Академический Документы

Профессиональный Документы

Культура Документы

Alkyl Amines Kurkumbh

Загружено:

Vishvajit PatilАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Alkyl Amines Kurkumbh

Загружено:

Vishvajit PatilАвторское право:

Доступные форматы

MAHARASHTRA POLLUTION CONTROL BOARD

Phone : 4010437/4020781

/4037124/4035273

Fax : 24044532/4024068/4023516

Email : enquiry@mpcb.gov.in

Visit At : http://mpcb.gov.in

MAHARASHTRA

Kalpataru Point, 3rd & 4th floor, Sion- Matunga

Scheme Road No. 8, Opp. Cine Planet Cinema, Near

Sion Circle, Sion (E),

Mumbai - 400 022

Consent order No :- Formatel.O/ BO/CAC-Cell/ EIC No PN-20155-13/5th CAC-

To,

M/s Alkyl Amines Chemicals Ltd,

Plot No.D-6/l,D-6/2,

MIDC Kurkumbh,

Tal-Daund,Dist-Pune

Subject: Consent to Establish for expansion RED category.

Ref : 1. Existing Consent granted vide no. BO/PAMS//EIC No.PN-12972-12/CAC-

409

dtd 27/4/2012

2. Minutes of CAC meeting held on 29.05.2014

Your application: CE1312000650

Dated:11.12.2013

For: Consent to Establish for expansion

under Section 25 of the Water (Prevention & Control of Pollution) Act, 1974 & under

Section 21 of the Air (Prevention & Control of Pollution) Act, 1981 and

Authorization under Rule 5 of the Hazardous Wastes (M, H & T M) Rules 2008 is

considered and the consent is hereby granted subject to the following terms and

conditions and as detailed in the schedule I, II ,111 & IV annexed to this order:

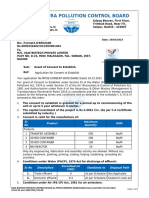

1. The consent is granted for a period up to Commissioning of the unit or 5 years

whichever is earlier

2. The proposed capital investment of the industry is Rs.SOCrs. (As per

Undertaking submitted by industry). Total capital investment of the industry

is Rs 101.45 +30= Rs 131.45 crs.

3. The Consent is valid for the manufacture of-

Sr. Product /By-Product Name Maximum Quantity

No. ' ' ^ ' ' ' -. / . ' - - - . '

A

1.

B

1.

C

1.

D

1.

E

1.

Speciality Intermediates

Acetonitrile 5000MT/Y

Aliphatic Amine Hydrochlorides

Dimethyl amine Hydrochloride powder -

(DMA HCI)

10000MT/Y

Aliphatic Amine Hydrochloride 50% solution

Dimethyl amine Hydrochloride - (DMA

HCI) 50% solution

15000MT/Y

Other Product

Sodium acetate aqueous solution 3400MT/Y

By-product

Caustic solution 1000MT/Y

j.

1

f\ Alkyl Amines Chemicals LtdSROPune I/I/R/L/97321000

4. Ccmditions under Water (P&CP), 1974 Act for discharge of effluent:

Sr.

no.

1.

2.

Description

Trade effluent

Domestic effluent

Permitted

quantity of

discharge

(CMD)

10

9.5

Standards to

be achieved

As per

Schedule -I

As per

Schedule -I

Disposal

Shall be totally

evaporated

On land for

gardening

5. Conditions under Air (P& CP) Act, 1981 for air emissions:

Sr.

no.

1.

2.

3.

Description of stack /

source

NEWTFH

HC1 Scrubber

DGset

Number of Stack

1

1

1

Standards to be

achieved

As per Schedule -II

As per Schedule -II

As per Schedule -II

6.

7.

Conditions about Non Hazardous Wastes:

Non-hazardous waste shall be segregated as and when generated and

disposed off by Sale / recycle / Municipal dump.

Conditions under Hazardous Waste (MH & TM) Rules, 2008 for treatment and

disposal of hazardous waste:

Sr. Type Of Waste Category Quantit UOM Treatment j Disposal

No. ' . . " - . ' y , |

1

2

3

Distillation

residue

Spent organic

solvent

Chemical

sludge from

waste water

treatment

(Inorganic

Solids from

Vaporiser in

ETP & DM

Plant)

20.3

28.5

34.3

10

10

330

MT/A

MT/A

MT/A

...

CHWTSDF

CHWTSDF

CHWTSDF

8. The Board reserves the right to review, amend, suspend, revoke etc. this consent

and the same shall be binding on the industry.

9. This consent should not be construed as exemption from obtaining necessary

NOC/permission from any other Government authorities.

