Академический Документы

Профессиональный Документы

Культура Документы

Materials Selection Guide Aluminia

Загружено:

Hardik AcharyaАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Materials Selection Guide Aluminia

Загружено:

Hardik AcharyaАвторское право:

Доступные форматы

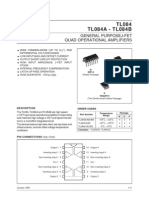

MATERIAL

SELECTION

GUIDE

ALUMINA

(92%)

ALUMINA

(94%)

ALUMINA

(96%)

ALUMINA

(99.5%)

ALUMINA

(99.5%)

TOUGHENED

ALUMINA

ZIRCONIA TITANIA STEATITE STEATITE

Properties Units ASTM Alotec 92 771 614 838 975 977 848 192 645 665

Density g/cc C373 3.65 3.6 3.7 3.9 3.9 4.0 6.0 4.0 2.7 2.8

Hardness HV 0.5 C1327 1300 1200 1350 1700 1700 1600 1150 800 450 420

Flexural Strength MPa (k PSI) C1161 240 (34.8) 290 (42) 296 (43) 310 (45) 305 (45) 448 (65) 752 (109) 138 (20) 131 (19) 145 (21)

Fracture Toughness MPa*m

1/2

C1421 5 3 4 4 4 4 10 3 NA NA

Youngs Modulus GPa (*10

6

PSI) C1259 300 (44) 289 (42) 303 (44) 372 (54) 376 (54) 186 (27) 227 (33) 108 (16) 112 (16)

Shear Modulus GPa (*10

6

PSI) C1259 120 (17) 121 (17.5) 127 (18.5) 152 (22.0) 152 (22.0) 80 (11.6) 90 (13.0) 43 (6.3) 45 (6.5)

Poisson C1259 0.24 0.21 0.21 0.21 0.21 0.33 0.27 0.23 0.25

Thermal Expansion *10

-6

/C E228

300C 7.0 6.6 6.5 6.8 6.7 7.9 8.3 8.2 6.9

700C 7.3 7.6 7.6 7.9 7.8 8.5 10.0 9.0 8.9 7.8

1000C 7.5 8.2 8.1 8.3 8.2 9.6 11.0 9.0 9.4 8.0

Thermal Conductivity @ 25C W/m-K E1461 21.0 21.0 24.0 30.0 30.0 25.0 2.7 11.9 5.5 5.9

Volume Resistivity ohm-cm D257 >e

14

>e

14

>e

14

>e

14

>e

14

3.6E+13 >e

12

>e

14

>e

14

Specic Heat J/g-K E1461 0.96 0.8 1.1 0.8 0.8 0.7 0.4 0.7 1.1 1.1

Dielectric Strength volts/mil D149 200 210 230 220 200 100 210 230

Dielectric Constant @ 1MHz D150 9.0 9.3 9.8 9.8 3.7 28 85 5.8 6.1

Dissipation Factor @ 1MHz D150 9.0E-04 3.0E-04 3.0E-04 1.0E-04 1.0E-04 4.5E-04 5.0E-04 1.9E-03 8.0E-04

Loss Factor @ 1MHz D150 3.0E-03 3.0E-03 1.0E-03 1.0E-03 1.1E-02 5.0E-03

Aluminas

Aluminas exhibit good mechanical properties such as

hardness, compressive and tensile strength, and elastic

modulus. They perform well at elevated temperatures.

Alotec 92 (92%) offers excellent abrasion resistance due to

its controlled grain size and microstructure. Its high density

and chemical composition also give it a greater impact

resistance than many other ceramics. This combination of

superior wear and impact resistance provides a cost saving

solution by having less down time and maintenance costs.

771 (94%) is an alumina ceramic with good electrical and

mechanical properties. It is easily metalized by the moly process.

614 (96%) is a high-strength alumina with good mechanical

properties, as well as good wear and chemical resistance. It

also features excellent electrical properties.

975 (99.5%) offers unique technology by virtue of its optimal

dispersion of the MgO phase with the alumina grains. With

virtually no transgranular porosity in its microstructure, 975

exhibits high density, superior wear resistance, and moderate

exural strength. Another advantage is its highly uniform

white color compared to conventional 99.5% aluminas.

The materials white color remains consistent under either

reducing or oxidizing conditions.

Steatites

Steatites used in place of aluminas are a cost-effective way to

meet performance requirements. They are easier to form and

re at lower temperatures.

