Академический Документы

Профессиональный Документы

Культура Документы

Liquid Hold Up Change and Slug Catcher Sizing

Загружено:

Ebby OnyekweИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Liquid Hold Up Change and Slug Catcher Sizing

Загружено:

Ebby OnyekweАвторское право:

Доступные форматы

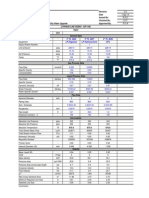

247859214.xls.

ms_office

Overview

This standard calculation spreadsheet is based on the paper "Condensate flow in wet-gas lines can be predicted", R.S. Cunliffe, Oil and Gas Journal, Oct 30, 1978.

The first part of this standard calculation spreadsheet uses Eaton's correlation to estimate liquid holdup in wet-gas pipelines for pressures up to 1500 psig, which traverse relatively

flat topography. Liquid holdup volumes calculated here for initial and final flowrates, can be used in the second part of the spreadsheet. Alternatively a more accurate method of

calculating liquid holdup may be to use a simulation program such as PIPESIM.

The second part of the spreadsheet uses the Cunliffe method to predict the volume of held up liquid that will be displaced and the time taken to displace it (and hence liquid flow

rate), resulting from a gas flow rate change. This is used to estimate the slug catcher holdup volume required.

Data to be input is in blue, calculated values are in black.

Eaton's Correlation

Eaton's correlation can be used to estimate liquid holdup in wet-gas pipelines for pressures up to 1500 psig, which traverse relatively flat topography.

This part of the spreadsheet can be used to estimate liquid holdup in the pipeline for initial steady state gas/liquid flow rates and then again for final steady state gas/liquid flow

rates.

Maximum and minimum flow rates should be used as these will give the greatest difference in liquid holdup and the most conservative amount of liquid that will be displaced due

the flow rate change.

The two liquid holdup values obtained from this part of the spreadsheet can be used in the second part of the spreadsheet, or alternatively values obtained from a program such as

PIPESIM can be used, which may be more accurate.

Slugcatcher sizing based on the Cunliffe method

1. Enter the initial and final steady state gas flow rates that the pipeline and downstream plant will see. Maximum and minimum values should be used to provide a conservative

sizing bases for the slug catcher.

2. Enter the calculated condensate holdup for the initial and final steady state gas flow rates. These can be calculated in the Eaton's correlation part of the spreadsheet or from a

program such as PIPESIM.

3. Enter the initial and final average condensate flow rates at the initial and final steady state gas flow rates.

4. The initial and final condensate/gas ratios are calculated.

5. Enter the initial and final average water flow rates at the initial and final gas flow rates. These may be zero if water has been included as part of the condensate flowrates.

6.The initial and final total liquid flow rates are calculated.

7. The initial and final liquid residence times are calculated based on the liquid holdup and the total liquid flowrate.

8. The incremental liquid flow rate is calculated based on the difference in liquid holdup and the final residence time.

9. The transition period flowrate is calculated which is the sum of the incremental flow rate and the final liquid flowrate.

10. Enter the maximum liquid outflow rate from the slug catcher to the plant that can be accommodated.

11. The liquid accumulation that the slug catcher should be designed for is calculated. This is the volume accumulated due to the transition period flow rate less the maximum

liquid outflow rate, for the transition time (final residence time). It assumes that the maximum liquid flow rate from the slug catcher to the plant will be maintained during the

transition period.

PROJ No.

PHASE/CTR

ACTIVITY CALCULATION NUMBER WS-CA-PR-016

PROJECT FILE

SUBJECT SHEET 1 OF 1

REVISION DATE BY CHECKED APP'D REVISION DATE BY CHECKED APP'D

0 25-Jul-03 MMc

Case: Slug catcher onshore for Subsea Wells at Kipper

Holdup calculation based on Eaton's correlation

Pipe internal diameter, D 6 in 152 mm

Pressure, P 400 psia 2758 kPa a

Base press for gas measurements, P

B 14.7 psia 101.4 kPa a

Gas flowrate 250 actual ft

3

/min 0.118 m

3

/s

Superficial gas velocity, V

SG 21.2 ft/s

Liquid flowrate 10 ft

3

/min 0.005 m

3

/s

Superficial liquid velocity, V

SL 0.85 ft/s

Liquid viscosity, 20 cp

Liquid density,

L 55 lb/ft

3

881 kg/m

3

Liquid surface tension, 15 dyne/cm

Liquid velocity influence No. N

LV 2.28

Gas velocity influence No. N

GV 56.91

Pipe diameter influence No. N

D 115.72

Liquid viscosity influence No. N

L 0.152

Correlation parameter, N

E 0.044

Liquid holdup fraction R

L 0.13 valid for approx. 0.006 < N

E

< 0.7

(based on Eaton's correlation)