10. The applicant should not take any effective steps for implementation of the

project before obtaining Environmental Clearance as per EIA Notification 2006

and amendments thereto.

11. As per Para 2 of EIA notification dated-14/09/2006, the effective steps include

starting of any construction work or preparation of land by the project

maifegement. However as clarified by the MoEF vfSe office memorandum no. J-

li03741/2006-IA.II(I); Dated-19/8/2010,fencing of the site to protect it from getting

encroached & construction of temporary shed(s) for the guard(s) & acquisition of

land shall not be treated as an effective steps.

M/s Alkyl Amines Chemicals LtdSROPune l/l/R/L/97321000

12. Industry shall carry out treatability study by 31.08.2014 and submit BG of Rs 2

lakhs for the compliance of the same.

13. Industry shall submit an affidavit in Board's prescribed format by 23.06.2014

regarding compliance of EC and C to E conditions.

For and on behalf of the

Maharashtra Pollution Control Board

( Rajee*

Me

Received Consent fee of-

Sr. Amount(Rs.)

No. " ' '

DD. No. Date Drawn On

2/12/2013 Axis Bank

Copy to:

1. Regional Officer -Pune and Sub-Regional Officer-Pune-lMPCB,They are

directed to ensure the compliance of the consent conditions.

2. Chief Accounts Officer, MPCB, Mumbai.

3. CC/CAC desk- for record & website updation purposes.

M/s Alkyl Amines Chemicals LtdSROPune l/I/R/L/97321000 Page 3of 9

Schedule-I

Terms & conditions for compliance of Water Pollution Control:

1) A] As per your application, you have proposed to install psychometric

evaporator.

B] The Applicant shall operate the effluent treatment plant (ETP) to treat the

trade effluent so as to achieve the following standards prescribed by the

Board or under EP Act, 1986 and Rules made there under from time to time,

whichever is stringent.

SrNo.

01

02

03

04

05

06

07

08

09

10

Parameters

pH

Oil & Grease

BOD (3 days 27oC )

Total Dissolved Solids

Phenolics (C6H5OH)

TAN

Suspended Solids

COD

Chloride

Sulphate

Standards prescribed

Board (If any)

by

Limiting Concentration in

mg/1, except for pH

5.5-9.0

10

100

2100

1.0

50

200

250

600

1000

C] The effluent generated from DM regeneration shall be totally evaporated

in psychometric evaporator.

2) A.] As per your consent application, you have provided the septic tank and

soak pits.

B] The Applicant shall operate the sewage treatment system to treat the

sewage so as to achieve the following standards/ prescribed under EP Act,

1986 and Jlules made there under from time to time, whichever is stringent.

(1) Suspended Solids. Not to exceed 100 mg/1.

(2) BOD 3 days 27C. Not to exceed 100 mg/1.

C] The treated sewage shall be soaked in a soak pit, which shall be got cleaned

periodically.

3) The Board reserves its rights to review plans, specifications or other data

relating to plant setup for the treatment of waterworks for the purification

thereof & the system for the disposal of sewage or trade effluent or in

connection with the grant of any consent conditions. The Applicant shall

obtain prior consent of the Board to take steps to establish the unit or establish

any treatment and disposal system or and extension or addition thereto.

4) The industry shall ensure replacement of'pollution control system or its parts

after expiry of its expected life as defined by manufacturer so as to ensure the

compliance of standards and safety of the operation thereof.

M/s Alkyl Amines Chemicals LtdSROPune I/l/R/L/97321000

5) The Applicant shall comply with the provisions of the Water (Prevention &

Control of Pollution) Cess Act, 1977 and as amended, by installing water

meters, filing water cess returns in Form-I and other provisions as contained

in the said act.

Sr.

no.

1.

2.

3.

4.

5

Purpose for water consumed

Industrial Cooling, spraying in mine pits or

boiler feed

Domestic purpose

Processing whereby water gets polluted &

pollutants are easily biodegradable

Processing whereby water gets polluted &

pollutants are not easily biodegradable and

are toxic

Agriculture/Gardening

Water consumption

quantity (CMD)

0

10

0

0

200

6) The Applicant shall provide Specific Water Pollution control system as per

the conditions of EP Act,1986 and rule made there under from time to time/

Environmental Clearance / CREP guidelines.

