Академический Документы

Профессиональный Документы

Культура Документы

Generación de Biogas de Aguas Residuales y Rellenos Sanitarios PDF

Загружено:

bvfernandoИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Generación de Biogas de Aguas Residuales y Rellenos Sanitarios PDF

Загружено:

bvfernandoАвторское право:

Доступные форматы

3

rd

BFC NET Workshop Site visit

Regional wastewater treatment plant LINZ

21.01.2005

Structure of Linz AG

Services provided by

Linz Service GmbH

Fresh water

Waste water / sewerage system and treatment

plant

Waste management / refuse disposal all types

Habour

Public swimming pools

Funeral and cemetery

Technical Services

IWA / physical, chemical and biological water

laboratory

Business unit of waste water

1. Sewerage system

Collection and diversion of all waste water (residents,

industries and business) for the City of Linz, operation and

maintenance

2. Serwerage planning

Engineering, services for surrounding communities

3. Regional waste water treatment plant

The treatment and handling of waste water and sludge for

the City of Linz, the 39 surrounding communities and

10 large industries

4. Customer relations

Tariffs, professional advice and expertise

Waste water treatment plant

Catchment area

Linz +

39 surrounding

communities

+ 10 industries

Consisting of

Sewers 551 km

16 pumping stations

3 rain retention basins

2 CSO`s

Sewerage system

Waste water treatment plant

The plant overviews

Pictures: waste water treatment plant Asten

0 25m 50m

KULTURTECHNIK UND WASSERWIRTSCHAFT

MASCHINENBAU (VERFAHRENSTECHNIK)

A-1030 WIEN, Fasangasse 25, Tel.:+43/1/7982400-0, Fax:-55

Waste water treatment plant

Waste water treatment plant

Capacity

- Population equivalent 950.000 pe

- Hydraulic capacity:

- Dry weather flow: 2.2 m

3

/s

- Max wet weather flow: 8.8 m

3

/s

- Average annual flow: 60 Mio m

3 /

a

Mechanical biological waste water treatment technique

- Active sludge system

- carbon+nitrogen+phosphorus removal

- Anaerobic sludge digestion

- Sludge dewatering by chamber filter press

- Sludge disposal in mono-landfill

- Biogas ( landfill digester ) use in co-generation units

Waste water treatment plant

Mechanical equipment of the treatment plant

Pictures: mechanical equipments

Sludge Digestion

Digester

- 3 digester

- total volume 31.200 m

- amount of digester sludge 1.000 m/d, 3 - 3,5 % TS

- Retention time 30 d, 37 C

Gas storage/mixing tank

- volume 5.500 m

Gas produktion

- Approx. 15.000 m

3

/d, 64 % CH

4

Municipal landfill site

Biogas system

- 36 Biogas wells, ( Suction side p = - 80 -150 mbar )

- 3 blower/compressors ( max 1.800 m

3

/h )

- Gas purification plant ( out of operation )

- Volume landfill site 3.200.000 m

Gas produktion/collection

- Approx. 18.600 m

3

/d, 43 % CH

4

Power station

Co generation units

- 7 Co generation units

- Electrical power 650 kW

- Total electrical power 4.550 kW

- Average production efficiency approx. 34 %

Energy production/use summary

Energy Balance ( 2004 ):

Co-Generation of Biogases from

- sludge digestion ( 5.5 mil. m

3

/a, 64 % CH

4

)

- municipal landfill site ( 6.8 mil. m

3

/a, 45 % CH

4

)

Total Production:

- 21 GWh / a - efficiency approx: 34 %

Own consumption for waste water treatment plant:

- 14 GWh / a

Excess production, feed into public power net:

- 7 GWh / a

Heat balance

Heat ( 2004 )

- Total capacity ( heat exchanger ) approx. 25.700.000 kWh/a

- Consumption of digester approx. 10.500.000 kWh/a

- Consumption hot water approx. 200.000 kWh/a

- Consumption heating approx. 1.000.000 kWh/a

- Ratio heat used related to heat exchanger capacity 45 %

Operational problems

Siloxanes within biogases

- from landfill approx. 15 mg Si / Nm

3

- from digester approx. 3 mg Si / Nm

3

Leads to Silicium precipitation/deposits within the Co generation units

Operational problems

Operational problems

Operational problems

Measures ( Study in preparation )

- Intensive maintenance procedure

Or

- activated carbon process for gas cleaning

Costs

Over all costs ( incl. building ): 7 Cent / kWh

el

produced

from that:

Maintenance costs incl. ( Material/Personal costs ) : 2 Cent / kWh

el

produced

Вам также может понравиться

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Allan ToddДокумент28 страницAllan ToddBilly SorianoОценок пока нет

