Академический Документы

Профессиональный Документы

Культура Документы

Progressive Press Die Design Add-On in Solidworks: White Paper

Загружено:

Elaine JohnsonОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Progressive Press Die Design Add-On in Solidworks: White Paper

Загружено:

Elaine JohnsonАвторское право:

Доступные форматы

White Paper

Progressive Press Die design add-on in SolidWorks

Oct. 1st, 2008

All Rights Reserved By Katori Oce and 3D QuickTools Limited 2008. 3DQuickPress, 3DQuickForm is a trademark of 3D QuickTools Ltd.

SolidWorks is a registered trademark of SolidWorks Corporaon. Drawing example provided by Nara Mold & Die Co., Ltd.

By Mr. Sadao Katori, Katori Oce, Japan

Progressive Press Die Design Add-on In SolidWorks | October, 2008

AllRightsReservedByKatoriOfficeand3DQuickToolsLimited2008. 1

Preface

Canthissoftwarereallyachieve3Dmanufacturing?Isthererealadvantagein3D

designing?Thesequestionsgrowlargerasyoucomeclosetoshopfloor.Onthe

other hand, 3D designing is a firmly established practice, as the advantage is

obvious in designing by the visibility and the ease of analysis. If a through

workflow is possible using 3D down to machining, the advantage of 3D is an

unquestionabletruth.

But problems exist. Is 3D data from the upper stream possibly be used in the

down stream as it is? Does the design fully take account of machining process?

Is the manufacturing information contained in the design correct? Can it be

properlypassedtoCAM?

3DQuickPress assures you of the advantage of 3D. Till now, 2D engineering has

been firmlyrooted in Progressive Die Designing. Unskilled 3D engineering could

never a rivalry against 2D expert. Overcoming this reality, 3DQuickPress along

withitsdevelopersandresellersinunityprovidesrealadvantageof3Dtousers.

Theresultedadvantageisequalforalltheusers,regardlesseitherlargeorsmall

incompanysize.

Since 2003, 3DQuickPress built up a solid market in US and Europe, then its

marketing started in Japan. Japanese resellers appreciated in particular its PRL

(Production Ready Library) technique, which creates the knowledge base of the

parts and die sets. As the development has progressed ahead, 3DQuickPress

reflected requests from users one after another to build in number of easy to

usefunctionalitiesintothesoftwareuntilitreachedtotodaysV3.

Progressive Press Die Design Add-on In SolidWorks | October, 2008

AllRightsReservedByKatoriOfficeand3DQuickToolsLimited2008. 2

Thepurposeofthiswritingistointroducenewimprovementsandfunctionalities

whichwerealreadydevelopedandbeingincludedinthenextV3.XXXversionof

3DQuickPress. These improvements reflected the requests from autoparts

manufacturersandelectronicdevicemanufacturers.Asfortheexistingfeatures

of 3DQuickPress, all the points are referred to in other materials and writings.

Above all the existing features, we like to call your particular attention to

3DQuickForm which produces blanks and thinning simulation of complex

forms.

Detailed Design

Thefollowingillustrationisanactualexampleofdrawingfrom3DQuickPress.

These icons are used to create the above drawing.

Creation of cross sections at will, standard ordinates and datum line setting,

Progressive Press Die Design Add-on In SolidWorks | October, 2008

AllRightsReservedByKatoriOfficeand3DQuickToolsLimited2008. 3

annotation to edges, call out of holes, various cosmetic hole simbles, revsion of

decimalplaces,etc.arepossible.3DQuickPressholetableprovidesyouabandant

information including grouping, flexible format, complex holes, description of

holesonwrongside,whicharenotavailablebytheSolidWorksnativeholetable.

Inthisway,3DQuickPressdelieversthedrawingsexactlymeetingyourneedsand

thedetailedholetable.

Increased Performance

SolidWorks 2009 will show you significant improvements in the speed and ease

of use. 3DQuickPress also provides increased performance in various technic in

the strip layout creation, concurrent designing, improved hole handling,

complete support of light weight which

helps opening punch assemblies and so

on.

Easy To Use

Any change of SolidWorks model can be

reflected into strip layout without

harming 3DQuickPress characteristics of

light weight operability. User defined

components can be inserted or swapped in a strip layout design. Drawings are

available directly from strip layout. Scrap shapes can be checked. Station

numbers are given automatically. Material width change is possible from either

sides.Youcancheckfinishedproductshapeaftermodification.

