Академический Документы

Профессиональный Документы

Культура Документы

Minor Project PDF

Загружено:

Hassan PeerzadИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Minor Project PDF

Загружено:

Hassan PeerzadАвторское право:

Доступные форматы

Concrete Mix Design as per IS 10262: 1982

1

Abstract

Concrete occupies unique position among the modern construction materials,

Concrete is a material used in building construction, consisting of a hard, chemically

inert particulate substance, known as an aggregate (usually made for different

types of sand and gravel), that is bond by cement and water.

The ultimate strength of concrete is influenced by the water-cementitious ratio

(w/cm), the design constituents, and the mixing, placement and curing methods

employed. All things being equal, concrete with a lower water-cement

(cementitious) ratio makes a stronger concrete than that with a higher ratio. The

total quantity of cementitious materials (Portland cement, slag cement, pozzolans)

can affect strength, water demand, shrinkage, abrasion resistance and density. All

concrete will crack independent of whether or not it has sufficient compressive

strength. In fact, high Portland cement content mixtures can actually crack more

readily due to increased hydration rate. As concrete transforms from its plastic

state, hydrating to a solid, the material undergoes shrinkage. Plastic shrinkage

cracks can occur soon after placement but if the evaporation rate is high they often

can actually occur during finishing operations, for example in hot weather or a

breezy day. In very high-strength concrete mixtures (greater than 70 MPa) the

crushing strength of the aggregate can be a limiting factor to the ultimate

compressive strength. In lean concretes (with a high water-cement ratio) the

crushing strength of the aggregates is not so significant.

The process of selecting suitable ingredients of concrete and determining their

relative amounts with an objective of producing a concrete of required strength,

durability, and workability as economically as possible is termed as concrete mix

design.

Concrete Mix Design as per IS 10262: 1982

2

Acknowledgement

We take this opportunity to thank all of those who have helped us to complete this

Project. It is a pleasure, at this time, to remember each and every one. Our special

thanks goes to project guide Dr. Abhay Sharma, who indeed helped us a lot to

complete this Project successfully.

We are extremely grateful to all other faculties of civil Engineering department for

valuable support, inspiration and guidance at all stages.

We should not forget to thank our parents, friends and all those who have encouraged

us to do this project.

Concrete Mix Design as per IS 10262: 1982

3

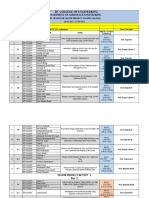

Table of content

Abstract...01

Acknowledgement...02

Introduction.....04

History timeline of Cement....05

Concrete mix Design...08

Indian standard Concrete Mix proportioning guidelines...09

Example on concrete Mix design (Practical conducted in lab)..15

Test results..28

Conclusion29

References...30

Concrete Mix Design as per IS 10262: 1982

4

Introduction of concrete

Concrete has relatively high compressive strength, but significantly lower tensile

strength, as a result, without compensating, concrete would almost always fail

from tensile stresses even when loaded in compression and is usually reinforced

with materials that are strong in tension (usually steel). concrete is relatively

constant at low stress levels but starts decreasing at higher stress levels as matrix

cracking develops. Concrete has a very low coefficient of thermal expansion, and

as it matures concrete shrinks. All concrete structures will crack to some extent,

due to shrinkage and tension. Concrete which is subjected to long-duration forces

is prone to creep.

The ultimate strength of concrete is influenced by the water-cementitious ratio

(w/cm), the design constituents, and the mixing, placement and curing methods

employed. All things being equal, concrete with a lower water-cement

(cementitious) ratio makes a stronger concrete than that with a higher ratio. The total

quantity of cementitious materials (Portland cement, slag cement, pozzolans) can

affect strength, water demand, shrinkage, abrasion resistance and density. All

concrete will crack independent of whether or not it has sufficient compressive

strength. In fact, high Portland cement content mixtures can actually crack more

readily due to increased hydration rate. As concrete transforms from its plastic state,

hydrating to a solid, the material undergoes shrinkage. Plastic shrinkage cracks can

occur soon after placement but if the evaporation rate is high they often can actually

occur during finishing operations, for example in hot weather or a breezy day. In

very high-strength concrete mixtures (greater than 70 MPa) the crushing strength of

the aggregate can be a limiting factor to the ultimate compressive strength. In lean

concretes (with a high water-cement ratio) the crushing strength of the aggregates

is not so significant.

Concrete Mix Design as per IS 10262: 1982

5

History Timeline of Cement

12,000,000

BC

Reactions between limestone and oil shale during spontaneous combustion

occurred in Israel to form a natural deposit of cement compounds. The

deposits were characterized by Israeli geologists in the 1960's and 70's.

3000 BC

Egyptians

Used mud mixed with straw to bind dried bricks. They also

used gypsum mortars and mortars of lime in the pyramids.

Chinese Used cementitious materials to hold bamboo together in their boats and in

the Great Wall.

800 BC

Greeks, Crete

& Cyprus

Used lime mortars which were much harder than later Roman mortars.

300 BC

Babylonians &

As Syrians

Used bitumen to bind stones and bricks.

300 BC - 476

AD

Romans

Used pozzolana cement from Pozzuoli, Italy near Mt. Vesuvius to build the

Appian Way, Roman baths, the Coliseum and Pantheon in Rome, and the

Pont du Gard aqueduct in south France. They used lime as a cementitious

material. Pliny reported a mortar mixture of 1 part lime to 4 parts sand.

Vitruvius reported a 2 parts pozzolana to 1 part lime. Animal fat, milk, and

blood were used as admixtures (substances added to cement to increase the

properties.) These structures still exist today!

1200 - 1500

The Middle

Ages

The quality of cementing materials deteriorated. The use of burning lime

and pozzolan (admixture) was lost, but reintroduced in the 1300's

1678 Joseph Moxon wrote about a hidden fire in heated lime that appears upon

the addition of water.

1779 Bry Higgins was issued a patent for hydraulic cement (stucco) for exterior

plastering use.

1780 Bry Higgins published "Experiments and Observations Made With the View

of Improving the Art of Composing and Applying Calcareous Cements and of

Preparing Quicklime."