645 L423C has good mechanical and electrical properties.

665 L523C has low dielectric loss. It makes excellent insulators

for radio frequency applications.

Toughened Alumina

977 is a zirconia toughened alumina ceramic which was

designed for use in ballistic and ceramic armor applications.

Titania

192 is an excellent material for textile and other structural

applications, where superior surface nishes are required with

high chemical resistance.

Zirconia

848 TZP (yellow) is recommended for applications where

high fracture toughness is required, with higher elastic

modulus.

STANDARD MATERIAL SPECIFICATION

All statements, technical information, and recommendations contained herein are based on tests we believe to be reliable, but the accuracy or completeness thereof is not guaranteed. Before using or purchasing any product described herein, the user shall determine the suitability of the product for its intended use; the user shall assume

all risks and liabilities whatsoever in connection with the use of such products.

Note: All purities percentages are nominal.

CeramTec North America Corporation

One Technology Place

Laurens, SC 29360-0089 USA

Phone: +1.864.682.3215

Fax: +1.864.682.1140

sales@ceramtec.com

www.ceramtec.com

Вам также может понравиться

- Volume Tank Sizing For Shutdown Valve ActuatorДокумент2 страницыVolume Tank Sizing For Shutdown Valve ActuatorHardik Acharya100% (1)

- DSMTS 0005 3 AlOДокумент4 страницыDSMTS 0005 3 AlOSimanchal KarОценок пока нет

- GS 126-5 PDFДокумент26 страницGS 126-5 PDFHardik Acharya100% (1)

- Accelerator Techniques: Chapter - 4Документ21 страницаAccelerator Techniques: Chapter - 4Joyal Jain100% (4)

- PLL & DLL Design in Simulink MatlabДокумент35 страницPLL & DLL Design in Simulink MatlabKartik Pal100% (1)

- RO3000 Pour Rogers 3006 PDFДокумент4 страницыRO3000 Pour Rogers 3006 PDFTeddy112Оценок пока нет

- Dymonic 100 Data SheetДокумент2 страницыDymonic 100 Data SheetDavid LuongОценок пока нет

- Alucoworld E CatalogueДокумент22 страницыAlucoworld E CatalogueRicardo Miguel Ayllon CamachoОценок пока нет

- 3M Scotch 50 51 Data SheetДокумент4 страницы3M Scotch 50 51 Data SheetPedro Francisco Hernandez MendozaОценок пока нет

- Hermes Catalog ENДокумент40 страницHermes Catalog ENTran Quoc Thinh - M&EОценок пока нет

- Mak Amocam: Premium Quality High Viscosity Index, Extreme Pressure Oils For Industrial GearsДокумент2 страницыMak Amocam: Premium Quality High Viscosity Index, Extreme Pressure Oils For Industrial Gearschandan sahooОценок пока нет

- Silicone Rubber Cold Shrink Connector Insulators 8440 SeriesДокумент4 страницыSilicone Rubber Cold Shrink Connector Insulators 8440 SerieshendrabudimanОценок пока нет

- Rogers Corp Product Selector GuideДокумент3 страницыRogers Corp Product Selector GuideGeorgios SarrisОценок пока нет

- PolykenYG IIIДокумент2 страницыPolykenYG IIISenthilkumar NarayananОценок пока нет

- Standard Geotextiles Iss 06 Group Product Data Sheet 1Документ2 страницыStandard Geotextiles Iss 06 Group Product Data Sheet 1Naufal IhsanОценок пока нет

- RT Duroid 6006 6010 Laminate Data SheetДокумент2 страницыRT Duroid 6006 6010 Laminate Data SheetdrhammoudaОценок пока нет

- Acp Alcolite Tds F 314Документ5 страницAcp Alcolite Tds F 314adjisetiaОценок пока нет

- Vanpanel Wall: External and Internal SheetДокумент3 страницыVanpanel Wall: External and Internal SheetMl JainОценок пока нет

- Polycarbonate Glazing SystemДокумент16 страницPolycarbonate Glazing SystemGirish DhawanОценок пока нет

- FRF Slabs: Rigid BoartdДокумент16 страницFRF Slabs: Rigid BoartdAmal RajОценок пока нет

- Halene - H : Technical Data SheetДокумент1 страницаHalene - H : Technical Data SheetDaya Shanker PalОценок пока нет

- Aluminum HoneycombДокумент8 страницAluminum HoneycombManoj ManoharanОценок пока нет

- Aludream Brochure-2018Документ16 страницAludream Brochure-2018mincho4104Оценок пока нет