Progressive Press Die Design Add-on In SolidWorks | October, 2008

AllRightsReservedByKatoriOfficeand3DQuickToolsLimited2008. 4

Swapping is possible in the die set process. Punches can be designed starting

from parts or assembly. By all these, you may even divert layout process.

Interference checkcanbe saved for further use while with SolidWorks only it is

visiblebutnosavingandnofurtheruse.

Translation, copy and rotation of parts require no steps and simple and easy.

SeethedetailsunderQuick3DInitiative

Concurrent Design

Creatingamasterstriplayoutanditsmultipledivisions,multipleuserscancarryoutdie

setdesigningseparatelyandsimultaneously.Thisisanuniquetechnologywhichmakes

3DQuickPressoutstandingamongallthesimilarproducts,highendormiddlerange.

Progressive Press Die Design Add-on In SolidWorks | October, 2008

AllRightsReservedByKatoriOfficeand3DQuickToolsLimited2008. 5

Complex Tooling

Using change over handle in the tooling manager and using multiple strip

layout,youcanproducemultipleproductsinsingledieset.Itcleverlysavestime

andlaborwhenyouhavemanysimilarshapestobepunchedorcutwithlargely

common tools. Some customer who produces 27 different but similar products

takesthisstrategy.

Ifyouhave3,000holes,3DQuickPressgivesagreatreliefbywayofclusteringto

userswhohavebeenannoyedfromtheknownextremelyslowperformance.

If you have different thicknesses in a material, you may not be disturbed any

longer. Gradual change of thickness could also be coped with by careful

approach.Counterbendscanbehandled.

Integration of Design and Manufacturing

Manufacturinginformationcanbepassedtothescreenimage,drawingandhole

table using color information. This is the first step towards total automation of

all the process to be followed including CAM programming. Not limited to

feature,sketchedgeometryisalsothesubjectofthecolorinformation.Youare

nolongerdependentonanyspecificCAMsystemandmayuseallwhatyouhave

or you may want to use. If any specific CAM system has to be employed, 3D

throughoutcannotbeachieved.

Progressive Press Die Design Add-on In SolidWorks | October, 2008

AllRightsReservedByKatoriOfficeand3DQuickToolsLimited2008. 6

Quick3D Initiative

ThepurposeofQuick3DInitiativeistosolvethecomplexityandheavyweight

of 3D, and help learning 3D by either expert or beginners. It will upgrade their

ability and eliminate their psychological resistance. Companies can immediately

bring in beginners to the real job, are no longer dependent on small number of

expertandnowcanmakeuseofhumanresourcessofarnotyetutilized.

Manufacturiginformation,decimal

places,numberofholesaredefinedinto

colorinformtion.

Color information of the parts is

automaticallypassedtohole.

Progressive Press Die Design Add-on In SolidWorks | October, 2008

AllRightsReservedByKatoriOfficeand3DQuickToolsLimited2008. 7

Problems of Parametric Design

Small number of engineers may well master the top down designing, mating,

incontext designing etc. and can achieve highest efficiency of 3D. But, large

number of people will face with insoluble difficulties such as cycled links. If an

assemblyconsistsofsmallnumberofparts,problemisnotthere.Inmediumsize

assembly typical for progressive dies, difficulty will possibly be too serious. The

processisgreatlydisturbedandalotoftimeislostbyreconstructionerrorsand

inabilityofcorrection.Companymayneedtohaveinhousetrainertokeepeyes

on the errors and accidents all the time. Further training will also take a long

time.Thelossoftimeandmoneyisquiteheavy.

Some will go back to 2D. But, smart users will go back to 3D Bottom Up

designing. Contrary to the Top Down designing, they will build up assembly

from less linked parts. It is a right answer. Yet, there are some difficulties in

handlingmultiplepartsinanassembly.Modificationisnotnecessarilyeasy,the

result of modification is unpredictable, definition of locations using mates is

tedious,revisioncontrolisdifficultandperformanceisnotgoodenough.

Quick3D proposes you

Quick3D concept suggests, Go back to Bottom Up and Use 2D approach.

3DQuickPressoffersiconmenutoassistyou.Bottomupistheeasywaytolearn

assembly design and 2D method is the way most of users were used to in the

past.

In2DapproachofQuick3D,partscaneasilyandcorrectlybeinsertedbypointing

thepositions.Fortranslationandcopyingparts,youjustspecifyfrom..toorx

Progressive Press Die Design Add-on In SolidWorks | October, 2008

AllRightsReservedByKatoriOfficeand3DQuickToolsLimited2008. 8

oryordirection.Rotationcanbedoneaboutanyaxisyoudefine.Geometrycan

be imported into file from other places. You may create blocks starting from

sketchoryoumaydoitfromcrosssectionviews.Allarenoparametric.

