Академический Документы

Профессиональный Документы

Культура Документы

AutoZine Technical School - Engine Smoothness 3

Загружено:

AshokАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

AutoZine Technical School - Engine Smoothness 3

Загружено:

AshokАвторское право:

Доступные форматы

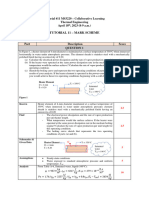

Inline 6-cylinder engines

As shown in the picture, straight-6 engine is simply two 3-cylinder engines mated symmetrically together, thus

piston 1 is always in the same position as piston 6, piston 2 the same as piston 5 .... in other words, the engine is

balanced end-to-end and requires no balancer shaft, unlike 3-cylinder engines.

What about vertical / transverse forces? like 3-cylinder engines, the vertical and transverse forces generated by

individual cylinders, no matter first order or second order, are completely balanced by one another. The resultant

vibration is nearly zero, thus inline-6 is virtually a perfect configuration.

Inline-6 is not the only configuration can deliver near perfect refinement, but it is the most compact one among

them. All boxer engines are perfectly balanced, but they are two wide and require duplicate of blocks, heads and

valve gears. V12 engines also achieve perfect balance, but obviously out of the reach of most mass production

cars. Automotive engineers knew that long ago, thats why you can see most of the best classic engines were

inline-6, such as Rolls-Royce Silver Ghost, Bentley Speed Six, Mercedes SSK, many Bugattis, Jaguar XK-series

and BMWs various models.

V6 engines

V6 engines, excluding Volkswagens 15VR6 (to be discussed later), are not just made from splitting inline-6 into

two banks arranged in V-shape. A V6 has a very different crankshaft - only 4 main bearings instead of 7. In other

words, between two adjacent bearings there are crank throws for 2 cylinders, one from bank A and another from

bank B. While V8 engines have those 2 cylinders shared the same crank pin, V6 engine has to split the crank pin

into two pieces, with a splay angle between those pins (30splay angle for 90V6; 60splay angle for 60V6).

These are shown in below.

AutoZine Technical School - Engine http://www.autozine.org/technical_school/engine/smooth3.htm

1 of 3 1/11/2012 10:19 AM

60V6 with 60splay angle

90V6 with 30splay angle

Split crank pins with

a 30splay angle

For better balance, most V6s are arranged such that the banks are placed at either 60or 90to each other. In

this way, the movement of cylinders in bank A matches those in bank B, thus there is no vibration generated

between banks. Besides, like 3-cylinder engines, there is no vertical and transverse vibration.

However, both 60or 90V6s have somewhat end-to-end vibration like 3-cylinder engines, especially is for 90

V6. (sorry, I dont have the theory) It needs a counter-rotating single balancer shaft, at crank speed, to suppress

the vibration. The balancer shaft is located inside the V-valley, so it is not space engaging. On the other hand, 90

V6 has a decisive advantage in production point of view - it can be machined in V8s production line because both

of them are 90. (unlike V6, V8 can only be optimised at 90) This save a lot of production cost. An example is

Mercedes supersmooth 2.4 to 3.2-litre V6s, which share the same architecture with V8s but added with a

balancer shaft.

End-to-end vibration

Single balancer shaft inside the V-valley

60V6 is smoother to the extent that, with adequate design engine mount, most of them could be made nearly as

smooth as inline-6 engines without the need of balancer shaft. It is also narrower, so easier to be packaged into a

FWD cars, mounted transversely.

60 V6 versus Inline-6

As space efficiency becomes more and more important, most car makers favour V6. The most influential V6 was

perhaps Alfa Romeos 2.5-litre 60V6 used in the GTV6. It established a reputation for V6 that it can be

compact, powerful and smooth. An equivalent inline-6 would have never fit the small and sloping engine

compartment of that car. Compare the shape of BMW with the Alfa and youll know the packaging advantage of

V6s.

Straight-six engines are nearly impossible to be used in front-wheel drive cars as well. Even a car as wide as

Volvo S80 has to introduce the worlds shortest gearbox in order to make space for the 2.9-litre straight-six

mounted transversely in the engine compartment.

Longitudinal mounted inline-6 doesnt have such problems, but it engages too much space in north-south direction,

thus engage some space which would have contributed to cockpit room.