1793 John Smeaton found that the calcination of limestone containing clay gave a

lime which hardened under water (hydraulic lime). He used hydraulic lime to

rebuild Eddy stone Lighthouse in Cornwall, England which he had been

commissioned to build in 1756, but had to first invent a material that would

not be affected by water. He wrote a book about his work.

1796 James Parker from England patented a natural hydraulic cement by calcining

nodules of impure limestone containing clay, called Parker's Cement or

Roman Cement.

Concrete Mix Design as per IS 10262: 1982

6

1802 In France, a similar Roman Cement process was used.

1810 Edgar Dobbs received a patent for hydraulic mortars, stucco, and plaster,

although they were of poor quality due to lack of kiln precautions.

1812 -1813 Louis Vicat of France prepared artificial hydraulic lime by calcining synthetic

mixtures of limestone and clay.

1818 Maurice St. Leger was issued patents for hydraulic cement. Natural Cement

was produced in the USA. Natural cement is limestone that naturally has the

appropriate amounts of clay to make the same type of concrete as John

Smeaton discovered.

1824 Joseph Aspdin of England invented Portland by burning finely ground chalk

with finely divided clay in a lime kiln until carbon dioxide was driven off. The

sintered product was then ground and he called it Portland cement named

after the high quality building stones quarried at Portland, England.

1828 I. K. Brunel is credited with the first engineering application of Portland

cement, which was used to fill a breach in the Thames Tunnel.

1830 The first production of lime and hydraulic cement took place in Canada

1886

The first rotary kiln was introduced in England to replace the vertical shaft

kilns

1889 The first concrete reinforced bridge is built.

1930 Air entraining agents were introduced to improve concrete's resistance to

freeze/thaw damage.

1936 The first major concrete dams, Hoover Dam and Grand Coulee Dam, were

built. They still exist today!

1967 First concrete domed sport structure, the Assembly Hall, was constructed at

The University of Illinois, at Urbana-Champaign.

1970's Fiber reinforcement in concrete was introduced.

1980's Superplasticizers were introduced as admixtures.

1985 Silica fume was introduced as a pozzolanic additive.

The "highest strength" concrete was used in building the Union Plaza

constructed in Seattle, Washington.

1992 The tallest reinforced concrete building in the world was constructed at 311

S. Wacker Dr., Chicago, Illinois.

Concrete Mix Design as per IS 10262: 1982

7

Concrete Mix Design

The concrete mix design for superstructure concrete must produce a workable

concrete mixture having properties that will not exceed the maximum and/or

minimum values defined in the special provision. Workability in concrete defines

its capacity to be placed, consolidated, and finished without harmful segregation

or bleeding. Workability is affected by aggregate gradation, particle shape,

proportioning of aggregate, amount and qualities of cementitious materials,

presence of entrained air, amount and quality of high range water reducer, and

consistency of mixture.

Consistency of the concrete mixture is its relative mobility and is measured in terms

of slump. The higher the slump the more mobile the concrete, affecting the ease

with which the concrete will flow during placement. Consistency is not synonymous

with workability. Two different mix designs may have the same slump; however,

their workability may be different.

Selection of target parameters by the contractor for any mix design must consider

the influence of the following:

1. Material availability and economics

2. Variability of each material throughout period of usage

3. Control capability of production plant

4. Ambient conditions expected at the time(s) of concrete placement

5. Logistics of concrete production, delivery, and placement

6. Variability in testing concrete properties

7. Generation of heat in large structural elements and differential in thermal

gradient

Concrete Mix Design as per IS 10262: 1982

8

Indian Standard Concrete Mix proportioning-Guidelines

Indian standard recommended method of concrete Mix Design (IS 10262 -1982)

was first introduced during the year of 1982. In the revision of IS 456:2000, a

number of changes were introduced which necessitated the revision of IS 10262 of

1982. A committee was set up to review the method of mix design in conformity

with IS 456:2000. The committee took long time and came up with a new guidelines

for concrete mix proportioning.

The information below is based on the guidelines given in Indian Standard IS

10262:2009 for concrete mix proportioning.

1. Data Required For Mix Proportioning.

Grade of concrete

Maximum size of aggregate

Minimum cement content

Maximum water/cement ratio

Workability in terms of slump

Maximum temperature at the pouring point

Early age strength (if required)

Grading zone of fine aggregate

Type of aggregate

Maximum cement content

Kind of admixture used

Specific gravity of all the material used and dosage etc.

Exposure condition

Method of placing

Degree of supervision

2. Target Mean Strength

Concrete mix should be designed for certain higher strength than characteristic

strength so that the field strength or site strength of concrete will not be falling

below the characteristic strength by certain percentage.

Assuming 5 percent of the site results are allowed to fall below the characteristic

strength, the target mean strength is given by the following relation.

Concrete Mix Design as per IS 10262: 1982

9

fck = fck + t* S

fck = fck + 1.65*S (1.65 is applicable for 5% of the result is allowed to fall below the

characteristic strength.)

Where, fck = Target mean compressive strength at 28 days

fck = Characteristic compressive strength in 28 days

S = Standard Deviation

t= Tolerance factor

Assumed standard Deviation (IS 456:2000.) Table 8

Grade of concrete Assumed standard Deviations

(N/mm

2

)

M 10

M 15

3.5

M 20

M 25

4.0

M 30

M 35

M 40

M 45

M 50

M 55

M60

5.0

NOTE: The above value to the site control having proper storage of cement, weigh

batching of all materials, controlled addition of water, regular checking of all

materials, and all periodical checking of workability and strength. If there is

deviation from above condition the given value in above table should be increased

by 1 N/mm

2

.

Value of tolerance factor (t) (Risk factor)

Tolerance level

Number of samples

1 in 10 1 in 15 1 in 20 1 in 40 1 in 100

10

20

30

Infinite

1.37

1.32

1.31

1.28

1.65

1.58

1.54

1.50

1.81

1.72

1.70

1.64

2.23

2.09

2.04

1.96

1.76

2.53

2.46

2.33

Concrete Mix Design as per IS 10262: 1982

10

NOTE: Some organizations directly specify the target mean strength for given

characteristic mean strength, without using the standard deviation value, while

some organization aim at the target mean strength of 20 percent more than the

characteristic mean strength for their preliminary trial in laboratory. They expect

that if the trail mix is done at 20% higher than characteristic strength the concrete

strength is sure to get strength satisfying the acceptance criteria given in IS: 456.

