Академический Документы

Профессиональный Документы

Культура Документы

SXV RXV Chassis

Загружено:

chili_s16Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

SXV RXV Chassis

Загружено:

chili_s16Авторское право:

Доступные форматы

SERVICE STATION MANUAL

854156

SXV RXV 450-550

SERVICE

STATION

MANUAL

SXV RXV 450-550

THE VALUE OF SERVICE

Thanks to continuous technical updates and specific training programs on aprilia products, only apriIia

OfficiaI Network mechanics know this vehicle fully and have the special tools necessary to carry out

maintenance and repair operations correctly.

The reliability of the vehicle also depends on its mechanical conditions. Checking the vehicle before

riding, its regular maintenance and the use of OriginaI apriIia Spare Parts only are essential factors!

For information about the nearest OfficiaI DeaIer and/or Service Centre, consult the Yellow Pages or

search directly on the inset map in our Official Website:

www.apriIia.com

Only aprilia Original Spare Parts ensure products already studied and tested during the vehicle design

stage. All aprilia Original Spare Parts undergo quality control procedures to guarantee full reliability

and duration.

The descriptions and illustrations given in this publication are not binding; While the basic

characteristics as described and illustrated in this manual remain unchanged, aprilia reserves the right,

at any time and without being required to update this publication beforehand, to make any changes to

components, parts or accessories, which it considers necessary to improve the product or which are

required for manufacturing or construction reasons.

Not all versions shown in this publication are available in all countries. The availability of individual

versions should be confirmed with the official aprilia sales network.

Copyright 2007- aprilia. All rights reserved. Reproduction of this publication in whole or in part is

prohibited. aprilia - After sales service.

aprilia trademark is property of Piaggio & C. S.p.A.

SERVICE STATION

MANUAL

SXV RXV 450-550

NOTE Provides key information to make the procedure easier to understand and carry out.

CAUTION Refers to specific procedures to carry out for preventing damages to the vehicle.

WARNING Refers to specific procedures to carry out to prevent injuries to the repairer.

PersonaI safety Failure to completely observe these instructions will result in serious risk of personal

injury.

Safeguarding the environment Sections marked with this symbol indicate the correct use of the

vehicle to prevent damaging the environment.

VehicIe intactness The incomplete or non-observance of these regulations leads to the risk of serious

damage to the vehicle and sometimes even the invalidity of the guarantee.

INDEX OF TOPICS

CHARACTERISTICS CHAR

SPECIAL TOOLS S-TOOLS

MAINTENANCE MAIN

ELECTRICAL SYSTEM ELE SYS

ENGINE FROM VEHICLE ENG VE

ENGINE ENG

POWER SUPPLY P SUPP

SUSPENSIONS SUSP

CHASSIS CHAS

BRAKING SYSTEM BRAK SYS

COOLING SYSTEM COOL SYS

BODYWORK BODYW

INDEX OF TOPICS

CHARACTERISTICS CHAR

RuIes

Safety ruIes

Carbon monoxide

f you need to keep the engine running in order to carry out any procedure, please ensure that you do

so in an open or very well ventilated area. Never let the engine run in an enclosed area. f you do

work in an enclosed area, make sure to use a smoke-extraction system.

CAUTION

EXHAUST EMISSIONS CONTAIN CARBON MONOXIDE, A POISONOUS GAS WHICH CAN

CAUSE LOSS OF CONSCIOUSNESS AND EVEN DEATH.

FueI

CAUTION

FUEL USED TO POWER INTERNAL COMBUSTION ENGINES IS HIGHLY FLAMMABLE AND

CAN BECOME EXPLOSIVE UNDER SPECIFIC CONDITIONS. IT IS THEREFORE RECOMMEN-

DED TO CARRY OUT REFUELLING AND MAINTENANCE PROCEDURES IN A VENTILATED

AREA WITH THE ENGINE SWITCHED OFF. DO NOT SMOKE DURING REFUELLING AND NEAR

FUEL VAPOURS, AVOIDING ANY CONTACT WITH NAKED FLAMES, SPARKS OR OTHER

SOURCES WHICH MAY CAUSE THEM TO IGNITE OR EXPLODE.

DO NOT DISPERSE FUEL IN THE ENVIRONMENT.

KEEP OUT OF THE REACH OF CHILDREN

Hot components

The engine and the exhaust system components get very hot and remain in this condition for a cer-

tain time interval after the engine has been switched off. Before handling these components, make

sure that you are wearing insulating gloves or wait until the engine and the exhaust system have

cooled down.

CooIant

The coolant contains ethylene glycol which, under certain conditions, can become flammable.

When it burns, ethylene glycol produces invisible flames which however can cause burns.

CAUTION

Characteristics SXV RXV 450-550

CHAR - 2

MAKE SURE NOT TO POUR THE COOLANT ON HOT ENGINE OR EXHAUST SYSTEM COM-

PONENTS; IT MAY CATCH FIRE PRODUCING INVISIBLE FLAMES. WHEN CARRYING OUT

MAINTENANCE OPERATIONS, IT IS ADVISABLE TO WEAR LATEX GLOVES. EVEN IF IT IS

TOXIC, THE COOLANT HAS A SWEET FLAVOUR WHICH MAKES IT VERY ATTRACTIVE TO

ANIMALS. NEVER LEAVE THE COOLANT IN OPEN CONTAINERS IN AREAS ACCESSIBLE TO

ANIMALS AS THEY MAY DRINK IT.

KEEP OUT OF THE REACH OF CHILDREN

DO NOT REMOVE THE RADIATOR CAP WHEN THE ENGINE IS STILL HOT. THE COOLANT IS

UNDER PRESSURE AND MAY CAUSE BURNS.

Used engine oiI and transmission oiI

CAUTION

IT IS ADVISABLE TO WEAR LATEX GLOVES WHEN SERVICING THE VEHICLE. THE ENGINE

OR TRANSMISSION OIL MAY CAUSE SERIOUS INJURIES TO THE SKIN IF HANDLED FOR

PROLONGED PERIODS OF TIME AND ON A REGULAR BASIS. WASH YOUR HANDS THOR-

OUGHLY AFTER HANDLING IT. HAND THE OIL OVER TO OR HAVE IT COLLECTED BY THE

NEAREST USED OIL RECYCLING COMPANY OR THE SUPPLIER. IT IS ADVISABLE TO WEAR

LATEX GLOVES WHEN SERVICING THE VEHICLE.

DO NOT DISPOSE OF OIL IN THE ENVIRONMENT

KEEP OUT OF THE REACH OF CHILDREN

Brake and cIutch fIuid

THE BRAKE AND CLUTCH FLUIDS CAN DAMAGE THE PLASTIC OR RUBBER PAINTED SUR-

FACES. WHEN SERVICING THE BRAKING SYSTEM OR THE CLUTCH SYSTEM PROTECT

THESE COMPONENTS WITH A CLEAN CLOTH. ALWAYS WEAR PROTECTIVE GOGGLES

WHEN SERVICING THE SYSTEMS. BRAKE AND CLUTCH FLUIDS ARE EXTREMELY HARM-

FUL FOR YOUR EYES. IN THE EVENT OF ACCIDENTAL CONTACT WITH THE EYES, RINSE

THEM IMMEDIATELY WITH ABUNDANT COLD, CLEAN WATER AND SEEK MEDICAL ADVICE.

KEEP OUT OF THE REACH OF CHILDREN

SXV RXV 450-550 Characteristics

CHAR - 3

Battery eIectroIyte and hydrogen gas

CAUTION

THE BATTERY ELECTROLYTE IS TOXIC, CORROSIVE AND AS IT CONTAINS SULPHURIC

ACID, IT CAN CAUSE BURNS WHEN IN CONTACT WITH THE SKIN. WHEN HANDLING BAT-

TERY ELECTROLYTE, WEAR TIGHT-FITTING GLOVES AND PROTECTIVE APPAREL. IF THE

FLUID GETS INTO CONTACT WITH THE SKIN, RINSE WELL WITH ABUNDANT FRESH WA-

TER. IT IS EXTREMELY IMPORTANT TO PROTECT THE EYES BECAUSE EVEN A SMALL

QUANTITY OF BATTERY ACID CAN CAUSE BLINDNESS. IF THE FLUID GETS INTO CONTACT

WITH THE EYES, WASH WITH ABUNDANT WATER FOR FIFTEEN MINUTES AND CONSULT

AN EYE SPECIALIST IMMEDIATELY. IF THE FLUID IS ACCIDENTALLY SWALLOWED, DRINK

LARGE QUANTITIES OF WATER OR MILK, FOLLOWED BY MILK OF MAGNESIA OR VEGET-

ABLE OIL AND SEEK MEDICAL ADVICE IMMEDIATELY. THE BATTERY RELEASES EXPLOS-

IVE GASES; KEEP IT AWAY FROM FLAMES, SPARKS, CIGARETTES OR ANY OTHER HEAT

SOURCES. ENSURE ADEQUATE VENTILATION WHEN SERVICING OR RECHARGING THE

BATTERY.

KEEP OUT OF THE REACH OF CHILDREN

BATTERY LIQUID IS CORROSIVE. DO NOT POUR IT OR SPILL IT, PARTICULARLY ON

PLASTIC COMPONENTS. ENSURE THAT THE ELECTROLYTIC ACID IS COMPATIBLE WITH

THE BATTERY TO BE ACTIVATED.

Maintenance ruIes

GENERAL PRECAUTIONS AND INFORMATION

When repairing, dismantling and reassembling the vehicle follow the recommendations reported be-

low carefully.

BEFORE REMOVING COMPONENTS

Before dismantling components, remove dirt, mud, dust and foreign bodies from the

vehicle. Use the special tools designed for this bike, as required.

COMPONENTS REMOVAL

Do not loosen and/or tighten screws and nuts using pliers or other tools than the espe-

cially designed wrench.

Mark positions on all connection joints (pipes, cables etc.) before separating them, and

identify them with distinctive symbols.

Characteristics SXV RXV 450-550

CHAR - 4

Each component needs to be clearly marked in order to be identified during reassembly.

Clean and wash the dismantled components carefully using a low-flammability detergent.

Keep coupled parts together since they have "adjusted" to each other due to normal wear

and tear.

Some components must be used together or replaced altogether.

Keep away from heat sources.

REASSEMBLY OF COMPONENTS

CAUTION

THE BEARINGS MUST BE ABLE TO ROTATE FREELY, WITHOUT BINDING AND/OR NOISE,

OTHERWISE THEY NEED REPLACING.

Only use ORGNAL APRLA SPARE PARTS.

Comply with lubricant and consumables usage guidelines.

Lubricate parts (whenever possible) before reassembling them.

When tightening nuts and screws, start from the ones with the largest section or from the

internal ones, moving diagonally. Tighten nuts and screws in successive steps before ap-

plying the tightening torque.

Always replace self-locking nuts, washers, sealing rings, circlips, O-rings(OR), split pins

and screws with new ones if their tread is damaged.

When assembling the bearings, make sure to lubricate them well.

Check that each component is assembled correctly.

