Академический Документы

Профессиональный Документы

Культура Документы

Interpreting PDF

Загружено:

Hồ Thắng0 оценок0% нашли этот документ полезным (0 голосов)

53 просмотров7 страницThis document discusses instrumentation used for measuring strain in bored piles during load testing. It describes how vibrating wire strain gauges embedded in or attached to piles can measure load distribution between side shear and end bearing. It provides details on vibrating wire strain gauge types like embedment gauges and "sister bars" attached to rebar cages. It also discusses challenges with interpreting strain measurements and load test methods like the Osterberg cell.

Исходное описание:

Оригинальное название

Interpreting.pdf

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документThis document discusses instrumentation used for measuring strain in bored piles during load testing. It describes how vibrating wire strain gauges embedded in or attached to piles can measure load distribution between side shear and end bearing. It provides details on vibrating wire strain gauge types like embedment gauges and "sister bars" attached to rebar cages. It also discusses challenges with interpreting strain measurements and load test methods like the Osterberg cell.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

53 просмотров7 страницInterpreting PDF

Загружено:

Hồ ThắngThis document discusses instrumentation used for measuring strain in bored piles during load testing. It describes how vibrating wire strain gauges embedded in or attached to piles can measure load distribution between side shear and end bearing. It provides details on vibrating wire strain gauge types like embedment gauges and "sister bars" attached to rebar cages. It also discusses challenges with interpreting strain measurements and load test methods like the Osterberg cell.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 7

INTERPRETING STRAIN MEASUREMENTS FROM LOAD TESTS IN BORED PILES

Jack Hayes, Loadtest Inc., Gainesville, Florida, USA

Tony Simmonds, Geokon Inc., Lebanon, New Hampshire, USA

Vibrating wire strain gages have proven to be a very reliable and effective tool for the

measurement of strains associated with the loading of bored piles (drilled shafts). However,

when these strains are used to calculate the load, or stresses in the pile, the results can

sometimes be confusing and/or difficult to interpret.

This paper describes some of these situations, using examples from actual case histories,

and discusses some of the difficulties associated with residual load effects, curing and

temperature induced strains, load stress distribution effects, estimated modulus and area.

PILE LOAD TEST INSTRUMENTATION

An expanding requirement to build on difficult terrain

has seen an increase in the use of piles for support of

buildings and infrastructure, and a growing need for

tests to determine pile load capacities.

The load distribution along a pile, among friction (side

shear) and end bearing, is often measured using strain

gages embedded in the pile.

Choice of Strain Gage.

In static load tests vibrating wire strain gages are

generally used. The advantage of vibrating wire

sensors over more conventional electrical resistance or

semi-conductor types lies mainly in the sensor output,

which is a frequency rather than a voltage or

resistance. The frequency output is easier to transmit

over long cables and is unaffected by voltage drops

such as those which can be brought about by corrosion

of terminal contacts, moisture penetration into either

the sensor or the signal cable, or temperature effects

on the cable, all of which would radically affect the

output of electrical resistance types. Also, shortening

or lengthening of the sensor cables does not affect the

frequency signal.

Vibrating wire gages are, by design, very robust,

allowing for quick and simple installations. Electrical

resistance strain gages, on the other hand, tend to be

fragile and their installation requires more care and

diligent waterproofing.

Recently fiber optic strain gages have been used but

they are comparatively expensive, especially the

readout equipment, and care is needed when handling

the delicate fiber optic cables during installation. They

can, however, be made in long lengths so that total

coverage of the entire length of pile is possible. As time

goes by, and as prices come down, we may well see

more widespread use of fiber optic sensors.

Vibrating wire gages are read electronically using

portable readout boxes or with dataloggers. In recent

years dataloggers, have become miniaturized, less

power demanding, more reliable and more affordable,

and consequently are seeing more widespread use,

even on relatively small scale projects such as pile

tests. Dataloggers are able to gather data more quickly

and with reduced manpower, and lighten the burden of

data analysis.