3. Selection Of Water Cement Ratio

In the recommended guideline for concrete mix design of IS 10262: 1982,

water/cement ratio was mainly selected from ABCDEF curve drawn in a graph

connecting strength of concrete and water/cement ratio. ABCDEF curves refer to

the strength of various cement. The way of finding water/cement ratio was giving

a very uneconomical mix design and also have to know the strength of cement.

Sticky speaking, Water/cement ratio for the concrete to be used in particular

project or for big project should be found out by large number of laboratory or site

trails using the type of aggregate and other materials actually to be used for

establishing the relationship between strength and water/cement ratio. But this

way of establishing strength Vs water/cement relationship will not become

practically feasible in most of the cases for lack of time and data.

In absence of such data following action may be taken.

Use ones experience in fixing the water/cement ratio.

Use the water cement ratio, successfully used in neighboring project or

project successfully completed, recently using nearly the similar materials.

Use the generalized relationship established by researchers. This generalized

relation between water/cement ratio and compressive strength of concrete

helps to decide water cement ratio.

Concrete Mix Design as per IS 10262: 1982

11

4. Selection Of Water Content

The water content of concrete is influenced by number of factors, such as

aggregate size, shape, texture, workability, cement and other supplementary

cementitious material type and content and admixtures. An increase in aggregate

size, reduction in water/cement ratio, reduction in slump, use of rounded

aggregate, use of natural sand, use of plasticizers will reduce the water content. On

the other hand increased temperature, increase in cement content, increase in

slump, and increase in water/cement ratio, angular aggregate, and use of

manufactured sand and larger percentage of fine aggregate as compared to coarse

aggregate will increase the water content.

Maximum water content per cubic meter of concrete for Nominal maximum size of

Aggregate.

Sl.No

Nominal maximum

size of aggregate

(mm)

Maximum water content

(Kg)

1

2

3

10

20

40

208

186

165

NOTE: The quantity of water given in the table is for angular coarse aggregate and

for 25 to 50 mm of slump range. The water quantity given in table can be reduced

by 10 kg for sub- angular aggregate, 20 kg for gravel with same crushed particles,

and 25 kg for rounded gravel.

For the required workability (other than 25 to 50 mm slump), the required water

content maybe established by trail or can be estimated by an increase of 3 percent

of water for every 25 mm of increased slump or alternatively by use of admixtures.

It is also indicated that plasticizers reduces water content up to 10 percent and

superplasticizers reduces the water content up to 30 percent.

Concrete Mix Design as per IS 10262: 1982

12

5. Calculation of Cementitious Material Content.

Cement plus supplementary cementitious material content per unit volume of

concrete maybe calculated from the free water/cement ratio and quantity of

water per unit volume of concrete.

The cementitious material content so calculated shall be checked against the

minimum cementitious content for durability requirement and greater of two

values is adopted.

Minimum Cement Content, maximum W/c ratio and minimum Grade of concrete for different

exposures with normal weight aggregate of 20 mm nominal maximum size. IS 456: 2000.

Table5.

Sl.No Exposure Plain Concrete Reinforced Concrete

Minimum

cement

contents

Kg/m

3

Maximum

free W/C

ratio

Minimum

Grade of

concrete

Minimum

cement

content

Kg/m

3

Maximum

free

W/C ratio

Minimum

Grade of

concrete

1.

2.

3.

4.

5.

Mild

Moderate

Severe

Very severe

Extreme

220

240

250

260

280

0.60

0.60

0.50

0.45

0.40

-

M 15

M 20

M 20

M 25

300

300

320

340

360

0.55

0.50

0.45

0.45

0.40

M 20

M 25

M 30

M 35

M 40

NOTES: Cement content given in the table is irrespective of the grade of cement and

it is inclusive of all the supplementary cementitious material. The additions of all

supplementary cementitious material may be taken into account in the concrete

composition with respect to the cement content and W/C ratio if the suitability is

established and as long as the maximum amounts taken into account do not exceed

the limit prescribed in relevant codes.

Minimum grade for plain concrete under mild condition is not specified.

Concrete Mix Design as per IS 10262: 1982

13

Adjustment to minimum Cement contents for aggregates other than 20 mm Nominal

maximum Size as per IS 456: 2000

Sl.No Nominal maximum

aggregate size

mm

Adjustment to minimum cement

content in above table

Kg/m

3

1.

2.

3.

10

20

40

+40

0

-30

6. Estimation Of Coarse Aggregate Proportion

The approximate aggregate volume is given in table below for W/C ratio of 0.5. This

volume maybe adjusted for other water/cement ratio in following way. For every

decrease of W/C ratio by 0.05, the coarse aggregate volume is increased by 1.0

percent to reduce the sand content and for every increase of W/C ratio by 0.05 the

coarse aggregate volume maybe decreased by 1.0 percent to increase the sand

content.

For more workable mixes for pumping, it may be desirable to reduce the coarse

aggregate content by about 10 percent.

Volume of coarse aggregate per unit volume of total aggregate for different zones of fine

aggregate for water cement ratio of 0.5

Sl.No Nominal maximum

size of aggregate

mm

Volume of coarse aggregate per unit volume of Total

aggregate for different zones of fine aggregate

Zone IV Zone III Zone II Zone I

1.

2.

3.

10

20

40

0.50

0.66

0.75

0.48

0.64

0.73

0.46

0.62

0.71

0.44

0.60

0.69

7. Combination Of Different Coarse Aggregate Fractions

The aggregate of different sizes maybe combined in different proportions so as to

get overall grading conforming to grading given in Table 2 of IS 383

Concrete Mix Design as per IS 10262: 1982

14

8. Estimation Of Fine Aggregate

To estimate the fine aggregate proportion, find out the absolute volume of all the

known ingredients and deduct the sum of all the absolute known volumes from

the unit volume. The result will give the total volume of coarse and fine aggregate

put together. We know the volume of coarse aggregate and hence volume of fine

aggregate can be calculated.

