Академический Документы

Профессиональный Документы

Культура Документы

Flash Point and Fire Point - Final

Загружено:

Anonymous QM0NLqZO0 оценок0% нашли этот документ полезным (0 голосов)

390 просмотров33 страницыThis document describes procedures for determining the flash point and fire point of fuel oils using a Pensky Martens closed tester apparatus. It also describes testing the distillation characteristics (boiling range) of samples using a distillation apparatus.

The flash point is the lowest temperature at which vapors above the fuel ignite when exposed to a flame. The fire point is the temperature at which the fuel continues burning after ignition. Both are measured using the Pensky Martens apparatus under controlled conditions.

Distillation characteristics provide information on a fuel's composition and volatility behavior. A sample is heated and the temperature and volume of condensate collected at intervals are recorded to calculate distillation limits specified in fuel standards. These

Исходное описание:

pro

Оригинальное название

Flash Point and Fire Point.final

Авторское право

© © All Rights Reserved

Доступные форматы

DOCX, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документThis document describes procedures for determining the flash point and fire point of fuel oils using a Pensky Martens closed tester apparatus. It also describes testing the distillation characteristics (boiling range) of samples using a distillation apparatus.

The flash point is the lowest temperature at which vapors above the fuel ignite when exposed to a flame. The fire point is the temperature at which the fuel continues burning after ignition. Both are measured using the Pensky Martens apparatus under controlled conditions.

Distillation characteristics provide information on a fuel's composition and volatility behavior. A sample is heated and the temperature and volume of condensate collected at intervals are recorded to calculate distillation limits specified in fuel standards. These

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOCX, PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

390 просмотров33 страницыFlash Point and Fire Point - Final

Загружено:

Anonymous QM0NLqZOThis document describes procedures for determining the flash point and fire point of fuel oils using a Pensky Martens closed tester apparatus. It also describes testing the distillation characteristics (boiling range) of samples using a distillation apparatus.

The flash point is the lowest temperature at which vapors above the fuel ignite when exposed to a flame. The fire point is the temperature at which the fuel continues burning after ignition. Both are measured using the Pensky Martens apparatus under controlled conditions.

Distillation characteristics provide information on a fuel's composition and volatility behavior. A sample is heated and the temperature and volume of condensate collected at intervals are recorded to calculate distillation limits specified in fuel standards. These

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOCX, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 33

1.

FLASH POINT AND FIRE POINT

BY PENSKY MARTENS APPARATUS

AIM

To determine the flash point and fire point of fuel oils by using Pensky Martens apparatus

(closed type).

DEFINITION

FLASH POI NT

The lowest temperature of the sample, corrected to a barometric pressure of 101.3 kPa 760

mm Hg , at which application of a test flame causes the vapour of the sample to ignite under

specified conditions of test.

FI RE POI NT

The fire point, is defined as the temperature at which the vapour continues to burn after being

ignited.

SUMMARY OF METHOD

The sample is heated at a slow, constant rate with continual stirring. A small flame is directed

into the cup at regular intervals with simultaneous interruption of stirring. The flash point is

the lowest temperature at which application of the test flame causes the vapour above the

sample to ignite.

SIGNIFICANCE

Flash point measures the response of the sample to heat and flame under controlled

laboratory conditions.

It is only one of a number of properties which must be considered in assessing the

overall flammability hazard of a material.

Flash point is used in shipping and safety regulations to define flammable and

combustible materials.

APPARATUS

Pensky Martens Closed Tester

Thermometers (Two standard thermometers shall be used with the Pensky-Martens

tester)

TABULATION

S.No.

SAMPLES

FLASH POINT (C)

FIRE POINT(C)

PREPARATION OF SAMPLE

Samples of asphalts or very viscous materials may be warmed until they are reasonable fluid

before they are tested. However, no sample should be heated more than is absolutely

necessary. It shall never be heated above a temperature of 17C ( 30F ) below its expected

flash point.

APPARATUS SPECIFICATIONS

A typical assembly of the apparatus, gas heated, is shown in Fig. The apparatus shall consist

of a test cup, cover, and stove conforming to the following requirements.

Cup - The cup shall be of brass, or other non-rusting metal of equivalent heat conductivity,

and shall conform to the dimensional requirements

Cover Proper - The cover shall be brass, and shall have a rim projecting downward almost

to the flange of the cup. The rim shall fit the outside of the cup with a clearance not

exceeding 0.36 mm 0.014 in on the diameter.

Shutter - The cover shall be equipped with a brass shutter approximately 2.4 mm ( 3/32 in )

thick operating on the plane of the upper surface of the cover. cover openings shall be exactly

open and the tip of the exposure tube shall be fully depressed.

Flame Exposure Device - The flame-exposure device shall have a tip with an opening 0.69

to 0.79 mm (0.027 to 0.031 in) in diameter. This tip shall be made preferably of stainless

steel, although it may be fabricated of other suitable metals

Pilot Flame - A pilot flame shall be provided for automatic relighting of the exposure flame.

Stirring Device - The cover shall be equipped with a stirring device mounted in the centre of

the cover and carrying two 2-bladed metal propellers.

Stove

Heat shall be supplied to the cup by means of a properly designed stove which is equivalent

to an air bath. The stove shall consist of an air-bath and a top plate on which the flange of the

cup rests.

Air Bath

The air bath shall have a cylindrical interior and shall conform to the dimensional

requirements in Fig.

Top Plate

The top plate shall be of metal, and shall be mounted with an air gap between it and the air

bath.

PROCEDURE

The oil cup was cleaned using solvent.

The cup was filled with fresh sample up to the mark.

The cup was placed in the apparatus bath.

The lid is placed on the cup and the thermometer was also inserted.

The electrical heater was turned to 50% of input volts and oil is heated.

After that spring handle was rotated at every degree rise from this point.

The temperature was noted at which the flash occurs.

The fire point was noted at which the fuel burnt continuously for 5 seconds.

The experiment was repeated for different samples.

RESULT

Flash point and fire point of given samples are ________________ is _______ oC

2. DISTILLATION CHARACTERISTICS

SCOPE

To determine the distillation characteristics (boiling range) of the given sample using

the distillation apparatus.