- Prorox WM 960 Sa PDFДокумент1 страницаProrox WM 960 Sa PDFr afriantoОценок пока нет

- Material Product Data Sheet Pure Aluminum Thermal Spray WiresДокумент4 страницыMaterial Product Data Sheet Pure Aluminum Thermal Spray WiresМихаил ИвахновОценок пока нет

- Schaeffer # 229Документ3 страницыSchaeffer # 229Ingeniero aicОценок пока нет

- Incoloy Alloy 825Документ4 страницыIncoloy Alloy 825Roman PaduaОценок пока нет

- Rubber Mastic and Sealant Tapes PDFДокумент18 страницRubber Mastic and Sealant Tapes PDFNikhil MathewОценок пока нет

- Mobil DTE 10 Excel SeriesДокумент3 страницыMobil DTE 10 Excel SeriesSuprastowo Bin SarinoОценок пока нет

- Prorox WM 950 SaДокумент1 страницаProrox WM 950 SaHanief AnsharОценок пока нет

- Insulation Selection Guide IIG-902Документ2 страницыInsulation Selection Guide IIG-902surawutwijarnОценок пока нет

- Ac-700 SpecificationДокумент10 страницAc-700 SpecificationTarek Abuzene100% (1)

- L111 SMCДокумент0 страницL111 SMCozy1979Оценок пока нет

- CuClad Laminates Data SheetДокумент4 страницыCuClad Laminates Data SheetDenis CarlosОценок пока нет

- Alucoworld E CatalogueДокумент22 страницыAlucoworld E Cataloguepyer odeОценок пока нет

- Katalog Inkalum 8 SeptemberДокумент101 страницаKatalog Inkalum 8 Septemberpurwanto budi prasetioОценок пока нет

- Ferri Um S 53 Carpenter Data SheДокумент2 страницыFerri Um S 53 Carpenter Data SherohithvijayakumarrОценок пока нет

- LR-C-VentureClad Catalogue 01Документ16 страницLR-C-VentureClad Catalogue 01himanshu desaiОценок пока нет

- 400 SeriesДокумент37 страниц400 SeriesShashank SaxenaОценок пока нет

- Stabilized Ferritic Stainless Steel: General CharacteristicsДокумент37 страницStabilized Ferritic Stainless Steel: General CharacteristicsBina Niaga MultiusahaОценок пока нет

- 2017 Kynar Wire and Cable SolutionsДокумент8 страниц2017 Kynar Wire and Cable SolutionsKaarthicNatarajanОценок пока нет

- TECASTVEKTONДокумент2 страницыTECASTVEKTONJonathan CruzОценок пока нет

- TECASINT 5000 - Cost-Effective Polyimide Types For The Semiconductor IndustryДокумент2 страницыTECASINT 5000 - Cost-Effective Polyimide Types For The Semiconductor Industryluciano_gularteОценок пока нет

- 2013 CCD Material ChartsДокумент18 страниц2013 CCD Material ChartsRegi Octa PerdanaОценок пока нет

- FMC - Novolastic Subsea Thermal Insulation - LOW RESДокумент3 страницыFMC - Novolastic Subsea Thermal Insulation - LOW RESalphading50% (2)

- Raychem Spec 44Документ8 страницRaychem Spec 44zakariiОценок пока нет

- Therm A Gap FillingДокумент9 страницTherm A Gap Fillingbakri10101Оценок пока нет

- 3M Cold Shrink Pre-Stretched Tubes Silicone RubberДокумент4 страницы3M Cold Shrink Pre-Stretched Tubes Silicone RubberJovelino SimãoОценок пока нет

- Steel AlloyДокумент4 страницыSteel AlloyRuffy OiraОценок пока нет

- Engineering Materials Data SheetДокумент6 страницEngineering Materials Data Sheetrajarao1234Оценок пока нет

- Controlled Volatility RTV Ablative Silicone: Description ApplicationДокумент3 страницыControlled Volatility RTV Ablative Silicone: Description ApplicationLU CHUNHUIОценок пока нет

- RW Ti Pds Prorox WM 968 Astm IndiaДокумент1 страницаRW Ti Pds Prorox WM 968 Astm IndiaMd Farid AhmedОценок пока нет

- Silicone Foam: Phucat Co.,Ltd - Moonphin Adhesive TapeДокумент2 страницыSilicone Foam: Phucat Co.,Ltd - Moonphin Adhesive TapeTran Tuan anhОценок пока нет