9. Trial mixes

The weight of all the ingredients in kg/m

3

can be found out. The weight of coarse

and fine aggregate are in saturated and surface dry condition. Depending upon

the absorption characteristic or presence of surface moisture the field corrections

are worked out.

Concrete Mix Design as per IS 10262: 1982

15

In laboratory carry out Trial number 1. Observe the workability, bleeding and

segregation characteristics and cohesiveness of concrete etc. If the measured

workability in terms of slump is different from the stipulated value, the water

and/or admixture content maybe adjust suitably. With this adjustment, Mix

proportion will be recalculated keeping the water/cement ratio at preselected

value, which will be Trial mix number 2.In addition trial mix number 3 and 4 shall

be made with the same water content as in trial mix number 2 and adjusting varying

water/cement ratio by 10 percent of preselected value.

Mix number 2 and 4 normally provide sufficient information, including the

relationship between compressive strength and water cement ratio.

Example number I

Design a concrete mix for M 35 grade of concrete with the following data

a) Type of cement OPC 43 Grades

b) Maximum size of aggregate 20 mm

c) Exposure condition Severe (RCC)

d) Workability 100 mm slump

e) Minimum cement content 320 kg/m

3

f) Maximum W/C ratio 0.45

g) Method of placing Pumping

h) Degree of supervision good

i) Type of aggregate crushed angular aggregate.

j) Super plasticizers will be used

k) Sp. Gr of coarse aggregate 2.80

l) Sp. Gr of fine aggregate 2.70

m) Water absorption

Coarse aggregate Nil

Fine aggregate Nil

n) Free surface moisture

Coarse aggregate Nil

Fine aggregate Nil

o) Grading of coarse aggregate conforming to Table 2 of IS 383

p) Grading of fine aggregate conforming to grading Zone II

Concrete Mix Design as per IS 10262: 1982

16

Solution: A

I. Target mean strength

Characteristic strength fc = 35

Target mean strength fck = fck + 1.65 *S

= 35 + 1.65 * 5 =43.25N/mm

2

Where standard Deviation S is taken as 5N/mm

2

II. Water/cement ratio

Water/cement ratio is taken from the experience of mix designer

W/C =0.42

W/C ratio mentioned in table 5 of IS 456 is 0.45. W/C proposed is 0.42. This

being lesser of two, adopt the W/C ratio as 0.42

III. Selection of water content

Maximum water content as per table given below. This is for the 50 mm

slump.

Estimated water content for 100 mm slump (with nominal maximum size of

aggregate 20 mm) = 186* 6/100 + 186 = 197 litre

(3% increase for every 25mm slump over and above 50 mm slump).

The efficiency of super plasticizers used = 25 percent

Therefore the actual water to be used = 197* 0.75 =148 litre

IV. Calculation of cement content

W/C = 0.42

Therefore Cement content =148/0.42 = 352Kg/m

3

Concrete Mix Design as per IS 10262: 1982

17

This cement content is checked with the minimum cement content given in table 5

of IS 456 for durability requirement.

As the calculated cement content 352 Kg/m

3

is more than the minimum cement

content mentioned in table 5 of IS 456, that is 320Kg/m

3

, the cement content of

352 Kg/m

3

is adopted.

V. Calculation of Coarse and Fine Aggregate Content

From the table given below the volume of coarse aggregate corresponding to 20

mm size of aggregate and fine aggregate zone II, for water cement ratio 0.50 is

found to be 0.62.

In the present case the water/cement ratio is 0.42, that is less by 0.08%. As the W/C

is reduced it is desirable to increase the coarse aggregate content in order to reduce

the fine aggregate content. The coarse aggregate is increased at the rate of 0.01

for every increase in W/C of 0.05.

Therefore, (0.01/0.05)* 0.08 = 0.016

Concrete Mix Design as per IS 10262: 1982

18

Volume of coarse aggregate = 0.62

Corrected proportion of volume of coarse aggregate =0.62 + 0.016 = 0.636

Since it is angular aggregate and the concrete is to be pumped, the coarse

aggregate can be reduced by 10 percent

Therefore, final volume of coarse aggregate = 0.636* 0.9 =0.572 (say 0.57)

So the volume of fine aggregate = 1.0 0.57 = 0.43.

VI. Calculation of mix proportion

Volume of concrete = 1 m

3

Absolute volume of cement = (352/3.15)*(1/1000) m

3

=0.112 m

3

Volume of water = 148 = 0.148 m

3

Volume of chemical admixture = {(1.2 *352)/(100*1.1)}*(1/1000)

=0.004m

3

(Dosage = 1.2 percent by weight of cementitious and specific gravity of super

plasticizers =1.1)

Absolute volume of all the material except Total Aggregates

=0.112 + 0.148 + 0.004 =0.264

Absolute volume of Total aggregate =1.0 0.264 = 0. 736

Weight of coarse aggregate = 0.736 * 0.57 * 2.80 * 1000 =1175 Kg/m

3

Weight of fine aggregate = 0.736 * 0.43 * 2.70 *1000 = 854 Kg/m

3

Concrete Mix Design as per IS 10262: 1982

19

Mix proportion for trial number I

Cement 352 Kg/m

3

Water 148 Kg/m

3

Fine aggregate 854 Kg/m

3

Coarse aggregate 1175 Kg/m

3

Chemical admixture 4 Kg/m

3

Wet density of concrete 2533 Kg/m

3

Using,

Cement = 175 grams

Fine aggregate = 425 grams

Coarse aggregate = 585 grams

Water/cement = 0.42

A cube is made to test its compressive strength after 7 days of curing.

Solution; B

I. Target mean strength

Characteristic strength fc = 35

Target mean strength fck = fck + 1.65 *S

= 35 + 1.65 * 5 =43.25N/mm

2

Where standard Deviation S is taken as 5N/mm

2

II. Water/cement ratio

Water/cement ratio is taken from the experience of mix designer

W/C =0.42

W/C ratio mentioned in table 5 of IS 456 is 0.45. W/C proposed is 0.42. This

being lesser of two, adopt the W/C ratio as 0.42

Concrete Mix Design as per IS 10262: 1982

20

III. Selection of water content

Estimated water content for 100 mm slump (with nominal maximum size of

aggregate 20 mm) = 186* 6/100 + 186 = 197 litre

(3% increase for every 25mm slump over and above 50 mm slump).