Figure 1 - Datalogger system used to monitor

instrumentation during a lateral load test

For long term monitoring, over extended periods of

time, vibrating wire sensors are the sensors of choice.

Properly constructed, (McRae et al. 1991) they have

an excellent long-term stability, far exceeding the best

of bonded foil type strain gages and equaling or

exceeding that of the unbonded (Carlson) type

sensors.

In one important respect only is the vibrating wire

sensor deficient, it is unable to monitor rapidly

changing parameters. It is better, where dynamic

responses are to be measured, to use electrical

resistance or semi-conductor type sensors.

Vibrating Wire Strain Gages

A technique for measuring strains using the vibrating

wire principle was developed in 1931 by Andre Coyne,

a French consulting engineer (Bordes et al. 1985).

Later, in the same decade, vibrating wire strain gages

were made commercially available by Maihak,

(Germany), and Telemac, (France). Other

manufacturers based designs on developments by the

Buildings Research Establishment, (Gage Technique)

in England, and by the Norwegian Geotechnical

Institute, (Geonor). Beginning in the 1970s and

continuing to the present day, the variety and versatility

of vibrating-wire sensors have been greatly expanded

by Geokon Inc, in the USA. Figure 2 shows a typical

vibrating wire concrete embedment strain gage.

Protective Tube

Instrument Cable

Pluck & Read Coils Thermistor

Wire

Coil & Thermistor Housing

O-ring Sealed End Block

Wire Grip Wire Grip

(4 conductor, 22 AWG)

Gage Length

(6", 152 mm)

O-ring Sealed End Block

(encased with shrink tube)

Figure 2 - Vibrating Wire Embedment Strain Gage

A tensioned steel wire is made to vibrate by means of

an electronic coil. This same coil, in conjunction with a

permanent magnet, is also able to measure the

frequency of this vibration, which changes as the strain

in the wire changes. The concrete embedment style

has flanges at each end to engage the concrete.

Larger gages are used in mass concrete with large

aggregate, up to 150mm (Sellers, 2002).

Sister Bar Strain Gage

A variant of the vibrating wire strain gage is the Rebar

Strain Meter or Sister Bar shown in Figures 3 and 4.

Strain Meter Body Rebar

Instrument Cable

Protective Epoxy

Strain Gage Electromagnetic Coil Heat Shrink

1378 mm

54.25"

Rebar

Thermistor

(encapsulated)

Weld

Figure 3 - Rebar Strain Meter

The Geokon 4911 Sister Bar consists of a miniature

vibrating wire strain gage installed inside a 150mm

length of high strength steel on the neutral axis. This

configuration, is preferable to types where a vibrating

wire strain gage is simply attached to the side of a

section of rebar as it is not sensitive to bending. The

strain meter body is then welded between 2 rebar

extensions. The welds are tested and the gage

calibrated in a testing machine (traceable to the

N.I.S.T.). The method of construction results in a very

robust strain gage, which will survive almost any kind

of concrete placement method. The long section of

reinforcement bar provides good contact with the

concrete over a long distance so there is less likelihood

of the active portion of the gage being influenced by

local cracks, fissures or air bubbles.

Sister bars, as the name implies, are attached

alongside the longitudinal rebars of the rebar cage

(Dunnicliff, 1988). Sometimes the sister bar is specified

to be of a size equal to the rebar. A section of the

rebar is to be removed and is to be replaced by a sister

bar welded directly into the rebar cage so that it

becomes part of it. This requires two more full strength

welds to be made. Since the performance of the strain

gage is in no way enhanced by this procedure, the

additional time and expense cannot be justified.

Figure 4 - Rebar Strain Meters

Sister Bars or Embedment Strain Gages?

Sister bars are often chosen for cast-in-place concrete

piles, where concrete is tremied or dropped into a

drilled shaft, because they are more rugged and better

able to maintain their alignment than embedment type

strain gages (as shown in Figure 2). In pre-cast

concrete piles, the smaller embedment types are

suitable. (High temperature versions of Sister Bars

and embedment types are available for heat cured

spun piles).