Pipe length 1.207 km

Approx. liquid holdup in pipe 2.916 m

3

Slug catcher sizing based on the Cunliffe method

Gas Flowrate MMsm

3

/d

MMscf/d

Predicted Liquid Holdup m

3

bbl

Average Condensate Rate m

3

/hr

bbl/hr

Condensate to Gas Ratio (GOR)

Average Water Rate m

3

/hr

bbl/hr

Total Liquid Rate m

3

/hr

bbl/hr

Liquid Residence Time hr

Incremental Liquid Flowrate m

3

/hr

bbl/hr

Transition Period Flowrate m

3

/hr

bbl/hr

Maximum Liquid Outflow Rate m

3

/hr

bbl/hr

Liquid Accumulation m

3

(for slug catcher sizing) bbl 3088

21.1

132.9

129.2

812.9

400.0

108.1

680.1

110

692.3

491

0 0

bbl/MMscf

63.56 108.06

52.0 25.6

0.0 0.0

63.6

64.0 65.3

4.247

3305.12

7.079

250.0

400.0 680.1

LIQUID HOLDUP CHANGE AND SLUG CATCHER SIZING

Initial Final

150.0

(Reference : Condensate flow in Wet-gas Lines Can be Predicted, Cunliffe, Oil and Gas Journal, 30/10/78)

20800

2764.86

17400

Вам также может понравиться

- A New Approach For Sizing Finger Slug CatcherДокумент15 страницA New Approach For Sizing Finger Slug CatcherHaryadiОценок пока нет

- Flare Ko Drum SizingДокумент5 страницFlare Ko Drum SizingSujith Sekar100% (2)

- Seperator Sizing v3Документ5 страницSeperator Sizing v3camasa2011Оценок пока нет

- Relief Valve Calculation For Distillation TowersДокумент5 страницRelief Valve Calculation For Distillation TowersAbhinav Jain100% (1)

- Vertical Knock Out Drum With Wire Mesh For NДокумент1 страницаVertical Knock Out Drum With Wire Mesh For Nteegala_1950% (2)

- Control Valve Sizing - EXXON Calculation MethodДокумент14 страницControl Valve Sizing - EXXON Calculation Methodm0% (1)

- Three Phase Separator Sizing - Overflow WeirДокумент2 страницыThree Phase Separator Sizing - Overflow WeirSaeid Rahimi MofradОценок пока нет

- All Sep CalcДокумент22 страницыAll Sep Calcbharathscds100% (3)

- Horizontal Three Phase Separator vap-IPДокумент5 страницHorizontal Three Phase Separator vap-IPasifhameed1100% (8)

- Spreadsheet To Design SeparatorsДокумент21 страницаSpreadsheet To Design SeparatorsreninbabaskiОценок пока нет

- Vertical Two-Phase Separator Sizing (SI Units) : Client Proj No Project Calc No Subject Sheet OFДокумент4 страницыVertical Two-Phase Separator Sizing (SI Units) : Client Proj No Project Calc No Subject Sheet OFJhonnatan Fredy Gomez DominguezОценок пока нет

- 2 Phase Flow Pressure Drop Calc Suresh1Документ6 страниц2 Phase Flow Pressure Drop Calc Suresh1NKОценок пока нет

- Datasheet For PACE Mist Eliminator/s (Demister) : Existing DetailsДокумент1 страницаDatasheet For PACE Mist Eliminator/s (Demister) : Existing DetailsAnonymous LLLK3pq50% (2)

- Line Sizing Philosophy PDFДокумент21 страницаLine Sizing Philosophy PDFmohammadhadiОценок пока нет

- Column PSV SizingДокумент10 страницColumn PSV SizingbalajikrishnanОценок пока нет

- Slug CatcherДокумент2 страницыSlug CatcherToyinОценок пока нет

- FlareTot - Total Flare AnalysisДокумент8 страницFlareTot - Total Flare AnalysisArjun KapoorОценок пока нет

- 9 - Horizontal Flare Knock Out Drum Sizing1Документ2 страницы9 - Horizontal Flare Knock Out Drum Sizing1Anonymous APc7I7100% (1)

- Line Sizing - 2PHASEДокумент11 страницLine Sizing - 2PHASEEbby Onyekwe100% (1)