The efficiency of super plasticizers used = 30 percent

Therefore the actual water to be used = 197* 0.70 =138 litre

IV. Calculation of cement content

W/C = 0.42

Therefore Cement content =138/0.42 = 329Kg/m

3

V. Calculation of Coarse and Fine Aggregate Content

From the table given above the volume of coarse aggregate corresponding to 20

mm size of aggregate and fine aggregate zone II, for water cement ratio 0.50 is

found to be 0.62.

In the present case the water/cement ratio is 0.42, that is less by 0.08%. As the W/C

is reduced it is desirable to increase the coarse aggregate content in order to reduce

the fine aggregate content. The coarse aggregate is increased at the rate of 0.01

for every increase in W/C of 0.05.

Therefore, (0.01/0.05)* 0.08 = 0.016

Volume of coarse aggregate = 0.62

Corrected proportion of volume of coarse aggregate =0.62 + 0.016 = 0.636

Since it is angular aggregate and the concrete is to be pumped, the coarse

aggregate can be reduced by 10 percent

Therefore, final volume of coarse aggregate = 0.636* 0.9 =0.572 (say 0.57)

So the volume of fine aggregate = 1.0 0.57 = 0.43.

Concrete Mix Design as per IS 10262: 1982

21

VI. Calculation of mix proportion

Volume of concrete = 1 m

3

Absolute volume of cement = (329/3.15)*(1/1000) m

3

=0.104 m

3

Volume of water = 138 = 0.138 m

3

Volume of chemical admixture = {(1.2 *329)/(100*1.1)}*(1/1000)

=0.004m

3

(Dosage = 1.2 percent by weight of cementitious and specific gravity of super

plasticizers =1.1)

Absolute volume of all the material except Total Aggregates

=0.104 + 0.138 + 0.004 =0.246

Absolute volume of Total aggregate =1.0 0.246 = 0. 754

Weight of coarse aggregate = 0.754 * 0.57 * 2.80 * 1000 =1203 Kg/m

3

Weight of fine aggregate = 0.754 * 0.43 * 2.70 *1000 = 875 Kg/m

3

Mix proportion for trial number II

Cement 329 Kg/m

3

Water 138 Kg/m

3

Fine aggregate 875 Kg/m

3

Coarse aggregate 1203 Kg/m

3

Chemical admixture 4 Kg/m

3

Wet density of concrete 2549 Kg/m

3

Concrete Mix Design as per IS 10262: 1982

22

Using,

Cement = 155 grams

Fine aggregate = 405 grams

Coarse aggregate = 555 grams

Water/cement = 0.42

A cube is made to test its compressive strength after 7 days of curing

Solution; C

I. Target mean strength

Characteristic strength fc = 35

Target mean strength fck = fck + 1.65 *S

= 35 + 1.65 * 5 =43.25N/mm

2

Where standard Deviation S is taken as 5N/mm

2

II. Water/cement ratio

Water cement ratio is increased by 10 percent that is; 0.42+0.042 =0.462 (say

0.46)

W/C ratio mentioned in table 5 of IS 456 is 0.45.Adopt the W/C ratio as 0.45

W/C =0.45

III. Selection of water content

Estimated water content for 100 mm slump (with nominal maximum size of

aggregate 20 mm) = 186* 6/100 + 186 = 197 litre

(3% increase for every 25mm slump over and above 50 mm slump).

The efficiency of super plasticizers used = 30 percent

Therefore the actual water to be used = 197* 0.70 =138 litre

Concrete Mix Design as per IS 10262: 1982

23

IV. Calculation of cement content

W/C = 0.45

Therefore Cement content =138/0.45 = 306Kg/m

3

Since minimum cement content as per IS 456 is 320 Kg/m

3

.Adopt the cement

content of 320kg/m

3

.

V. Calculation of Coarse and Fine Aggregate Content

From the table given above the volume of coarse aggregate corresponding to 20

mm size of aggregate and fine aggregate zone II, for water cement ratio 0.50 is

found to be 0.62.

In the present case the water/cement ratio is 0.45, that is less by 0.05%. As the W/C

is reduced it is desirable to increase the coarse aggregate content in order to reduce

the fine aggregate content. The coarse aggregate is increased at the rate of 0.01

for every increase in W/C of 0.05.

Therefore, (0.01/0.05)* 0.05 = 0.01

Volume of coarse aggregate = 0.62

Corrected proportion of volume of coarse aggregate =0.62 + 0.01 = 0.63

Since it is angular aggregate and the concrete is to be pumped, the coarse

aggregate can be reduced by 10 percent

Therefore, final volume of coarse aggregate = 0.63* 0.9 =0.567 (say 0.57)

So the volume of fine aggregate = 1.0 0.57 = 0.43.

VI. Calculation of mix proportion

Volume of concrete = 1 m

3

Absolute volume of cement = (320/3.15)*(1/1000) m

3

=0.102 m

3

Volume of water = 138 = 0.138 m

3

Volume of chemical admixture = {(1.2 *320)/(100*1.1)}*(1/1000) =0.003m

3

Concrete Mix Design as per IS 10262: 1982

24

(Dosage = 1.2 percent by weight of cementitious and specific gravity of super

plasticizers =1.1)

Absolute volume of all the material except Total Aggregates

=0.102 + 0.138 + 0.003 =0.243

Absolute volume of Total aggregate =1.0 0.243 = 0. 757

Weight of coarse aggregate = 0.757 * 0.57 * 2.80 * 1000 =1208Kg/m

3

Weight of fine aggregate = 0.757 * 0.43 * 2.70 *1000 = 879 Kg/m

3

Mix proportion for trial number III

Cement 320 Kg/m

3

Water 138 Kg/m

3

Fine aggregate 879 Kg/m

3

Coarse aggregate 1208 Kg/m

3

Chemical admixture 4 Kg/m

3

Wet density of concrete 2549Kg/m

3

Using,

Cement = 145 grams

Fine aggregate = 395 grams

Coarse aggregate = 540grams

Water/cement = 0.45

A cube is made to test its compressive strength after 7 days of curing.