DISTILLATION

This method of test covers the distillation of motor gasoline, aviation gasoline, aviation

turbine fuels, special boiling point spirits, naphtha, white spirit, kerosene, gas oils, distillate

fuel oils and similar petroleum products. A 100 ml sample is distilled under prescribed

conditions which are appropriate to its nature. Systematic observations of thermometer

readings and volumes of condensate are made, and from the data, the results of the test are

calculated and reported.

The distillation (volatility) characteristics of hydrocarbons have an important effect on their

safety and performance, especially in the case of fuels and solvents. The boiling range gives

information on the composition, the properties, and the behavior of the fuel during storage

and use. Volatility is the major determinant of the tendency of a hydrocarbon mixture to

produce potentially explosive vapors.

The distillation characteristics are critically important for both automotive and aviation

gasoline, affecting starting, warm-up, and tendency to vapor lock at high operating

temperature or at high altitude, or both. The presence of high boiling point components in

these and other fuels can significantly affect the degree of formation of solid combustion

deposits.

Distillation limits are often included in petroleum product specifications, in commercial

contract agreements, process refinery/control applications, and for compliance to regulatory

rules.

This test method can be applied to contaminated products or hydrocarbon mixtures. This is

valuable for fast product quality screening, refining process monitoring, fuel adulteration

control, or other purposes including use as a portable apparatus for field testing.

SIGNIFICANCE

Distillation (volatility) characteristics of petroleum products are indicative of

performance in their intended applications.

Petroleum product specifications generally include distillation limits to ensure

products of suitable volatility performance.

The empirical results obtained by use of this distillation method have been found to

correlate with automotive equipment performance factors and with other

characteristics of petroleum products related to volatility.

For motor spirit the 10% distillation value gives an indication of the engine start

conditions, also the final boiling point.

OBSERVATION

S.No

Volume of Distillate collected (ml)

Temperature C

TERMINOLOGY

Initial Boiling Point

The thermometer reading which is observed at the instant that the first drop of condensate

falls from the lower end of the condenser tube,

End-Point or Final Boiling Point

The maximum thermometer reading obtained during the test. This usually occurs after the

evaporation of all liquid from the bottom of the flask. The term maximum temperature is a

frequently used synonym.

Dry Point

The thermometer reading observed at the instant the last drop of liquid evaporates from the

lowest point in the flask. Any drops or film of liquid on the side of the flask or on the

thermometer are disregarded.

Decomposition Point

The thermometer reading which coincides with the first indication of thermal decomposition

of the liquid in the flask.

Percent Recovered

The volume in ml of condensate observed in the receiving graduate, in connection with a

simultaneous thermometer reading.

Percent Recovery

The maximum percent that is recovered.

Percent Total Recovery

The combined percent recovery and residue in the flask.

Percent Loss

100 minus the percent total recovery.

Percent Residue

The percent total recovery minus the percent recovery, or the volume of residue in milliliters

if measured directly.

Percent Evaporated

The sum of the percent recovered and the percent loss.

PROCEDURE

The given flask is to be thoroughly cleaned using solvent and dried.

The given test sample is then taken inside the flask and the cork with appropriate

thermometer is placed on the neck of the flask.

The flask is placed on the asbestos board and fixed to the metal condensers with a

cork. The asbestos board is raised of lowered till the flask is properly supported.

The 100cc measuring cylinder is placed below the condenser outlet. The heater is then

switched on and the temperature variation is noted.

The temperature at which the first drop of distillate is collected in the measuring

cylinder is noted and reported as the initial boiling point.

Heat is controlled, so that the distillation process is at a uniform state.

Middle boiling point is the temperature at which 50% of oil distills off.

RESULT

The Distillation characteristics are studied for the given samples and the values are noted as

follows:

1. Initial boiling point = C

2. Middle boiling point = C

3. Percentage of recovery =

4. Percentage of non-volatile residue =

5. Film boiling point = C

API GRAVITY - DIAGRAM

3. DETERMINATION OF API GRAVITY OF CRUDE PETROLEUM AND

LIQUID PETROLEUM PRODUCTS BY HYDROMETER METHOD AND

SPECIFIC GRAVITY BOTTLE METHOD

AIM

To determine the API gravity of crude petroleum and liquid petroleum products by

hydrometer method and specific gravity bottle method.

THEORY

This method covers the laboratory determination, using a glass hydrometer, of the

density, relative density, or API gravity of crude petroleum, petroleum products, or mixtures

of petroleum and non-petroleum products normally handled as liquids and having a Reid

vapour pressure of 1.8 bar (179 KPa) or less. The values are measured on a hydrometer at

convenient temperatures, readings of density being reduced to 15

o

C, and that of specific

gravity and API gravity to 15.6

o

C, by means of international standard tables.

CLASSIFICATIONS OR GRADES

Crude oil is classified as light, medium or heavy, according to its measured API gravity.

Light crude oil is defined as having API gravity higher than 31.1 API.

Medium oil is defined as having API gravity between 22.3 API and 31.1 API.

Heavy oil is defined as having API gravity below 22.3 API.

SIGNIFICANCE

Accurate determination of density, relative density, or API gravity of petroleum and

its products is necessary for the conversion of measured volumes to volumes at standard

temperature of 15C.

FORMULA

API Gravity

A special function of specific gravity at 15.6/15.6

o

C is represented by:

API gravity, degrees = [141.5 /Specific gravity at 15.6/15.6

o

C] - 131.5

APPARATUS REQUIRED

Hydrometer

Hydrometer cylinders

Specific gravity bottle

OBSERVATIONS

Sl.No

SAMPLES

SPECIFIC GRAVITY

At room temperature

using Hydrometer

At room temperature

using Specific gravity

bottle method

SPECIFIC GRAVITY BOTTLE METHOD

Weight of the empty specific gravity bottle =

Weight of the specific gravity bottle with sample 1 =

Weight of the specific gravity bottle with sample 2 =

Weight of the specific gravity bottle with sample 3 =

Weight of the specific gravity bottle with sample 4 =

PROCEDURE

Hydrometer method

The samples were transferred to hydrometer cylinders without any splashing to avoid

air bubbles.