- Gas Line SizingДокумент11 страницGas Line SizingEbby OnyekweОценок пока нет

- Separator SizingДокумент11 страницSeparator Sizingmusaveer50% (2)

- Vertical Separator SizingДокумент4 страницыVertical Separator SizingSyed Waqas HaiderОценок пока нет

- The Lease Pumper Testing, Treating, and Selling Crude Oil Section B Methods Used To Treat BS&W B-1. Overview of Treating MethodsДокумент4 страницыThe Lease Pumper Testing, Treating, and Selling Crude Oil Section B Methods Used To Treat BS&W B-1. Overview of Treating Methodsgad48050% (2)

- Three Phase Separator Sizing - Submerged WierДокумент2 страницыThree Phase Separator Sizing - Submerged WierSaeid Rahimi MofradОценок пока нет

- Memoria de Calculo Separadores BifasicosДокумент1 страницаMemoria de Calculo Separadores BifasicosJhonnatan Fredy Gomez DominguezОценок пока нет

- Master - Three Phase Horizontal Separator Rev 0Документ6 страницMaster - Three Phase Horizontal Separator Rev 0Naeem HussainОценок пока нет

- Scenarios in PSV Sizing During Gas BlowbyДокумент94 страницыScenarios in PSV Sizing During Gas BlowbyMiquel Àngel Artiol FerroОценок пока нет

- Gas-Liquid Vertical Separator PDFДокумент2 страницыGas-Liquid Vertical Separator PDFRathish RagooОценок пока нет

- Process Engineer - PSV SizingДокумент3 страницыProcess Engineer - PSV SizingLaorenciaОценок пока нет

- PSV Blocked Fire Relief Valve CasesДокумент21 страницаPSV Blocked Fire Relief Valve CasesTun Naing WinОценок пока нет

- Line Sizing Design Guide, Rev 1Документ24 страницыLine Sizing Design Guide, Rev 1mohsen ranjbarОценок пока нет

- Validated SheetДокумент12 страницValidated SheetrohitkushОценок пока нет

- Gas Blow-By From A Production Separator To Tank PDFДокумент7 страницGas Blow-By From A Production Separator To Tank PDFebby1100% (1)

- Gas Line Size-1Документ12 страницGas Line Size-1svnaik14Оценок пока нет

- CPF-010 Utility Line Sizing Attachment - 0Документ31 страницаCPF-010 Utility Line Sizing Attachment - 0goodspeed_phОценок пока нет

- Pressure Drop and Pipeline Flow CalculatorДокумент1 страницаPressure Drop and Pipeline Flow CalculatorgrabettyОценок пока нет

- Supercritical Fluids PSV SizingДокумент5 страницSupercritical Fluids PSV SizingVikram Singh100% (5)

- Three Phase Separators - Times DefinitionДокумент5 страницThree Phase Separators - Times DefinitionMohsin MohammedОценок пока нет

- Separator CalcsДокумент20 страницSeparator CalcsHoney Tiwari100% (3)

- Warning - Total DP 10% Inlet Pressure! Use Compressible Flow Calculator!Документ2 страницыWarning - Total DP 10% Inlet Pressure! Use Compressible Flow Calculator!Ajay TiwariОценок пока нет

- Three Phase Separators - Times DefinitionДокумент5 страницThree Phase Separators - Times DefinitionaytihdaОценок пока нет

- Relief Valve Sizing - FireДокумент2 страницыRelief Valve Sizing - Firevlcmstne04Оценок пока нет

- PSV 0764 CD Vent KO Drum Liquid Pump - L03Документ3 страницыPSV 0764 CD Vent KO Drum Liquid Pump - L03Ebby OnyekweОценок пока нет

- Vapor Liquid Separator PDFДокумент10 страницVapor Liquid Separator PDFClemenОценок пока нет

- CPF-010 Process Line Sizing Attachment - 0Документ38 страницCPF-010 Process Line Sizing Attachment - 0goodspeed_ph100% (1)

- 3Ph Vert Sep 2010 Weir VerA FPS PDFДокумент5 страниц3Ph Vert Sep 2010 Weir VerA FPS PDFhaiderОценок пока нет

- Rigorously Size Relief Valves For Critical FluidsДокумент10 страницRigorously Size Relief Valves For Critical Fluidsashirwad shetty100% (2)

- of 3-Phase-Separator PDFДокумент25 страницof 3-Phase-Separator PDFD K SОценок пока нет

- Vessel - Vertical Sizing - IPunitsДокумент25 страницVessel - Vertical Sizing - IPunitsAnders FTОценок пока нет