Concrete Mix Design as per IS 10262: 1982

25

Solution; D

I. Target mean strength

Characteristic strength fc = 35

Target mean strength fck = fck + 1.65 *S

= 35 + 1.65 * 5 =43.25N/mm

2

Where standard Deviation S is taken as 5N/mm

2

II. Water/cement ratio

Water cement ratio is decreased by 10 percent that is; 0.42 - 0.042 =0.378

(say 0.38)

W/C ratio mentioned in table 5 of IS 456 is 0.45.Adopt the W/C ratio as 0.38

W/C =0.45

III. Selection of water content

Estimated water content for 100 mm slump (with nominal maximum size of

aggregate 20 mm) = 186* 6/100 + 186 = 197 litre

(3% increase for every 25mm slump over and above 50 mm slump).

The efficiency of super plasticizers used = 30 percent

Therefore the actual water to be used = 197* 0.70 =138 litre

IV. Calculation of cement content

W/C = 0.38

Therefore Cement content =138/0.38 = 363Kg/m

3

Since minimum cement content as per IS 456 is 320 Kg/m

3

.Adopt the cement

content of 363kg/m

3

.

V. Calculation of Coarse and Fine Aggregate Content

From the table given above the volume of coarse aggregate corresponding to 20

mm size of aggregate and fine aggregate zone II, for water cement ratio 0.50 is

found to be 0.62.

Concrete Mix Design as per IS 10262: 1982

26

In the present case the water/cement ratio is 0.38, that is less by 0.12%. As the W/C

is reduced it is desirable to increase the coarse aggregate content in order to reduce

the fine aggregate content. The coarse aggregate is increased at the rate of 0.01

for every increase in W/C of 0.05.

Therefore, (0.01/0.05)* 0.12 = 0.024

Volume of coarse aggregate = 0.62

Corrected proportion of volume of coarse aggregate =0.62 + 0.024 = 0.644

Since it is angular aggregate and the concrete is to be pumped, the coarse

aggregate can be reduced by 10 percent

Therefore, final volume of coarse aggregate = 0.644* 0.9 =0.579 (say 0.58)

So the volume of fine aggregate = 1.0 0.58 = 0.42.

VI. Calculation of mix proportion

Volume of concrete = 1 m

3

Absolute volume of cement = (363/3.15)*(1/1000) m

3

=0.115 m

3

Volume of water = 138 = 0.138 m

3

Volume of chemical admixture = {(1.2 *363)/(100*1.1)}*(1/1000)

=0.004m

3

(Dosage = 1.2 percent by weight of cementitious and specific gravity of super

plasticizers =1.1)

Absolute volume of all the material except Total Aggregates

=0.115 + 0.138 + 0.004 =0.257

Absolute volume of Total aggregate =1.0 0.257 = 0. 743

Weight of coarse aggregate = 0.743 * 0.57 * 2.80 * 1000 =1186Kg/m

3

Weight of fine aggregate = 0.743 * 0.43 * 2.70 *1000 = 863 Kg/m

3

Concrete Mix Design as per IS 10262: 1982

27

Mix proportion for trial number IV

Cement 363 Kg/m

3

Water 138 Kg/m

3

Fine aggregate 863 Kg/m

3

Coarse aggregate 1185 Kg/m

3

Chemical admixture 4 Kg/m

3

Wet density of concrete 2553Kg/m

3

Using,

Cement = 180 grams

Fine aggregate = 440 grams

Coarse aggregate = 600 grams

Water/cement = 0.38

A cube is made to test its compressive strength after 7 days of curing.

Concrete Mix Design as per IS 10262: 1982

28

The four cubes made have be tested after 7 days of curing. In the 7

th

day test, it

should have 90 percent of its strength development. The following result are

obtained during the test.

cubes properties Load (tonnes) strength(N/mm

2

)

A Cement = 175 grams

Fine aggregate = 425 grams

Coarse aggregate = 585 grams

Water/cement = 0.42

70

31.1

B Cement = 155 grams

Fine aggregate = 405 grams

Coarse aggregate = 555 grams

Water/cement = 0.42

70

31.1

C Cement = 145 grams

Fine aggregate = 395 grams

Coarse aggregate = 540grams

Water/cement = 0.45

69

30.6

D Cement = 180 grams

Fine aggregate = 440 grams

Coarse aggregate = 600 grams

Water/cement = 0.38

72

32.0

Concrete Mix Design as per IS 10262: 1982

29

Conclusion

We have discussed the Concrete Mix Design as per IS 10262: 1982.Concrete Mix

designed should give required Strength but also should be economical. The mix

Design in this project and its testing in laboratory have given a better picture of

how the strength varies with varying water/cement ratio, with all other factor

remaining same.

The process of selecting suitable ingredients of concrete and determining their

relative amounts with an objective of producing a concrete of required strength,

durability, and workability as economically as possible is termed as concrete mix

design.

Concrete occupies unique position among the modern construction materials,

Concrete is a material used in building construction, consisting of a hard, chemically

inert particulate substance, known as an aggregate (usually made for different

types of sand and gravel), that is bond by cement and water.

Concrete Mix Design as per IS 10262: 1982

30

References

1. History of concrete and cement Wikipedia

2. Examples on concrete mix design Wikipedia

3. A textbook on Concrete technology (Theory & Practical) M.S Shetty

4. IS code 456 : 2000

Вам также может понравиться

- Pratial Replacement of Fine Aggregates With Copper SlagДокумент18 страницPratial Replacement of Fine Aggregates With Copper SlagSachin N100% (1)

- Brick and Stone Masonry (1) 2Документ24 страницыBrick and Stone Masonry (1) 2Rohan100% (1)

- Seminar 33 1gd17cv012Документ22 страницыSeminar 33 1gd17cv012Nithesh KumarОценок пока нет

- Seminar Report On Highway Management SystemДокумент22 страницыSeminar Report On Highway Management SystemAditya ansuman RoutОценок пока нет

- 2nd Year Training ReportДокумент26 страниц2nd Year Training ReportAyush Garg100% (1)

- Alternatives of Sand PDFДокумент27 страницAlternatives of Sand PDFRaviteja100% (1)

- Civil Engineering Training College ReportДокумент23 страницыCivil Engineering Training College ReportabhishekОценок пока нет