Sister bars may also be chosen because they allow a

direct measurement of the rebar stress, whereas the

embedment strain gage measures the concrete strain

a combination of shrinkage, swelling, creep and that

due to applied stress.

Gage Protection

Sister bars (and embedment gages) are usually

located at the same circumference as the rebar cage

and are thus protected from being scraped off as the

rebar cage is lowered into the drilled shaft. Under

normal circumstances, the survivability of either type of

gage is close to 100 percent.

Cables need to be protected by tying them off to the

longitudinal rebars at about 2-meter spacing. If the

cables are tucked into the angle between the spiral

rebar and the longitudinal rebars, and kept tight, they

will be safe (Sellers, 1995).

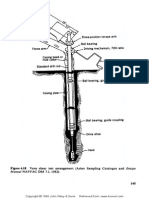

PILE LOAD TEST OSTERBERG METHOD

A new way of load testing piles uses the Osterberg

Cell, a hydraulic jack-like device embedded in the pile

(Osterberg, 1989). In the case of a caisson or cast-in-

place pile the device (or O-cell) is attached to the rebar

cage. Hydraulic lines and telltales extend from the O-

cell to the top of the pile to monitor the movement of

the bottom of the pile as the O-cell load is applied.

Either dial gages or displacement transducers measure

movement of the top of the pile.

More sophisticated instrumentation schemes use strain

gages to measure the load distribution in the pile in the

zone above and below the O-cell. In this way, as the

loads are applied, the distribution of the load

transference to the ground by induced shear forces

can be measured. Figure 5 shows a typical

arrangement of instruments in an Osterberg Cell load

test.

Figure 5 - Typical Instrumentation for an

O-cell Test

Strange Strain Situations

One of the distinct advantages of a static load test on a

pile or drilled shaft is that it can provide the engineer

with valuable information about the actual ultimate end

bearing or side shear characteristics of the pile or

drilled shaft. In a conventional topdown load test, the

separation of the end bearing and side shear

components requires embedded strain gages to

determine the resisting shear loads developed along

the shaft. The shear load resistance, so determined, is

subtracted from the total applied top load to estimate

the end bearing resistance.

A significant advantage of carrying out static load tests

using the O-cell method is that separation of end

bearing and side shear resistance is generally provided

without the need to rely on strain gages for that

purpose. Nevertheless, even with an O-cell test, the

engineer is often interested in the distribution of side

shear along the shaft. Thus most O-cell tests also

have strain gages embedded in the shaft.

Determining loads from strain gages requires an

analysis of the strain gage data that is usually more

sophisticated than many engineers realize. For

example Fellenius (2002) provides convincing

evidence of the impact of residual loads on strain gage

data when testing either driven piles or bored piles

(drilled shafts). From our experiences with analyzing

the data from hundreds of static load tests we can

confirm that converting strain into loads in a drill shaft

is not a simple matter. We have encountered many

apparently strange strain situations that sometimes

seem to defy logic. Often one of the hardest things to

do when interpreting strain gage data is to trust the

strain gages. Virtually all of the strain measurements

in our tests have been made with vibrating wire sister

bar strain gages (Geokon 4911). After analyzing the

data from many thousands of this type of vibrating wire

strain gages we have learned to trust them. Thus

when the data seem unrealistic we have become

accustomed to looking for a reason and we now are

aware of many reasons for strange-looking strain gage

data.

Residual Load Effects

As illustrated in Figure 6, the presence of residual toe

loads in driven piles is readily evident from O-cell end

bearing (loading and unloading) movement curves.

Residual side shear loads are, however somewhat

more difficult to detect, especially in drilled shafts.

Although not done routinely, strain gages in test shafts

can be monitored throughout the installation,

construction and concrete curing phases. As noted by

Fellenius (2002) using only zero readings taken at

zero time at the beginning of a load test ignores the

strain history of the shaft which can lead to the locked

in loads.