The cylinders containing samples were placed in vertical position in a location free

from air currents.

The hydrometer was gently lowered into the sample in cylinders such that the

hydrometer should not touch the walls of the cylinder.

The hydrometer was allowed to float and when it comes to rest, the specific gravity

indicated by the hydrometer for different samples at room temperature were noted.

From the specific gravity values the API gravity for the given samples were

calculated.

Specific gravity bottle method

The samples were taken in each specific gravity bottle.

The specific gravity bottle with the samples and the weight of the empty specific

gravity bottle were measured.

The readings were tabulated and the specific gravity for different samples was

calculated. From the specific gravity values the API gravity for the given samples

were calculated.

RESULT

The API gravity of the given samples using hydrometer and specific gravity bottles

were calculated and tabulated as follows

Sl.No.

Samples

API gravity

Hydrometer method Specific gravity bottle

method

4. SOFTENING POINT

AIM

To determine the softening point of the given sample bitumen using ball and ring

apparatus.

APPARATUS REQUIRED

Ring and ball apparatus

Steel balls

Brass rings

Thermometer

Stirrer

Water bath

SIGNIFICANCE

To find the consistency of bitumen

It is regarded by same indication of viscosity

It is used in the designation of hard as oxidized bitumen.

THEORY

The temperature at which the substance attains a particular degree of softness under

specified condition of test is called softening point.

Bitumen is specified by softening point. Bitumen being amorphous does not melt

sharply but gradually becomes softer and less viscous as the temperature rises.

For this reason, the determination of the softening point must be made by fixed

arbitrary and closely defined method.

The softening point of bitumen is rounded out by the ball and ring test.

APPLICATION

Used in annealing of bitumen.

Processing of plastics.

Determining the quality of bitumen.

PROCEDURE

A beaker is taken and filled with of it with water.

The sample is placed in the ring and the steel ball is kept over the sample at the

middle of the ring.

The whole ring and ball is immersed into the beaker which is filled with water.

The water in the beaker is heated by electrical coil.

A thermometer is inserted to note the temperature.

As the temperature increase, the sample gets softens and the steel ball over the sample

gets immersed and finally drops out.

The temperature at which the ball falls down from the ring is noted as softening point

of the sample.

The ring is washed and replaced with another sample and the process is repeated.

RESULT

The softening point of given first sample =

The softening point of given second sample =

5. ANILINE POINT

AIM

To determine the aniline point of the given sample.

APPARATUS

The tube approximately 25mm in diameter and 150mm in length made of heat-

resistant glass.

A Jacket-approximately 37 to 42mm in diameter and 175mm in length made of heat-

resistant glass.

A Stirrer-manually operated, approximately 2mm in diameter soft iron wire.

THEORY

Aniline point

Aniline is a poor solvent for aliphatic hydrocarbons and excellent one for aromatics.

This property is used in the aniline point test. Aniline point of oil is the lowest temperature at

which the oil is completely miscible with an equal volume of aniline.

Equal volumes of the sample and aniline (5 ml each) are heated or cooled with

stirring in a jacketed test tube and temperature at which complete miscibility occurs is noted.

High aniline point indicates that the fuel is highly paraffinic and hence has a high

diesel index and very good ignition quality. In case of aromatics the aniline point is low and

the ignition quality is poor

Diesel index

Diesel index is an indication of the ignition quality of a diesel fuel. This is determined

by calculation from the specific gravity and the aniline point of the sample. Although it is of

the same order as the cetane number, it may differ widely from the cetane number. Higher the

diesel index better is the ignition quality of the diesel fuel. It is normally used as a guide to

ignition quality of the diesel fuel in the absence of test engine for the direct measurement of

cetane number.

The diesel index is calculated as follows:

(a) Diesel index = (Aniline point,F API)/100

(b) Diesel index = (Aniline gravity constant)/100

(c) Diesel index = (Cetane number 10)/0.72

Cetane number

Cetane number is related to the ignition delay of a fuel in a diesel engine, i.e. how

rapidly combustion begins after injection of the fuel into the combustion chamber.

The shorter the ignition delay period, higher is the cetane number of the fuel

Cetane number is the index of the ignition quality of a fuel. High cetane number

fuels will facilitate easy starting of compression ignition engines, particularly in cold

weathers, and faster warm up. These also result in increased engine efficiency and power

output, reduced exhaust smoke and odour and combustion noise. In the absence of test

engine, the diesel index or the calculated cetane index will give an approximate idea of the

ignition quality of the fuel.

Cetane number= 0.72Diesel index + 10

PROCEDURE

The apparatus was dried and cleaned.

10ml of aniline and 10ml of the sample were dried and pipetted into the test tube

fitted with stirrer and thermometer.

The thermometer in the test tube was centered to make the immersion mark at the

liquid level; it is assured that the thermometer bulb does not touch the side of the tube.

In the case of not mixing of aniline-sample at normal temperature, heat is applied

directly to the jacket tube so that the temperature raised at a rate of 1-3C/min till

complete miscibility was obtained.

Stirring is continued and the mixture is allowed to cool at a rate of 0.5 to 1C/min.

Cooling is continued to a temperature of 1 to 2C below the first appearance of

turbidity.

The temperature at which the mixture suddenly became cloudy throughout is recorded

as the aniline point.

RESULT

Results for the aniline point experiment were found to be

Aniline point =

Diesel index =

Cetane number =

6. CLOUD AND POUR POINT DETERMINATION

AIM

To determine the Cloud point and pour point of the given sample.

REQUIREMENTS

Cloud and pour point apparatus, Thermometer, Ice crystals.

DEFINITIONS

The cloud point of a fluid is the temperature at which dissolved solids are no longer

completely soluble, precipitating as a second phase giving the fluid a cloudy appearance. This

term is relevant to several applications with different consequences.

Also, the pour point can be defined as the lowest temperature expressed in multiples of 3C

at which the oil is observed to flow when cooled and examined under prescribed conditions.

THEORY

Cloud point and pour point are indicators of the lowest temperature of utility for petroleum

products. Cloud Point gives a rough idea of temperature above which the oil can be safely

handled without any fear of congealing or filter clogging. The sample is periodically

examined while it is being cooled in the cloud and pour point apparatus. The highest

temperature at which haziness is observed (cloud point), or the lowest temperature at which

the oil ceased to flow is observed (pour point), is reported as the test result.