M/s Alkyl Amines Chemicals UdSROPune l/I/R/L/97321000

Schedule-II

Terms & conditions for compliance of Air Pollution Control:

1. As per your application, you have proposed to install the Air pollution

control (APC)system and also proposed to erect following stack (s) and to

observe the following fuel pattern-

Sr. Stack APC Height Type of Quantity S % SO2

No. Attached To System in Mtrs. Fuel & UoM K g/ D ay

1

2

3

New TFH

Process stack

to HCL

scrubber

D .G.Set

( 1000K VA)

Scrubber

31

15.30

7

P.O.

HSD

125K g/ Hr

243Lit/ Hr

4.5

1

270

116

2.

3.

The Applicant shall provide Specific Air Pollution control equipments as

per the conditions of EP Act, 1986 and rule made there under from time to

time / Environmental Clearance / CREP guidelines.

The applicant shall operate and maintain above mentioned air pollution

control system, so as to achieve the level of pollutants to the following

standards:

Particulate

matter

SC-2 Process

HCL

NOx

NH3

Not to exceed

Not to exceed

Not to exceed

Not to exceed

Not to exceed

150 mg/ Nm3.

..50 mg/ Nm3

35 mg/ Nm3

50 ppm

50 ppm

4. The Applicant shall obtain necessary prior permission for providing

additional control equipment with necessary specifications and operation

thereof or alteration or replacemenalteration well before its life come to an

end or erection of new pollution control equipment.

5. The Board reserves its rights to vary all or any of the condition in the

consent, if due to any technological improvement or otherwise such

variation (including the change of any control equipment, other in whole or

in paiHt is necessary).

M/s Alkyl Amines Chemicals Ltd SROPune I/I/R/L/97321000

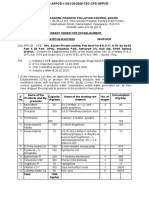

Schedule-Ill

Details of Bank Guarantees

Sr.

No.

1

2

Consent

(Cto

E/O/R)

Ct oE

Ct oE

Amt of

BG

Imposed

Rs 5

lakhs

Rs 2

lakhs

Submissi

on Period

Within 15

days

from the

date of

issue of

consent

Within 15

days

from the

date of

issue of

consent

Purpose of BG

Not to take any

effective steps

before obtaining

EC

Carrying out

treatability

study of ETP

Complianc

e Period

30.06.2019

31.08.2014

Validity

Date

30.10.2019

31.12.2014

M/s Alkyl Amines Chemicals UdSROPune l/l/R/L/97321000 Page 7 o f 9

ScheduIe-IV

General Conditions:

1) The applicant shall provide facility for collection of environmental samples and

samples of trade and sewage effluents, air emissions and hazardous waste to the

Board staff at the terminal or designated points and shall pay to the Board for the

services rendered in this behalf.

2) Industry should monitor effluent quality, stack emissions and ambient air quality

monthly/quarterly.

3) The applicant shall provide ports in the chimney/(s) and facilities such as ladder,

platform etc. for monitoring the air emissions and the same shall be open for

inspection to/and for use of the Board's Staff. The chimney(s) vents attached to

various sources of emission shall be designated by numbers such as S-l, S-2, etc. and

these shall be painted/ displayed to facilitate identification.

4) Whenever due to any accident or other unforeseen act or even, such emissions occur

or is apprehended to occur in excess of standards laid down, such information shall be

forthwith Reported to Board, concerned Police Station, office of Directorate of Health

Services, Department of Explosives, Inspectorate of Factories and Local Body. In case

of failure of pollution control equipments, the production process connected to it shall

be stopped.

5) The applicant shall provide an alternate electric power source sufficient to operate all

pollution control facilities installed to maintain compliance with the terms and

conditions of the consent. In the absence, the applicant shall stop, reduce or

otherwise, control production to abide by terms and conditions of this consent.

6) The firm shall submit to this office, the 30th day of September every year , the

Environmental Statement Report for the financial year ending 31st March in the

prescribed Form-V as per the provisions of rule 14 of the Environment (Protection)

(Second Amendment) Rules, 1992.

7) The industry shall recycle/reprocess/reuse/recover Hazardous Waste as per the

provision contain in the HW(MH&TM) Rules 2008, which can be

recycled/processed/reused/recovered and only waste which has to be incinerated shall

go to incineration and waste which can be used for land filling and cannot be

recycled/reprocessed etc should go for that purpose, in order to reduce load on

incineration and landfill site/environment.

8) The industry should comply with the Hazardous Waste (M,H & TM) Rules, 2008 and

submit the Annual Returns as per Rule 5(6) & 22(2) of Hazardous Waste (M,H & TM)

Rules, 2008 for the preceding year April to March in Form-IV by 30th June of every

year.

9) An inspection book shall be opened and made available to the Board's officers during

their visit to' the applicant.