QIC (Quick Insert Components) of 3DQuickPress inserts components without

mating relations. Operation is simple and supports both parts and assemblies.

Youmayalsoprojectontofreesurfaces.

Withutilities,youmaydeletecomponents,rename,searchandholdinhandfullcontrol

oftheassemblymanagement.Ifnecessary,youmaysetonBeginnersMode.Thiswill

prevent users to be drugged into the trouble of context problems as it prohibits too

manylinkagestobeattached.

In the multibody designing, automatic naming and conversion of multibody to an

assemblyarepossible.Interferencechecksupportsthecheckonreferencesurfaces.The

results can be exported to parts documents and short cut to the parts is automatically

created.

Concept of Quick3D

Thequickestwayfor2Dexperiencedusertobethemasterof3Ddesigningisto

makeupaworkflowbasedon2Dconceptandmakehimselftobefullycapable

ofutilizingassemblies.Forthosewhoarealreadyknowledgeableof3D,themost

comfortablewayfordesigningassembliesistogetridofrelations.3DQuickPress

willhelpthemwiththeQuick3Dconcept.

Quick3D is the most practical way for all the engineers to become skillful 3D

designersandexpertofprogressivediedesigningwithoutanyfalloutbehind.

Progressive Press Die Design Add-on In SolidWorks | October, 2008

AllRightsReservedByKatoriOfficeand3DQuickToolsLimited2008. 9

Conclusion

Bythe3DThroughout,companiesmaydriverationalization,withinandaround

themselveswithassociatedcompanies,alsocancutthedeliverylags,laborcosts

andfurtherenlargethebenefitlimitlessly.3DQuickPressanditsrelatedsoftware,

backed up by the support of the developer, resellers and the engineers team,

will provide a solid proof that such success is within your reach. Nanosoft Co.,

Ltd., at ShinYokohama is always ready to give a few hour demo and

presentation if requested. Please contact 3dquickpress@nanosoft.co.jp. Their

parent, Sofix Co., Ltd. is a system developer for machine controlling programs

and other industrial software. We wish to go hand in hand for cooperation not

onlywithexistingusersbutalsowithmachinebuilders,relatedsoftwarevenders

inordertoincreasebusinesschancesforthebenefitofallthepartiesconcerned.

3DQuickToolsLimited

Unit115,No.5ScienceParkWestAvenue,HongKongSciencePark,Shatin,N.T.,HongKong

Phone: +85227882832

Web: www.3dquicktools.com

Mail: info@3dquickpress.com

KatoriOffice

10623Morookacho,Kohoku,Yokohama,Japan222000

Phone: +0455491275

Web: quickpress.jp

Mail: katori@quickpress.jp

Вам также может понравиться

- How Hackers Use Your IP Address To Hack Your Computer & How To Stop It Null ByteДокумент6 страницHow Hackers Use Your IP Address To Hack Your Computer & How To Stop It Null ByteChasiful AnwarОценок пока нет

- CAD Engineering Essentials: Hands-on Help for Small Manufacturers and Smart Technical People: No Nonsence Manuals, #3От EverandCAD Engineering Essentials: Hands-on Help for Small Manufacturers and Smart Technical People: No Nonsence Manuals, #3Рейтинг: 4.5 из 5 звезд4.5/5 (4)

- Pharmagard Recirculating Compounding Aseptic Isolator Models NU-PR797-400/600 Bench/Console Operation & Maintenance ManualДокумент45 страницPharmagard Recirculating Compounding Aseptic Isolator Models NU-PR797-400/600 Bench/Console Operation & Maintenance ManualmikeОценок пока нет

- Ac 133Документ7 страницAc 133thirumalaichettiar100% (2)

- Phillip Absolon: Cassie Thinking About CubismДокумент51 страницаPhillip Absolon: Cassie Thinking About CubismNabid AhmedОценок пока нет

- 3D: Designing Competitive Advantage.Документ9 страниц3D: Designing Competitive Advantage.Bruno GraneroОценок пока нет

- 3D Printing: A Seminar Report OnДокумент19 страниц3D Printing: A Seminar Report OnSidharth MethreОценок пока нет

- Autocad Full ReportДокумент45 страницAutocad Full ReportMady Mathur50% (2)

- Autocad Full ReportДокумент47 страницAutocad Full ReportAnkur Monga78% (23)