- Slug Catcher Sizing SpreadsheetДокумент14 страницSlug Catcher Sizing Spreadsheetsegunoyes50% (4)

- Elseiver - Liquid LoadingДокумент15 страницElseiver - Liquid LoadingSowmyanarayananОценок пока нет

- LAB #2 Flow Regime Map For Air-Water Two-Phase Flow in A Horizontal PipeДокумент4 страницыLAB #2 Flow Regime Map For Air-Water Two-Phase Flow in A Horizontal PipeTochi Krishna AbhishekОценок пока нет

- LabReport4 322 UploadedДокумент12 страницLabReport4 322 UploadedepsilonnaughtОценок пока нет

- CHAPTER 8 Natural Gas MeasurementДокумент38 страницCHAPTER 8 Natural Gas Measurementfaitholiks841Оценок пока нет

- Lea 1Документ7 страницLea 1vika1301Оценок пока нет

- Pipe Flow HydraulicsДокумент8 страницPipe Flow HydraulicsNeel DodhiaОценок пока нет

- Subsea Engineering Flow Assurance: Hold-Up Flow RegimesДокумент56 страницSubsea Engineering Flow Assurance: Hold-Up Flow RegimesgetmellowОценок пока нет

- Geseran BendalirДокумент9 страницGeseran BendalirYaakub MYОценок пока нет

- HydraulicsДокумент65 страницHydraulicsMohsin EhsanОценок пока нет

- ACS11Документ3 страницыACS11Ebby OnyekweОценок пока нет

- 7405Документ8 страниц7405Ebby OnyekweОценок пока нет

- Restriction Orifice Plate Calculator GasДокумент25 страницRestriction Orifice Plate Calculator GaseshraghianОценок пока нет

- Crude Tower Simulation-HYSYS v8.6Документ42 страницыCrude Tower Simulation-HYSYS v8.6EstrellaОценок пока нет

- What Is Hydrocarbon DewPointДокумент2 страницыWhat Is Hydrocarbon DewPointEbby OnyekweОценок пока нет

- Mooc Sustainable Mobility Example of Working Timetable: 1h 20minДокумент1 страницаMooc Sustainable Mobility Example of Working Timetable: 1h 20minEbby OnyekweОценок пока нет

- Spec Speed PrimerДокумент11 страницSpec Speed PrimerEbby OnyekweОценок пока нет

- Norsok Process Design P100 Edition 3Документ42 страницыNorsok Process Design P100 Edition 3angry_granОценок пока нет

- Pressure Drop CalculationДокумент30 страницPressure Drop CalculationEbby Onyekwe100% (1)

- Ogbuiyi YolandaДокумент13 страницOgbuiyi YolandaEbby OnyekweОценок пока нет

- Book 1Документ2 страницыBook 1Ebby OnyekweОценок пока нет

- Minimum Expense Form 2015-2016: School of Graduate StudiesДокумент2 страницыMinimum Expense Form 2015-2016: School of Graduate StudiesEbby OnyekweОценок пока нет

- Pollutants and Ways To Reduce ThemДокумент1 страницаPollutants and Ways To Reduce ThemEbby OnyekweОценок пока нет

- Nigeria Fact SheetДокумент5 страницNigeria Fact SheetEbby OnyekweОценок пока нет

- 5 Principles of PrayerДокумент4 страницы5 Principles of PrayerEbby OnyekweОценок пока нет

- Joyce University Study Guide Get To Know The ProfessorДокумент3 страницыJoyce University Study Guide Get To Know The ProfessorEbby OnyekweОценок пока нет

- Special Edition, February 2015: 2015 Training and Development GuideДокумент20 страницSpecial Edition, February 2015: 2015 Training and Development GuideEbby OnyekweОценок пока нет

- 1 - Electrostatics - Theory - PDF Module-4Документ28 страниц1 - Electrostatics - Theory - PDF Module-4Raju SinghОценок пока нет

- Basic Electrical Circuits DR Nagendra Krishnapura Department of Electrical Engineering Indian Institute of Technology Madras Lecture - 02Документ4 страницыBasic Electrical Circuits DR Nagendra Krishnapura Department of Electrical Engineering Indian Institute of Technology Madras Lecture - 02Deeban BabuОценок пока нет

- Riemann Hypothesis PDFДокумент19 страницRiemann Hypothesis PDFFlyLove100% (1)

- Htri FileДокумент24 страницыHtri FileEalumalai Muthu100% (1)

- Hydrogen-Induced Cracking Susceptibility in High-Strength Weld MetalДокумент6 страницHydrogen-Induced Cracking Susceptibility in High-Strength Weld MetalgrandecaciqueОценок пока нет