10)Th,e applicant shall obtain Consent to Operate from Maharashtra Pollution

Control Board before actual commencement of the Unit/ Activity.

11) Industry shall strictly comply with the Water (P&CP) Act, 1974, Air (P&CP) Act, 1981

and Environmental Protection Act, 1986 and industry specific standard under EP

Rules 1986 which are available on MPCB website(www.mpcb.gov.m).

12) The industry shall constitute an Environmental cell with qualified

staff/personnel/agency to see the day to day compliance of consent condition towards

Environment Protection.

13) Separate drainage system shall be provided for collection of trade and sewage

effluents. Terminal manholes shall be provided at the end of the collection system

with arrangement for measuring the flow. No effluent shall be admitted in .the

pipes/sewers downstream^pf the terminal manholes. No effluent shall find itsjfay

other than in designed and provided collection system.

14) Neither storm water nor discharge from other premises shall be allowed to mix with

the effluents from the factory. P.

v

M/sAlkyI Amines Chemicals Ltd SROPune I/I/R/L/97321000 \\8 o f 9

15) The applicant shall install a separate meter showing the consumption of energy for

operation of domestic and industrial effluent treatment plants and air pollution

control system. A register showing consumption of chemicals used for treatment shall

be maintained.

16) Conditions for D.G. Set

a) Noise from the D.G. Set should be controlled by providing an acoustic enclosure or

by treating the room acoustically.

b) Industry should provide acoustic enclosure for control of noise. The acoustic

enclosure/ acoustic treatment of the room should be designed for minimum 25 dB

(A) insertion loss or for meeting the ambient noise standards, whichever is on

higher side. A suitable exhaust muffler with insertion loss of 25 dB (A) shall also

be provided. The measurement of insertion loss will be done at different points at

0.5 meters from acoustic enclosure/room and then average.

c) Industry should make efforts to bring down noise level due to DG set, outside

industrial premises, within ambient noise requirements by proper sitting and

control measures.

d) Installation of DG Set must be strictly in compliance with recommendations of DG

Set manufacturer.

e) A proper routine and preventive maintenance procedure for DG set should be set

and followed in consultation with the DG manufacturer which would help to

prevent noise levels of DG set from deteriorating with use

f) D.G. Set shall be operated only in case of power failure.

g) The applicant should not cause any nuisance in the surrounding area due to

operation of D.G. Set.

h) The applicant shall comply with the notification of MoEF dated 17.05.2002

regarding noise limit for generator sets run with diesel

17) The industry should not cause any nuisance in surrounding area.

18) The industry shall take adequate measures for control of noise levels from its own

sources within the premises so as to maintain ambient air quality standard in respect

of noise to less than 75 dB (A) during day time and 70 dB (A) during night time. Day

time is reckoned in between 6 a.m. and 10 p.m. and night time is reckoned between

10 p.m. and 6 a.m.

19) The applicant shall maintain good housekeeping.

20) The applicant shall bring minimum 33% of the available open land under green

coverage/ plantation. The applicant shall submit a statement on available open plot

area, number of trees surviving as on 31st March of the year and number of trees

planted by September end, with the Environment Statement.

21) The non-hazardous solid waste arising in the factory premises, sweepings, etc. be

disposed of scientifically so as not to cause any nuisance / pollution. The applicant

shall take necessary permissions from civic authorities for disposal of solid waste.

22) The applicant shall not change or alter the quantity, quality, the rate of discharge,

temperature or the mode of the effluent/emissions or hazardous wastes or control

equipments provided for without previous written permission of the Board. The

industry will not carry out any activity, for which this consent has not been

granted/without prior consent of the Board.

23) The industry shall ensure that fugitive emissions from the activity are controlled so

as to maintain clean and safe environment in and around the factory premises.

24) The industry shall submit official e-mail address and any change will be duly

informed to the MPCB.

25) The industry shall achieve the National Ambient Air Quality standards prescribed

vide Government of India, Notification dtd. 16.11.2009 as amended.

*i

T

?