- SCOPE+OF+ACCREDITATION (Construction+Materials+Testing) DCL TestingДокумент34 страницыSCOPE+OF+ACCREDITATION (Construction+Materials+Testing) DCL TestingGhayas JawedОценок пока нет

- Kerbstones Installation GuidelinesДокумент4 страницыKerbstones Installation Guidelinespartha_svnitОценок пока нет

- GSHPA Vertical Borehole Standard PDFДокумент45 страницGSHPA Vertical Borehole Standard PDFSibolga SatuОценок пока нет

- Heidelberg Herkules Pro ManualДокумент143 страницыHeidelberg Herkules Pro ManualBoris Stanković100% (3)

- Nokia Lte Smart Scheduler White PaperДокумент16 страницNokia Lte Smart Scheduler White PaperSri VagiralaОценок пока нет

- Solid Edge. Design BetterДокумент8 страницSolid Edge. Design Betterprashant6942Оценок пока нет

- Solid Edge: Solutions For The Top 10 Engineering Challenges: White PaperДокумент18 страницSolid Edge: Solutions For The Top 10 Engineering Challenges: White PaperReyhanWahyoedhiОценок пока нет

- What Is Cad and Its Uses?: Quality of 3D RepresentationДокумент5 страницWhat Is Cad and Its Uses?: Quality of 3D RepresentationZeeshan NazirОценок пока нет

- Getting It Right The First TimeДокумент8 страницGetting It Right The First TimeanaloghomeОценок пока нет

- Reforming Manufacturing Using Digital Information: - Improving Lean Manufacturing Through 3D DataДокумент10 страницReforming Manufacturing Using Digital Information: - Improving Lean Manufacturing Through 3D Dataavw410Оценок пока нет

- Term Paper of Mechanical SciencesДокумент12 страницTerm Paper of Mechanical SciencesamitmaheshpurОценок пока нет

- Top Five Reasons: To Integrate 3D Printing Into Your Product Development LifecycleДокумент5 страницTop Five Reasons: To Integrate 3D Printing Into Your Product Development LifecycleARUNarrОценок пока нет

- A New Mindset in Product DesignДокумент5 страницA New Mindset in Product DesignKoen BidlotОценок пока нет

- Khumulwng, West TripuraДокумент17 страницKhumulwng, West TripuraJuaneОценок пока нет

- Cad/Cam: Md. Mazharul HelalДокумент42 страницыCad/Cam: Md. Mazharul HelalGreen University TextileОценок пока нет

- Unlock The Full Potential Across Your Company: Topic SheetДокумент3 страницыUnlock The Full Potential Across Your Company: Topic SheetMoto ManiacОценок пока нет

- Digital Engineering - 2017-05Документ52 страницыDigital Engineering - 2017-05Бушинкин ВладиславОценок пока нет

- CM6739 Hardware Wonk's GuideДокумент77 страницCM6739 Hardware Wonk's GuideNekras1Оценок пока нет

- Class Handout PM323879 Peggy LinДокумент26 страницClass Handout PM323879 Peggy LinArun KumarОценок пока нет

- Autodesk Civil 3D, Dynamo or The API. Why and When?: Learning ObjectivesДокумент9 страницAutodesk Civil 3D, Dynamo or The API. Why and When?: Learning ObjectivesAravinth PichamaniОценок пока нет

- Solid Edge Overview: Siemens PLM SoftwareДокумент3 страницыSolid Edge Overview: Siemens PLM SoftwareparthasutradharОценок пока нет

- Oracle AutoVue 3DДокумент5 страницOracle AutoVue 3DToni IbrahimОценок пока нет

- Class Handout ENR323208 Quentin ContrerasДокумент19 страницClass Handout ENR323208 Quentin ContrerasSin KovacevОценок пока нет

- Questions and AnswersДокумент9 страницQuestions and AnswersNgopreker PtkОценок пока нет

- Solid Edge v20Документ5 страницSolid Edge v20Fabio Pompeu Eleuterio NogueiraОценок пока нет

- Solid Edge: Siemens PLM SoftwareДокумент8 страницSolid Edge: Siemens PLM SoftwareamonneoxОценок пока нет

- (MFG Engg HDBK, CHP 9) : 9.1.1 What Is CAD?Документ2 страницы(MFG Engg HDBK, CHP 9) : 9.1.1 What Is CAD?Sufian HijazОценок пока нет

- The Evolution of Manufacturing Using Digital Information TechnologyДокумент14 страницThe Evolution of Manufacturing Using Digital Information Technologyavw410Оценок пока нет