After a repair or routine maintenance procedure, carry out pre-ride checks and test the

vehicle on private grounds or in an area with low traffic density.

Clean all junction planes, oil guard rims and washers before refitting them. Smear a light

layer of lithium-based grease on the oil guard rims. Reassembly the oil guard and the

bearings with the brand or lot number facing outward (visible side).

ELECTRIC CONNECTORS

Electric connectors must be disconnected as described below; failure to comply with this procedure

causes irreparable damages to both the connector and the cable harness:

Press the relevant safety hooks, if any.

Grip the two connectors and disconnect them by pulling them in opposite directions.

f there are signs of dirt, rust, humidity, etc., clean the connector internal parts carefully

using a pressurised air jet.

Make sure that the cables are correctly linked to the connector internal terminal ends.

Then insert the two connectors making sure that they couple correctly (if the relevant

SXV RXV 450-550 Characteristics

CHAR - 5

hooks are provided, you will hear them "click" into place).

CAUTION

TO DISCONNECT THE TWO CONNECTORS, DO NOT PULL THE CABLES.

NOTE

THE TWO CONNECTORS CONNECT ONLY FROM ONE SIDE: CONNECT THEM THE RIGHT

WAY ROUND.

TIGHTENING TORQUE

CAUTION

DO NOT FORGET THAT TIGHTENING TORQUES OF ALL FASTENING ELEMENTS ON

WHEELS, BRAKES, WHEEL PINS AND ANY OTHER SUSPENSION COMPONENTS PLAY A

KEY ROLE IN ENSURING VEHICLE SAFETY AND MUST COMPLY WITH SPECIFIED VALUES.

CHECK THE TIGHTENING TORQUES OF FASTENING PARTS ON A REGULAR BASIS AND AL-

WAYS USE A TORQUE WRENCH TO REASSEMBLE THESE COMPONENTS. FAILURE TO

COMPLY WITH THESE RECOMMENDATIONS MAY CAUSE ONE OF THESE COMPONENTS TO

GET LOOSE AND EVEN DETACHED, THUS BLOCKING A WHEEL, OR OTHERWISE COM-

PROMISE VEHICLE HANDLING. THIS CAN LEAD TO FALLS, WITH THE RISK OF SERIOUS IN-

JURY OR DEATH.

Running-in

Engine run-in is essential to ensure engine long life and correct operation. Twisty roads and gradi-

ents are ideal to run in engine, brakes and suspensions effectively. Vary your driving speed during

the run-in. n this way, you allow for the work of components to be "loaded" and then "unloaded", thus

cooling the engine parts. Even if it is important to "stretch" engine components during run-in, make

sure not to strain them.

FoIIow the guideIines detaiIed beIow:

Do not twist the throttle grip abruptly and completely when the engine is working at a low

revs, either during or after run-in.

for the first 3 operating hours, do not exceed 50% of the throttle grip travel and never go

over 8000 rpm,

for the next 12 hours, do not exceed 75% of the throttle grip travel.

NOTE

EVEN AFTER THE RUNNING-IN PERIOD, AVOID RUNNING THE ENGINE AT TOP SPEED,

WHEN THE LIMITER CUTS IN:

Characteristics SXV RXV 450-550

CHAR - 6

SXV 450 12000 rpm

SXV 550 11500 rpm

RXV 450 11500 rpm

RXV 550 11000 rpm

CAUTION

THE SPEED LIMITER (NOT THE CONTROL UNIT LIMITER) WARNING LIGHT HAS BEEN FACT-

ORY SET AT 8000 rpm

Dimensions and mass

WEIGHT AND DIMENSIONS

Specification Desc./Quantity

Maximum length - SXV (450/550) 2165 mm (85.23 in)

Maximum length - RXV (450/550) 2240 mm (88.19 in)

Maximum width - SXV (450/550) 815 mm (32.08 in)

Maximum width - RXV (450/550) 2240 mm (88.19 in)

Maximum height (to windshield) - SXV (450/550) 1170 mm (46.06 in)

Maximum height (to windshield) - RXV (450/550) 1250 mm (49.21 in)

Saddle height - SXV (450/550) 880 mm (34.64 in)

Saddle height - RXV (450/550) 950 mm (37.40 in)

Wheelbase - SXV (450/550) 1470 mm (57.87 in)

Wheelbase - RXV (450/550) 1485 mm (58.46 in)

Minimum ground clearance - SXV (450/550) 270 mm (10.63 in)

Minimum ground clearance - RXV (450/550) 320 mm (12.60 in)

Kerb weight - SXV (450/550) 125 kg (275.58 lb)

Kerb weight - RXV (450/550) 123 kg (271.12 lb)

Engine

ENGINE

Specification Desc./Quantity

Model: SXV (450) 45SX

Model: RXV (450) 45RX

Model: SXV (550) 55SX

Model: RXV (550) 55RX

Type: SXV/RXV (450/550) V-twin, 4-stroke, 4 valves, single overhead cam-

shaft

SXV RXV 450-550 Characteristics

CHAR - 7

Specification Desc./Quantity

Number of cylinders for SXV/RXV (450/550) 2

Total engine capacity - SXV/RXV (450) 449 cm (27.40 cu.in)

Total engine capacity - SXV/RXV (550) 553 cm (33.75 cu.in)

Bore/stroke - SXV/RXV (450) 76 mm x 49.5 mm (2.99 in x 1.95 in)

Bore/stroke - SXV/RXV (550) 80 mm x 55.0 mm (3.15 in x 2.16 in)

Compression ratio - SXV/RXV (450) (13:1) +/- 0.5

Compression ratio - SXV/RXV (550) (12.5:1) +/- 0.5

dle speed - SXV/RXV (450) (1800 - 2000) +/- 100 rpm

Piston pin hole inside diameter 16.02 - 17.02 mm (0.6307 - 0.6701 in)

Piston outside diameter 75.94 - 79.94 mm (2.9897 - 3.1472 in)

Cylinder liners inside diameter 76.02 - 80.02 mm (2.9929 - 3.1504 in)

Camshaft eccentricity - maximum limit 0.05 mm (0.0020 in)

Valve timing - SXV (450/550) ntake opening: 18 before TDC

ntake closing: 48 after BDC

Outlet opening: 49 before BDC

Outlet closing: 15 after TDC

Valve timing - RXV (450/550) ntake opening: 18 before TDC

ntake closing: 48 after BDC

Outlet opening: 49 before BDC

Outlet closing: 15 after TDC

Valve stem diameter - minimum limit 4.96 mm (0.1952 in)

Bowl diameter - maximum limit: 25.96 mm (1.022 in)

Bowl seating diameter on head - maximum limit: 26.04 mm (1.025 in)

ntake valve seat support width - maximum limit 1.3 mm (0.0512 in)

Outlet valve seat support width - maximum limit 1.5 mm (0.059 in)

ntake valve thickness, sealing side - minimum

limit

2.2 mm (0.0866 in)

Outlet valve thickness, sealing side - minimum

limit

2.5 mm (0.098 in)

ntake valve clearance - SXV/RXV (450/550) 0.07 - 0.12 mm (0.0027 - 0.0047 in)

Outlet valve clearance - SXV/RXV (450/550) 0.17 - 0.22 mm (0.0067 - 0.0087 in)

gnition - SXV/RXV (450/550) Electrical digital

Starting - SXV/RXV (450/550) electric

gnition advance - SXV/RXV (450/550) Variable, controlled by CD

Air filter - SXV/RXV (450/550) with dry cartridge filter

Clutch type - SXV/RXV (450/550) Multiple-disk, oil-bathed clutch with control on the

left side of the handlebar

Characteristics SXV RXV 450-550

CHAR - 8

Specification Desc./Quantity

Driving discs 1 - clutch - SXV/RXV (450/550) number of discs: 2; thickness: 1.5 mm (0.059 in)

Driving discs 2 - clutch - SXV/RXV (450/550) number of discs: 5; thickness: 2.0 mm thick

(0.079 in)

Clutch discs - SXV/RXV (450/550) number of discs: 8; thickness: 2.75 mm (0.108 in)

Full disc pack thickness- minimum limit 34 mm (1.34 in)

Clutch disc distortion - maximum limit 0.2 mm (0.0079 in)

Clutch springs - SXV/RXV (450) Number of springs: 6

Unloaded spring length: 46 mm (1.81 in)

Clutch springs - SXV/RXV (550) Number of springs: 6

Unloaded spring length: 46 mm (1.81 in)

Clutch spring length - minimum limit 45.1 mm (1.77 in)

Transmission - SXV/RXV (450/550) Mechanical, 5 speeds with foot lever on the left

hand side of the engine

Lubrication - SXV/RXV (450/550) Separate twin-sump lubrication system with ex-

ternal reservoir:

- gearbox lubrication by splashing specific oil

- engine forced lubrication system with scavenge

oil pump and external reservoir

Oil filter - SXV/RXV (450/550) Paper

Cooling - SXV/RXV (450/550) Fluid

Water pump - SXV/RXV (450/550) Single centrifugal intake pump

Reduction ratio: 44/22

Top ring end clearance 0.45 mm (0.0177 in)

Transmission

TRANSMISSION

Specification Desc./Quantity

Main transmission - SXV/RXV (450/550) 22/56 = 1 : 2.545

Secondary transmission - SXV (450/550) First gear: 12/30 = 1:2.307

Second gear: 15/27 = 1:1.800

Third gear: 16/23 = 1:1.437

Fourth gear: 20/23 = 1:1.150

Fifth gear: 21/21 = 1:1.000

Secondary transmission - RXV (450/550) First gear: 12/31 = 1:1.583

Second gear: 13/25 = 1:1.923

Third gear: 15/23 = 1:1.533

Fourth gear: 19/24 = 1:1.263

Fifth gear: 21/22 = 1:1.047

Final ratio - SXV (450) 15/48: 1:3.067

SXV RXV 450-550 Characteristics

CHAR - 9

Specification Desc./Quantity

Final ratio - SXV (550) 15/48: 1:2.875

Final ratio - RXV (450/550) 15/48: 1:3.200

Total ratio - SXV (450) First gear: 1:18.013

Second gear: 1:14.050

Third gear: 1:11.221

Fourth gear: 1:8.897

Fifth gear: 1:7.806

Total ratio - SXV (550) First gear: 1:16.888

Second gear: 1:13.172

Third gear: 1:10.519

Fourth gear: 1:8.415

Fifth gear: 1:7.318

Total ratio - RXV (450/550) First gear: 1:21.042

Second gear: 1:15.664

Third gear: 1 :12.489

Fourth gear: 1:10.288

Fifth gear: 1:8.533

Capacities

CAPACITY

Specification Desc./Quantity

Fuel (reserve included) - SXV/RXV (450/550) 7.5 l (1.650 UKgal; 1.981 USgal)

Fuel reserve - SXV/RXV (450/550) 2.2 l (0.484 UKgal; 0.581 USgal)

Coolant - SXV/RXV (450/550) 1.1 l (0.242 UKgal; 0.290 l (50% water + 50%

ethylene glycol antifreeze fluid)

Engine oil - SXV/RXV (450/550) 1.3 l (0.286 UKgal; 0.343 USgal)