-4

-3

-2

-1

0

1

2

3

4

0 200 400 600 800 1000 1200 1400 1600 1800 2000 2200 2400

Load (kN)

M

o

v

e

m

e

n

t

(

m

m

)

LT Reference 0768

Residual Load

Loading

Unloading

Figure 6 - Residual Toe Load in a Driven Pile

We believe that the physical expansion and contraction

of the pile shaft concrete during the curing period

results in significant residual side shear loads. Using

the full capability of Geokon 4911 strain gages to

monitor both temperature and internal strain during the

curing period produces the kind of data shown in

Figures 7 and 8.

0

10

20

30

40

50

60

70

0 1 2 3 4 5 6 7 8 9 10 11 12 13

Days

T

e

m

p

e

r

a

t

u

r

e

(

o

C

)

LT Reference 0568

Shaft Diameter = 2.34 m

Shaft Length = 24.36 m

Figure 7 - Concrete Curing Temperature

Figure 7 shows the internal temperature history of the

curing shaft with a diameter of 2.34 meters and a

length of 24.4 meters. Figure 8 illustrates the internal

strain history for two levels of gages in the same drilled

shaft.

0

50

100

150

200

250

300

350

400

450

500

0 1 2 3 4 5 6 7 8 9 10 11 12 13

Days

M

i

c

r

o

s

t

r

a

i

n

LT Reference 0568

Shaft Diameter = 2.34 m

Shaft Length = 24.36 m

Figure 8 Internal Strain History During Curing

From these strains we can make an estimate of the

side shear loads that appear to have developed during

the curing period in the zone between these two strain

gage levels. We computed the side shear values from

the strain data using concrete moduli estimated, with

the ACI formula, from concrete cylinder strengths. We

obtained test cylinder data over the curing period of

one to fourteen days. (This method of estimating

moduli is, of course, subject to all of the limitations and

error margins subsequently discussed.) In this case

the movement of the shaft during the curing period

resulted in an estimated tension and then compression

locked in shear of 130 kPa. (See Figure 9.)

-200

-100

0

100

200

300

400

0 1 2 3 4 5 6 7 8 9 10 11 12 13

Days

S

h

e

a

r

S

t

r

e

s

s

(

k

P

a

)

LT Reference 0568

Shaft Diameter = 2.34 m

Shaft Length = 24.36 m

Figure 9 Estimated Side Shear Stresses

During Curing Period

Influence of Tension Cracks

We are aware of incidents of tension micro-fractures

forming on the plane of embedded strain gages during

the curing period. Such micro-fractures can distort the

shaft loads computed during the early stages of

loading. Until the subsequent applied compression

loads close the micro-fractures, only the modulus and

the area of the reinforcing steel should be used to

compute the shear load distribution. This impact of

micro-fractures on gage data would normally apply

only to relatively low loads at the beginning of a test.

Concrete Modulus Influences

Typically the loads at the plane of the strain gages are

computed from the measured strains and an estimated

modulus using the formula:

P = !AE

Where:

P = load

! = measured strain from gages

A = composite cross-sectional area of

concrete and steel in the shaft at the plane of

strain gages

E = composite modulus of concrete and steel

at the strain gage plane.

The concrete modulus is often estimated from the ACI

formula:

Ec = k (f

c

)

0.5

which is based on the square root of the unconfined

compressive strength, fc, of the concrete. Commonly

we use a value for the constant, k, of 4,700 when fc is

in MPa units. This method may provide reasonable

values for the Ec used to calculate loads from strains,

but not always, for the following reasons:

1. The ACI formula is based on retrogression through

scattered data. Various researchers have found that

the constant, k, can vary significantly for different

concrete mixes. In fact the ACI formula constant of

4,700 is supposed to apply to normal weight concrete

of 2320 kg/m

3

. The ACI Building Code actually

recommends that the constant, k, be determined from

the expression

0.043 w

1.5

(Oluokun et al, 1991)

where

w = unit weight of the concrete in MPa

This implies that, for an increase in unit weight from

2240 to 2500 kg/m

3

, k increases by 17%. Based on

other studies (Shah and Ahmad, 1985 and Freedman,

1971) researchers have concluded that concretes

comply with the ACI formulations within 20 percent.