0000

M/s Alkyl Amines Chemicals Ltd SROPune l/I/R/L/97321000

Вам также может понравиться

- Damages on Pumps and Systems: The Handbook for the Operation of Centrifugal PumpsОт EverandDamages on Pumps and Systems: The Handbook for the Operation of Centrifugal PumpsРейтинг: 4.5 из 5 звезд4.5/5 (2)

- BHEL Bhandara MPCB FileДокумент9 страницBHEL Bhandara MPCB FileVishvajit PatilОценок пока нет

- Vineet Tex FabДокумент7 страницVineet Tex FabSharon SusmithaОценок пока нет

- Allegro Speciality Cfo OrderДокумент5 страницAllegro Speciality Cfo Orderap26n1389Оценок пока нет

- Chrome HardДокумент23 страницыChrome Hardpallavan.kОценок пока нет

- Maharashtra Pollution Board grants consentДокумент7 страницMaharashtra Pollution Board grants consentSharon SusmithaОценок пока нет

- CertiFicate For Water - NEWДокумент6 страницCertiFicate For Water - NEWMohan RajОценок пока нет

- Regional Office:: Guntur D.No:4-5-4/5C, 4/3 - Navabharath Nagar, Ring Road, Guntur - 522 006Документ6 страницRegional Office:: Guntur D.No:4-5-4/5C, 4/3 - Navabharath Nagar, Ring Road, Guntur - 522 006ROOPDIP MUKHOPADHYAYОценок пока нет

- PollДокумент35 страницPollmahfooz.salujasteelОценок пока нет

- Maharashtra Pollution Control Board grants consent to V&W BiotechДокумент8 страницMaharashtra Pollution Control Board grants consent to V&W BiotechSharon SusmithaОценок пока нет

- Consent Order: J&K Pollution Control Committee Jammu/Kashmir (WWW - Jkspcb.nicДокумент3 страницыConsent Order: J&K Pollution Control Committee Jammu/Kashmir (WWW - Jkspcb.nickrish659Оценок пока нет

- Lodha Palava ConsentДокумент8 страницLodha Palava ConsentkrayОценок пока нет

- Slaughter House by Eluru Municipality, ELR (1) - 221029 - 174130Документ4 страницыSlaughter House by Eluru Municipality, ELR (1) - 221029 - 174130Rao GОценок пока нет

- New CFO PHASE VI LANDFILL EXPANSIONДокумент6 страницNew CFO PHASE VI LANDFILL EXPANSIONShiva SunuОценок пока нет

- A Missoula County Air Quality Permit Will Be Required For Locations Within Missoula County. A List of The Permitted Equipment Is Contained in Section I.A of The PermitДокумент20 страницA Missoula County Air Quality Permit Will Be Required For Locations Within Missoula County. A List of The Permitted Equipment Is Contained in Section I.A of The Permitmacross086Оценок пока нет

- Ardex Endura - CFOДокумент5 страницArdex Endura - CFOAPIIC EEОценок пока нет

- EMP Raheja MindspaceДокумент5 страницEMP Raheja MindspaceJohn SharonОценок пока нет

- Kejriwal Geotech Pvt. LTDДокумент4 страницыKejriwal Geotech Pvt. LTDTerapanth Yuvak Parishad VapiОценок пока нет

- CATEGORY - Green (III) Consent To EstablishДокумент4 страницыCATEGORY - Green (III) Consent To EstablishROOPDIP MUKHOPADHYAYОценок пока нет

- OfficemanualДокумент33 страницыOfficemanualPrasenjit DasОценок пока нет

- TNPCB and PublicДокумент187 страницTNPCB and Publicsaravana_ravichandra100% (1)

- R K CashewsДокумент5 страницR K CashewsVijay SethupathiОценок пока нет

- Tech Specs For ETPДокумент26 страницTech Specs For ETPNarayanan MenonОценок пока нет

- Module 2Документ9 страницModule 2ikhwanstorageОценок пока нет

- SOP LeadДокумент7 страницSOP LeadKishan MauryaОценок пока нет

- With DIC: To Establish Renew Under The Control ofДокумент2 страницыWith DIC: To Establish Renew Under The Control ofkrish659Оценок пока нет

- Apar Silvassa LubesДокумент8 страницApar Silvassa LubesROOPDIP MUKHOPADHYAYОценок пока нет

- Trade Effluent Regulations GuideДокумент58 страницTrade Effluent Regulations Guidetriggs1971Оценок пока нет

- GPCB Infor CcaДокумент4 страницыGPCB Infor CcaTejas PatelОценок пока нет

- Technical InstrumentationДокумент209 страницTechnical Instrumentationrenjithv_40% (1)

- Application Filed by The Applicant/organization On: LocationДокумент5 страницApplication Filed by The Applicant/organization On: Locationkrish659Оценок пока нет

- State Pollution Control Board, Odisha: No. Date Office MemorandumДокумент3 страницыState Pollution Control Board, Odisha: No. Date Office Memorandumkrish659Оценок пока нет

- 0 0 71116121212161149FinalMinutesДокумент81 страница0 0 71116121212161149FinalMinutesSandeep PatidarОценок пока нет