After service: 1400 cm (0.308 UKgal; 0.370 US-

gal)

Periodic oil change: 1300 cm (0.286 UKgal;

0.343 USgal)

Fork oil - SXV (450/550) 125 mm (4.92 in) of clearance (for each stem,

measured without spring and under compression)

Fork oil - RXV (450/550) 100 mm (3.94 in) of clearance (for each stem,

measured without spring and under compression)

Seats 1

Drive chain

TRANSMISSION

Specification Desc./Quantity

Main transmission - SXV/RXV (450/550) 22/56 = 1 : 2.545

Characteristics SXV RXV 450-550

CHAR - 10

Specification Desc./Quantity

Secondary transmission - SXV (450/550) First gear: 12/30 = 1:2.307

Second gear: 15/27 = 1:1.800

Third gear: 16/23 = 1:1.437

Fourth gear: 20/23 = 1:1.150

Fifth gear: 21/21 = 1:1.000

Secondary transmission - RXV (450/550) First gear: 12/31 = 1:1.583

Second gear: 13/25 = 1:1.923

Third gear: 15/23 = 1:1.533

Fourth gear: 19/24 = 1:1.263

Fifth gear: 21/22 = 1:1.047

Final ratio - SXV (450) 15/48: 1:3.067

Final ratio - SXV (550) 15/48: 1:2.875

Final ratio - RXV (450/550) 15/48: 1:3.200

Total ratio - SXV (450) First gear: 1:18.013

Second gear: 1:14.050

Third gear: 1:11.221

Fourth gear: 1:8.897

Fifth gear: 1:7.806

Total ratio - SXV (550) First gear: 1:16.888

Second gear: 1:13.172

Third gear: 1:10.519

Fourth gear: 1:8.415

Fifth gear: 1:7.318

Total ratio - RXV (450/550) First gear: 1:21.042

Second gear: 1:15.664

Third gear: 1 :12.489

Fourth gear: 1:10.288

Fifth gear: 1:8.533

EIectricaI system

ELECTRICAL SYSTEM

Specification Desc./Quantity

1 (Permanent-magnet) generator - SXV/RXV

(450/550)

12V - 350 W

2 Battery 12V - 6 Ah

3 Secondary fuses 5A; 15A; 20A

4 Starter motor - SXV/RXV (450/550) 12V - 350 W

5 Standard spark plug - SXV/RXV (450/550) NGK CR8EB

6 Spark plug electrode gap - SXV/RXV

(450/550)

0.7 - 0.8 mm (0.028 - 0.031 in)

7 Resistance - SXV/RXV (450/550) 5 kOhm

SXV RXV 450-550 Characteristics

CHAR - 11

Specification Desc./Quantity

8 High-beam light 12V - 60W

9 Low-beam light 12V - 55W

10 Front tail light 12V - 3 W

11 Rear tail light /stop light LED

12 License plate light 12V - 5W

13 Turn indicator lights with micro bulbs (not replaceable)

14 nstrument panel lighting LED

15 Overrevving warning light LED

16 Turn indicator warning light LED

17 High-beam warning light LED

18 Low fuel warning light LED

19 Engine control system warning light LED

20 Engine oil pressure warning light LED

21 Gear in neutral warning light LED

Frame and suspensions

CHASSIS AND SUSPENSIONS

Specification Desc./Quantity

Chassis - SXV/RXV (450/550) Tubular steel perimeter frame and aluminium ver-

tical members

Front suspension - SXV (450/550) Hydraulic action telescopic fork; 48 mm (1.89

in) stems

Front suspension - RXV (450/550) Hydraulic action telescopic fork; 45 mm (1.77

in) stems

Front suspension travel - SXV (450/550) 275 mm (10.83 in)

Front suspension travel - RXV (450/550) 298.5 mm (11.75 in)

Rear suspension - SXV/RXV (450/550) oscillating fork and adjustable hydraulic single

shock absorber

Wheel travel - SXV (450/550) 252 mm (9.92 in) (usable)

Wheel travel - RXV (450/550) 300 mm (11.81 in) (usable)

Brakes

BRAKES

BRAKES

Characteristics SXV RXV 450-550

CHAR - 12

Specification Desc./Quantity

Front disc -SXV (450/550) 320 mm (12.60 in) disc with hydraulic transmis-

sion

Front disc - RXV(450/550) 270 mm (10.63 in) disc with hydraulic transmis-

sion

Rear disc - SXV/RXV (450/550) 240 mm (9.45 in) disc with hydraulic transmis-

sion

WheeIs and tyres

WHEELS AND TYRES

Specification Desc./Quantity

Wheel rims - SXV/RXV (450/550) with spokes

Front rim - SXV (450/550) 3.50 x 17''

Front rim - RXV(450/550) 1.60 x 21''

Rear rim -SXV (450/550) 5.50 x 17''

Rear rim - RXV (450/550) 2.15 x 18''

Front tyre - SXV (450/550) 120/70 ZR17 (58W)

Front tyre - RXV(450/550) 90/90 21 54R

Front tyre inflation pressure - SXV (450/550) 180 kPa (1.8 bar) (26.11 PS)

Front tyre inflation pressure - RXV(450/550) 100 kPa (1.0 bar) (14.50 PS)

Rear tyre - SXV (450/550) 180/55 ZR17 (73W)

Rear tyre - RXV (450/550) 140/80 18 70R

Rear tyre inflation pressure - SXV (450/550) 200 kPa (2.0 bar) (29.00 PS)

Rear tyre inflation pressure - RXV (450/550) 110 kPa (1.1 bar) (15.95 PS)

SuppIy

FUEL SUPPLY

Specification Desc./Quantity

Type: SXV/RXV (450/550) V-twin, 4-stroke, 4 valves, single overhead cam-

shaft

Diffuser - SXV/RXV (550) 40 mm (1.57 in)

Diffuser - SXV/RXV (450) 38 mm (1.49 in)

Fuel supply - SXV/RXV (450/550) Electronic injection

Tightening Torques

HANDLEBAR AND CONTROLS LOCKING TORQUES

SXV RXV 450-550 Characteristics

CHAR - 13

Name Torque in Nm

Clutch control-handlebar fixing screw - M6 10 Nm (7.37 lbf ft)

Throttle grip fixing screw - M6 4 Nm (2.95 lbf ft)

gnition lock fixing screw - M8 24 Nm (17.70 lbf ft)

FOOTRESTS LOCKING TORQUES

Name Torque in Nm

Footrest support bracket fixing screw - M12 55 Nm (40.56 lbf ft) - Loctite 243

Footrest support bracket fixing screw - M8 25 Nm (18.44 lbf ft) - Loctite 243

BODYWORK LOCKING TORQUES

Name Torque in Nm

Rod - mudguard front fixing screw - M6 12 Nm (8.85 lbf ft)

Rod - mudguard rear fixing screw - M6 12 Nm (8.85 lbf ft)

Mudguard - steering base fixing screw - M6 12 Nm (8.85 lbf ft)

Air deflector fixing screws - M6 12 Nm (8.85 lbf ft)

Fairings fixing screws - M6 12 Nm (8.85 lbf ft)

Front tail - frame fixing screw - M6 12 Nm (8.85 lbf ft)

Tail - mudguard - frame central fixing nut - M6 12 Nm (8.85 lbf ft)

Tail - frame rear fixing nut - M6 12 Nm (8.85 lbf ft)

Tail - mudguard fixing screw - M6 12 Nm (8.85 lbf ft)

Upper screw fixing undertail to license plate hold-

er - M5

7 Nm (5.16 lbf ft)

Lower screw fixing undertail to license plate hold-

er - M5

7 Nm (5.16 lbf ft)

Screw fixing undertail - mudguard - remote con-

trol extension - M6

12 Nm (8.85 lbf ft)

Shock absorber protection fixing screw - M5 6 Nm (4.42 lbf ft)

Windshield - instrument panel support fixing

screw - M5

6 Nm (4.42 lbf ft)

nstrument panel support fixing screw - M5 6 Nm (4.42 lbf ft)

Undertail lower fixing screw - M6 12 Nm (8.85 lbf ft)

LIGHTS AND INSTRUMENT PANEL TIGHTENING TORQUES

Name Torque in Nm

Front headlight fixing screw - M6 6 Nm (4.42 lbf ft)

Turn indicators fixing nut - M8 6 Nm (4.42 lbf ft)

Digital instrument panel fixing nut - M5 6 Nm (4.42 lbf ft)

Rear light fixing screw - 3.9 2 Nm (1.47 lbf ft)

Characteristics SXV RXV 450-550

CHAR - 14

TANKS/RESERVOIRS TIGHTENING TORQUES

Name Torque in Nm

Plate - fuel tank fixing screw - M6 12 Nm (8.85 lbf ft)

Fuel tank - chassis fixing screw - M6 12 Nm (8.85 lbf ft)

Pump body - fuel tank fixing screw - M6 10 Nm (7.37 lbf ft)

Oil reservoir fixing nut - M6 5 Nm (3.69 lbf ft)

CHASSIS TIGHTENING TORQUES

Name Torque in Nm

Frame fixing screw - M10 49 Nm (36.14 lbf ft)

Upper chain roller fixing screw - M8 22 Nm (16.23 lbf ft)

Lower slider rear fixing screw - M5 4.4 Nm (3.24 lbf ft)

Lower slider front fixing screw - M5 4.4 Nm (3.24 lbf ft)

STAND TIGHTENING TORQUES

Name Torque in Nm

Stand locking plate fixing screw - M8 22 Nm (16.23 lbf ft) - Loctite 243

Side stand fixing nut - M10 34 Nm (25.08 lbf ft) - Loctite 243

EXHAUST LOCKING TORQUES

Name Torque in Nm

Muffler - frame fixing screw - M8 22 Nm (16.23 lbf ft)

Exhaust pipes fixing nut - M6 12 Nm (8.85 lbf ft)

Pipes - head fixing screw - M6 12 Nm (8.85 lbf ft)

Brake - handlebar fixing screw - M6 10 Nm (7.37 lbf ft)

COOLING SYSTEM LOCKING TORQUES

Name Torque in Nm

Radiators upper fixing screw - M6 5 Nm (3.69 lbf ft)

Radiators lower fixing screw - M6 12 Nm (8.85 lbf ft)

FRONT BRAKE LOCKING TORQUES

Name Torque in Nm

SXV 450/550 - Front brake calliper fixing screw -

M10

50 Nm (36.88 lbf ft)

RXV 450/550 - Front brake calliper fixing screw -

M8

25 Nm (18.44 lbf ft)

REAR BRAKE LOCKING TORQUES

Name Torque in Nm

Rear brake pump fixing screw - M6 10 Nm (7.37 lbf ft)

SXV RXV 450-550 Characteristics

CHAR - 15

Name Torque in Nm

Brake pedal fixing screw - M8 25 Nm (18.44 lbf ft) - Loctite 243

FRONT WHEEL LOCKING TORQUES

Name Torque in Nm

Wheel pin cover - M22 60 Nm (44.25 lbf ft)