2. The unconfined compressive strength may not

reflect the actual strength of the concrete in the shaft.

It is generally acknowledged that the elastic modulus of

concrete correlates well to the 0.5 power of the

compressive strength of the concrete in the shaft.

Studies by Khan et al (1995) suggest that the normal

methods used to cure concrete test cylinders result in

compressive strengths that are significantly lower than

those of the mass concrete in the shaft.

3. The modulus of the concrete will generally not be

constant through the range of compressive loads

during a test. As noted by Fellenius (2001), over the

large stress range imposed during a static loading test,

the difference between the initial and the final moduli

for the pile material can be substantial.

Tangent Modulus Estimates

Fortunately the shortcomings of using the ACI formula

for estimating the concrete moduli can be overcome by

using the procedures described by Fellenius (1989),

(2001) to determine the tangent modulus of the

concrete from the test data. The procedure is based

on the fact that, after the side shear on a shaft is fully

mobilized and no longer changes with loading, the

changes in stress and strain at the plane of the strain

gages reflect the composite modulus of the shaft at

that loading. An example of a tangent modulus plot

from Loadtest, Inc. data is shown on Figure 10.

0

25

50

75

100

125

150

175

200

225

250

0 10 20 30 40 50 60 70 80 90 100

Microstrain

M

o

d

u

l

u

s

,

E

(

G

P

a

)

SG4 - Located 4.88m above O-cell

SG3 - Located 3.05m below O-cell

COMP

LT Reference 7-0568

Figure 10 Tangent Modulus Plot

We sometimes have the opportunity to compare the

results of a tangent modulus analysis with a more

direct measurement of the modulus in a multi-level O-

cell as illustrated in Figure 11. By applying equal and

opposing loads with O-cells 1 and 2 while measuring

the shaft compression with embedded telltales we can

carry out a full-scale modulus test. The results of such

a test are shown on Figure 10 (" comp) providing an

example of a good comparison.

One of the additional benefits of the tangent modulus

technique for analyzing strain gage data is that it also

compensates for any uncertainty that may exist about

the area of the shaft on the strain gage plane. In a

driven pile of fixed dimensions the value for area, A, is

well known. In a drilled shaft, however, we usually

know the diameter of the shaft only approximately,

making it difficult to derive the correct value for E. We

can, however, use the tangent modulus technique to

determine the value of AE with some confidence. The

technique plots the known increase in load with respect

to the measured increase in strain allowing us to

calculate AE =

#

P/#$. The plot shown in Figure 12

indicates AE values relative to strain.

Figure 11 - Multi-level O-Cell Setup Used for

Compression Test

Although the tangent modulus analytical tool does

help to overcome some of the drawbacks of traditional

analysis, it does have limitations. One has already

been mentioned; the need to reach or exceed ultimate

side shear values during the test. A second limitation

is that the total strain at the plane of interest, based on

our experience with drilled shafts, must reach at least

50 micro-strain and preferably more than 200 micro-

strain. Figure 12 (SG1 and SG2) shows a typical

tangent modulus plot with relatively low concrete

compressive strains.

0

10

20

30

40

50

0 50 100 150 200 250

Microstrain

P

i

l

e

S

t

i

f

f

n

e

s

s

A

E

(

M

N

)

Strain Gage Level 1

Strain Gage Level 2

Strain Gage Level 3

Estimated from ACI Formula

Used For Analysis

Figure 12 -Tangent Pile Stiffness Analysis for Strain

Gage Levels 1, 2, and 3

The Influence of Shape

One of the significant uncertainties relating to drilled

shafts is the actual size and/or shape of the shaft.

