu, Young K. JuANUBHAV CHAUDHARYОценок пока нет

- 1Документ9 страниц1bardock277Оценок пока нет

- Experimental Analysis On Friction Materials For Supplemental Damping DevicesДокумент33 страницыExperimental Analysis On Friction Materials For Supplemental Damping DevicesVincenzo PilusoОценок пока нет

- Numerical Analysis of Cyclically Loaded Concrete Under Large Tensile Strains by The Plastic-Damage ModelДокумент15 страницNumerical Analysis of Cyclically Loaded Concrete Under Large Tensile Strains by The Plastic-Damage Modelsacharya2011Оценок пока нет

- Models For Filled Rubber in Simple Shear: E. Tubaldi, H.R. Ahmadi, A.H. Muhr & J. KingstonДокумент6 страницModels For Filled Rubber in Simple Shear: E. Tubaldi, H.R. Ahmadi, A.H. Muhr & J. KingstonEnrico CalcettoОценок пока нет

- Experimental Investigation of The Stress-Stretch Behavior of EPDM Rubber With Loading Rate EffectsДокумент20 страницExperimental Investigation of The Stress-Stretch Behavior of EPDM Rubber With Loading Rate EffectsPaulo Venicio Alves VieiraОценок пока нет

- Explicit Modeling of Damping of A Single-Layer Latticed Dome With Isolation System (Zhang, Et Al. 2014)Документ12 страницExplicit Modeling of Damping of A Single-Layer Latticed Dome With Isolation System (Zhang, Et Al. 2014)Jose ManuelОценок пока нет

- Non-Associated Plasticity For Soils, Concrete and RockДокумент64 страницыNon-Associated Plasticity For Soils, Concrete and RockErnest NsabimanaОценок пока нет

- Deformation Parameters - Shear ModulusДокумент1 страницаDeformation Parameters - Shear ModulusFernando FanteОценок пока нет

- Some Contributions of Physical and Numerical Modelling To The Assessment of Existing Masonry Infilled RC Frames Under Extreme LoadingДокумент10 страницSome Contributions of Physical and Numerical Modelling To The Assessment of Existing Masonry Infilled RC Frames Under Extreme LoadingRick HunterОценок пока нет

- Uryadov DEM Vibratory Conveyors FinalДокумент11 страницUryadov DEM Vibratory Conveyors FinalSupattarachai SudsawatОценок пока нет

- Pavement Response Ullidtz& ZhangДокумент22 страницыPavement Response Ullidtz& ZhangsmouroОценок пока нет

- Manuscript Final VersionДокумент24 страницыManuscript Final VersionMyron ZhongОценок пока нет

- Epoxy Rubber MountДокумент14 страницEpoxy Rubber MountMIC MECHОценок пока нет

- Manufacturing Properties of EngineeringДокумент11 страницManufacturing Properties of EngineeringSanjay KumarОценок пока нет

- Author Final VersionДокумент18 страницAuthor Final VersionLeslie FanyОценок пока нет

- Symmetry: Seismic Behavior of Moment-Resisting Frames With Conventional and Innovative ConnectionsДокумент23 страницыSymmetry: Seismic Behavior of Moment-Resisting Frames With Conventional and Innovative ConnectionsVincenzo PilusoОценок пока нет

- Lajss 2012 1 644854 1 737194Документ18 страницLajss 2012 1 644854 1 737194CristoferОценок пока нет

- Dynamic Compressive Behavior of Thick Composite Materials: Experimental Mechanics January 1998Документ10 страницDynamic Compressive Behavior of Thick Composite Materials: Experimental Mechanics January 1998Bhasker RamagiriОценок пока нет

- 10 1 1 627 5898 PDFДокумент15 страниц10 1 1 627 5898 PDFosmanОценок пока нет

- Reducing Wear of A Coal Reclaimer Belt Feeder Through DEM AnalysisДокумент5 страницReducing Wear of A Coal Reclaimer Belt Feeder Through DEM AnalysisBin ChenОценок пока нет