REAR WHEEL LOCKING TORQUES

Name Torque in Nm

Wheel pin nut - M25 127 Nm (93.67 lbf ft)

FRONT SUSPENSION LOCKING TORQUES

Name Torque in Nm

Steering head fixing screw - M8 24 Nm (17.70 lbf ft)

Steering base fixing screw - M8 22 Nm (16.23 lbf ft)

SXV 450/550 - Fork feet fixing screw - M8 22 Nm (16.23 lbf ft)

RXV 450/550 - Fork feet fixing screw - M6 10 Nm (7.37 lbf ft)

Upper clamp - handlebar fixing screw - M8 24 Nm (17.70 lbf ft)

Steering pin nut - M26 108 Nm (79.66 lbf ft)

Steering pin ring nut - M30 7 Nm (5.16 lbf ft)

Lower clamp - handlebar fixing nut - M10 32 Nm (23.60 lbf ft)

Stem protection fixing screw - M6 12 Nm (8.85 lbf ft)

REAR SUSPENSION LOCKING TORQUES

Name Torque in Nm

Chassis - rod fixing nut - M12 80 Nm (59.00 lbf ft)

Rod - rocking lever fixing nut - M12 80 Nm (59.00 lbf ft)

Rocking lever - fork fixing nut - M12 80 Nm (59.00 lbf ft)

Shock absorber fixing nut - M10 52 Nm (38.35 lbf ft)

FORK LOCKING TORQUES

Name Torque in Nm

Chain guide fixing nut - M6 12 Nm (8.85 lbf ft)

Fork pin fixing nut - M14 100 Nm (73.76 lbf ft)

Chain tightener set screw - M8 26 Nm (19.18 lbf ft)

Chain slider and pipe guides - rear brake fixing

screw - 4.8

4.4 Nm (3.24 lbf ft)

Rear chain guard fixing screw - 4.8 4.4 Nm (3.24 lbf ft)

Chain guide fixing screw - M6 12 Nm (8.85 lbf ft)

Characteristics SXV RXV 450-550

CHAR - 16

ENGINE LOCKING TORQUES

Name Torque in Nm

Engine - chassis fixing nut M10 54 Nm (39.82 lbf ft)

Screw fixing control unit to plate - M4 3.24 lbf ft (4.4 Nm) - Loctite 243

Screw fixing regulator and control unit to chassis -

M6

12 Nm (8.85 lbf ft)

Coil fixing screw - M6 12 Nm (8.85 lbf ft)

Pinion cover - chain guide plate fixing screw - M6 12 Nm (8.85 lbf ft)

Engine oil drainage plug - M12x1.5 18 Nm (13.28 lbf ft)

Gearbox oil drainage plug - M12x1.5 18 Nm (13.28 lbf ft)

Oil filter cover - M56x1.5 25 Nm (18.44 lbf ft)

Piston fitting hole cover - M30x2 30 Nm (22.13 lbf ft)

Spark plug - M10x1.25 12 Nm (8.85 lbf ft)

Gearbox oil check screw - M6x1 9.8 Nm (7.23 lbf ft)

Water pump rotor - M7x1 12 Nm (8.85 lbf ft)

Head cover screw - M6x1 9.8 Nm (7.23 lbf ft)

Water pump cover screw - M6x1 9.8 Nm (7.23 lbf ft)

Clutch cover screw - M6x1 8.0 Nm (5.90 lbf ft)

Right crankcase cover screw - M6x1 9.8 Nm (7.23 lbf ft)

Crankcase clamping screw - M6x1 12 Nm (8.85 lbf ft)

Crankcase clamping screw - M7x1 15 Nm (11.06 lbf ft)

gnition cover screw - M6x1 9.8 Nm (7.23 lbf ft)

Pick-up fixing screw - M5x0.8 8 Nm (5.90 lbf ft) - Loctite 270

Stator fitting screw - M5x0.8 8 Nm (5.90 lbf ft) - Loctite 270

Chain tightener slider screw - M6x1 9.8 Nm (7.23 lbf ft) - Loctite 270

Timing chain tightener fitting screw - M6x1 10 Nm (7.37 lbf ft)

Cable guide ring fixing screw - M6x1 10 Nm (7.37 lbf ft)

Oil pipe plate screw - M6x1 9.8 Nm (7.23 lbf ft) - Loctite 270

Blow-by breather joint - M12x1 18 Nm (13.28 lbf ft) - Use compound

Flywheel nut - M14x1 108 Nm (79.66 lbf ft)

Starter screw - M6x1 9.8 Nm (7.23 lbf ft)

Chain guide plate screw - M6x1 12 Nm (8.85 lbf ft)

Secondary shaft bearing fixing screw - M6x1 10 Nm (7.37 lbf ft) - Loctite 270

Main shaft bearing fixing screw - M6x1 10 Nm (7.37 lbf ft) - Loctite 270

Screw fixing the gear selector drum bearing -

M5x0.8

8 Nm (5.90 lbf ft) - Loctite 270

SXV RXV 450-550 Characteristics

CHAR - 17

Name Torque in Nm

Gear indicator screw - M5x0.8 6 Nm (4.43 lbf ft) - Loctite 270

Gear pedal fixing screw - M6x1 12 Nm (8.85 lbf ft)

Head fitting screw (pre-torque) - M10x1.25 30 Nm (22.13 lbf ft) - Oil screws and washers

Head fitting screw - M10x1.25 50 Nm (36.88 lbf ft)

Head fitting screw - M6x1 12 Nm (8.85 lbf ft)

Timing system gear fixing nut - M12x1 50 Nm (36.88 lbf ft)

Timing compartment closing cover screw -

M5x0.8

6 Nm (4.42 lbf ft) - Loctite 243

Main transmission pinion nut - M18x1.25 160 Nm (118.00 lbf ft)

Selector locking plate screw - M6x1 12 Nm (8.85 lbf ft) - Loctite 270

Oil collecting plate screw - M6x1 12 Nm (8.85 lbf ft) - Loctite 270

Selector shaft lock screw - M10x1.25 25 Nm (18.44 lbf ft) - Loctite 270

Gear locking pawl rotation screw - M6x1 12 Nm (8.85 lbf ft) - Loctite 243

Selector pin - M18x1.25 22 Nm (16.23 lbf ft)

Clutch hub fixing nut - M18x1.25 75 Nm (55.32 lbf ft)

Clutch spring screw - M6x1 12 Nm (8.85 lbf ft)

Pressure relief valve - M14x.5 20 Nm (14.75 lbf ft)

Pressure pump fitting screw - M6x1 9.8 Nm (7.23 lbf ft)

Scavenge pump fitting screw - M6x1 9.8 Nm (7.23 lbf ft)

Head lubrication nozzle - M7x1 2.5 Nm (1.84 lbf ft)

Valve lifter lock screw - M5x0.8 9 Nm (6.64 lbf ft) - Loctite 270

Water joint plate screw - M6x1 9.8 Nm (7.23 lbf ft)

Crankshaft locking screw - M8x1.25 22 Nm (16.23 lbf ft) - Loctite 270

Freewheel outside ring screws - M6x1 13 Nm (9.58 lbf ft) - Loctite 270

Throttle body fixing screw - M6x1 13 Nm (9.58 lbf ft) - Loctite 243

Camshaft gear fixing screw - M16x1 35 Nm (25.82 lbf ft)

Connecting rod cap screw - M8x1 15+(48-50) Nm (11.06+(48-50) lbf ft)

Oil pressure sensor M10x1 15 Nm (11.06 lbf ft)

Water temperature sensor 18 Nm (13.27 lbf ft)

ELECTRICAL COMPONENTS TIGHTENING TORQUES

Name Torque in Nm

Remote control - fuse box fixing screw - M5 7 Nm (5.16 lbf ft) - Loctite 243

Chassis - ground lead fixing screw - M6 12 Nm (8.85 lbf ft)

Remote control cables fixing screw - M6 12 Nm (8.85 lbf ft)

Characteristics SXV RXV 450-550

CHAR - 18

Name Torque in Nm

Horn fixing screw - M8 22 Nm (16.23 lbf ft)

OverhauI data

AssembIy cIearances

Crankcase - crankshaft - connecting rod

To choose the appropriate spare parts for the coupling bushings, check the type of original compon-

ents and the correct bushing on the table.

The type of component is engraved with laser pen

on the components themselves.

NOTE

THE CRANKCASE TYPE IS ENGRAVED ON

BOTH CRANKCASE HALVES.

COUPLING TYPES - SHAFT - CONNECTING ROD

Specification Desc./Quantity

Shaft - Connecting rod: A - A - BLUE types Shaft- A 34.984 mm - 34.991 mm (1.37732 in -

1.37759 in)

Connecting rod - A 38.000 mm - 38.012 mm

(1.49606 in - 1.49653 in)

Colour: BLUE

Shaft - Connecting rod: A - B - YELLOW types Shaft- A 34.984 mm - 34.991 mm (1.37732 in -

1.37791 in)

Connecting rod - B 38.013 mm - 38.025 mm

(1.49657 in - 1.49704 in)

Colour: YELLOW

Shaft - Connecting rod: B - A - GREEN types Shaft- B 34.992 mm - 35.000 mm (1.37763 in -

1.37795 in)

Connecting rod - A 38.000 mm - 38.012 mm

(1.49606 in - 1.50078 in)

Colour: GREEN

Shaft - Connecting rod: B - B - BLUE types Shaft- B 34.992 mm - 35.000 mm (1.37763 in -

1.37795 in)

Connecting rod - B 38.013 mm - 38.025 mm

(1.49657 in - 1.49704 in)

Colour: BLUE

SXV RXV 450-550 Characteristics

CHAR - 19

Specification Desc./Quantity

COUPLING TYPES - SHAFT - MAIN BEARING

Specification Desc./Quantity

Shaft - Main bearing: A - A - BLUE types Shaft- A 34.984 mm - 34.991 mm (1.37732 in -

1.37759 in)

Main bearing - A 41.000 mm - 41.007 mm

(1.61417 in - 1.61444 in)

Colour: BLUE

Shaft - Main bearing: A - B - YELLOW types Shaft- A 34.984 mm - 34.991 mm (1.37732 in -

1.37759 in)

Main bearing - B 41.008 mm - 41.016 mm

(1.61448 in - 1.61480 in)

Colour: YELLOW

Shaft - Main bearing: B - A - GREEN types Shaft- B 37.992 mm - 38.000 mm (1.49574 in -

1.49606 in)

Main bearing - A 41.000 mm - 41.007 mm

(1.61417 in - 1.61444 in)

Colour: GREEN

Shaft - Main bearing: B - B - BLUE types Shaft- B 37.992 mm - 38.000 mm (1.49574 in -

1.49606 in)

Main bearing - B 41.008 mm - 41.016 mm

(1.61448 in - 1.61480 in)

Colour: BLUE

Characteristics SXV RXV 450-550

CHAR - 20

Recommended products chart

RECOMMENDED PRODUCTS TABLE

Product Description Specifications

AGP RACNG 4T, SAE 10W -

60

Engine oil As an alternative, use top-

branded oils that meet or ex-

ceed the requirements of CCMC

G-4 AP SG SAE 10W - 60 spe-

cifications

AGP GEAR SYNTH SAE

75W-90

Engine oil As an alternative for recommen-

ded oils, top-branded oils that

meet or exceed the require-

ments of CCMC G-4, AP spe-

cifications can be used.