The cold filter plugging point test is used to determine the extent to which diesel fuel or gas

oil will flow, even though the temperature is below that at which wax crystals normally

appear, i.e. cloud point.

Pour point is a well established test to estimate the temperature at which a sample of oil

becomes sufficiently solid to prevent its movement by pumping. The pour point indicates the

waxy nature of the oils.

SAMPLES SHOWING CLOUD AND POUR POINT

CLOUD AND POUR POINT EXPERIMENTAL SETUP

CLOUD AND POUR POINT EXPERIMENTAL SETUP

PROCEDURE

Measuring cloud point of petroleum product:

The test oil is required to be transparent in layers 40mm in thickness (in accordance

with ASTM D2500). The crystals of the sample typically first form at the lower

circumferential wall with the appearance of a whitish or milky cloud. The cloud point is the

temperature at which these crystals first appear.

The test sample is first poured into a test jar to a level approximately half full. A cork

carrying the test thermometer is used to close the jar. The thermometer bulb is positioned to

rest at the bottom of the jar. The entire test subject is then placed in a constant temperature

cooling bath on top of a gasket to prevent excessive cooling.

At every 1C, the sample is taken out and inspected for cloud then quickly replaced.

Successively lower temperature cooling baths may be used depending on the cloud point.

Lower temperature cooling bath must have temperature stability not less than 1.5 K for this

test.

Measuring pour point of petroleum product:

Two pour points can be derived which can give an approximate temperature window

depending on its thermal history. Within this temperature range, the sample may appear

liquid or solid. This peculiarity happens because sample crystals form more readily when it

has been heated within the past 24hrs and contributes to the lower pour point.

The upper pour point is measured by pouring the test sample directly into a test jar. The

sample is then cooled and then inspected for pour point as per the usual pour point method.

The lower pour point is measured by first pouring the sample into a stainless steel pressure

vessel. The vessel is then screwed tight and heated to above 100

o

C in an oil bath. After a

specified time, the vessel is removed and cooled for a short while. The sample is then poured

into a test jar and immediately closed with a cork carrying the thermometer. The sample is

then cooled and then inspected for pour point as per the usual pour point method

RESULT

The pour point of the given sample was found to be ---------

0

C.

The cloud point of the given sample was found to be ---------

0

C

7. COPPER STRIP CORROSION TEST

AIM

To detect the corrosiveness of the given sample using copper strip corrosion test.

PRINCIPLE

The method covers the detection of corrosiveness to copper of aviation gasoline from

tractor fuel, solvent, kerosene, diesel, fuel oil, lube oil, certain other petroleum products.

A polished copper strip is immersed in a given quantity of sample and heated at a

temperature and for a time characteristics of the material being tested. At the end of this

period, the copper strip is removed, washed and compared with copper strip corrosion

standards. It is particularly important that all types of feed sample which should pass a

tarnished strip classification. We collected clean glass bottles, plastic bottles or other suitable

containers that will not affect the corrosiveness properties of the sample.

REQUIREMENTS

Copper strip corrosion test bomb

Constant temperature water bath

Polishing ice

Glass test tube

Polishing paper

SIGNIFICANCE AND USE

This test method is suitable for setting specifications, for use as an internal quality

control tool, and for use in development or research work on industrial aromatic

hydrocarbons and related materials. It also gives an indication of the presence of certain

corrosive substances which may corrode equipment, such as acidic compounds or sulfur

compounds.

PROCEDURE

The test is to be operated at 50

o

C constant temperature.

The bath is set at the desired working temperature and waits for 20 minutes of

time after the start.

The copper strip is prepared for performing test. It is washed properly with

solvent (acetone) and surface of strip is prepared by rubbing with silicon

carbide grid paper.

Clamp the strip with ice and polish it until uniform rubbing, when strip is

clean immerse it in prepared sample.

The strip is kept into 30 ml of sample which is kept inside the test bomb and

the lid is screwed tight.

After two hours in the bath the bomb is withdrawn and it is cooled with water.

The bomb is opened, the test tube is taken out and carefully the strip is

withdrawn from the sample.

The strip is compared with ASTM corrosion standards comparison chart and

report the tarnish level.

RESULT

The corrosiveness of the given sample is found out using the copper strip and

comparing it with ASTM standards and its value is found to be ---------------------------

8. BOMB CALORIMETER

AIM:

To determine the calorific value of a given fuel

INTRODUCTION:

The heating value or calorific value of a substance, usually a fuel or food, is the amount of

heat released during the combustion of a specified amount of it. The calorific value is a

characteristic for each substance. It is measured in units of energy per unit of the substance,

usually mass, such as: kcal/kg, kJ/kg, J/mol, Btu/m. Heating value is commonly determined

by use of a bomb calorimeter.

The bomb calorimeter is the most common device for measuring the heat of combustion or

calorific value of a material. With this apparatus a test specimen of specified mass is burned

under standardized conditions. The heat of combustion determined under these conditions is

calculated on the basis of the observed temperature rise while taking account of heat loss. The

combustion process is initiated inside an atmosphere of oxygen in a constant volume

container, the bomb, which is a vessel built to withstand high pressures. It is immersed in a

stirred water bath, and the whole device is the calorimeter vessel. The calorimeter vessel is

also immersed in an outer water bath. The water temperature in the calorimeter vessel and

that of the outer bath are both monitored

THEORY:

The calorific value of a fuel is the amount of energy liberated by burning completely unit

quantity of fuel. A small amount is burned under high pressure oxygen. The calorific value

calculated by measured the energy liberated.

Heat liberated = Heat gained by water and calorimeter

m

f

*CV = (m

w

+ m

c

) (T

2

-T

1

)*(Cp)

where

m

f

: mass of the fuel.

m

w

: mass of water in calorimeter.

m

c

: mass of water equivalent of the calorimeter which should be determined using a fuel of

know calorific value.

T

2

-T

1

: temperature rise.

Cp: specific heat of water.