- Se Synch Tech2 Top 10reasons WP W16Документ18 страницSe Synch Tech2 Top 10reasons WP W16Ferney AlexisОценок пока нет

- Maximizing The Benefits of 3D Printing With Facet ModelingДокумент10 страницMaximizing The Benefits of 3D Printing With Facet ModelingthiagomcasimiroОценок пока нет

- Creo ParametricДокумент5 страницCreo ParametricsaptagunungОценок пока нет

- 3DQSV3CatalogLetter PDFДокумент2 страницы3DQSV3CatalogLetter PDFNisargОценок пока нет

- Top5 Reasons White Paper v2Документ7 страницTop5 Reasons White Paper v2gilcasertaОценок пока нет

- Optitex Main Products-BrochureДокумент2 страницыOptitex Main Products-BrochureJulio PaucarОценок пока нет

- QuestionДокумент6 страницQuestionmoizabbas33% (3)

- Shraddha Udawant A-58-1Документ16 страницShraddha Udawant A-58-1G-20 Papai ShahaОценок пока нет

- 3DQuickPress SolidWorks Case BookДокумент16 страниц3DQuickPress SolidWorks Case BookgfgfОценок пока нет

- IJRET20160516038Документ4 страницыIJRET20160516038Youssef AliОценок пока нет

- DetailingДокумент3 страницыDetailingSubin S NairОценок пока нет

- Articles - Automating Die Design - A Case Study - MetalForming MagazineДокумент3 страницыArticles - Automating Die Design - A Case Study - MetalForming MagazineSIMONEОценок пока нет

- 3D Printing: Slicing: From 3D Model To 3D PrinterДокумент10 страниц3D Printing: Slicing: From 3D Model To 3D PrinterAadil KakarОценок пока нет

- Additive ManufacturingДокумент10 страницAdditive ManufacturingENGINEERING MECHANICSОценок пока нет

- What Is 3D Printing? How Does A 3D Printer Work? Learn 3D PrintingДокумент21 страницаWhat Is 3D Printing? How Does A 3D Printer Work? Learn 3D PrintingAveОценок пока нет

- Develop3d Complete Visi18Документ6 страницDevelop3d Complete Visi18Marc FreebreyОценок пока нет

- Shraddha Udawant A-58-1Документ17 страницShraddha Udawant A-58-1G-20 Papai ShahaОценок пока нет

- Bridging The Worlds of 2D and 3D: White PaperДокумент17 страницBridging The Worlds of 2D and 3D: White Paper022freeОценок пока нет

- Top Ten Reasons To Upgrade From Pro/Engineer To PTC Creo ParametricДокумент5 страницTop Ten Reasons To Upgrade From Pro/Engineer To PTC Creo Parametricg1763970Оценок пока нет

- Design and Development of Cartesian Co-Ordinate Based 3D PrinterДокумент8 страницDesign and Development of Cartesian Co-Ordinate Based 3D PrinterTJPRC PublicationsОценок пока нет

- Lecture Note Related To Lab Assessment 1Документ23 страницыLecture Note Related To Lab Assessment 1I-zad MJОценок пока нет

- Additive Manufacturing Technologies: An Introduction To 3D Printing MethodsДокумент13 страницAdditive Manufacturing Technologies: An Introduction To 3D Printing MethodsFrançoise NicolasОценок пока нет

- Additive Manufacturing - Lecture Notes and Scheme For EME PDFДокумент10 страницAdditive Manufacturing - Lecture Notes and Scheme For EME PDFjohnnyОценок пока нет

- Develop3D Ebook - The Importance of Drawings - tcm27-2694Документ4 страницыDevelop3D Ebook - The Importance of Drawings - tcm27-2694schumiizz2bestОценок пока нет

- CAD/CAM Technologies - VR HeadsetДокумент10 страницCAD/CAM Technologies - VR HeadsetChristian PiponidesОценок пока нет

- Real Estate Settlement Act Procedures - Property Act ProceduresДокумент10 страницReal Estate Settlement Act Procedures - Property Act ProceduresFoyr NeoОценок пока нет

- 3 DDDДокумент6 страниц3 DDDAlie AlieОценок пока нет

- Chapter 1 Module CADДокумент33 страницыChapter 1 Module CADJemson VictorioОценок пока нет

- What Is 3D PrintingДокумент32 страницыWhat Is 3D PrintingSantiago PatitucciОценок пока нет