- Conceptual Design and Analysis of Long Span StructureДокумент13 страницConceptual Design and Analysis of Long Span StructureMuhd YazidОценок пока нет

- Experimental Study of Sliding Friction DamperДокумент13 страницExperimental Study of Sliding Friction DamperDominic FloresОценок пока нет

- Analysis of The Air Bending Test Using FДокумент11 страницAnalysis of The Air Bending Test Using FDens MОценок пока нет

- Materials and Design: Chen Ling, Alessandro Cernicchi, Michael D. Gilchrist, Philip CardiffДокумент13 страницMaterials and Design: Chen Ling, Alessandro Cernicchi, Michael D. Gilchrist, Philip CardiffGunaseelanMurugesanОценок пока нет

- Dynamic Tensile Testing of Fabric CompositesДокумент11 страницDynamic Tensile Testing of Fabric CompositesSHEIKH MUHAMMAD FAHADОценок пока нет

- Vermeer 1984Документ64 страницыVermeer 1984anarОценок пока нет

- Elastic-Plastic MDOFДокумент19 страницElastic-Plastic MDOFDan AlexandrescuОценок пока нет

- 1 s2.0 S0168874X98000572 MainДокумент13 страниц1 s2.0 S0168874X98000572 MainDevarajuОценок пока нет

- Overview of The Plastic Hinge AnalysisДокумент34 страницыOverview of The Plastic Hinge Analysisclam2014Оценок пока нет

- Overview Plastic Hinge Analysis PDFДокумент34 страницыOverview Plastic Hinge Analysis PDFclam2014Оценок пока нет

- Investigation of The Effects of Geometric and Load Perturbation To Buckling in Multilayered Torispherical Pressure Vessel HeadsДокумент7 страницInvestigation of The Effects of Geometric and Load Perturbation To Buckling in Multilayered Torispherical Pressure Vessel HeadsBib GmzОценок пока нет

- Metodo Simplificado para Muro CLTДокумент15 страницMetodo Simplificado para Muro CLTFrancisco ArriagadaОценок пока нет

- Barrios Carlos PDFДокумент4 страницыBarrios Carlos PDFRamon CharlestienОценок пока нет

- Vol15No4 9Документ12 страницVol15No4 92005511057 Kadek Hindhu Putra KedatonОценок пока нет

- (3 - 5) Adherend Thickness Effect On The Tensile Fracture Toughness of AДокумент8 страниц(3 - 5) Adherend Thickness Effect On The Tensile Fracture Toughness of Ashahbazbegian.uniОценок пока нет

- R5 - Design of R C Slabs - 2015!01!28Документ41 страницаR5 - Design of R C Slabs - 2015!01!28Udaysingh Patil100% (1)

- Numericals 1Документ19 страницNumericals 1Udaysingh PatilОценок пока нет

- Civil Engineering: Reinforced Cement Concrete & Pre-Stressed ConcreteДокумент33 страницыCivil Engineering: Reinforced Cement Concrete & Pre-Stressed ConcreteDebendra Dev KhanalОценок пока нет

- Gate SurvingДокумент114 страницGate SurvingBhushan PatilОценок пока нет

- 2 Way SlabДокумент28 страниц2 Way SlabGautam PaulОценок пока нет

- SDFДокумент120 страницSDFUdaysingh PatilОценок пока нет

- Be Civil Paper PDFДокумент136 страницBe Civil Paper PDFUdaysingh PatilОценок пока нет

- Compression MembersДокумент22 страницыCompression MembersAnonymous dlSmlsymHОценок пока нет

- Moment RedistributionДокумент32 страницыMoment Redistributionfattah1867% (3)

- 8Документ15 страниц8api-3696315Оценок пока нет

- One Way Slab - NptelДокумент25 страницOne Way Slab - Npteljindal_bharatОценок пока нет

- CRITERION - 3: Course Outcomes and Program Outcomes 3. Course Outcomes and Program OutcomesДокумент2 страницыCRITERION - 3: Course Outcomes and Program Outcomes 3. Course Outcomes and Program OutcomesUdaysingh PatilОценок пока нет