- Transparent ConcreteДокумент26 страницTransparent Concretekapil more67% (3)

- 2016-17 Autumn 8952 20792616Документ13 страниц2016-17 Autumn 8952 20792616Deb PradhanОценок пока нет

- Sludge Bricks NewДокумент14 страницSludge Bricks Newvadluri NishiОценок пока нет

- Internship Trainning ReportДокумент38 страницInternship Trainning ReportRahul Kumar DabotraОценок пока нет

- A Study On Water AbsorbingДокумент2 страницыA Study On Water AbsorbingInternational Journal of Innovative Science and Research Technology100% (1)

- 22501-2022-Winter-Model-Answer-Paper (Msbte Study Resources)Документ19 страниц22501-2022-Winter-Model-Answer-Paper (Msbte Study Resources)shivaysonuleОценок пока нет

- Transparent Concrete Report 11Документ13 страницTransparent Concrete Report 11Rachitha PrachithaОценок пока нет

- Project FINAAL 11Документ16 страницProject FINAAL 11vaibhavmnprОценок пока нет

- Internship PPT 1Документ23 страницыInternship PPT 1Aditya Kumar100% (1)

- Experimental Study On Concrete (M30) by Partial Replacement of Fine Aggregate With Copper SlagДокумент8 страницExperimental Study On Concrete (M30) by Partial Replacement of Fine Aggregate With Copper SlagIAEME PublicationОценок пока нет

- To Find The Strength of Concrete Block Using Waste Material Project ReportДокумент49 страницTo Find The Strength of Concrete Block Using Waste Material Project ReportSahil Bali100% (1)

- Iternship ReportДокумент40 страницIternship Reportpavan coorgОценок пока нет

- Shivaji Polytechnic College, SangolaДокумент22 страницыShivaji Polytechnic College, SangolaShripad KulkarniОценок пока нет

- Visvesvaraya Technological University, BELAGAVI - 590001: A Project Report OnДокумент44 страницыVisvesvaraya Technological University, BELAGAVI - 590001: A Project Report OnShain100% (1)

- Report On Fiber Reinforced ConcreteДокумент21 страницаReport On Fiber Reinforced Concreteঅরিজিৎ বোসОценок пока нет

- PPTДокумент28 страницPPTRama Arul SakthiОценок пока нет

- DE Sem 5Документ24 страницыDE Sem 5Yamin Devgadhwala100% (1)

- Fly Ash Soil BlocksДокумент42 страницыFly Ash Soil Blocksrafilu100% (1)

- Pervious ConcreteДокумент31 страницаPervious ConcreteYaangki Moqktan100% (1)

- Study of Partial Replacement of Fine Aggregate by Oyster Shell and Partial Replacement of Cement by Rice Husk AshДокумент53 страницыStudy of Partial Replacement of Fine Aggregate by Oyster Shell and Partial Replacement of Cement by Rice Husk AshRadix Citizen100% (1)

- Literature Review ZairadziДокумент5 страницLiterature Review Zairadzisiti elferaОценок пока нет

- Project ReportДокумент28 страницProject ReportD G PrasathОценок пока нет

- Green ConcreteДокумент19 страницGreen ConcreteAnubhav KalОценок пока нет

- Civilcprojectbook PDFДокумент89 страницCivilcprojectbook PDFAnonymous ueXqEGHkxОценок пока нет

- Industrial Training On HighwayДокумент35 страницIndustrial Training On HighwayAnil Yadav100% (1)

- Summer Training ReДокумент23 страницыSummer Training ReWalid AdnanОценок пока нет

- 1.1 Concrete: Partial Replacement of Coarse Aggregate With Ceramic Tile 2019-2020Документ25 страниц1.1 Concrete: Partial Replacement of Coarse Aggregate With Ceramic Tile 2019-2020Naveen S100% (2)

- An Experimental Study On Strength of Concrete With Silica Fume and Partial Replacement of Cement by Brick PowderДокумент5 страницAn Experimental Study On Strength of Concrete With Silica Fume and Partial Replacement of Cement by Brick PowderInternational Journal of Innovative Science and Research TechnologyОценок пока нет

- MINI PROJECT REPORT. (Original)Документ19 страницMINI PROJECT REPORT. (Original)Yashaswi M Gowda100% (1)

- Industrial Training ReportДокумент32 страницыIndustrial Training ReportMattam AbhishekОценок пока нет

- Ready Mix Concrete: Technical Seminar Report OnДокумент7 страницReady Mix Concrete: Technical Seminar Report OnadityaОценок пока нет

- Water Absorbing Raod PPT 2k23Документ20 страницWater Absorbing Raod PPT 2k23Video Cloud100% (3)

- Final Project Report Batch 4Документ44 страницыFinal Project Report Batch 4Manu P SОценок пока нет

- Partial Replacement of Cement by Marble SlurryДокумент31 страницаPartial Replacement of Cement by Marble SlurryDhanendra SinghОценок пока нет

- Major Project ReportДокумент49 страницMajor Project ReportMohini BhartiОценок пока нет

- Arya College of Engg&Research Centre, Jaipur: Road WorkДокумент24 страницыArya College of Engg&Research Centre, Jaipur: Road WorkPradhumna Adhikari100% (2)

- Casting of Plinth Beam 1Документ8 страницCasting of Plinth Beam 1RAJA BASUMATARYОценок пока нет

- Water Cement RatioДокумент6 страницWater Cement RatioPrashant PradhanОценок пока нет

- Use of Fly Ash in Highway Embankment: Final Year Project PresentationДокумент25 страницUse of Fly Ash in Highway Embankment: Final Year Project Presentationjg100% (1)

- Study of Light Weight Fibre Reinforced Concrete by Partial Replacement of Coarse Aggregate With Pumice StoneДокумент10 страницStudy of Light Weight Fibre Reinforced Concrete by Partial Replacement of Coarse Aggregate With Pumice StoneMohammed Sohel AhmedОценок пока нет

- ABM Seminar ReportДокумент24 страницыABM Seminar Reportmd MuzammilОценок пока нет

- Seminar ReportДокумент29 страницSeminar ReportSreelakshmi Mohan100% (1)

