Академический Документы

Профессиональный Документы

Культура Документы

InteractiveFormQW 485 PDF

Загружено:

mtbecerrap0 оценок0% нашли этот документ полезным (0 голосов)

21 просмотров1 страницаОригинальное название

InteractiveFormQW-485.pdf

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

21 просмотров1 страницаInteractiveFormQW 485 PDF

Загружено:

mtbecerrapАвторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 1

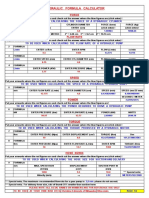

QW-485 SUGGESTED FORMAT FOR DEMONSTRATION OF STANDARD WELDING

PROCEDURE SPECIFICATIONS (SWPS)

(See Article V)

Identification of Standard Welding Procedure Specification Demonstrated

Demonstration Welding Conditions

Specification, Type, and Grade or UNS Number of Base Metal(s):

to Specification, Type, and Grade or UNS Number of Base Metal(s):

Base Metal P- or S- Number To Base Metal P- or S- Number Thickness

Welding Process (es) used

Plate Pipe (Enter Diameter, of Pipe or Tube)

Groove Type (Single V, Double V, Single U, etc.)

Initial Cleaning Method

Backing (with/without)

Filler Metal (SFA) Specification:

Filler Metal or Electrode Classification

Filler Metal or Electrode Trade Name

Size of Consumable Electrode or filler metal

Tungsten Electrode Classification and Size for GTAW

Consumable Insert Classification and Size for GTAW or PAW

Shielding Gas Composition and Flow Rate for GTAW, PAW, GMAW (FCAW)

Preheat Temperature

Position (1G, 2G,etc.) of Weld

Progression (Uphill or Downhill)

Interpass Cleaning Method:

Measured Interpass Temperature :

Approximate Deposit Thickness for Each Filler Metal or Electrode Type

Current Type / Polarity (AC, DCEP, DCEN)

Postweld Heat Treatment Time and temperature:

Visual Examination of Completed Weld (QW-302.4) Date of Test

Bend Test (QW-302.1) Transverse Root and Face [QW-462.3 (a)] Side [QW-462.2]

Type Result Type Result Type Result

Alternative Radiographic Examination Results: (QW-302.2)

Specimens Evaluated by Title Company

Welding Supervised by Title Company

Mechanical testing by: Laboratory Test no.

Welders Name Stamp No.

We certify that the statements in this record are correct and that the test coupons were prepared, welded and tested in accordance with the

requirements of Section IX of the ASME Code.

Manufacturer or Contractor:

By: Date: Demonstration Number

Вам также может понравиться

- BPVCДокумент1 страницаBPVCmtbecerrapОценок пока нет

- Mechanical FiberingДокумент1 страницаMechanical FiberingmtbecerrapОценок пока нет

- Piping Design InfoДокумент279 страницPiping Design InfoPradeep SarodeОценок пока нет

- Control - Tuberia - 530 IVAN TUAДокумент58 страницControl - Tuberia - 530 IVAN TUAmtbecerrapОценок пока нет

- Catalogo Leeson Electric Co PDFДокумент534 страницыCatalogo Leeson Electric Co PDFmtbecerrapОценок пока нет

- Copia de Hirsch-Hydraulic-CalculatorДокумент1 страницаCopia de Hirsch-Hydraulic-Calculatormtbecerrap0% (1)

- Pesos de Componentes SPG-SBRG-SPRGДокумент3 страницыPesos de Componentes SPG-SBRG-SPRGmtbecerrapОценок пока нет

- Ev DG05Документ14 страницEv DG05mtbecerrapОценок пока нет

- Boston ReducersДокумент356 страницBoston ReducersVicente Banda ZuñigaОценок пока нет

- Renold Conveyor Section1&2 0508 PDFДокумент51 страницаRenold Conveyor Section1&2 0508 PDFmtbecerrapОценок пока нет

- Astm D2657 - 07Документ7 страницAstm D2657 - 07dsalguero_2100% (2)

- Tsubaki Backstop AntiretornoДокумент12 страницTsubaki Backstop Antiretornomtbecerrap100% (1)

- Lincoln Er-308l Gtaw Acero InoxidableДокумент2 страницыLincoln Er-308l Gtaw Acero InoxidablemtbecerrapОценок пока нет

- Boiler Material and Typical ApplicationsДокумент1 страницаBoiler Material and Typical Applicationsmtbecerrap100% (1)