AGP ANTFREEZE PLUS Engine coolant -

AGP BRAKE FLUD DOT 4 Brake fluid FMVSS DOT4+

AGP MP GREASE Bearings and other lubrication

points

As an alternative to the recom-

mended product, use top-

branded grease for roller bear-

ings, useful temperature range: -

30C - +140C (-22F - +284F),

drop point: 150C - +230C

(302F - 446F), high anticorros-

ive protection, good water and

rust resistance.

AGP FORK 7,5W and AGP

FORK 10W

Fork oil SXV 450/550 - AGP FORK

7,5W

RXV 450/550 - AGP FORK

10W

SXV RXV 450-550 Characteristics

CHAR - 21

Characteristics SXV RXV 450-550

CHAR - 22

INDEX OF TOPICS

SPECIAL TOOLS S-TOOLS

SPECIAL TOOLS

Stores code Description

853713 Pin ring tool - 450

853714 Pin ring tool - 550

853715 Water pump oil seal guide

853716 Water pump oil seal punch

8140179 Valve spring compressor

8140187 Engine support stand

Special tools SXV RXV 450-550

S-TOOLS - 2

Stores code Description

8140188 Engine support

8140838 Flywheel rotor locking

8127819 Walbro Cable for Axone

9100838 Tool for pump pressure plate

9100839 Flywheel extractor

9100840 Punch for crankshaft bushings

SXV RXV 450-550 Special tools

S-TOOLS - 3

Stores code Description

9100843 Crankshaft pinion locking tool

9100844 Crankshaft locking tool (timing

pin)

9100884 Crankshaft bushing extractor

9100885 Main shaft/ right side - second-

ary shaft/left side

9100886 Secondary shaft/right side -

Main shaft/left side

9100887 Punch for right crankcase

desmo

Special tools SXV RXV 450-550

S-TOOLS - 4

Stores code Description

9100888 Oil pump oil seal punch

9100889 Timing gear crankshaft punch

9100890 Timing gear crankshaft punch

9100892 Left crankcase desmodromic +

wheel hub

9100893 Left timing gear punch

9100894 Secondary shaft oil seal punch

SXV RXV 450-550 Special tools

S-TOOLS - 5

Stores code Description

9100895 Water pump oil seal punch

9100896 Clutch bell locking tool

9100897 Cylinder liner extractor

9100898 Fork cages punch

9100900 Punch for fork linkage cages

9100903 Marzocchi fork oil seal; 45 mm

(1.77 in)

Special tools SXV RXV 450-550

S-TOOLS - 6

Stores code Description

9100904 Sachs fork oil seal; 48 mm

(1.89 in)

9100938 Pump rotor wrench

9100943 Piston pin extractor

9100841 Engine support

9100942 Crankcase halves support

SXV RXV 450-550 Special tools

S-TOOLS - 7

Special tools SXV RXV 450-550

S-TOOLS - 8

INDEX OF TOPICS

MAINTENANCE MAIN

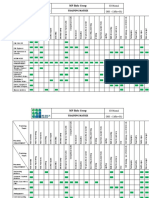

Maintenance chart

Periodic maintenance chart for vehicles in the original version (throttled) for road operation,

CAUTION

THE MAINTENANCE OPERATIONS LISTED MUST BE CARRIED OUT BY A DEALER OR AU-

THORISED APRILIA WORKSHOP, OTHERWISE THE WARRANTY WILL BE VOIDED.

NOTE

CARRY OUT THE MAINTENANCE OPERATIONS AT HALF THE INTERVALS SHOWN IF THE

VEHICLE IS USED IN WET OR DUSTY AREAS, OFF ROAD OR FOR SPORTING APPLICA-

TIONS.

END OF RUN-IN PERIOD 500 KM (311 MILES)

Action

Throttle body assembly bolt torque - Check

Throttle bodies - Synchronisation

Air filter and filter case - Check and cleaning

Fuel lines - Check condition and position

dle speed adjustment - Check

Transmission oil - change

Clutch control - Check and adjustment

Coolant level in radiator and expansion tank - Check

Engine oil and engine oil filter - Change

Oil lines - Check condition and position

Throttle cables - Adjustment

Cold start key - Adjustment

Brake fluid level - Check

Brake lines - Check condition and for leaks

Brake circuit screws tightening - Check

Light operation/direction

Electrical system operation - Check

Tyre condition and pressure - Check

Wheel bearing clearance - Check

Wheel spokes and rim coaxiality - Check tension

Tightening of wheel pin nuts and screws - Check

Maintenance SXV RXV 450-550

MAN - 2

Action

Engine mounting bolt torque - Check

Tightening of chassis screws and nuts - Check

Fork - Check for sealing and operation

Tightening of fork plates and feet screws - Check

Shock absorber pins tightening - Check

Shock absorber - Check for sealing and operation

Steering bearings - Check and adjust

Headstock dust guards - Cleaning

Drive chain - Tension

Chain links (RXV), sealed links (SXV), chain sprocket and chain guide - Check for wear

Chain - lubricate

EVERY 3000 KM (1864 MILES)

Action

Throttle body assembly bolt torque - Check

Throttle bodies - Synchronisation

Air filter and filter case - Check and cleaning

Fuel lines - Check condition and position

dle speed adjustment - Check

Transmission oil - change

Clutch springs - check length

Clutch discs - Check for wear

Clutch control - Check and adjustment

Coolant level in radiator and expansion tank - Check

System sealing - Check

Engine oil and engine oil filter - Change

Oil lines - Check condition and position

Throttle cables - Adjustment

Cold start key - Adjustment

Brake fluid level - Check

Brake lines - Check condition and for leaks

Brake circuit screws tightening - Check

Brake discs thickness - Check

Brake pad thickness - Check

Electrical contacts and switches - Treatment with contact activator spray

SXV RXV 450-550 Maintenance

MAN - 3

Action

Battery connections - Greasing

Light operation/direction

Electrical system operation - Check

Drainage - check for leaks and alignment

Tyre condition and pressure - Check

Wheel bearings - check

Wheel spokes and rim coaxiality - Check tension

Tightening of wheel pin nuts and screws - Check

Engine mounting bolt torque - Check

Tightening of chassis screws and nuts - Check

Fork dust guards - Cleaning

Fork legs - Bleed

Fork - Check for sealing and operation

Tightening of fork plates and feet screws - Check

Shock absorber pins tightening - Check

Shock absorber - Check for sealing and operation

Steering bearing clearance - Check

Headstock dust guards - Cleaning

Drive chain - Tension

Chain links (RXV), sealed links (SXV), chain sprocket and chain guide - Check for wear

Steering bearings - Lubricate

Clutch lever pin - Lubricate

Throttle cables - Lubricate

Rider footrest bolts - Lubricate

Chain - lubricate

Rear suspension linkage system - Lubricate

Side stand bolt - Lubricate

Front wheel bolt and bearings - Lubricate

Rear fork bolt - Lubricate

Rear wheel bolt and bearings - Lubricate

EVERY 6000 KM (3728 MILES)

Action

Paper air filter - Replacement

Maintenance SXV RXV 450-550

MAN - 4

Action

Spark plugs - change

EVERY 9000 KM (5592 MILES)

Action

Complete transmission - Check for wear

Pressure relief and non-return valve spring - Check

Cylinder liners - Check for wear

Connecting rods and main bushings - Check for wear

Start-up gears - Check for wear

Oil pump gears - Check

Head lubrication nozzles - Cleaning

Pistons and piston rings - Replacement

Piston pin - Check

Cam rockers - radial check

Valve lifter - Check

Camshaft wear - Check

Camshaft bearings - Check

Valve seat sealing - Check

Valves - Check for wear

Valve clearance - Check and adjustment

Valve guides - check for wear

Spring washers, caps, bowls - Check for wear

Chain tightener toothing - Check for wear

Valve springs - check length

Timing chain - Stretching measurement

Drive chain sliders - Check for wear

Fuel pump - Check

Fork - Comprehensive maintenance

Fork oil - Replacement

Shock absorber - Comprehensive maintenance

Crankshaft and connecting rod bearing clearance - Check

Chain guide slider - Check for wear

Chain guide - Check for wear

Chain tightener roller - Check for wear

Chain tightener slider - Check for wear

SXV RXV 450-550 Maintenance

MAN - 5

EVERY YEAR

Action

Brake fluid - Change

Periodic maintenance chart for vehicles in free version for hobby sports applications.

AFTER THE RUN-IN PERIOD AND EVERY 3 HOURS OF OPERATION

Action

Throttle body assembly bolt torque - Check

Throttle bodies - Synchronisation

Air filter and filter case - Check and cleaning

Fuel lines - Check condition and position

dle speed adjustment - Check

Transmission oil - change

Clutch control - Check and adjustment

Coolant level in radiator and expansion tank - Check

Engine oil and engine oil filter - Change

Oil lines - Check condition and position

Throttle cables - Adjustment

Cold start key - Adjustment

Brake fluid level - Check

Brake lines - Check condition and for leaks

Brake circuit screws tightening - Check

Light operation/direction

Electrical system operation - Check

Tyre condition and pressure - Check

Wheel bearing clearance - Check

Wheel spokes and rim coaxiality - Check tension

Tightening of wheel pin nuts and screws - Check

Engine mounting bolt torque - Check

Tightening of chassis screws and nuts - Check

Fork - Check for sealing and operation

Tightening of fork plates and feet screws - Check

Shock absorber pins tightening - Check

Shock absorber - Check for sealing and operation

Steering bearings - Check and adjust

Headstock dust guards - Cleaning

Maintenance SXV RXV 450-550

MAN - 6

Action

Drive chain - Tension

Chain links (RXV), sealed links (SXV), chain sprocket and chain guide - Check for wear

Chain - lubricate

EVERY 15 HOURS OF OPERATION

Action

Throttle body assembly bolt torque - Check

Throttle bodies - Synchronisation

Air filter and filter case - Check and cleaning

Fuel lines - Check condition and position

dle speed adjustment - Check

Transmission oil - change

Clutch springs - check length

Clutch discs - Check for wear

Clutch control - Check and adjustment

Coolant level in radiator and expansion tank - Check

System sealing - Check

Engine oil and engine oil filter - Change

Oil lines - Check condition and position

Throttle cables - Adjustment

Cold start key - Adjustment

Brake fluid level - Check

Brake lines - Check condition and for leaks

Brake circuit screws tightening - Check

Brake discs thickness - Check

Brake pad thickness - Check

Electrical contacts and switches - Treatment with contact activator spray

Battery connections - Greasing

Light operation/direction

Electrical system operation - Check

Drainage - check for leaks and alignment

Tyre condition and pressure - Check

Wheel bearings - check

Wheel spokes and rim coaxiality - Check tension

Tightening of wheel pin nuts and screws - Check

SXV RXV 450-550 Maintenance

MAN - 7

Action

Engine mounting bolt torque - Check

Tightening of chassis screws and nuts - Check

Fork dust guards - Cleaning

Fork legs - Bleed

Fork - Check for sealing and operation

Tightening of fork plates and feet screws - Check

Shock absorber pins tightening - Check

Shock absorber - Check for sealing and operation

Steering bearing clearance - Check

Headstock dust guards - Cleaning

Drive chain - Tension

Chain links (RXV), sealed links (SXV), chain sprocket and chain guide - Check for wear