AutoZine Technical School - Engine http://www.autozine.org/technical_school/engine/smooth3.htm

2 of 3 1/11/2012 10:19 AM

However, BMW is still loyal to inline-6 engines. Ultimately, inline-6 engine is more efficient yet smoother. V6 has

more energy loss because it duplicates valve gears and camshafts (which increase frictional loss), while the use

of 2 cylinder banks leads to more heat loss. In terms of production cost, although V6 has 3 fewer main bearings,

it has more valve gears - which is getting more and more costly these days, with the introduction of twin-cam,

hydraulic tappets / finger follower and variable valve timing. Inline-6 is going to be cheaper than equivalent V6.

Continue ...

Copyright 1998-2000 by Mark Wan

AutoZine Technical School

Return to AutoZine home page

AutoZine Technical School - Engine http://www.autozine.org/technical_school/engine/smooth3.htm

3 of 3 1/11/2012 10:19 AM

Вам также может понравиться

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- 25 Best Short Animal Stories For Kids With MoralsДокумент23 страницы25 Best Short Animal Stories For Kids With MoralsAshok83% (6)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Bobcat Manual PDFДокумент292 страницыBobcat Manual PDFAhmed MagedОценок пока нет

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Multi-Cone Synchronizer SystemsДокумент30 страницMulti-Cone Synchronizer Systemsgrnflash100% (1)

- Instructions for Oil Accessory Kit InstallationДокумент7 страницInstructions for Oil Accessory Kit InstallationOnofreОценок пока нет

- Moral Stories IllustratedДокумент74 страницыMoral Stories IllustratedAshok100% (1)

- Touch and See Your Solution: Finding Solutions For Your Problems in Bhagvad GitaДокумент1 страницаTouch and See Your Solution: Finding Solutions For Your Problems in Bhagvad Gitaanu50% (2)

- NASA Fastener Design ManualДокумент100 страницNASA Fastener Design ManualAaron D. MillerОценок пока нет

- ABB LV Motor ManualДокумент16 страницABB LV Motor Manualleeyuen_aОценок пока нет

- Computational Fluid Dynamics - Getting Started Quickly With ANSYS CFX 18 Through Simple Examples - Stefan Lecheler - Springer (2023)Документ211 страницComputational Fluid Dynamics - Getting Started Quickly With ANSYS CFX 18 Through Simple Examples - Stefan Lecheler - Springer (2023)Trịnh Thanh Tùng100% (1)

- Mechanical SectionДокумент16 страницMechanical SectionFrancis DimeОценок пока нет

- Baby Mait PDFДокумент2 страницыBaby Mait PDFChris LuОценок пока нет

- Fatigue CrankshaftДокумент31 страницаFatigue CrankshaftAngel Zanotti100% (1)

- Extrusion of Thermoplastics EXTRUSION Plays A Prominent Part On The Plastics Industry. Extrusion, UnlikeДокумент21 страницаExtrusion of Thermoplastics EXTRUSION Plays A Prominent Part On The Plastics Industry. Extrusion, UnlikeParag NambiarОценок пока нет

- Pump Types Guide - Find The Right Pump FoДокумент5 страницPump Types Guide - Find The Right Pump FoROHIT CHOUDHURYОценок пока нет

- General Tolerances DIN ISO 2768Документ2 страницыGeneral Tolerances DIN ISO 2768Vasil Gospodinov83% (23)

- 10speed EatonДокумент2 страницы10speed EatonChristopherОценок пока нет

- Design & Analysis of Crankshaft Bending Test Rig For Actual Engine Condition PDFДокумент8 страницDesign & Analysis of Crankshaft Bending Test Rig For Actual Engine Condition PDFAshokОценок пока нет

- A General Review of The Causes and Acceptance of Shape ImperfectionsДокумент7 страницA General Review of The Causes and Acceptance of Shape ImperfectionsMuhammed SulfeekОценок пока нет

- Geometry PuzzlesДокумент14 страницGeometry PuzzlesAshokОценок пока нет

- Air Bearing Fundamentals-Rev AДокумент13 страницAir Bearing Fundamentals-Rev AAshokОценок пока нет

- 24 Generator SelectionДокумент45 страниц24 Generator SelectionAshokОценок пока нет

- Backlash MitraДокумент8 страницBacklash MitraAshokОценок пока нет

- Selection of GeneratorДокумент11 страницSelection of GeneratorsbpathiОценок пока нет

- Basic Tools 1Документ13 страницBasic Tools 1Kannan Nehru100% (1)

- Crankshaft Design GuideДокумент16 страницCrankshaft Design GuideAshokОценок пока нет

- Ed 7002 Efm NotesДокумент58 страницEd 7002 Efm NotesAshokОценок пока нет

- Chapter10 Design of GearsДокумент16 страницChapter10 Design of GearsAshokОценок пока нет