- CanadOil CladДокумент2 страницыCanadOil CladsuparnaОценок пока нет

- High Frequency Laminates - Product Selector Guide and Standard Thicknesses and Tolerances Low Resolution PDFДокумент12 страницHigh Frequency Laminates - Product Selector Guide and Standard Thicknesses and Tolerances Low Resolution PDFrahul05singhaОценок пока нет

- 275 287Документ14 страниц275 287Anonymous I7dJ0lmdОценок пока нет

- Aluminum Oxide - Al2O3 Material PropertiesДокумент3 страницыAluminum Oxide - Al2O3 Material PropertiesRing MasterОценок пока нет

- Capacitor Tantalio SMT 1206KEM T2005 T491Документ24 страницыCapacitor Tantalio SMT 1206KEM T2005 T491Jeziel Vazquez NavaОценок пока нет

- Shell Omala Oil 320 Eng M0010Документ2 страницыShell Omala Oil 320 Eng M0010Ady MihailaОценок пока нет

- Arc Insulations BrochureДокумент5 страницArc Insulations BrochureacompositesОценок пока нет

- Data Sheet Polyken 980 & 955Документ4 страницыData Sheet Polyken 980 & 955Teguh SilaОценок пока нет

- RT Duroid 6006 6010 Laminate Data SheetДокумент2 страницыRT Duroid 6006 6010 Laminate Data SheetSaravanakumar SermarajaОценок пока нет

- Corrosion Testing for Metal Finishing: Institute of Metal FinishingОт EverandCorrosion Testing for Metal Finishing: Institute of Metal FinishingОценок пока нет

- Atmospheric Storage Tanks: 11-1-1 BP Oil Co. RPДокумент54 страницыAtmospheric Storage Tanks: 11-1-1 BP Oil Co. RPHardik AcharyaОценок пока нет

- Atmospheric Data Sheet Storage Tanks: 11-1-1 DS BP Oil Co. RPДокумент6 страницAtmospheric Data Sheet Storage Tanks: 11-1-1 DS BP Oil Co. RPHardik AcharyaОценок пока нет

- Tema Shell and Tube Heat Exchangers: 8-1-1 BP Oil Co. RPДокумент25 страницTema Shell and Tube Heat Exchangers: 8-1-1 BP Oil Co. RPHardik AcharyaОценок пока нет

- GS 118-3 PDFДокумент12 страницGS 118-3 PDFHardik AcharyaОценок пока нет

- General Piping Design: 5-1-1 BP Oil Co. RPДокумент27 страницGeneral Piping Design: 5-1-1 BP Oil Co. RPHardik AcharyaОценок пока нет

- Steam Traps: 5-11-2 BP Oil Co. RPДокумент14 страницSteam Traps: 5-11-2 BP Oil Co. RPHardik AcharyaОценок пока нет

- XH5 Hydraulic Wellhead Control Panel Manual 2018aДокумент12 страницXH5 Hydraulic Wellhead Control Panel Manual 2018aHardik Acharya100% (1)

- GS 140-3Документ13 страницGS 140-3Hardik Acharya0% (1)

- Wellheads and Christmas Trees - Is There A DifferenceДокумент8 страницWellheads and Christmas Trees - Is There A DifferenceHardik AcharyaОценок пока нет

- Level Transmitter - DP Type: by Ganesh PolДокумент25 страницLevel Transmitter - DP Type: by Ganesh PolHardik Acharya100% (1)

- Americas Gland CatalogueДокумент36 страницAmericas Gland CatalogueHardik AcharyaОценок пока нет

- Safety Integrity LevelДокумент4 страницыSafety Integrity LevelHardik AcharyaОценок пока нет

- Zyqad EquipmentДокумент29 страницZyqad EquipmentHardik AcharyaОценок пока нет

- Valves Terminology and SymbolsДокумент1 страницаValves Terminology and SymbolsHardik AcharyaОценок пока нет

- KLINGERsilC-4500 Gasket MaterialДокумент2 страницыKLINGERsilC-4500 Gasket MaterialHardik AcharyaОценок пока нет

- F&G 3D MarkupДокумент5 страницF&G 3D MarkupHardik AcharyaОценок пока нет

- MDS Metro Pocket GuideДокумент1 страницаMDS Metro Pocket GuideHardik AcharyaОценок пока нет

- Control ValvesДокумент95 страницControl ValvesHardik Acharya100% (1)