Steering bearings - Lubricate

Clutch lever pin - Lubricate

Throttle cables - Lubricate

Rider footrest bolts - Lubricate

Chain - lubricate

Rear suspension linkage system - Lubricate

Side stand bolt - Lubricate

Front wheel bolt and bearings - Lubricate

Rear fork bolt - Lubricate

Rear wheel bolt and bearings - Lubricate

EVERY 60 HOURS OF OPERATION

Action

Paper air filter - Replacement

Spark plugs - change

EVERY 90 HOURS OF OPERATION

Action

Complete transmission - Check for wear

Pressure relief and non-return valve spring - Check

Cylinder liners - Check for wear

Connecting rods and main bushings - Check for wear

Start-up gears - Check for wear

Maintenance SXV RXV 450-550

MAN - 8

Action

Oil pump gears - Check

Head lubrication nozzles - Cleaning

Pistons and piston rings - Replacement

Piston pin - Check

Cam rockers - radial check

Valve lifter - Check

Camshaft wear - Check

Camshaft bearings - Check

Valve seat sealing - Check

Valves - Check for wear

Valve clearance - Check and adjustment

Valve guides - check for wear

Spring washers, caps, bowls - Check for wear

Chain tightener toothing - Check for wear

Valve springs - check length

Timing chain - Stretching measurement

Drive chain sliders - Check for wear

Fuel pump - Check

Fork - Comprehensive maintenance

Fork oil - Replacement

Shock absorber - Comprehensive maintenance

Crankshaft and connecting rod bearing clearance - Check

Chain guide slider - Check for wear

Chain guide - Check for wear

Chain tightener roller - Check for wear

Chain tightener slider - Check for wear

EVERY YEAR

Action

Brake fluid - Change

Periodic maintenance chart for vehicles in free version for competitive sports applications.

END OF RUN-IN PERIOD AND EVERY 3 HOURS OF OPERATION

Action

Throttle body assembly bolt torque - Check

Throttle bodies - Synchronisation

SXV RXV 450-550 Maintenance

MAN - 9

Action

Air filter and filter case - Check and cleaning

Fuel lines - Check condition and position

dle speed adjustment - Check

Transmission oil - change

Clutch control - Check and adjustment

Coolant level in radiator and expansion tank - Check

Engine oil and engine oil filter - Change

Oil lines - Check condition and position

Throttle cables - Adjustment

Cold start key - Adjustment

Brake fluid level - Check

Brake lines - Check condition and for leaks

Brake circuit screws tightening - Check

Light operation/direction

Electrical system operation - Check

Tyre condition and pressure - Check

Wheel bearing clearance - Check

Wheel spokes and rim coaxiality - Check tension

Tightening of wheel pin nuts and screws - Check

Engine mounting bolt torque - Check

Tightening of chassis screws and nuts - Check

Fork - Check for sealing and operation

Tightening of fork plates and feet screws - Check

Shock absorber pins tightening - Check

Shock absorber - Check for sealing and operation

Steering bearings - Check and adjust

Headstock dust guards - Cleaning

Drive chain - Tension

Chain links (RXV), sealed links (SXV), chain sprocket and chain guide - Check for wear

Chain - lubricate

EVERY 15 HOURS OF OPERATION

Action

Throttle body assembly bolt torque - Check

Throttle bodies - Synchronisation

Maintenance SXV RXV 450-550

MAN - 10

Action

Air filter and filter case - Check and cleaning

Fuel lines - Check condition and position

dle speed adjustment - Check

Transmission oil - change

Clutch springs - check length

Clutch discs - Check for wear

Clutch control - Check and adjustment

Coolant level in radiator and expansion tank - Check

System sealing - Check

Engine oil and engine oil filter - Change

Oil lines - Check condition and position

Throttle cables - Adjustment

Cold start key - Adjustment

Brake fluid level - Check

Brake lines - Check condition and for leaks

Brake circuit screws tightening - Check

Brake discs thickness - Check

Brake pad thickness - Check

Electrical contacts and switches - Treatment with contact activator spray

Battery connections - Greasing

Light operation/direction

Electrical system operation - Check

Drainage - check for leaks and alignment

Tyre condition and pressure - Check

Wheel bearings - check

Wheel spokes and rim coaxiality - Check tension

Tightening of wheel pin nuts and screws - Check

Engine mounting bolt torque - Check

Tightening of chassis screws and nuts - Check

Fork dust guards - Cleaning

Fork legs - Bleed

Fork - Check for sealing and operation

Tightening of fork plates and feet screws - Check

Shock absorber pins tightening - Check

SXV RXV 450-550 Maintenance

MAN - 11

Action

Shock absorber - Check for sealing and operation

Steering bearing clearance - Check

Headstock dust guards - Cleaning

Drive chain - Tension

Chain links (RXV), sealed links (SXV), chain sprocket and chain guide - Check for wear

Steering bearings - Lubricate

Clutch lever pin - Lubricate

Throttle cables - Lubricate

Rider footrest bolts - Lubricate

Chain - lubricate

Rear suspension linkage system - Lubricate

Side stand bolt - Lubricate

Front wheel bolt and bearings - Lubricate

Rear fork bolt - Lubricate

Rear wheel bolt and bearings - Lubricate

EVERY 30 HOURS OF OPERATION

Action

Paper air filter - Replacement

Spark plugs - change

EVERY 45 HOURS OF OPERATION

Action

Complete transmission - Check for wear

Pressure relief and non-return valve spring - Check

Cylinder liners - Check for wear

Connecting rods and main bushings - Check for wear

Start-up gears - Check for wear

Oil pump gears - Check

Head lubrication nozzles - Cleaning

Pistons and piston rings - Replacement

Piston pin - Check

Cam rockers - radial check

Valve lifter - Check

Camshaft wear - Check

Maintenance SXV RXV 450-550

MAN - 12

Action

Camshaft bearings - Check

Valve seat sealing - Check

Valves - Check for wear

Valve clearance - Check and adjustment

Valve guides - check for wear

Spring washers, caps, bowls - Check for wear

Chain tightener toothing - Check for wear

Valve springs - check length

Timing chain - Stretching measurement

Drive chain sliders - Check for wear

Fuel pump - Check

Fork - Comprehensive maintenance

Fork oil - Replacement

Shock absorber - Comprehensive maintenance

Crankshaft and connecting rod bearing clearance - Check

Chain guide slider - Check for wear

Chain guide - Check for wear

Chain tightener roller - Check for wear

Chain tightener slider - Check for wear

EVERY YEAR

Action

Brake fluid - Change

CAUTION

IF THE VEHICLE IS USED FOR COMPETITIONS, CARRY OUT THE 15-HOUR SERVICE AFTER

EVERY RACE.

NOTE

- MAINTENANCE OPERATIONS BY THE SPECIALISED APRILIA WORKSHOP DO NOT RE-

PLACE DAILY CHECKING BY THE RIDER!

- IF DISTORTIONS, DAMAGES OR WEAR EXCEEDING THE TOLERATED VALUES ARE

FOUND, REPLACE THE INVOLVED COMPONENTS

- BEFORE CARRYING OUT ANY OPERATION, CLEAN YOUR VEHICLE CAREFULLY

- RIDING ON SANDY OR DUSTY ROADS OR UNDER EXTREME SITUATIONS MAY WEAR

DOWN SOME COMPONENTS EVEN BEFORE THE SCHEDULED CHECK.

- ONLY FOR THE RXV MODEL: IF THE VEHICLE IS USED MAINLY FOR MOTOCROSS RACING,

SXV RXV 450-550 Maintenance

MAN - 13

CARRY OUT ALL THE MAINTENANCE SERVICES INDICATED IN THE 45-HOUR COLUMN

EVERY 30 HOURS OF USE.

Spark pIug

At regular intervals, remove the spark plug and clean off any carbon deposits or replace as required.

CAUTION

ALWAYS REPLACE BOTH SPARK PLUGS, EVEN IF ONLY ONE NEEDS REPLACING.

n order to gain access to the spark plugs:

CAUTION

BEFORE CARRYING OUT THE FOLLOWING OPERATIONS AND IN ORDER TO AVOID BURNS,

LEAVE THE ENGINE AND MUFFLER TO COOL OFF TO AMBIENT TEMPERATURE.

Place the vehicle on the stand.

NOTE

THE VEHICLE HAS A SPARK PLUG (2) FOR EACH CYLINDER. THE FOLLOWING STEPS RE-

LATE TO JUST ONE SPARK PLUG BUT APPLY TO BOTH.

Remove the tube (1) of the spark plug

(2).

Clean off any trace of dirt from the

spark plug (2) base.

nsert the spanner supplied in the tool

kit into the hexagonal head of the

spark plug (2).

Unscrew the spark plug (2) and re-

move it from its seat, making sure no

dust or dirt gets into the cylinder.

Checking and cleaning:

CAUTION

Maintenance SXV RXV 450-550

MAN - 14

THE ELECTRODES OF THE SPARK PLUGS

INSTALLED ON THIS VEHICLE ARE PLATIN-

UM ELECTRODES. DO NOT USE METAL

BRUSHES AND/OR ABRASIVE PRODUCTS TO

CLEAN THE SPARK PLUGS. USE ONLY A

COMPRESSED AIR JET.

KEY:

central electrode (3);

insulator (4);

side electrode (5).

Check that the electrodes and the in-

sulator of the spark plug (2) do not

show signs of carbon deposits and

corrosion. f necessary, clean them

using a compressed air jet.

Replace the spark (2) if its insulator is cracked,

the electrodes show signs of corrosion or excess-

ive deposits, or the top of the central electrode

gets rounded (6).

CAUTION

WHEN REPLACING THE SPARK PLUG (2),

CHECK THE PITCH AND LENGTH OF THE

THREAD. IF THE THREADED PART IS TOO

SHORT, CARBON DEPOSITS WILL BUILD UP

ON THE THREAD'S SEAT AND MAY THUS

CAUSE DAMAGE TO THE ENGINE WHEN THE

CORRECT THREADED PART IS INSTALLED.

USE RECOMMENDED SPARK PLUGS ONLY.

USING A SPARK PLUG OTHER THAN SPE-

CIFIED MIGHT COMPROMISE ENGINE PER-

FORMANCE AND LIFE. CHECK THE GAP

BETWEEN THE ELECTRODES WITH A FEEL-

SXV RXV 450-550 Maintenance

MAN - 15

ER GAUGE TO AVOID DAMAGING THE PLAT-

INUM COATING.

Checking the gap between the electrodes with a feeler gauge.

CAUTION

DO NOT ATTEMPT TO READJUST THE ELECTRODE GAP.