- Transfer CaseДокумент41 страницаTransfer CaseAshok67% (3)

- Mechanical Behavior Simulation For SynchromechДокумент27 страницMechanical Behavior Simulation For SynchromechAshokОценок пока нет

- Engine Troubleshooting GuideДокумент16 страницEngine Troubleshooting GuideAshokОценок пока нет

- Automotive Transmissions - Fundamentals Selection Design and Application by AshokДокумент470 страницAutomotive Transmissions - Fundamentals Selection Design and Application by AshokAshokОценок пока нет

- Combustion Chamber Sae-Ref PaperДокумент9 страницCombustion Chamber Sae-Ref PaperAshokОценок пока нет

- Time ManagementДокумент30 страницTime ManagementAshokОценок пока нет

- Synchro RingДокумент9 страницSynchro RingAshokОценок пока нет

- Development of A Program For Calculating Gearbox SynchronizationДокумент86 страницDevelopment of A Program For Calculating Gearbox SynchronizationAshok50% (2)

- Effect of Injection Rate and Split Injections On Diesel EngineДокумент14 страницEffect of Injection Rate and Split Injections On Diesel EngineAshokОценок пока нет

- Basic Hydro Dynamic DriveДокумент68 страницBasic Hydro Dynamic DriveAshokОценок пока нет

- Synchroniser 2Документ9 страницSynchroniser 2AshokОценок пока нет

- Synchroniser Ring 1Документ6 страницSynchroniser Ring 1AshokОценок пока нет

- Basics of SynchronizersДокумент78 страницBasics of SynchronizersAnish PaiОценок пока нет

- Catalogo Cny1000Документ1 страницаCatalogo Cny1000humbertoОценок пока нет

- G LIT API-650-Tanks PDFДокумент2 страницыG LIT API-650-Tanks PDFAlexanderОценок пока нет

- DNV-CG-0037 2021-11Документ74 страницыDNV-CG-0037 2021-11wfxОценок пока нет

- Cosfb - Composite Slim-Floor Beam: Experimental Test Campaign and EvaluationДокумент15 страницCosfb - Composite Slim-Floor Beam: Experimental Test Campaign and EvaluationDima OvsiiОценок пока нет

- Keep 316Документ68 страницKeep 316AdityaОценок пока нет

- Electric Drives Nen 701Документ2 страницыElectric Drives Nen 701sriharshitha vegesnaОценок пока нет

- Engg MechanicsДокумент284 страницыEngg Mechanicsmukesh_mlbОценок пока нет

- Fiitjee: Answers, Hints & SolutionsДокумент10 страницFiitjee: Answers, Hints & SolutionsZayanmalikОценок пока нет

- List of IllustrationsДокумент12 страницList of IllustrationsJorge LopesОценок пока нет

- MC 10168039 0001 PDFДокумент12 страницMC 10168039 0001 PDFLuis Pirry MejíaОценок пока нет

- Part Number Per 1 Maret 13Документ266 страницPart Number Per 1 Maret 13Muhammad FaridОценок пока нет

- Beam Design CalculationДокумент3 страницыBeam Design Calculationgovind narayan ShuklaОценок пока нет

- Elder Equipments PVTДокумент7 страницElder Equipments PVTGeorge GОценок пока нет

- SB MV FourWayCassette2x2 ARNU053TRD4Документ2 страницыSB MV FourWayCassette2x2 ARNU053TRD4Giann CarlosОценок пока нет

- Service N ValveДокумент30 страницService N ValvesenamotoОценок пока нет

- Models - Mbd.washing Machine Vibration PDFДокумент36 страницModels - Mbd.washing Machine Vibration PDFgf-antaresОценок пока нет

- Tutorial 11 - MS3220 Rekayasa Termal (Mark Scheme)Документ6 страницTutorial 11 - MS3220 Rekayasa Termal (Mark Scheme)i need documentsОценок пока нет

- COMPRESOR Powerex Scroll Sed-Set-Seq (1) Sistema ExistenteДокумент2 страницыCOMPRESOR Powerex Scroll Sed-Set-Seq (1) Sistema ExistenteCAROLINA MONGUIОценок пока нет

- Steer Epz ProductsДокумент40 страницSteer Epz ProductsReha YelkenОценок пока нет

- Solar Energy Week 8 Assignment (Due: November 13)Документ3 страницыSolar Energy Week 8 Assignment (Due: November 13)batlax0000Оценок пока нет