- Design For Torsion in Steel (To NZS 3404)Документ22 страницыDesign For Torsion in Steel (To NZS 3404)Vivek PremjiОценок пока нет

- dcs1 Kolhapur PDFДокумент110 страницdcs1 Kolhapur PDFUdaysingh PatilОценок пока нет

- Subject Matrix - IV Sem GT - (A) - 2015-16 - SessionalДокумент8 страницSubject Matrix - IV Sem GT - (A) - 2015-16 - SessionalUdaysingh PatilОценок пока нет

- Ground Improvement Techniques by Purushothama Raj PDFДокумент134 страницыGround Improvement Techniques by Purushothama Raj PDFdevendra0palkeОценок пока нет

- SOIL MECHANICS AND FOUNDATION ENGINEERING, K.R. Arora, Delhi, 2004. 903p PDFДокумент903 страницыSOIL MECHANICS AND FOUNDATION ENGINEERING, K.R. Arora, Delhi, 2004. 903p PDFMANUEL ARTURO FIGUEROA LEON85% (52)

- Subject Attainment PPT GT-IДокумент25 страницSubject Attainment PPT GT-IUdaysingh PatilОценок пока нет

- Syllabus For: Applied Mathematics-III (Civil Engineering) Unit - I: Fourier Series (06Hrs)Документ28 страницSyllabus For: Applied Mathematics-III (Civil Engineering) Unit - I: Fourier Series (06Hrs)Udaysingh PatilОценок пока нет

- Subject Matrix - IV Sem GT - (A) - 2015-16-PUTДокумент8 страницSubject Matrix - IV Sem GT - (A) - 2015-16-PUTUdaysingh PatilОценок пока нет

- 7th, 8th Sem SyllabusДокумент60 страниц7th, 8th Sem SyllabusDevendra_dreamerОценок пока нет

- Mapping of Co PoДокумент37 страницMapping of Co PoUdaysingh PatilОценок пока нет

- Civil - Syllabus and Scheme PDFДокумент35 страницCivil - Syllabus and Scheme PDFUdaysingh PatilОценок пока нет

- Subject Attainment PPT GT-IДокумент25 страницSubject Attainment PPT GT-IUdaysingh PatilОценок пока нет

- Course Outcome From S-I & PUTДокумент8 страницCourse Outcome From S-I & PUTUdaysingh PatilОценок пока нет

- Earthquake Protection of Buildings by Seismic Isolation. Devices and Concepts PDFДокумент8 страницEarthquake Protection of Buildings by Seismic Isolation. Devices and Concepts PDFUdaysingh PatilОценок пока нет

- Aug201402 PDFДокумент4 страницыAug201402 PDFUdaysingh PatilОценок пока нет

- PDFДокумент20 страницPDFUdaysingh PatilОценок пока нет

- Article1380712780 - Islam Et Al PDFДокумент8 страницArticle1380712780 - Islam Et Al PDFUdaysingh PatilОценок пока нет

- MPPWD 2014 SOR CH 1 To 5 in ExcelДокумент66 страницMPPWD 2014 SOR CH 1 To 5 in ExcelElvis GrayОценок пока нет

- MP 221 Tanael PLUMBING CODE Definition of Terms 2Документ3 страницыMP 221 Tanael PLUMBING CODE Definition of Terms 2Louie BarredoОценок пока нет

- Sappi Mccoy 75 Selections From The AIGA ArchivesДокумент105 страницSappi Mccoy 75 Selections From The AIGA ArchivesSappiETCОценок пока нет

- A Perspective Study On Fly Ash-Lime-Gypsum Bricks and Hollow Blocks For Low Cost Housing DevelopmentДокумент7 страницA Perspective Study On Fly Ash-Lime-Gypsum Bricks and Hollow Blocks For Low Cost Housing DevelopmentNadiah AUlia SalihiОценок пока нет