The gap between the electrodes should be

between 0.7 0.8 mm (0.027 0.031 in). Other-

wise, replace the spark plug (2).

Make sure the washer is in good con-

ditions.

nstallation:

Once the washer is fitted, screw the

spark plug (2) manually to avoid dam-

aging the thread.

Tighten using the spanner supplied in

the tool kit. Make each spark plug (2)

complete 1/2 of a turn to compress the

washer.

CAUTION

IT IS ESSENTIAL TO TIGHTEN THE SPARK

PLUG (2) PROPERLY. A LOOSE SPARK PLUG

MAY CAUSE ENGINE OVERHEATING AND

RESULT IN SEVERE DAMAGE.

Locking torques (N*m)

Spark pIug - M10x1.25 12 Nm (8.85 Ibf ft)

Position the spark plug tube (1) correctly so that it does not get detached due to engine vi-

brations.

NOTE

REPEAT THE DESCRIBED OPERATIONS FOR THE SPARK PLUG (2) OF THE OTHER CYLIN-

Maintenance SXV RXV 450-550

MAN - 16

DER.

Engine oiI

CAUTION

ENGINE OIL MAY CAUSE SKIN DAMAGE IF HANDLED FREQUENTLY AND FOR LONG PERI-

ODS. IT IS ADVISABLE TO WASH YOUR HANDS CAREFULLY AFTER HANDLING IT.

CAUTION

KEEP OUT OF THE REACH OF CHILDREN

DO NOT DISPOSE OF OIL INTO THE ENVIRONMENT.

DISPOSE OF ENGINE OIL STORED IN A SEALED CONTAINER AND TAKE IT TO YOUR SUP-

PLIER OR TO THE NEAREST USED OIL RECLAMATION FIRM.

IT IS ADVISABLE TO WEAR LATEX GLOVES WHEN SERVICING THE VEHICLE.

CAUTION

IF THE ENGINE OIL PRESSURE WARNING LIGHT COMES ON DURING NORMAL ENGINE OP-

ERATION, IT MEANS THAT THE ENGINE OIL PRESSURE IN THE CIRCUIT IS TOO LOW.

IN THIS CASE, CHECK THE ENGINE OIL LEVEL AND IF IT IS NOT CORRECT, SHUT OFF THE

ENGINE IMMEDIATELY AND CONTACT AN OfficiaI apriIia deaIer. HANDLE CAREFULLY.

DO NOT SPILL OIL!

AVOID SPILLING OIL OVER COMPONENTS, THE AREA YOUR ARE WORKING IN AND ITS

SURROUNDS. REMOVE ANY TRACE OF OIL CAREFULLY.

IN THE EVENT OF LEAKS OR MALFUNCTIONING, CONTACT AN OfficiaI apriIia deaIer.

NOTE

CARRY OUT THE MAINTENANCE OPERATIONS AT HALF THE INTERVALS SHOWN IF THE

VEHICLE IS USED IN WET OR DUSTY AREAS, OFF ROAD OR FOR SPORTS APPLICATIONS.

Check

To check:

CAUTION

THIS TYPE OF VEHICLE HAS SEPARATE LUBRICATION CIRCUITS FOR ENGINE AND TRANS-

MISSION/CLUTCH. OIL LEVEL CHECK AND REPLACEMENT MUST BE CARRIED OUT FOR

SXV RXV 450-550 Maintenance

MAN - 17

BOTH CIRCUITS.

CAUTION

THE ENGINE MUST BE WARM TO CHECK ENGINE OIL LEVEL. IF ENGINE OIL LEVEL IS

CHECKED WHEN THE ENGINE IS COLD, THE OIL MAY GO TEMPORARILY BELOW THE MIN-

IMUM LEVEL. THIS IS NOT A PROBLEM AS LONG AS THE ENGINE OIL PRESSURE WARNING

LIGHT DOES NOT COME ON.

NOTE

IN ORDER TO WARM-UP THE ENGINE AND BRING THE OIL TO THE RIGHT TEMPERATURE,

RIDE THE VEHICLE FOR A SHORT PERIOD OF TIME (10 - 15 MIN), KEEP THE ENGINE RUN-

NING AT IDLE FOR AT LEAST 30 SECONDS AFTER YOU HAVE COME TO A HALT, THEN CUT

OFF THE ENGINE.

Keep the vehicle upright with the two

wheels on the ground.

Check oil level through the appropriate

transparent pipe (1).

MAX = maximum level

MIN = minimum level

The oil level is correct when it is close

to the MAX level reference mark.

Top up as required:

CAUTION

IF YOU RIDE YOUR VEHICLE IN A SPORTY FASHION WITH OIL LEVEL TOO HIGH, SOME OIL

MAY SPLATTER AND GET INTO THE FILTER CASE THROUGH THE ENGINE VENT.

CAUTION

DO NOT GO BEYOND THE MAX AND BELOW THE MIN LEVEL MARKS TO AVOID SEVERE EN-

GINE DAMAGE.

Unscrew and remove the filler plug

(2).

NOTE

DO NOT ADD ADDITIVES OR OTHER SUB-

STANCES TO THE OIL.

Maintenance SXV RXV 450-550

MAN - 18

WHEN USING A FUNNEL OR ANY OTHER

ELEMENT, MAKE SURE IT IS PERFECTLY

CLEAN.

Top-up the oil in the reservoir until you reach the correct level.

RepIacement

Park the vehicle on firm and level

ground.

Rest the vehicle on its stand.

CAUTION

WAIT SOME MINUTES UNTIL THE ENGINE

AND THE EXHAUST SYSTEM ARE COLD.

Stop the engine and let it cool off so

that the oil in the crankcase flows

down and cools as well.

Unscrew and take out the plug.

Place a container to collect the oil un-

derneath the engine oil drainage plug

on the flywheel side.

Unscrew and remove the oil drainage

plug and drain off all the engine oil.

CAUTION

USED OIL CONTAINS SUBSTANCES HARM-

FUL TO THE ENVIRONMENT. DISPOSE OF

USED OIL ACCORDING TO THE REGULA-

TIONS IN FORCE.

SXV RXV 450-550 Maintenance

MAN - 19

Unscrew the engine oil filter cover.

Remove the engine oil filter cover and

the gasket, collecting the O-ring.

Remove the engine oil filter.

Place a container underneath the en-

gine oil drainage plug of the recovery

reservoir.

Unscrew and remove the oil drainage

plug from the reservoir and drain all

the engine oil.

Fit a new engine oil filter.

Screw the engine oil filter cover.

Screw and tighten the oil drainage

plug.

Pour approx. 1250 cm (76.3 cu.in) of

engine oil through the filler opening.

Screw and tighten the plug.

Start the engine and let it run for sev-

eral minutes.

Stop the engine and let it cool down.

Check the engine oil level.

Gearbox OiI

Inspection

CAUTION

GEAR OIL LEVEL MUST BE CHECKED WHEN THE ENGINE IS WARM.

Stop the engine.

Wait some minutes for the oil to flow

from the transmission to the clutch.

Keep the vehicle upright with the two

wheels on the ground.

Maintenance SXV RXV 450-550

MAN - 20

Remove the rear brake lever by undo-

ing the screw (1); collect the washer.

Unscrew and remove the cap/dipstick (2).

The oil level is correct when it is close to the cap/dipstick (2) opening.

f necessary:

Remove the filler cap (3).

Top-up with oil up to the cap/dipstick

(2) opening.

CAUTION

DO NOT ADD ADDITIVES OR OTHER SUB-

STANCES TO THE FLUID.

WHEN USING A FUNNEL OR ANY OTHER

ELEMENT, MAKE SURE IT IS PERFECTLY

CLEAN.

Wait some minutes to allow the oil to flow from the clutch to the transmission. Then check

the oil level again.

RepIacement

Lower the oil pan guard.

Place a container with suitable capa-

city under the drainage plug (3).

Unscrew and remove the drainage

SXV RXV 450-550 Maintenance

MAN - 21

plug (3).

Unscrew and remove the filler plug

(2).

Drain the oil into the container; allow

several minutes for oil to drain out

completely.

Check and if necessary, replace the

drainage plug (3) sealing washers.

Screw and tighten the drainage plug

(3).

Remove the rear brake lever by undo-

ing the screw (1); collect the washer.

Unscrew and remove the cap/dipstick.

Pour new oil up to the cap/dipstick

opening.

Wait several minutes to allow the oil to

flow from the clutch to the transmis-

sion.

Then check the oil level again.

Tighten the filler cap (2).

CAUTION

OIL FLOWING FROM THE CLUTCH TO THE

TRANSMISSION AND FROM THE TRANSMIS-

SION TO THE CLUTCH CAN BE PARTICU-

LARLY SLOW WHEN THE OIL OR ENGINE

TEMPERATURE IS LOW.

CAUTION

DO NOT ADD ADDITIVES OR OTHER SUB-

STANCES TO THE FLUID.

WHEN USING A FUNNEL OR ANY OTHER

ELEMENT, MAKE SURE IT IS PERFECTLY

CLEAN.

Maintenance SXV RXV 450-550

MAN - 22

Refit the rear brake lever, remember to insert the washer between the lever and the

crankcase, by tightening the screw (1).

Air fiIter

Remove the saddle.

Lift the tank.

Release the air filter cover by gripping

and lifting the handles from both sides.

Slide out the air filter case cover from

behind together with the filter.

NOTE

UPON REFITTING THE AIR FILTER, ENSURE

THAT ITS CASE IS PERFECTLY CLEAN. RE-

MOVE ANY TRACE OF DIRT THAT MAY HAVE

ENTERED DURING REMOVAL. UPON REFIT-

TING, MAKE SURE THAT THE AIR INTAKES

ARE CORRECTLY FITTED.

CAUTION

MAKE SURE THAT THE RESERVOIR RETAIN-

ING EDGE NEVER COMES INTO CONTACT

WITH THE BATTERY POSITIVE LEAD.

CAUTION

IN THE EVENT OF A FALL, CLEAN THE AIR

FILTER AND ITS HOUSING CAREFULLY, RE-

MOVING ANY TRACES OF OIL WHICH MAY

HAVE ENTERED FROM THE OIL RESERVOIR

THROUGH THE OIL VAPOUR BREATHER

PIPES.

CAUTION

SXV RXV 450-550 Maintenance

MAN - 23

REMOVE THE AIR FILTER COVER ONLY

WHEN THE VEHICLE IS PERFECTLY CLEAN

SO AS TO PREVENT ANY TRACE OF DIRT

FROM GETTING INTO THE HOUSING.

CooIing system

LeveI check

Check and top-up

CAUTION

WAIT FOR THE ENGINE TO COOL DOWN BEFORE CHECKING OR TOPPING-UP THE

COOLANT LEVEL.

Shut off the engine and wait until it

cools off.

Park the vehicle on firm and level

ground.

Keep the vehicle upright with the two

wheels on the ground.

Turn the radiator cap (1) anticlockwise

just one click.

Wait a few seconds so that possible

pressure in the circuit may be purged.

Turn the radiator cap (1) anticlockwise

again and remove it.