- Maharashtra Pollution Control Board: SR No Product Maximum Quantity UOMДокумент10 страницMaharashtra Pollution Control Board: SR No Product Maximum Quantity UOMuser-402057Оценок пока нет

- Haryana State Pollution Control Board C-11, Sector-6, PanchkulaДокумент3 страницыHaryana State Pollution Control Board C-11, Sector-6, PanchkulaRaj KumarОценок пока нет

- Karnataka State Pollution Control Board - 73weez We-, 1: MT) OccДокумент9 страницKarnataka State Pollution Control Board - 73weez We-, 1: MT) OccGiriraj DagaОценок пока нет

- Indus Coffee - CFEДокумент7 страницIndus Coffee - CFEAPIIC EEОценок пока нет

- Coffee Roasting ManualДокумент20 страницCoffee Roasting ManualNaeem GherianyОценок пока нет

- Environment Audit Report Format - GPCBДокумент8 страницEnvironment Audit Report Format - GPCBmaikalrОценок пока нет

- LEGAL AND REGULATORY REQUIREMENTSДокумент21 страницаLEGAL AND REGULATORY REQUIREMENTSNishit RupaparaОценок пока нет

- ANDHRA PRADESH POLLUTION CONTROL BOARD CONSENT ORDERДокумент4 страницыANDHRA PRADESH POLLUTION CONTROL BOARD CONSENT ORDERPRAVEEN KUMARОценок пока нет

- ES 24 Webinar Series Topic 2 Presentation - Clean Air ActДокумент39 страницES 24 Webinar Series Topic 2 Presentation - Clean Air ActCharlie Boy CalundreОценок пока нет

- Module 2Документ4 страницыModule 2Ikhwan AlifОценок пока нет

- Attachment 14h Environmental Quality Industrial Effluent Regulation 2009Документ22 страницыAttachment 14h Environmental Quality Industrial Effluent Regulation 2009kktayОценок пока нет

- Uploaded CertificateДокумент4 страницыUploaded Certificateinfohazardous1Оценок пока нет

- Certi FicateДокумент4 страницыCerti Ficatekrish659Оценок пока нет

- Ultramarine Specialty Chemicals - CFE-30-10-2021Документ9 страницUltramarine Specialty Chemicals - CFE-30-10-2021APIIC EEОценок пока нет

- Sample Sugar CtoДокумент5 страницSample Sugar CtosanketdesОценок пока нет

- MSIG Volume V - Septic TanksДокумент64 страницыMSIG Volume V - Septic TanksBFang Ku50% (2)

- Allastir PVT LTD - CFE OrderДокумент7 страницAllastir PVT LTD - CFE Orderap26n1389Оценок пока нет

- Standard procedures for importing and recycling waste tyres, PET bottles and leadДокумент19 страницStandard procedures for importing and recycling waste tyres, PET bottles and leadBAlaОценок пока нет

- Reg Review of Eng Eval For Application No 475623 475624 FCC Bypass SCR - Waste Heat Boiler 2f-7 2Документ11 страницReg Review of Eng Eval For Application No 475623 475624 FCC Bypass SCR - Waste Heat Boiler 2f-7 2api-242947664Оценок пока нет

- Cto 2022Документ7 страницCto 2022Business IntelligenceОценок пока нет

- (To Be Submitted in Triplicate) : Member Secretary, Chhattisgarh Environment Conservation Board Raipur (C.G.)Документ4 страницы(To Be Submitted in Triplicate) : Member Secretary, Chhattisgarh Environment Conservation Board Raipur (C.G.)Shekhar Srivastava AssociatesОценок пока нет

- Cfo GRCДокумент5 страницCfo GRCgrck7 marketing.Оценок пока нет

- STP 125 KLDДокумент9 страницSTP 125 KLDAbhay SisodiaОценок пока нет

- Depots Guidelines 2009Документ50 страницDepots Guidelines 2009Harkynollar HarkyntehyeОценок пока нет

- Code of Safe Working Practices for Merchant Seafarers Consolidated 2015 edition, including amendments 1-7От EverandCode of Safe Working Practices for Merchant Seafarers Consolidated 2015 edition, including amendments 1-7Оценок пока нет

- Sai Galaxy-ReraДокумент6 страницSai Galaxy-ReraVishvajit PatilОценок пока нет

- Ramchandra Residency A & D - Revised EstimateДокумент1 страницаRamchandra Residency A & D - Revised EstimateVishvajit PatilОценок пока нет

- Most Important Question 10thДокумент7 страницMost Important Question 10thhacker TayadeОценок пока нет