- scx4521f SeriesДокумент173 страницыscx4521f SeriesVuleticJovanОценок пока нет

- Seminar Report of Automatic Street Light: Presented byДокумент14 страницSeminar Report of Automatic Street Light: Presented byTeri Maa Ki100% (2)

- Hoja Tecnica Item 2 DRC-9-04X12-D-H-D UV BK LSZH - F904804Q6B PDFДокумент2 страницыHoja Tecnica Item 2 DRC-9-04X12-D-H-D UV BK LSZH - F904804Q6B PDFMarco Antonio Gutierrez PulchaОценок пока нет

- Well Stimulation TechniquesДокумент165 страницWell Stimulation TechniquesRafael MorenoОценок пока нет

- 1.2 The Main Components of Computer SystemsДокумент11 страниц1.2 The Main Components of Computer SystemsAdithya ShettyОценок пока нет

- Strategic Management ModelsДокумент4 страницыStrategic Management ModelsBarno NicholusОценок пока нет

- CORDLESS PLUNGE SAW PTS 20-Li A1 PDFДокумент68 страницCORDLESS PLUNGE SAW PTS 20-Li A1 PDFΑλεξης ΝεοφυτουОценок пока нет

- Andrews C145385 Shareholders DebriefДокумент9 страницAndrews C145385 Shareholders DebriefmrdlbishtОценок пока нет

- 01 RFI Technical Form BiodataДокумент8 страниц01 RFI Technical Form BiodataRafiq RizkiОценок пока нет

- Admission Notice: Weekend Masters Program (WMES)Документ4 страницыAdmission Notice: Weekend Masters Program (WMES)masud100% (1)

- Module 5 - Multimedia Storage DevicesДокумент10 страницModule 5 - Multimedia Storage Devicesjussan roaringОценок пока нет

- Applications of MathematicsДокумент35 страницApplications of MathematicsRamdas Sonawane100% (1)

- Design of Open Channels US Department of Agriculture SCSДокумент293 страницыDesign of Open Channels US Department of Agriculture SCSMiguelGuavitaRojasОценок пока нет

- MSEA News, Jan-Feb 2014Документ20 страницMSEA News, Jan-Feb 2014Justin HinkleyОценок пока нет

- A Varactor Tuned Indoor Loop AntennaДокумент12 страницA Varactor Tuned Indoor Loop Antennabayman66Оценок пока нет

- Unit List MUZAFFARPUR - Feb 18 PDFДокумент28 страницUnit List MUZAFFARPUR - Feb 18 PDFPawan Kumar100% (1)

- Sec2 8 PDFДокумент3 страницыSec2 8 PDFpolistaОценок пока нет

- Province of Camarines Sur vs. CAДокумент8 страницProvince of Camarines Sur vs. CACrisDBОценок пока нет

- DC0002A Lhires III Assembling Procedure EnglishДокумент17 страницDC0002A Lhires III Assembling Procedure EnglishНикола ЉубичићОценок пока нет

- Toshiba Satellite L200 M200 M203 M206 KBTIДокумент59 страницToshiba Satellite L200 M200 M203 M206 KBTIYakub LismaОценок пока нет

- EMI-EMC - SHORT Q and AДокумент5 страницEMI-EMC - SHORT Q and AVENKAT PATILОценок пока нет

- On Applied EthicsДокумент34 страницыOn Applied Ethicsamanpatel78667% (3)

- Oddball NichesДокумент43 страницыOddball NichesRey Fuego100% (1)

- PRELEC 1 Updates in Managerial Accounting Notes PDFДокумент6 страницPRELEC 1 Updates in Managerial Accounting Notes PDFRaichele FranciscoОценок пока нет

- DTMF Controlled Robot Without Microcontroller (Aranju Peter)Документ10 страницDTMF Controlled Robot Without Microcontroller (Aranju Peter)adebayo gabrielОценок пока нет

- Enumerator ResumeДокумент1 страницаEnumerator Resumesaid mohamudОценок пока нет

- Dark Matter and the Dinosaurs: The Astounding Interconnectedness of the UniverseОт EverandDark Matter and the Dinosaurs: The Astounding Interconnectedness of the UniverseРейтинг: 3.5 из 5 звезд3.5/5 (69)

- Roxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingОт EverandRoxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingРейтинг: 5 из 5 звезд5/5 (5)

- Alex & Me: How a Scientist and a Parrot Discovered a Hidden World of Animal Intelligence—and Formed a Deep Bond in the ProcessОт EverandAlex & Me: How a Scientist and a Parrot Discovered a Hidden World of Animal Intelligence—and Formed a Deep Bond in the ProcessОценок пока нет

- The Other End of the Leash: Why We Do What We Do Around DogsОт EverandThe Other End of the Leash: Why We Do What We Do Around DogsРейтинг: 5 из 5 звезд5/5 (65)

- Roxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingОт EverandRoxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingРейтинг: 3.5 из 5 звезд3.5/5 (34)

- Fire Season: Field Notes from a Wilderness LookoutОт EverandFire Season: Field Notes from a Wilderness LookoutРейтинг: 4 из 5 звезд4/5 (142)

- The Big, Bad Book of Botany: The World's Most Fascinating FloraОт EverandThe Big, Bad Book of Botany: The World's Most Fascinating FloraРейтинг: 3 из 5 звезд3/5 (10)

- The Ancestor's Tale: A Pilgrimage to the Dawn of EvolutionОт EverandThe Ancestor's Tale: A Pilgrimage to the Dawn of EvolutionРейтинг: 4 из 5 звезд4/5 (811)

- World of Wonders: In Praise of Fireflies, Whale Sharks, and Other AstonishmentsОт EverandWorld of Wonders: In Praise of Fireflies, Whale Sharks, and Other AstonishmentsРейтинг: 4 из 5 звезд4/5 (223)

- Wayfinding: The Science and Mystery of How Humans Navigate the WorldОт EverandWayfinding: The Science and Mystery of How Humans Navigate the WorldРейтинг: 4.5 из 5 звезд4.5/5 (18)

- Spoiled Rotten America: Outrages of Everyday LifeОт EverandSpoiled Rotten America: Outrages of Everyday LifeРейтинг: 3 из 5 звезд3/5 (19)

- The Lives of Bees: The Untold Story of the Honey Bee in the WildОт EverandThe Lives of Bees: The Untold Story of the Honey Bee in the WildРейтинг: 4.5 из 5 звезд4.5/5 (44)

- Why Fish Don't Exist: A Story of Loss, Love, and the Hidden Order of LifeОт EverandWhy Fish Don't Exist: A Story of Loss, Love, and the Hidden Order of LifeРейтинг: 4.5 из 5 звезд4.5/5 (699)

- When You Find Out the World Is Against You: And Other Funny Memories About Awful MomentsОт EverandWhen You Find Out the World Is Against You: And Other Funny Memories About Awful MomentsРейтинг: 3.5 из 5 звезд3.5/5 (13)

- The Rise and Fall of the Dinosaurs: A New History of a Lost WorldОт EverandThe Rise and Fall of the Dinosaurs: A New History of a Lost WorldРейтинг: 4 из 5 звезд4/5 (593)

- The Revolutionary Genius of Plants: A New Understanding of Plant Intelligence and BehaviorОт EverandThe Revolutionary Genius of Plants: A New Understanding of Plant Intelligence and BehaviorРейтинг: 4.5 из 5 звезд4.5/5 (137)

- Come Back, Como: Winning the Heart of a Reluctant DogОт EverandCome Back, Como: Winning the Heart of a Reluctant DogРейтинг: 3.5 из 5 звезд3.5/5 (10)

- When the Sahara Was Green: How Our Greatest Desert Came to BeОт EverandWhen the Sahara Was Green: How Our Greatest Desert Came to BeРейтинг: 4.5 из 5 звезд4.5/5 (6)

- Last Child in the Woods: Saving Our Children From Nature-Deficit DisorderОт EverandLast Child in the Woods: Saving Our Children From Nature-Deficit DisorderРейтинг: 4 из 5 звезд4/5 (283)