Make sure the fluid covers the radiator

plates completely.

Also check the level in the expansion

tank (under the engine sump cover)

through the appropriate sight glass.

The level should be between the MN

and MAX reference marks.

CAUTION

Maintenance SXV RXV 450-550

MAN - 24

DO NOT ADD ADDITIVES OR OTHER SUB-

STANCES TO THE FLUID.

WHEN USING A FUNNEL OR ANY OTHER

ELEMENT, MAKE SURE IT IS PERFECTLY

CLEAN.

CAUTION

COOLANT IS TOXIC IF INGESTED; CONTACT

WITH EYES OR SKIN MAY CAUSE IRRITA-

TION. DO NOT INTRODUCE YOUR FINGERS

OR ANY OTHER OBJECT TO CHECK IF

THERE IS COOLANT OR NOT.

Top-up

Check the coolant level.

f required, top-up with coolant until

the radiator plates are covered. Do not

exceed this level, otherwise the

coolant will spill during engine opera-

tion. When using a funnel or any other

element, make sure it is perfectly

clean.

Refit the radiator cap (1).

CAUTION

IN THE EVENT OF EXCESSIVE COOLANT

CONSUMPTION, CHECK COOLING SYSTEM

FOR LEAKS.

HAVE ANY MALFUNCTIONS REPAIRED BY

AN apriIia OfficiaI DeaIer.

Braking system

SXV RXV 450-550 Maintenance

MAN - 25

CAUTION

THIS VEHICLE IS EQUIPPED WITH FRONT AND REAR DISC BRAKES, EACH OF THEM OPER-

ATED BY AN INDEPENDENT HYDRAULIC CIRCUIT.

NOTE

THE FOLLOWING INFORMATION REFERS TO ONE BRAKING CIRCUIT BUT IS VALID FOR

BOTH.

CAUTION

UNEXPECTED CLEARANCE VARIATIONS OR ELASTIC RESISTANCE IN THE BRAKE LEVER

ARE DUE TO FAILURE IN THE HYDRAULIC CIRCUIT. CONTACT AN OfficiaI apriIia deaIer IN

CASE OF DOUBTS ON THE CORRECT BRAKING CIRCUIT OPERATION AND WHEN UNABLE

TO CARRY OUT ROUTINE CHECKS. PAY SPECIAL ATTENTION TO THE BRAKE DISC AND

THE FRICTION GASKETS AND CHECK THAT THEY ARE NOT OILY OR GREASY, SPECIALLY

AFTER MAINTENANCE OPERATIONS OR CHECKS. CHECK THAT BRAKE PIPES ARE NOT

TWISTED OR WORN. PAY UTMOST ATTENTION THAT NO WATER OR DUST INADVERT-

ENTLY GETS INTO THE CIRCUIT. IT IS ADVISABLE TO WEAR LATEX GLOVES WHEN SERVI-

CING THE HYDRAULIC CIRCUIT. BRAKE FLUID MAY CAUSE IRRITATION IF IN CONTACT

WITH SKIN OR EYES. RINSE CAREFULLY ALL BODY PARTS THAT HAVE COME INTO CON-

TACT WITH THE FLUID. SHOULD THE FLUID COME INTO CONTACT WITH YOUR EYES, SEEK

MEDICAL ADVICE OR CONTACT AN EYE SPECIALIST. DO NOT DISPOSE OF THE FLUID INTO

THE ENVIRONMENT. KEEP OUT OF THE REACH OF CHILDREN WHEN USING BRAKE FLUID,

PAY ATTENTION NOT TO SPILL IT ONTO PLASTIC OR PAINTED COMPONENTS AS IT WILL

IRREPARABLY DAMAGE THEM.

LeveI check

FRONT BRAKE

Place the vehicle upright and keep the

handlebar right.

Make sure the fluid level in the reser-

voir (1) is above the 'MN' level refer-

ence mark.

MIN = minimum level

MAX = maximum level

Maintenance SXV RXV 450-550

MAN - 26

f the fluid does not reach the "MIN" level reference mark:

CAUTION

BRAKE LEVEL DECREASES GRADUALLY AS BRAKE PADS WEAR DOWN.

Check brake pads and discs for wear.

f the pads and/or the disc do not need replacing, top-up the fluid.

REAR BRAKE

Place the vehicle upright

Make sure the fluid level in the reser-

voir (2) is above the "MN" level refer-

ence mark.

f the fluid does not reach at least the "MIN" reference mark:

CAUTION

BRAKE LEVEL DECREASES GRADUALLY AS BRAKE PADS WEAR DOWN.

Check brake pads and discs for wear.

f the pads and/or the disc do not need replacing, top-up the fluid.

Top-up

FRONT BRAKING CIRCUIT TOPPING-UP - SXV

NOTE

RISK OF BRAKE FLUID SPILLS. DO NOT

PULL THE FRONT BRAKE LEVER WHEN THE

SCREWS (1) ARE LOOSE OR, MAINLY, WHEN

SXV RXV 450-550 Maintenance

MAN - 27

THE BRAKE FLUID RESERVOIR CAP (2) HAS

BEEN REMOVED.

Undo the screws (1) of the brake fluid reservoir using a short Phillips screwdriver.

CAUTION

AVOID PROLONGED AIR EXPOSURE OF THE BRAKE FLUID. BRAKE FLUID IS HYGROSCOP-

IC AND ABSORBS MOISTURE WHEN IN CONTACT WITH AIR. LEAVE THE BRAKE FLUID

RESERVOIR OPEN ONLY FOR THE TIME NEEDED TO COMPLETE THE TOPPING UP PRO-

CEDURE.

Lift and remove the cover (2) together with the screws (1) and the gasket (3).

CAUTION

TO AVOID SPILLING BRAKE FLUID DURING TOP-UP, DO NOT SHAKE THE VEHICLE. DO NOT

ADD ADDITIVES OR OTHER SUBSTANCES TO THE FLUID. WHEN USING A FUNNEL OR ANY

OTHER ELEMENT, MAKE SURE IT IS PERFECTLY CLEAN.

Top-up the reservoir with the brake fluid until the level is over the "MN" level reference

mark.

CAUTION

TOP-UP TO MAX LEVEL MARK ONLY WHEN THE BRAKE PADS ARE NEW. IT IS ADVISABLE

NOT TO TOP-UP TO THE MAX LEVEL MARK WHEN THE BRAKE PADS ARE WORN BECAUSE

YOUR RISK SPILLING FLUID WHEN CHANGING THE BRAKE PADS.

CHECK BRAKING EFFICIENCY.

IN CASE OF EXCESSIVE BRAKE LEVER TRAVEL OR POOR PERFORMANCE OF THE BRAK-

ING CIRCUIT, TAKE YOUR VEHICLE TO AN OfficiaI apriIia deaIer, AS IT MAY BE NECESSARY

TO PURGE AIR IN THE CIRCUIT.

FRONT BRAKING CIRCUIT TOPPING-UP -

Maintenance SXV RXV 450-550

MAN - 28

RXV

NOTE

RISK OF BRAKE FLUID SPILLS. DO NOT

PULL THE FRONT BRAKE LEVER WHEN THE

SCREWS (4) ARE LOOSE OR, MAINLY, WHEN

THE BRAKE FLUID RESERVOIR CAP (5) HAS

BEEN REMOVED.

Undo the screws (4) of the brake fluid reservoir using a short Phillips screwdriver.

CAUTION

AVOID PROLONGED AIR EXPOSURE OF THE BRAKE FLUID. BRAKE FLUID IS HYGROSCOP-

IC AND ABSORBS MOISTURE WHEN IN CONTACT WITH AIR. LEAVE THE BRAKE FLUID

RESERVOIR OPEN ONLY FOR THE TIME NEEDED TO COMPLETE THE TOPPING UP PRO-

CEDURE.

Lift and remove the cover (5) together with the screws (4) and the gasket (6).

CAUTION

TO AVOID SPILLING BRAKE FLUID DURING TOP-UP, DO NOT SHAKE THE VEHICLE. DO NOT

ADD ADDITIVES OR OTHER SUBSTANCES TO THE FLUID. WHEN USING A FUNNEL OR ANY

OTHER ELEMENT, MAKE SURE IT IS PERFECTLY CLEAN.

Top-up the reservoir with the brake fluid until the level is over the "MN" level reference

mark.

CAUTION

TOP-UP TO MAX LEVEL MARK ONLY WHEN THE BRAKE PADS ARE NEW. IT IS ADVISABLE

NOT TO TOP-UP TO THE MAX LEVEL MARK WHEN THE BRAKE PADS ARE WORN BECAUSE

YOUR RISK SPILLING FLUID WHEN CHANGING THE BRAKE PADS.

CHECK BRAKING EFFICIENCY.

IN CASE OF EXCESSIVE BRAKE LEVER TRAVEL OR POOR PERFORMANCE OF THE BRAK-

ING CIRCUIT, TAKE YOUR VEHICLE TO AN OfficiaI apriIia deaIer, AS IT MAY BE NECESSARY

TO PURGE AIR IN THE CIRCUIT.

REAR BRAKING CIRCUIT TOPPING-UP - SXV - RXV

SXV RXV 450-550 Maintenance

MAN - 29

NOTE

RISK OF BRAKE FLUID SPILLS. DO NOT PULL THE FRONT BRAKE LEVER WHEN THE

SCREWS (7) ARE LOOSE OR, MAINLY, WHEN THE BRAKE FLUID RESERVOIR CAP (8) HAS

BEEN REMOVED.

Undo the two screws (7) of the brake

fluid reservoir using a short Phillips

screwdriver.

CAUTION

AVOID PROLONGED AIR EXPOSURE OF THE

BRAKE FLUID. BRAKE FLUID IS HYGRO-

SCOPIC AND ABSORBS MOISTURE WHEN IN

CONTACT WITH AIR. LEAVE THE BRAKE

FLUID RESERVOIR OPEN ONLY FOR THE

TIME NEEDED TO COMPLETE THE TOPPING

UP PROCEDURE.

Lift and remove the cover (8) together with the screws (7) and the gasket (9).

CAUTION

TO AVOID SPILLING BRAKE FLUID DURING TOP-UP, DO NOT SHAKE THE VEHICLE. DO NOT

ADD ADDITIVES OR OTHER SUBSTANCES TO THE FLUID. WHEN USING A FUNNEL OR ANY

OTHER ELEMENT, MAKE SURE IT IS PERFECTLY CLEAN.

Top-up the reservoir with the brake fluid until the level is over the "MN" level reference

mark.

CAUTION

TOP-UP TO MAX LEVEL MARK ONLY WHEN THE BRAKE PADS ARE NEW. IT IS ADVISABLE

NOT TO TOP-UP TO THE MAX LEVEL MARK WHEN THE BRAKE PADS ARE WORN BECAUSE

YOUR RISK SPILLING FLUID WHEN CHANGING THE BRAKE PADS.

CHECK BRAKING EFFICIENCY.

IN CASE OF EXCESSIVE BRAKE LEVER TRAVEL OR POOR PERFORMANCE OF THE BRAK-