PROCEDURE:

1. A small quantity of fuel (about 1 gram) is weighted.

2. The ignition wire is fixed and the bomb is closed.

3. The bomb is charged with oxygen to a pressure of about 30 bars.

4. The bomb is inserted in the calorimeter and about 2 Kg of water is poured.

5. The Beckman thermometer is inserted and the stirrer is started.

6. Temperature of water is recorded every 10 seconds.

EXPERIMENTAL SETUP:

Figure shows the experiment setup: bomb calorimeter and Beckman thermometer.

The Beckmann thermometer was invented by Ernest Otto Beckmann (1853-1923), also noted

for the Beckmann transformation in organic chemistry, as a result of his work with oximes.

His interest in the physical properties of these molecules lead him to invent a number of

ingenious apparatus for measuring colligate properties based on the theoretical work of

Francois Marie Raoult (1830-1901). He began publishing this work around 1888. Beckmann

developed the differential thermometer bearing his name, which could accurately measure

temperatures to about 0.001 C, in order to measure the very small temperature changes

found in boiling point and freezing point determinations of molecular weight.

An adiabatic bomb calorimeter has the metal bomb inside of a metal bucket containing water.

That metal bucket sits loosely inside an insulated jacket. There is a stirrer that sticks into the

water in the bucket and is driven by a motor outside of the calorimeter. A thermometer also

sticks into the water in the bucket and is the device that will be used to determine the change

in temperature during the reaction. Two electrical leads connect to the top of the bomb from

outside and they will deliver the current that initiates the reaction.

The metal bomb provides a constant-volume system in which the combustion will reaction

take place. The sample pellet is placed in the ignition cup and the fuse wire is carefully

arranged to touch the pellet but not the cup. The bomb is sealed by screwing the cap on and

then filled with a high pressure of pure oxygen. The electrical connections are made at the top

and the bomb is placed into the water bucket. Figure 2 shows a sketch of the bomb

calorimeter cross section.

Figure 2 a sketch of the bomb calorimeter cross section

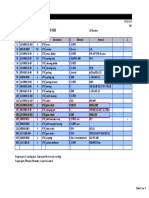

Data observed

Table 1:

Change of temperature with time

Time

[ s ]

Temperature

[

o

C ]

Time

[ s ]

Temperature

[

o

C ]

0 28.4 250 32.5

10 28.5 260 32.5

20 28.7 270 32.5

30 29.1 280 32.5

40 29.6 290 32.6

50 29.9 300 32.6

60 30.7 310 32.6

70 31.0 320 32.6

80 31.4 330 32.6

Pressure in =30 bar

Mass of water = 2 Kg

Mass of fuel = 1 g

Sample calculation:

Heat liberated from fuel = Heat gained by water and calorimeter

m

f

* C.V = ( m

w

+ m

c

) ( T

2

T

1

) (c

p

)

1 * 10

-3

* C.V = (2 + 0.856) (32.5 28.4) (4186)

C.V = 49016385.6 [ J / Kg ]

90 31.5 340 32.6

100 31.6 350 32.6

110 31.8 360 32.6

120 31.9 370 32.6

130 32.0 380 32.6

140 32.1 390 32.6

150 32.2 400 32.5

160 32.2 410 32.5

170 32.3 420 32.5

180 32.3 430 32.5

190 32.4 440 32.5

200 32.4 450 32.5

210 32.4 460 32.5

220 32.4 470 32.5

230 32.5 480 32.5

240 32.5

Results and discussion

The change of temperature with the time can be shown in figure 2.

Figure 3. Water Temperatures versus Time

Figure 2 shows that the temperature of water increased very fast in the first 80 seconds, this

may happen according to the sudden change in temperature between the bomb and

calorimeter. Eighteen second represents an infection point so the increase in water

temperature becomes slowly and it goes to finish the transient change in water temperature

until it becomes constant at 200 seconds.

The heat transferred to water is stored in the water and calorimeter and increase the

temperature so in the sample calculation the value of calorific value of the diesel is found as

49016.4 [KJ/Kg].

Conclusions

The calorific value of the diesel in this experiment is 49016.4 [KJ/Kg] which effected by

many sources of errors. This value can be compared with others values for fuels to select

best option.

The experiment show that water (in liquid phase) stored energy by increasing its

temperature.

28

28.5

29

29.5

30

30.5

31

31.5

32

32.5

33

0 100 200 300 400 500

Time [ s ]

T

e

m

p

e

r

a

t

u

r

e

[

C

]

KFR TITRATION

AIM:

To determine the water content in the given petroleum sample.

APPARATUS REQUIRED:

Base unit consists of rear panel and front panel. Front panel has stirrer on switch.

Stirrer speed regulator 3 LED and MVP set potentiometer

Green LED O - equipment on

Yellow LEDP- nearing end point indication

Red LED E - endpoint indication

Rear panel has main ON switch. Plug socket, fuse 500 mA and electrode terminals e.

Magnetic stirrer

Stirrer on - off switch is located on the front panel. Use regulator to set the required speed.

After setting required speed, use on off switch only for operating the stirrer. Avoid using the

regulator frequently.

Setting up the equipment for operation

Fix stand rod to the base unit and mount the burette assembly on the instrument. The burette

assembly will freely slide up and down and revolve around the standard.

Reaction assembly

Pressure filling auto zero setting burette assembly.KFR bottle can be screwed on the plastic

cap. Operate bellow holding vertically and closing the T joint connection tube. Air pressure

in the KFR bottle increases and lifts KFR to fill the burette. When the level crosses o mark

remove the finger zero level sets automatically. Reaction vessel can be filled or removed by

lifting the burette assembly.

Reaction vessel is connected to the electrode terminals on rear panel through pair of

connecting jack wires. Using methanol bottle instead of KFR bottle can wash the burette

assembly. If you want to adjust the zero level, adjust the Teflon tip i.e. just pull out or insert

the Teflon tip and set to zero.

PROCEDURE:

Neutralization of KFR:

Place magnetic stirring paddle into reactor carefully ,using the forceps. Never drop the Teflon

magnetic paddle into the reactor after mounting on the magnetic stirrer.

The paddle will be pulled down with great force and damage the reaction flask

Pour about 20 ml grade methanol into the reactor.