Without good caliper data, we usually do not know,

with any precision, the area of the concrete on the

strain gage plane. Table 1 provides a reminder that

relatively small changes in shaft diameter translate to

significant changes in area. It is not hard to imagine

situations with a 20% error in the assumed value for

the area, A. Combine that with a 20% error in the

estimate of E from the ACI formula and we have a

potential 40% error in the estimated value for AE.

Sometimes these errors may compensate, producing

an accurate result but we can never be certain about

that.

Table 1 Impact of Uncertain Shaft Diameter

Nominal

Diam. (m)

Nominal

Area (m

2

)

Actual

Diam. (m)

Actual Area

(m

2

)

Percent

Increase

1.0 0.79 1.1 0.95 21.0

1.2 1.13 1.3 1.33 17.4

1.5 1.77 1.6 2.01 13.8

2.0 3.14 2.1 3.46 10.3

2.5 4.91 2.6 5.31 8.2

3.0 7.07 3.1 7.54 6.8

1.0 0.79 1.2 1.13 44.0

1.2 1.13 1.4 1.54 36.1

1.5 1.77 1.7 2.27 28.4

2.0 3.14 2.2 3.80 21.0

2.5 4.91 2.7 5.72 16.6

3.0 7.07 3.2 8.04 13.8

Figure 13 - Influence of Shape on Strain Measurements

The shape can also influence strain measurements in

other, less obvious ways. Figure 13 illustrates a

situation where the shaft diameter between strain gage

levels is larger than at the strain gage planes above

and below. An axial load applied from below will result

in abnormally high strains at level 1 and abnormally

lower strains at level 2 because of the bulge in the

shaft. The consequence will be a false indication of

higher unit shear values in the zone between Levels 1

and 2. We can only conclude that a proper strain gage

analysis requires good caliper data.

Figure 14 - Influence of Installation Technique

Influence of Gage Positions

A number of apparently anomalous strain

measurements can be related to the position of the

strain gage relative to the applied load. For example,

in an O-cell test, it is important to position strain gages

more than one shaft diameter above the top of the O-

cell itself. Figure 14 illustrates how a gage placed too

close to the point of load application can actually

indicate tensile strains in a shaft loaded in

compression.

The position of the gage can also produce results that

illustrate defects in shaft design and/or construction.

As shown in Figure 14, a shaft cage with tight hoop

spacing and inadequate cage centralizers can both

drag material from the sidewalls onto the rebar hoops

and also come to rest with one side of the cage in

contact with the sidewalls. In such situations a sister

bar strain gage attached to the hoops may not

(probably will not) get embedded in concrete. Such a

gage merely goes along for the ride during the test

and thus measures apparently very low strains. Since

the gage located on the opposite side, being fully

embedded in concrete, produces much higher strains,

engineers sometimes conclude that the shaft is being

loaded eccentrically. In reality, however, the strain

gages have simply let us know that we have a defect in

the design and/or construction of the shaft.

CONCLUSIONS

Calibrated vibrating wire sister bar strain

gages with thermistors can provide very

reliable and useful data for analyzing drilled

shaft performance, but unfortunately not

unambiguously.

Calculating loads from strain gage data

requires an awareness that pre-test strain

history can result in significant locked-in shear

and end bearing loads.

Conventional methods used to estimate both

area and modulus for concrete can lead to

errors of 40% in loads computed from strain

data.

The tangent modulus analytical technique

described by Fellenius sometimes provides a

superior method for assessing loads from

strain data.

The shape of a drilled shaft can influence both

the strain and the calculated shear loads. A

good strain gage analysis needs good caliper

data.

Seemingly strange data should not be

discarded as they may point to a defect in

design or construction. Each strain gage gives

data that means something.

.

REFERENCES

BORDES, J.L., DEBREUILLE, P.J., 1985. Some facts

about long term stability of vibrating wire instruments,

Reliability of Geotechnical Instrumentation, T.R.B.