- Low Cost Building ConstructionДокумент15 страницLow Cost Building ConstructionAtta RehmanОценок пока нет

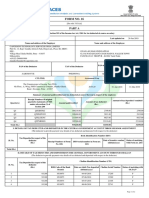

- Form16 2018 2019Документ10 страницForm16 2018 2019LogeshwaranОценок пока нет

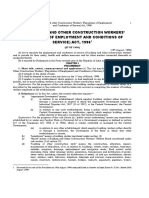

- Building and Other Construction Workers Act 1996Документ151 страницаBuilding and Other Construction Workers Act 1996Rajesh KodavatiОценок пока нет

- Social Media Marketing Advice To Get You StartedmhogmДокумент2 страницыSocial Media Marketing Advice To Get You StartedmhogmSanchezCowan8Оценок пока нет

- Information Security Chapter 1Документ44 страницыInformation Security Chapter 1bscitsemvОценок пока нет

- IPO Ordinance 2005Документ13 страницIPO Ordinance 2005Altaf SheikhОценок пока нет

- Binary File MCQ Question Bank For Class 12 - CBSE PythonДокумент51 страницаBinary File MCQ Question Bank For Class 12 - CBSE Python09whitedevil90Оценок пока нет

- Abu Hamza Al Masri Wolf Notice of Compliance With SAMs AffirmationДокумент27 страницAbu Hamza Al Masri Wolf Notice of Compliance With SAMs AffirmationPaulWolfОценок пока нет

- CIR Vs PAL - ConstructionДокумент8 страницCIR Vs PAL - ConstructionEvan NervezaОценок пока нет

- Heavy LiftДокумент4 страницыHeavy Liftmaersk01Оценок пока нет

- Cic Tips Part 1&2Документ27 страницCic Tips Part 1&2Yousef AlalawiОценок пока нет

- Level 3 Repair: 8-1. Block DiagramДокумент30 страницLevel 3 Repair: 8-1. Block DiagramPaulo HenriqueОценок пока нет

- Convention On The Rights of Persons With Disabilities: United NationsДокумент13 страницConvention On The Rights of Persons With Disabilities: United NationssofiabloemОценок пока нет

- Catalogo AWSДокумент46 страницCatalogo AWScesarОценок пока нет

- Research Article: Finite Element Simulation of Medium-Range Blast Loading Using LS-DYNAДокумент10 страницResearch Article: Finite Element Simulation of Medium-Range Blast Loading Using LS-DYNAAnonymous cgcKzFtXОценок пока нет

- Mat Boundary Spring Generator With KX Ky KZ KMX KMy KMZДокумент3 страницыMat Boundary Spring Generator With KX Ky KZ KMX KMy KMZcesar rodriguezОценок пока нет

- Expectation Vs Reality: Job Order and Contract of ServiceДокумент10 страницExpectation Vs Reality: Job Order and Contract of ServiceMikee Louise MirasolОценок пока нет

- PCДокумент4 страницыPCHrithik AryaОценок пока нет

- XgxyДокумент22 страницыXgxyLïkïth RäjОценок пока нет

- Republic of The Philippines National Capital Judicial Region Regional Trial Court Manila, Branch 1Документ4 страницыRepublic of The Philippines National Capital Judicial Region Regional Trial Court Manila, Branch 1brendamanganaanОценок пока нет

- PeopleSoft Application Engine Program PDFДокумент17 страницPeopleSoft Application Engine Program PDFSaurabh MehtaОценок пока нет

- Shubham Tonk - ResumeДокумент2 страницыShubham Tonk - ResumerajivОценок пока нет

- Continue: Rudolf Bultmann Theology of The New Testament PDFДокумент3 страницыContinue: Rudolf Bultmann Theology of The New Testament PDFpishoi gerges0% (1)

- T1500Z / T2500Z: Coated Cermet Grades With Brilliant Coat For Steel TurningДокумент16 страницT1500Z / T2500Z: Coated Cermet Grades With Brilliant Coat For Steel TurninghosseinОценок пока нет

- Separation PayДокумент3 страницыSeparation PayMalen Roque Saludes100% (1)

- Epidemiologi DialipidemiaДокумент5 страницEpidemiologi DialipidemianurfitrizuhurhurОценок пока нет

- Banjara EmbroideryДокумент34 страницыBanjara EmbroideryKriti Rama ManiОценок пока нет

- TEVTA Fin Pay 1 107Документ3 страницыTEVTA Fin Pay 1 107Abdul BasitОценок пока нет

- CodebreakerДокумент3 страницыCodebreakerwarrenОценок пока нет