- Yees (& Ke Àefleheef$Ekeàe: Cee®E& Mebmke Àle - CevoeefkeàveerДокумент8 страницYees (& Ke Àefleheef$Ekeàe: Cee®E& Mebmke Àle - CevoeefkeàveerVishvajit PatilОценок пока нет

- Board Question Paper: March 2020 Science & Technology Part - 2Документ3 страницыBoard Question Paper: March 2020 Science & Technology Part - 2Vishvajit PatilОценок пока нет

- Board Question Paper: March 2018: Geography and EconomicsДокумент2 страницыBoard Question Paper: March 2018: Geography and EconomicsVishvajit PatilОценок пока нет

- Board Question Paper: March 2019 GeographyДокумент4 страницыBoard Question Paper: March 2019 GeographyVishvajit PatilОценок пока нет

- CERSAIДокумент3 страницыCERSAIVishvajit PatilОценок пока нет

- BuildMaster StartupGuideДокумент11 страницBuildMaster StartupGuideVishvajit PatilОценок пока нет

- Board Question Paper: March 2019 History and Political ScienceДокумент4 страницыBoard Question Paper: March 2019 History and Political ScienceVishvajit PatilОценок пока нет

- Yees (& Ke Àefleheef$Ekeàe: Cee®E& 2018: Cejeþer Jee®EveheeþДокумент8 страницYees (& Ke Àefleheef$Ekeàe: Cee®E& 2018: Cejeþer Jee®EveheeþVishvajit PatilОценок пока нет

- Board Question Paper: March 2018: History and Political ScienceДокумент2 страницыBoard Question Paper: March 2018: History and Political ScienceVishvajit PatilОценок пока нет

- Board Question Paper: March 2018Документ7 страницBoard Question Paper: March 2018Vishvajit PatilОценок пока нет

- 5061603420Документ10 страниц5061603420Vishvajit PatilОценок пока нет

- SEM 4 (Gender, School and Society)Документ72 страницыSEM 4 (Gender, School and Society)Vishvajit PatilОценок пока нет

- The Hindu Review May 2020Документ36 страницThe Hindu Review May 2020NACHIKETH89Оценок пока нет

- Structural Audit Report for Ramanand Co-op Housing SocietyДокумент1 страницаStructural Audit Report for Ramanand Co-op Housing SocietyVishvajit PatilОценок пока нет

- Standardized Format for Declaration about Commencement CertificateДокумент2 страницыStandardized Format for Declaration about Commencement CertificateVishvajit PatilОценок пока нет

- Handbook SP34Документ286 страницHandbook SP34Vishvajit PatilОценок пока нет

- Service Request Form - New Format PDFДокумент1 страницаService Request Form - New Format PDFVishvajit PatilОценок пока нет

- Structural Audit: A Need of An Hour: Rushabh Karnavat Vivek SinghДокумент3 страницыStructural Audit: A Need of An Hour: Rushabh Karnavat Vivek SinghVishvajit PatilОценок пока нет

- Handbook SP34Документ286 страницHandbook SP34Vishvajit PatilОценок пока нет

- 4 PDFДокумент94 страницы4 PDFVishvajit PatilОценок пока нет

- Form 7 Data Sheet Loads Gravity Live DeadДокумент1 страницаForm 7 Data Sheet Loads Gravity Live DeadGoanengineerОценок пока нет

- Research Priorities For Maintaining Structural Fire Resistance After Seismic DamageДокумент8 страницResearch Priorities For Maintaining Structural Fire Resistance After Seismic DamageVishvajit PatilОценок пока нет

- Ijcerv5n4spl 17Документ6 страницIjcerv5n4spl 17Virubinnya ViruОценок пока нет

- (Asce) 1audit PDFДокумент8 страниц(Asce) 1audit PDFVishvajit PatilОценок пока нет

- A Case Study On The Structural Assessment of FireДокумент8 страницA Case Study On The Structural Assessment of FireHarshsav SethiОценок пока нет

- Advanced Structural Audit Scheme - Case Study On Bishop's House Building, PalaiДокумент8 страницAdvanced Structural Audit Scheme - Case Study On Bishop's House Building, PalaiVishvajit PatilОценок пока нет

- Evaluating Damaged Concrete Depth in Reinforced Concrete Structures Under Different Fire Exposure Times by Means of NDT and DT TechniquesДокумент17 страницEvaluating Damaged Concrete Depth in Reinforced Concrete Structures Under Different Fire Exposure Times by Means of NDT and DT TechniquesVishvajit PatilОценок пока нет