Record No. 1004, pgs. 20-27

DUNNICLIFF, J., 1988. Geotechnical instrumentation

for monitoring field performance. John Wiley & Sons.

FELLENIUS, B.H., 2002. Determining the true

distributions of load in instrumented piles, ASCE

International Deep Foundation Congress, Orlando,

Florida.

FELLENIUS, B.H., 2001. We have determined the

capacity, then what? Fulcrum, Newsletter of the Deep

Foundations Institute.

FELLENIUS, B.H., 2001. From strain measurements

to load in an instrumented pile, Geotechnical News

Magazine, Vol. 19, No.1 pgs. 35-38.

FELLENIUS, B.H., BRUSEY, W.G., and PEPE, F.,

2000. Soil set-up, variable concrete modulus, and

residual load for tapered instrumented piles in sand,

American Society of Civil Engineers, ASCE, Specialty

Conference on Performance Confirmation of

Constructed Geotechnical Facilities, ASCE

Geotechnical Special Publication, GSP 94, p. 16.

FREEDMAN, S., 1971. High strength concrete, Modern

Concrete, Vol. 34, No. 9, pp. 15-22.

KHAN, ARSHAD A., COOK, WILLIAM D., and

MITCHELL, DENNIS, 1995. Early age compressive

stress-strain properties of low, medium, and high-

strength concretes, ACI Materials Journal, vol. 92, No.

6, p. 617.

McRAE, J.B., SIMMONDS, T., 1991. Long-term

stability of vibrating wire instruments; One

manufacturers perspective, Proceedings of the 3

rd

International Symposium on Field Measurements in

Geomechanics, Oslo, Norway, Sorum (Ed), pgs. 283-

293.

OLUOKUN, FRANCIS A., BURDETTE, EDWIN G.,

and DEATHRAGE, HAROLD J., 1991. Elastic

modulus, Poissons ratio, and compressive strength

relationships at early ages, ACI Materials Journal, Vol.

88, P. 3.

SELLERS, J.B., 1995. Pile load test instrumentation,

Instrumentation in Geotechnical Engineering,

Proceedings of Geotechnical Division of the Hong

Kong Institute of Civil Engineers, pgs. 23-33.

SELLERS, J.B., 2002. The measurement of stress in

concrete. Japan. (to be published).

SHAH, S. P., and AHMAD, S. H., 1985. Structural

properties of high strength concrete and its implications

for precast prestressed concrete, Journal of the

Prestressed Concrete Institute, Vol. 30, No. 6, pp. 92-

119.

Вам также может понравиться

- CoorsTek SmWedgeДокумент60 страницCoorsTek SmWedgeRonnie MagsinoОценок пока нет

- Insulation Co-ordination in High-voltage Electric Power SystemsОт EverandInsulation Co-ordination in High-voltage Electric Power SystemsРейтинг: 4.5 из 5 звезд4.5/5 (5)

- Interpreting Strain Measurements From Load Tests in Bored PilesДокумент7 страницInterpreting Strain Measurements From Load Tests in Bored PilesMustafa SütcüoğluОценок пока нет

- Strain GaugeДокумент3 страницыStrain GaugeNatalio GarzonОценок пока нет

- ME 402 UNIT 4 IC Force Strain InstrumentsДокумент43 страницыME 402 UNIT 4 IC Force Strain InstrumentsYASH KUMARОценок пока нет

- STRUT Load MonitoringДокумент12 страницSTRUT Load Monitoringtun20000Оценок пока нет

- Strain GaugeДокумент7 страницStrain GaugeIanosi SorinОценок пока нет

- Strain Measurement MEASUREMENT EXPERIMENT: 1. ObjectДокумент7 страницStrain Measurement MEASUREMENT EXPERIMENT: 1. ObjectKenny KenzoОценок пока нет

- Lecture 4Документ32 страницыLecture 4yashagrawal.be18aeroОценок пока нет

- Physical Operation: Electrical Conductance Electrical Conductor ElasticityДокумент4 страницыPhysical Operation: Electrical Conductance Electrical Conductor Elasticitydwarika2006100% (1)