- Sample Midterm Physics 130Документ9 страницSample Midterm Physics 130Peter LiОценок пока нет

- Amplifier Frequency ResponseДокумент33 страницыAmplifier Frequency ResponseHidayah HadiОценок пока нет

- Activities 6Документ4 страницыActivities 6Zenith DebbarmaОценок пока нет

- Year 9 Chemistry LOF WorkbookДокумент47 страницYear 9 Chemistry LOF WorkbookHailey CaruanaОценок пока нет

- Direct Torque Control Scheme For Dual-Three-Phase Induction MotorДокумент8 страницDirect Torque Control Scheme For Dual-Three-Phase Induction Motorcoyote533Оценок пока нет

- Microwave Spectroscopy BSc-Lect-2-1Документ43 страницыMicrowave Spectroscopy BSc-Lect-2-1Varun JogiОценок пока нет

- Portable Vibration CalibratorДокумент23 страницыPortable Vibration CalibratorNovato300% (1)

- Polarity of MoleculesДокумент35 страницPolarity of Moleculesmarizel salcedoОценок пока нет

- Exercises Section6Документ21 страницаExercises Section6hhhОценок пока нет

- Chapt21 Lecture1Документ25 страницChapt21 Lecture1baig79Оценок пока нет

- Redox ReactionsДокумент25 страницRedox Reactionsregis100% (1)

- Internship Final Report - Applications of Quantum MechanicsДокумент11 страницInternship Final Report - Applications of Quantum MechanicsMuhammad HareesОценок пока нет

- Chap3 - Chemical Bonding and Molecular Structure NotesДокумент74 страницыChap3 - Chemical Bonding and Molecular Structure NotesManit RubiksОценок пока нет

- Cambridge International AS & A Level: Further Mathematics 9231/31Документ16 страницCambridge International AS & A Level: Further Mathematics 9231/31Trần Sỹ Minh TiếnОценок пока нет

- [Grundlehren der mathematischen Wissenschaften 343] Hajer Bahouri, Jean-Yves Chemin, Raphaël Danchin (auth.) - Fourier Analysis and Nonlinear Partial Differential Equations (2011, Springer-Verlag Berlin Heidelbe.pdfДокумент540 страниц[Grundlehren der mathematischen Wissenschaften 343] Hajer Bahouri, Jean-Yves Chemin, Raphaël Danchin (auth.) - Fourier Analysis and Nonlinear Partial Differential Equations (2011, Springer-Verlag Berlin Heidelbe.pdfarvinkaushalОценок пока нет

- 10 - Grain Size MeasurementДокумент27 страниц10 - Grain Size MeasurementRohib RohibОценок пока нет

- Working Principle of DC Generator, Construction, Diagram PDFДокумент10 страницWorking Principle of DC Generator, Construction, Diagram PDFRidhiОценок пока нет

- Modules in Mechanics of Materials List of SymbolsДокумент3 страницыModules in Mechanics of Materials List of SymbolsBenjali D. DinagatОценок пока нет

- Steel Chap5 Ultimate Limit StateДокумент35 страницSteel Chap5 Ultimate Limit StateMesfin Derbew86% (7)

- Chapter 10 Radioactivity Teacher Guide1Документ29 страницChapter 10 Radioactivity Teacher Guide1Mohd Nurul Hafiz AlawiОценок пока нет

- Lecture4 Static and Dynamic Fluid PDFДокумент13 страницLecture4 Static and Dynamic Fluid PDFRudi BerlianОценок пока нет

- Comminution (Automaticky Uloženo) PDFДокумент21 страницаComminution (Automaticky Uloženo) PDFAntonioJavierOstosMachadoОценок пока нет

- Multiphysics Simulation of Thermoelectric Systems - Modeling of Peltier-Cooling and Thermoelectric GenerationДокумент7 страницMultiphysics Simulation of Thermoelectric Systems - Modeling of Peltier-Cooling and Thermoelectric GenerationWeeIngОценок пока нет

- Heat Diffusion EquationДокумент8 страницHeat Diffusion EquationSrikar GhooliОценок пока нет

![[Grundlehren der mathematischen Wissenschaften 343] Hajer Bahouri, Jean-Yves Chemin, Raphaël Danchin (auth.) - Fourier Analysis and Nonlinear Partial Differential Equations (2011, Springer-Verlag Berlin Heidelbe.pdf](https://imgv2-1-f.scribdassets.com/img/document/412382047/149x198/e2ea34ee8d/1559669412?v=1)