- List of Standards - InstrumentationДокумент3 страницыList of Standards - InstrumentationHardik Acharya100% (1)

- Solar Energy SystemДокумент19 страницSolar Energy Systemanup chauhanОценок пока нет

- Optoelectronic Devices SyllabusДокумент1 страницаOptoelectronic Devices SyllabusRAJESHОценок пока нет

- Chapter 15 Cooling of Electronic Equipment Hkmuu RybtgnoДокумент10 страницChapter 15 Cooling of Electronic Equipment Hkmuu Rybtgnosmith jekysОценок пока нет

- Study of Reactive Power CompensationДокумент15 страницStudy of Reactive Power CompensationpraneethОценок пока нет

- Operating Instructions SubracksДокумент21 страницаOperating Instructions SubracksOma Ouali50% (2)

- BC556B, BC557A, B, C, BC558B Amplifier Transistors: PNP SiliconДокумент9 страницBC556B, BC557A, B, C, BC558B Amplifier Transistors: PNP SiliconoridecomОценок пока нет

- TL084Документ11 страницTL084Jose Adrian MarquezОценок пока нет

- NOC Error CorrectionДокумент7 страницNOC Error CorrectionNavin KumarОценок пока нет

- V270SДокумент2 страницыV270SlainstanОценок пока нет

- Three-Port Rectifier-Based AC-DC Power Converters With Sigma Architecture and Reduced Conversion StagesДокумент10 страницThree-Port Rectifier-Based AC-DC Power Converters With Sigma Architecture and Reduced Conversion StagesifyОценок пока нет

- Telwin Technika 145 165 200 BДокумент12 страницTelwin Technika 145 165 200 BDennis Xenos100% (3)

- 8na50 N - ChannelДокумент10 страниц8na50 N - Channeladda chariОценок пока нет

- 052 MMIC DesignДокумент4 страницы052 MMIC DesignSupriya PrabhakarОценок пока нет

- Wire Fuse and SwitchДокумент47 страницWire Fuse and SwitchMacy RiegoОценок пока нет

- Part 7.0 - List of Testing Services - AD (19.05.2016)Документ28 страницPart 7.0 - List of Testing Services - AD (19.05.2016)Anonymous G6ceYCzwtОценок пока нет

- An Overview of NASA Automotive Component Reliability StudiesДокумент37 страницAn Overview of NASA Automotive Component Reliability StudiesKent WaiОценок пока нет

- Wiring Diagram: UMO Shield 1.5.7 Picture by UltimakerДокумент2 страницыWiring Diagram: UMO Shield 1.5.7 Picture by UltimakerGonzalo GarciaОценок пока нет

- GBD26KS La26r71b GBD32KS La32r71b GBD40KS La40r71b GBD32KS La32r71wДокумент177 страницGBD26KS La26r71b GBD32KS La32r71b GBD40KS La40r71b GBD32KS La32r71wARTMehr Eng. GroupОценок пока нет

- Specially Time Delay RelaysДокумент8 страницSpecially Time Delay RelaysMohammad HosseinОценок пока нет

- Automatic Pneumatic Bumper System For Four WheelerДокумент33 страницыAutomatic Pneumatic Bumper System For Four WheelerRaj EndranОценок пока нет

- Modelling and Simulation of High Step Up DC To AC Converter For Microsource ApplicationДокумент5 страницModelling and Simulation of High Step Up DC To AC Converter For Microsource ApplicationtheijesОценок пока нет

- Project of Dcs 1Документ13 страницProject of Dcs 1Pranil KambleОценок пока нет

- Nema Ics 19-2002 (R2007, R2011, R2016) WatermarkedДокумент43 страницыNema Ics 19-2002 (R2007, R2011, R2016) WatermarkedJesus SalazarОценок пока нет

- Self Cleaning GlassДокумент2 страницыSelf Cleaning GlassAnOnYmOuS_1995Оценок пока нет

- Multisim Diode IV CharacteristicДокумент10 страницMultisim Diode IV CharacteristicNelson WongОценок пока нет

- LD7530M/LD7530N: Green-Mode PWM Controller With Programmable OLP Delay Time and Integrated ProtectionsДокумент20 страницLD7530M/LD7530N: Green-Mode PWM Controller With Programmable OLP Delay Time and Integrated Protectionsmauricio alfonsoОценок пока нет

- Advantages of Computer-Based Processing (5 Files Merged)Документ45 страницAdvantages of Computer-Based Processing (5 Files Merged)Simple FunОценок пока нет