- Maker Bot ROIWhite PaperДокумент7 страницMaker Bot ROIWhite PaperP StuartОценок пока нет

- Modeling and Simulation For: EveryoneДокумент38 страницModeling and Simulation For: EveryoneElaine JohnsonОценок пока нет

- Ltu Lic 0596 Se PDFДокумент61 страницаLtu Lic 0596 Se PDFElaine JohnsonОценок пока нет

- Magnesium With HariДокумент9 страницMagnesium With HariElaine JohnsonОценок пока нет

- Taper BlankДокумент13 страницTaper BlankElaine JohnsonОценок пока нет

- ADMET Sheet Metal Testing Guide July 2013Документ9 страницADMET Sheet Metal Testing Guide July 2013Elaine JohnsonОценок пока нет

- 17 - AHSS Forming Simulation For Shear Fracture and Edge Cracking PDFДокумент37 страниц17 - AHSS Forming Simulation For Shear Fracture and Edge Cracking PDFElaine JohnsonОценок пока нет

- BSE Tip Curve Binder With SheetДокумент5 страницBSE Tip Curve Binder With SheetElaine JohnsonОценок пока нет

- Integrated Process Simulation and Die-Design in Sheet Metal FormingДокумент4 страницыIntegrated Process Simulation and Die-Design in Sheet Metal FormingElaine JohnsonОценок пока нет

- Fast&Accurate AutosetupДокумент6 страницFast&Accurate AutosetupElaine JohnsonОценок пока нет

- PDFДокумент11 страницPDFElaine JohnsonОценок пока нет

- Hot Forming IntroductionДокумент19 страницHot Forming IntroductionElaine JohnsonОценок пока нет

- Nexiez-Lite Catalog PDFДокумент8 страницNexiez-Lite Catalog PDFpramods_8Оценок пока нет

- CsigДокумент14 страницCsigsskumar_nОценок пока нет

- 3com NBX V3000 Admin GuideДокумент482 страницы3com NBX V3000 Admin GuideshemuzОценок пока нет

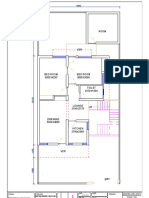

- Plan - Vikas NagarДокумент1 страницаPlan - Vikas NagarPrakhar AgrawalОценок пока нет

- Spaulding Lighting Rockford Spec Sheet 5-82Документ2 страницыSpaulding Lighting Rockford Spec Sheet 5-82Alan MastersОценок пока нет

- Catalog Bbs2fr 25Документ1 страницаCatalog Bbs2fr 25SYARULNIZAM ROSLANОценок пока нет

- Key+Script TOEIC B - EditedДокумент287 страницKey+Script TOEIC B - EditedDuc Tai VuОценок пока нет

- Med2 PC Building Uk HR PDFДокумент1 страницаMed2 PC Building Uk HR PDFfiorenzorОценок пока нет

- VoorSun 091411Документ20 страницVoorSun 091411elauwitОценок пока нет

- Ijeted: Design and Analysis of A Secure and Efficient Data Transfer in A Cluster Based Wireless Sensor NetworksДокумент7 страницIjeted: Design and Analysis of A Secure and Efficient Data Transfer in A Cluster Based Wireless Sensor NetworksArnav GudduОценок пока нет

- Ds OpenbalanceДокумент4 страницыDs OpenbalanceelorОценок пока нет

- DebugДокумент3 страницыDebugAriefENstОценок пока нет

- Construction of Precast Prestressed Folded Plate Structures in HondurasДокумент16 страницConstruction of Precast Prestressed Folded Plate Structures in Hondurasmanojkumar.boddupallyОценок пока нет

- ConstructionДокумент38 страницConstructionChakravarthi NagaОценок пока нет

- Practical IGCSE Soils Organic MatterДокумент5 страницPractical IGCSE Soils Organic MatterMO62Оценок пока нет

- Assignment On Evolution and History of CДокумент18 страницAssignment On Evolution and History of Cabbas raza shafqatОценок пока нет

- Oracle Managed ErrorsДокумент44 страницыOracle Managed ErrorsparyabОценок пока нет

- Front Elevation: ExistingДокумент1 страницаFront Elevation: ExistingAce LangОценок пока нет

- Embedded SystemsДокумент27 страницEmbedded SystemsYashwanth KondisettyОценок пока нет

- 3 Jet GroutingДокумент5 страниц3 Jet GroutingshubhamОценок пока нет

- Bead and Mesh PDFДокумент7 страницBead and Mesh PDFjerconsОценок пока нет