Fill the burette with KFR.

Connect jack wire to the reactor and electrode terminals marked e.Lift the burette assembly

by 50 cm and place the reactor on the magnetic stirrer lower the burette assembly and allow it

to rest on the reactor.

Switch on the equipment power on o green LED will glow.

Switch on the stirrer.

Set required speed for vigorous stirring with minimum spurting. Wait for10 to 15 seconds for

uniform stirring.

Add KFR reagent by drops into the burette valve.

Add KFR reagent until pre end point p yellow LED glows, this will indicate nearing end

point. Now add KFR by drops slowly giving 10-20 seconds between additions until E red

LED glows continuously for 30 seconds. At the end point of the titration P yellow LED will

go off and E red LED will glow continuously at the point wait and watch for 30 seconds

indicating current flow is steady and continuous.

Standardization of KFR

For finding out the factor of water equivalent

Fill the burette

Weigh 1 ml of distiller water using electronic balance in a syringe.

Close the reaction vessel with stopper .start magnetic stirrer and allow the contents to

dissolve for some time. Distilled water dissolves immediately.

Fill the burette and titrate up to the end point as described in neutralization.

After completion of cycle, note the burette reading.

F factor of equivalent = M/A

M is the weight of the water

A is the volume of KFR

Estimation of water content in unknown sample

Viscous liquids can be weighed and dropped into the reactor using droppers, light liquids can

be measured and added into the reactor using pipettes or syringe.

Percentage of water content = B *F

______

V*D* 10

B is the volume of KFR

F is the factor of water equivalent

V is the volume of the sample

D is the density of the sample.

Result

The percentage of water present in the given petroleum sample is -----------.

TABULATION:

Neutralization of KFR

Burette reading ( KFR volume) =

Standardization of KFR

Weight of water M =

Volume of KFR A =

Factor of water equivalent F= M

------

A

Estimation of water content in the unknown sample

Volume of KFR =

Volume of sample =

Density = 1 mg/ml

Percentage of water content = B*F

-----

V*D*10

Вам также может понравиться

- High-Pressure Fluid Phase Equilibria: Phenomenology and ComputationОт EverandHigh-Pressure Fluid Phase Equilibria: Phenomenology and ComputationОценок пока нет

- Phase Equilibria: Basic Principles, Applications, Experimental TechniquesОт EverandPhase Equilibria: Basic Principles, Applications, Experimental TechniquesОценок пока нет

- Pensky Martin (2015uch1708)Документ6 страницPensky Martin (2015uch1708)Manoj MorwalОценок пока нет

- Aim: To Determine The Smoke Point of Given Petroleum Product. ApparatusДокумент2 страницыAim: To Determine The Smoke Point of Given Petroleum Product. ApparatusHitesh N. PanchalОценок пока нет

- Flash and Fire Point TestДокумент4 страницыFlash and Fire Point TestSAQAR ALGHAMDIОценок пока нет

- Flash PointДокумент6 страницFlash PointAbhilash AbhiОценок пока нет

- Flash and Fire PointДокумент6 страницFlash and Fire Pointabth99Оценок пока нет

- WINSEM2021-22 CHE2006 TH VL2021220501413 Reference Material I 11-03-2022 Module-5 CombustionДокумент63 страницыWINSEM2021-22 CHE2006 TH VL2021220501413 Reference Material I 11-03-2022 Module-5 Combustionswastik vijayОценок пока нет

- Continuous Regenerative (Moving Bed) CCR PlatformingДокумент4 страницыContinuous Regenerative (Moving Bed) CCR PlatformingAnnissa Nur HidayatiОценок пока нет

- Lec 6Документ5 страницLec 6Abderrahim HAMDAOUIОценок пока нет

- Distillation Curve of Fuel SamplesДокумент4 страницыDistillation Curve of Fuel SamplesRais Alfiansyah TaufiqОценок пока нет

- Lec 3Документ4 страницыLec 3Lizbeth Fiallos AvilaОценок пока нет

- Natural GAs Compressor LubrcantsДокумент34 страницыNatural GAs Compressor LubrcantsPrakash JoshiОценок пока нет

- Summer Internship At: Haldia Petrochemicals LTDДокумент11 страницSummer Internship At: Haldia Petrochemicals LTDJyoti PrakashОценок пока нет

- Aniline Point (Astm D-611) & Diesel Index & Cetane Number (Astm D-613 10A) ObjectДокумент3 страницыAniline Point (Astm D-611) & Diesel Index & Cetane Number (Astm D-613 10A) ObjectFAH MAN100% (1)

- LITERATURE REVIEW Exp 6Документ3 страницыLITERATURE REVIEW Exp 6Meenakchi Anuradha100% (2)

- Experiment 3 - Atmospheric DistillationДокумент3 страницыExperiment 3 - Atmospheric DistillationrestofficalОценок пока нет

- CrackerДокумент5 страницCrackerDami TaiwoОценок пока нет

- Solvent DewaxingДокумент14 страницSolvent Dewaxingابوالحروف العربي ابوالحروفОценок пока нет

- 3 Fuel Properties and EffectsДокумент28 страниц3 Fuel Properties and EffectsZohaib AhmedОценок пока нет

- Heat Transfer Process TUT (After Mid Semester)Документ11 страницHeat Transfer Process TUT (After Mid Semester)vaishnavi singh100% (1)

- Determination of Flash and Fire Point Using Cleveland ApparatusДокумент10 страницDetermination of Flash and Fire Point Using Cleveland ApparatusJawaria AhmedОценок пока нет

- Flue Gas AnalysisДокумент11 страницFlue Gas AnalysisRaunit VermaОценок пока нет

- Thermochemistry and FuelДокумент51 страницаThermochemistry and Fuelsureshkanna2100% (2)

- Evaluation of Crude Oil: Department of Chemical Engineering, National Institute of Technology, CalicutДокумент38 страницEvaluation of Crude Oil: Department of Chemical Engineering, National Institute of Technology, Calicutjohn paul.jaisonОценок пока нет

- Reciprocating CompressorДокумент7 страницReciprocating CompressorAlphy Thomas100% (1)

- PonaДокумент6 страницPonaMahjabin Nadia100% (1)