- Pipe Dimensions Imperial/MetricДокумент3 страницыPipe Dimensions Imperial/MetricmtbecerrapОценок пока нет

- SSPC Vis 1Документ2 страницыSSPC Vis 1cesar100% (3)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Normal HS 2073 - 2016-12-02-12-30-16 PDFДокумент562 страницыNormal HS 2073 - 2016-12-02-12-30-16 PDFSandeep JoshiОценок пока нет

- NuclearДокумент10 страницNuclearUsman MunirОценок пока нет

- Co 2Документ6 страницCo 2Sitti Nur QomariahОценок пока нет

- Basf Masterflow 649 TdsДокумент4 страницыBasf Masterflow 649 Tdsgazwang478Оценок пока нет

- Atoms and Elements (Chemistry Notes)Документ4 страницыAtoms and Elements (Chemistry Notes)wlkernanОценок пока нет

- Hydraulic Fracturing Theory and Practice: R. D. Barree Barree & Associates LLCДокумент18 страницHydraulic Fracturing Theory and Practice: R. D. Barree Barree & Associates LLCmoorpvrОценок пока нет

- 0653 - w12 - QP - 11 (Combined)Документ20 страниц0653 - w12 - QP - 11 (Combined)MCHОценок пока нет

- Embuild BrochureДокумент38 страницEmbuild BrochureKawish TamourОценок пока нет

- Electrooculography and It's ApplicationsДокумент48 страницElectrooculography and It's ApplicationsRose Edward50% (6)

- Planar MetalsДокумент11 страницPlanar MetalsSilvano Prado0% (1)

- Folder GluingДокумент3 страницыFolder GluingSyed Mujtaba Ali Bukhari100% (1)

- Welding Technology NotesДокумент89 страницWelding Technology NotesSanjay JangraОценок пока нет

- MorphologyДокумент5 страницMorphologyJimi LeeОценок пока нет

- Semester/Concrete Technology (9021) /experiment-02 PDFДокумент14 страницSemester/Concrete Technology (9021) /experiment-02 PDFjestinvthomasОценок пока нет

- Data Sheet N2XH-J, N2XH-O: DB 1550556EN ApplicationДокумент1 страницаData Sheet N2XH-J, N2XH-O: DB 1550556EN ApplicationMihai BancuОценок пока нет

- Lectureone Introduction To BioChE - 2Документ20 страницLectureone Introduction To BioChE - 2desalegn abera100% (1)

- 905 3SДокумент4 страницы905 3SyasafyОценок пока нет

- Process Pipeline Repair ClampsДокумент4 страницыProcess Pipeline Repair ClampsHeru SuryoОценок пока нет

- Zhang 2022Документ10 страницZhang 2022Statistics LearningОценок пока нет

- Description and Solubility - MTZДокумент6 страницDescription and Solubility - MTZPityu PíОценок пока нет

- Experiment No. 2 Classes of Chemical Reactions BackgroundДокумент5 страницExperiment No. 2 Classes of Chemical Reactions BackgroundjonastolentinoОценок пока нет

- PGK-L1 The Following Text Is For Question No. 1Документ2 страницыPGK-L1 The Following Text Is For Question No. 1Sri AyamiОценок пока нет

- Method For Ultra High Purity Gold - Gold Refining ForumДокумент11 страницMethod For Ultra High Purity Gold - Gold Refining Forummladen lakic100% (1)

- Article WJPR 1467266667Документ10 страницArticle WJPR 1467266667Atthapu ThirupathaiahОценок пока нет

- Batch Reactor Manual PDFДокумент4 страницыBatch Reactor Manual PDFPradeep DiwakarОценок пока нет

- LP Hydrocarbons Theresa Mae LlosaДокумент3 страницыLP Hydrocarbons Theresa Mae LlosaMae ThereseОценок пока нет

- RNA Structure, Functions WebДокумент25 страницRNA Structure, Functions WebEmad ManniОценок пока нет

- Ethylenediamine Complexes of ChromiumДокумент5 страницEthylenediamine Complexes of ChromiumMatt PraterОценок пока нет

- TDS OF H-408 Silicone Adjuvant For AgricultureДокумент2 страницыTDS OF H-408 Silicone Adjuvant For AgricultureAda FuОценок пока нет

- Project 4 Ethylene OxideДокумент12 страницProject 4 Ethylene OxideNhan Nguyen Van100% (4)