- KHRI Webinar (29-05-2020) - Pervious Concrete Pavement Systems - 29 May 20 - Dr. Krishna Prapoorna IITT PDFДокумент83 страницыKHRI Webinar (29-05-2020) - Pervious Concrete Pavement Systems - 29 May 20 - Dr. Krishna Prapoorna IITT PDFassistant directorОценок пока нет

- Project Report PDFДокумент41 страницаProject Report PDFAKRAMA HASANОценок пока нет

- Bco Micro Project Group 4Документ13 страницBco Micro Project Group 4Aayush PatilОценок пока нет

- EAC Micro ProjectДокумент19 страницEAC Micro ProjectSwapnil MandaleОценок пока нет

- Eac Micro Project ReportДокумент19 страницEac Micro Project Report53 Hirole Aadesh100% (1)

- Major Project On Experimental Study On Stabilization of Black Cotton SoilДокумент58 страницMajor Project On Experimental Study On Stabilization of Black Cotton SoilGouthami Sunkapaka100% (1)

- Replacement of Natural Sand With Robosand in Making Concrete PDFДокумент55 страницReplacement of Natural Sand With Robosand in Making Concrete PDFsumankanthnelluri773% (30)

- Transparent Concrete SeminarДокумент17 страницTransparent Concrete Seminarimul100% (2)

- Fly Ash For Cement Concrete: NTPC LimitedДокумент51 страницаFly Ash For Cement Concrete: NTPC LimitedMd AwesshadabОценок пока нет

- WRE ReportДокумент15 страницWRE ReportRudra BasugadeОценок пока нет

- Orata - Arc222 - Cement and ConcreteДокумент5 страницOrata - Arc222 - Cement and ConcreteAnthony OrataОценок пока нет

- UTP Student Industrial ReportДокумент50 страницUTP Student Industrial ReportAnwar HalimОценок пока нет

- Lithuania DalinaДокумент16 страницLithuania DalinaStunt BackОценок пока нет

- CT SizingДокумент62 страницыCT SizingMohamed TalebОценок пока нет

- 3 ALCE Insulators 12R03.1Документ12 страниц3 ALCE Insulators 12R03.1Amílcar Duarte100% (1)

- Tribal Banditry in Ottoman Ayntab (1690-1730)Документ191 страницаTribal Banditry in Ottoman Ayntab (1690-1730)Mahir DemirОценок пока нет

- Companyprofil E: Erfanconstructionsolut IonДокумент14 страницCompanyprofil E: Erfanconstructionsolut IonNurin AleesyaОценок пока нет

- 11-03 TB Value Chains and BPs - WolfДокумент3 страницы11-03 TB Value Chains and BPs - WolfPrakash PandeyОценок пока нет

- Dialogue Au Restaurant, Clients Et ServeurДокумент9 страницDialogue Au Restaurant, Clients Et ServeurbanuОценок пока нет

- SSGC-RSGLEG Draft Study On The Applicability of IAL To Cyber Threats Against Civil AviationДокумент41 страницаSSGC-RSGLEG Draft Study On The Applicability of IAL To Cyber Threats Against Civil AviationPrachita AgrawalОценок пока нет

- Pavement Design1Документ57 страницPavement Design1Mobin AhmadОценок пока нет

- Thermally Curable Polystyrene Via Click ChemistryДокумент4 страницыThermally Curable Polystyrene Via Click ChemistryDanesh AzОценок пока нет

- Famous Russian PianoДокумент10 страницFamous Russian PianoClara-Schumann-198550% (2)

- LEIA Home Lifts Guide FNLДокумент5 страницLEIA Home Lifts Guide FNLTejinder SinghОценок пока нет

- The Doshas in A Nutshell - : Vata Pitta KaphaДокумент1 страницаThe Doshas in A Nutshell - : Vata Pitta KaphaCheryl LynnОценок пока нет

- Elements of ArtДокумент1 страницаElements of Artsamson8cindy8louОценок пока нет

- FDA Approves First Gene Therapy, Betibeglogene Autotemcel (Zynteglo), For Beta-ThalassemiaДокумент3 страницыFDA Approves First Gene Therapy, Betibeglogene Autotemcel (Zynteglo), For Beta-ThalassemiaGiorgi PopiashviliОценок пока нет

- Review1 ScheduleДокумент3 страницыReview1 Schedulejayasuryam.ae18Оценок пока нет

- Radiation Safety Densitometer Baker PDFДокумент4 страницыRadiation Safety Densitometer Baker PDFLenis CeronОценок пока нет

- Assessment of Students' Oral Communication in English ClassДокумент10 страницAssessment of Students' Oral Communication in English ClassKeebeek S ArbasОценок пока нет

- User Manual For Speed Control of BLDC Motor Using DspicДокумент12 страницUser Manual For Speed Control of BLDC Motor Using DspicTrung TrựcОценок пока нет

- Pivot TableДокумент19 страницPivot TablePrince AroraОценок пока нет

- 5c3f1a8b262ec7a Ek PDFДокумент5 страниц5c3f1a8b262ec7a Ek PDFIsmet HizyoluОценок пока нет

- NDY 9332v3Документ8 страницNDY 9332v3sulphurdioxideОценок пока нет

- MRBR ATR 72 Rev18Документ424 страницыMRBR ATR 72 Rev18Juan Forero OrtizОценок пока нет

- Modulo EminicДокумент13 страницModulo EminicAndreaОценок пока нет

- Arens - Auditing and Assurance Services 15e-2Документ17 страницArens - Auditing and Assurance Services 15e-2Magdaline ChuaОценок пока нет

- Electro Fashion Sewable LED Kits WebДокумент10 страницElectro Fashion Sewable LED Kits WebAndrei VasileОценок пока нет

- Hdfs Default XML ParametersДокумент14 страницHdfs Default XML ParametersVinod BihalОценок пока нет

- Negotiating Skills Negotiating Skills: To Provide You With The Skills To Plan & Implement Successful NegotiationДокумент32 страницыNegotiating Skills Negotiating Skills: To Provide You With The Skills To Plan & Implement Successful NegotiationKanimozhi.SОценок пока нет

- Theories of International InvestmentДокумент2 страницыTheories of International InvestmentSamish DhakalОценок пока нет