- Reid Vapour PressureДокумент2 страницыReid Vapour PressureShazia Nazz Malik100% (1)

- Iso 2719-2016Документ11 страницIso 2719-2016Jozsef FazekadОценок пока нет

- Specific Gravity of Crude Oil PDFДокумент3 страницыSpecific Gravity of Crude Oil PDFANKIT SHARMAОценок пока нет

- Smoke Point ManualДокумент10 страницSmoke Point ManualYasir MahmoodОценок пока нет

- Reid Vapour PressureДокумент2 страницыReid Vapour PressureHicoolguy RiqОценок пока нет

- Prediction of Temperature Drop Accompanying A Given Pressure Drop For Natural Gas WellstreamsДокумент5 страницPrediction of Temperature Drop Accompanying A Given Pressure Drop For Natural Gas Wellstreamsmisterno2Оценок пока нет

- Properties of Mixtures and CombustionДокумент7 страницProperties of Mixtures and CombustionKhairul NajmiОценок пока нет

- PDF FileДокумент50 страницPDF FileHussein AyoubОценок пока нет

- Alkylation PDFДокумент7 страницAlkylation PDFVasthadu Vasu Khanan DLОценок пока нет

- TurboExpander ProcessДокумент18 страницTurboExpander ProcessdndudcОценок пока нет

- 0110 Introduction of Condensation Heat Transfer Over Horisontal Tubes and Enhanchement TechniquesДокумент39 страниц0110 Introduction of Condensation Heat Transfer Over Horisontal Tubes and Enhanchement Techniquesdian_2108Оценок пока нет

- D5016Sulfur in AshДокумент3 страницыD5016Sulfur in AshAdam PerkasaОценок пока нет

- Jet Aircraft Engine Lubrication Systems: Learning ObjectivesДокумент24 страницыJet Aircraft Engine Lubrication Systems: Learning ObjectivesArun AkОценок пока нет

- Reciprocating Compressor Trouble Shooting GuidesДокумент3 страницыReciprocating Compressor Trouble Shooting GuidesRahul ChandrawarОценок пока нет

- Startup Paralel Turbo CompressorДокумент24 страницыStartup Paralel Turbo Compressorilmu2Оценок пока нет

- Heat and Mass Transfer PropertiesДокумент63 страницыHeat and Mass Transfer Propertieskaushita banerjeeОценок пока нет

- Pona Calculation and Octane Rating Experiment For Motor GasolineДокумент4 страницыPona Calculation and Octane Rating Experiment For Motor GasolineEditor IJIRT0% (1)

- Cloud Point & Pour Point of Petroleum DistillatesДокумент3 страницыCloud Point & Pour Point of Petroleum Distillatessaleh4060100% (1)

- Boling Point CurvesДокумент28 страницBoling Point CurvesMuhammad MohtashimОценок пока нет

- Heat and Mass Transfer ManualДокумент30 страницHeat and Mass Transfer ManualSushil ThakkarОценок пока нет

- Gas Absorption LabДокумент8 страницGas Absorption Labsolehah misni100% (1)

- Heating+Value+ Fundamentals+of+Natural+Gas+ProcessingДокумент4 страницыHeating+Value+ Fundamentals+of+Natural+Gas+ProcessingJaime Andres Villegas MansillaОценок пока нет

- Product Blending: 1-Reid Vapour Pressure BlendingДокумент5 страницProduct Blending: 1-Reid Vapour Pressure BlendingEmad AliОценок пока нет

- Dropping Point of Lubricating GreaseДокумент2 страницыDropping Point of Lubricating GreaseAnonymous 1VhXp1Оценок пока нет

- Octane PDFДокумент7 страницOctane PDFAli Tatar100% (1)

- Combustion ChemistryДокумент17 страницCombustion Chemistryrajeev50588Оценок пока нет

- Gas Cylinder Filling ModellingДокумент8 страницGas Cylinder Filling Modellingchemsac2Оценок пока нет

- Fuel Tank Rule BookДокумент3 страницыFuel Tank Rule Book14MME Nandani GuptaОценок пока нет

- Aeroshell Book PDFДокумент297 страницAeroshell Book PDFFebry MulyaОценок пока нет

- ASTM D5191 - Jtvo9242Документ5 страницASTM D5191 - Jtvo9242Nayth Andres GalazОценок пока нет

- DistillationДокумент25 страницDistillationMohammadAslam100% (1)

- Petroleum Product Testing Lab ManualДокумент40 страницPetroleum Product Testing Lab ManualVishesh Sharma100% (1)

- Properties of Water 3Документ2 страницыProperties of Water 3Anonymous QM0NLqZOОценок пока нет

- Properties of Water 2Документ1 страницаProperties of Water 2Anonymous QM0NLqZOОценок пока нет

- Chemical and Physical Properties: StatesДокумент3 страницыChemical and Physical Properties: StatesAnonymous QM0NLqZOОценок пока нет

- Properties of Water 5Документ3 страницыProperties of Water 5Anonymous QM0NLqZOОценок пока нет

- Ground Floor ConstructionДокумент3 страницыGround Floor ConstructionAnonymous QM0NLqZOОценок пока нет

- Floor Covering: FlooringДокумент2 страницыFloor Covering: FlooringAnonymous QM0NLqZOОценок пока нет

- Special Floor Structures: StoreyДокумент1 страницаSpecial Floor Structures: StoreyAnonymous QM0NLqZOОценок пока нет

- Meaning of Sedimentary RocksДокумент19 страницMeaning of Sedimentary RocksAnonymous QM0NLqZOОценок пока нет

- S.No Month/Year 0ffice Ram Srini P.Samy Mami Tahsildhar Total MaintenaДокумент4 страницыS.No Month/Year 0ffice Ram Srini P.Samy Mami Tahsildhar Total MaintenaAnonymous QM0NLqZOОценок пока нет

- Earth Is The Third Planet From The Sun and The Only Astronomical Object Known To Harbor LifeДокумент6 страницEarth Is The Third Planet From The Sun and The Only Astronomical Object Known To Harbor LifeAnonymous QM0NLqZOОценок пока нет