- Environmental Incidents in Northeastern Alberta's Bitumen Sands RegionДокумент677 страницEnvironmental Incidents in Northeastern Alberta's Bitumen Sands Regionanna_mehler_papernyОценок пока нет

- Air Quality Monitoring and Control Syste PDFДокумент4 страницыAir Quality Monitoring and Control Syste PDFmuhammad saimОценок пока нет

- EVS - NotesДокумент73 страницыEVS - NotesTamilan TamilОценок пока нет

- Temporal and Spatial Environmental Impact of The COVID-19 PandemicДокумент161 страницаTemporal and Spatial Environmental Impact of The COVID-19 PandemicSachin GuptaОценок пока нет

- Jobs For Clean AirДокумент164 страницыJobs For Clean AirVishal ThakurОценок пока нет

- Husky Energy Exploration Drilling Project - Project Description SummaryДокумент38 страницHusky Energy Exploration Drilling Project - Project Description SummaryOmeruo EmekaОценок пока нет

- Global Warming ThesisДокумент15 страницGlobal Warming ThesisSaira Caritan100% (1)

- Speech Script Alternative Cigarettes (Vape) and LifestyleДокумент2 страницыSpeech Script Alternative Cigarettes (Vape) and LifestyleSabrina munawarti25100% (1)

- Carbon Nanodots Effect on Algae GrowthДокумент32 страницыCarbon Nanodots Effect on Algae GrowthMayank PanchalОценок пока нет

- KM4 G1 YDGAdditional ReportДокумент153 страницыKM4 G1 YDGAdditional ReportManjunathОценок пока нет

- Safe and Environmentally Sound Ship Recycling: Devendra Singh 1403608021Документ20 страницSafe and Environmentally Sound Ship Recycling: Devendra Singh 1403608021devendra singhОценок пока нет

- Unido Full Report EbookДокумент259 страницUnido Full Report EbookDayat LaodengkoweОценок пока нет

- Part 24 - Construction DewateringДокумент58 страницPart 24 - Construction Dewateringcivil engineer100% (1)

- Introduction To Air PollutionДокумент31 страницаIntroduction To Air PollutionAshish SharmaОценок пока нет

- A Sustainability Overview of The Best Practices in The Airport SectorДокумент17 страницA Sustainability Overview of The Best Practices in The Airport SectorTiciano Costa JordãoОценок пока нет

- What Are Eco Friendly ProductsДокумент4 страницыWhat Are Eco Friendly Productsmukul1234Оценок пока нет

- An Alternative Fuel Source: Dried Banana Leaves As Charcoal BriquettesДокумент28 страницAn Alternative Fuel Source: Dried Banana Leaves As Charcoal BriquettesjosephivanramonesОценок пока нет

- English 2 Unit I Module 6Документ31 страницаEnglish 2 Unit I Module 6Boy SawagaОценок пока нет

- Delivering On Our TargetsДокумент26 страницDelivering On Our TargetsMihaelaZavoianuОценок пока нет

- Lesson 14 - Environmental Education, Protection and ManagementДокумент13 страницLesson 14 - Environmental Education, Protection and ManagementMary Joy CuetoОценок пока нет

- Introduction To Environmental Chemistry PDFДокумент30 страницIntroduction To Environmental Chemistry PDFraj mohanОценок пока нет

- Elec 111 Module - 1 - L.A 1Документ3 страницыElec 111 Module - 1 - L.A 1JOHN BRAINARD PEJOОценок пока нет

- Acid RainДокумент20 страницAcid RainSmita Dhutraj100% (1)

- 18CYM101T (Environmental Science) Date:22.10-20Документ4 страницы18CYM101T (Environmental Science) Date:22.10-20Shivanshu Tripathi100% (1)

- Earth Building in Scotland - Past, Present, and Future - Morton and Little 2001Документ18 страницEarth Building in Scotland - Past, Present, and Future - Morton and Little 2001David PeiróОценок пока нет

- Strengthening Environmental Reviews in Urban AreasДокумент45 страницStrengthening Environmental Reviews in Urban AreasUsalama100% (1)

- Sample Speaking 4 MayДокумент6 страницSample Speaking 4 MayMinh Nghĩa HàОценок пока нет

- DLL - Mapeh-Health 6 - Q3 - W2Документ3 страницыDLL - Mapeh-Health 6 - Q3 - W2RyanОценок пока нет

- MMY Environment Aspect & Significant Impact (EASI) RegisterДокумент11 страницMMY Environment Aspect & Significant Impact (EASI) RegisterThirumaran MuthusamyОценок пока нет

- Chap 7 Air PollutionДокумент129 страницChap 7 Air PollutionTapan Kumar100% (2)