- Oil Well Stimulation by Energy Fracturing MethodДокумент10 страницOil Well Stimulation by Energy Fracturing MethodAnonymous QM0NLqZOОценок пока нет

- Physical CharacteristicsДокумент13 страницPhysical CharacteristicsAnonymous QM0NLqZOОценок пока нет

- Enhancement of The Imbibition Recovery by Surfactants in Tight OilДокумент11 страницEnhancement of The Imbibition Recovery by Surfactants in Tight OilAnonymous QM0NLqZOОценок пока нет

- Hydraulic Fracturing (Also Fracking, Fraccing, Frac'ing, Hydrofracturing or Hydr Ofracking) Is AДокумент2 страницыHydraulic Fracturing (Also Fracking, Fraccing, Frac'ing, Hydrofracturing or Hydr Ofracking) Is AAnonymous QM0NLqZOОценок пока нет

- Coal Bed MethaneДокумент6 страницCoal Bed MethaneAnonymous QM0NLqZOОценок пока нет

- ONGC Discovers Oil and Gas Reserves in Madhya Pradesh, West BengalДокумент6 страницONGC Discovers Oil and Gas Reserves in Madhya Pradesh, West BengalAnonymous QM0NLqZOОценок пока нет

- Hydraulic Fracturing (Also Fracking, Fraccing, Frac'ing, Hydrofracturing or Hydrofracking) IsДокумент1 страницаHydraulic Fracturing (Also Fracking, Fraccing, Frac'ing, Hydrofracturing or Hydrofracking) IsAnonymous QM0NLqZOОценок пока нет

- Tight ReservoirДокумент11 страницTight ReservoirAnonymous QM0NLqZOОценок пока нет

- Reservoir Rock: Figure 1:porosityДокумент9 страницReservoir Rock: Figure 1:porosityAnonymous QM0NLqZOОценок пока нет

- IDRW MagazineДокумент10 страницIDRW MagazineVirarya100% (1)

- CSEC Chemistry June 2018 P2 AnswersДокумент7 страницCSEC Chemistry June 2018 P2 AnswerscxcchemistryОценок пока нет

- Practical - 2: Preparation of The FixativeДокумент14 страницPractical - 2: Preparation of The FixativeIseth ISethОценок пока нет

- Lecture 1 - Reinforced Concrete - IntroductionДокумент62 страницыLecture 1 - Reinforced Concrete - IntroductionChristopher PaladioОценок пока нет

- Anchor Chart-Describing Words-Descriptive Details of Setting and Character PDFДокумент2 страницыAnchor Chart-Describing Words-Descriptive Details of Setting and Character PDFdellindiaОценок пока нет

- Mechanism Design: A SeriesДокумент3 страницыMechanism Design: A Seriesamirmasood kholojiniОценок пока нет

- Mathematics 7 LAS Quarter 3Документ97 страницMathematics 7 LAS Quarter 3Villamor Baculi82% (17)

- Product Specifications: MB3F-PSA4-19DEДокумент2 страницыProduct Specifications: MB3F-PSA4-19DEВадим ЧеховскийОценок пока нет

- TXN Alarms 18022014Документ12 страницTXN Alarms 18022014Sid GrgОценок пока нет

- EMV Card Reader Upgrade Kit Instructions - 05162016Документ6 страницEMV Card Reader Upgrade Kit Instructions - 05162016Shashi K KumarОценок пока нет

- Third Quarter Pre-Test Mathematics 7 Directions: RДокумент4 страницыThird Quarter Pre-Test Mathematics 7 Directions: RAhron RivasОценок пока нет

- Battery Installation ProcedureДокумент5 страницBattery Installation ProceduresantoshkumarОценок пока нет

- ADC ManualДокумент47 страницADC ManualRavi ShuklaОценок пока нет

- DSR Codes - 1Документ108 страницDSR Codes - 1lakkireddy seshireddyОценок пока нет

- Introduction To The New 8-Bit PIC MCU Hardware Peripherals (CLC, Nco, Cog)Документ161 страницаIntroduction To The New 8-Bit PIC MCU Hardware Peripherals (CLC, Nco, Cog)Andres Bruno SaraviaОценок пока нет

- Pantalla Anterior Bienvenido: Cr080vbesДокумент3 страницыPantalla Anterior Bienvenido: Cr080vbesJuan Pablo Virreyra TriguerosОценок пока нет

- Water Reuse RoundtableДокумент10 страницWater Reuse RoundtableajiiithОценок пока нет

- Hydraulics Course FileДокумент81 страницаHydraulics Course FileSwarna LathaОценок пока нет

- XYZprint User Manual en V1 1003Документ25 страницXYZprint User Manual en V1 1003reza rizaldiОценок пока нет

- ZW250-7 BROCHURE LowresДокумент12 страницZW250-7 BROCHURE Lowresbjrock123Оценок пока нет

- Ceu Guidance Problematic Bleeding Hormonal ContraceptionДокумент28 страницCeu Guidance Problematic Bleeding Hormonal Contraceptionmarina_shawkyОценок пока нет

- Good Practices in Tray DesignДокумент7 страницGood Practices in Tray Designmehul10941100% (2)

- Bsi MD Ivdr Conformity Assessment Routes Booklet Uk enДокумент15 страницBsi MD Ivdr Conformity Assessment Routes Booklet Uk enGuillaumeОценок пока нет

- The Hollow Boy Excerpt PDFДокумент52 страницыThe Hollow Boy Excerpt PDFCathy Mars100% (1)

- Biasing Opamps Into Class AДокумент11 страницBiasing Opamps Into Class AsddfsdcascОценок пока нет

- Inverse Curve Trip Time Calculation: Enter Values in White CellДокумент3 страницыInverse Curve Trip Time Calculation: Enter Values in White CellVijay FxОценок пока нет

- Etl 213-1208.10 enДокумент1 страницаEtl 213-1208.10 enhossamОценок пока нет

- Case Study (Co2 Flooding)Документ10 страницCase Study (Co2 Flooding)Jessica KingОценок пока нет

- Frequency Converter English ManualДокумент33 страницыFrequency Converter English Manualproduccion multipack100% (2)

- UntitledДокумент413 страницUntitledjgj38j90Оценок пока нет