- Vibrating Wire Strain Gauges: I N S T R U C T I O NДокумент44 страницыVibrating Wire Strain Gauges: I N S T R U C T I O NWandyy GonçalvesОценок пока нет

- Strain GaugesДокумент7 страницStrain GaugesRoss Jay MichelОценок пока нет

- Vibrating Wire Strain GaugesДокумент9 страницVibrating Wire Strain Gaugessannan azizОценок пока нет

- DP CellДокумент18 страницDP CellbrindaОценок пока нет

- Chapter-1: 1.1 GeneralДокумент53 страницыChapter-1: 1.1 GeneralsmkdigitechОценок пока нет

- Investigation of Long Riser VIV PDFДокумент6 страницInvestigation of Long Riser VIV PDFsuzilamatsallehОценок пока нет

- Cuerda Vibrantes Articulo FMGMДокумент0 страницCuerda Vibrantes Articulo FMGMealvarez_27683Оценок пока нет

- Strain GaugesДокумент35 страницStrain GaugesSnigdhaОценок пока нет

- VORTXcatpgДокумент5 страницVORTXcatpgJaime Arellano HuertaОценок пока нет

- p5 En303 Sankalp Purwar 2Документ14 страницp5 En303 Sankalp Purwar 22K20 EN 63 Sankalp PurwarОценок пока нет

- ACSR Thermal Mechanical White PaperДокумент9 страницACSR Thermal Mechanical White PaperleonardonaiteОценок пока нет

- p5 En303 Sankalp PurwarДокумент14 страницp5 En303 Sankalp Purwar2K20 EN 63 Sankalp PurwarОценок пока нет

- Tirtharaj Pati - Details of Strain Gauge Sensor PDFДокумент13 страницTirtharaj Pati - Details of Strain Gauge Sensor PDFTirtharaj PatiОценок пока нет

- Assignment-3: MN 332: Writeup Listing Different Geotechnical InstrumentДокумент5 страницAssignment-3: MN 332: Writeup Listing Different Geotechnical InstrumentVinayak ChaturvediОценок пока нет

- Group 4Документ23 страницыGroup 4Ankur47Оценок пока нет

- Resistance Strain GaugeДокумент28 страницResistance Strain GaugeKarunesh PiwaniaОценок пока нет

- Strain Gauge July12Документ6 страницStrain Gauge July12kg704939Оценок пока нет

- The Performance of Mesh, Shotcrete and Membranes For Surface Ground SupportДокумент13 страницThe Performance of Mesh, Shotcrete and Membranes For Surface Ground SupportCristopher HernándezОценок пока нет

- Extenso MeterДокумент8 страницExtenso MeterVijayanandh Raja100% (1)

- STRAIN GageДокумент5 страницSTRAIN Gagemanoish07Оценок пока нет

- Findings From Instrumented Pile Load TestsДокумент5 страницFindings From Instrumented Pile Load TestsMuhammad ShoaibОценок пока нет

- Bhalala Dhruv Emmi Exp-4Документ8 страницBhalala Dhruv Emmi Exp-4CLINIXОценок пока нет

- Strain Gage InstrumentationДокумент15 страницStrain Gage InstrumentationOnofre Algara Jr.Оценок пока нет

- Strata Monitoring (Lokhande Sir)Документ10 страницStrata Monitoring (Lokhande Sir)Anshul yadavОценок пока нет

- Resentation ON Strain Gauge: by Altab Hossain EIE, 4 Year Roll No-46Документ18 страницResentation ON Strain Gauge: by Altab Hossain EIE, 4 Year Roll No-46aslamhossainОценок пока нет

- Strain Gages (ME305)Документ20 страницStrain Gages (ME305)Ammar QaziОценок пока нет

- Silo Weigh PDFДокумент7 страницSilo Weigh PDFOleg AndrisanОценок пока нет

- Condition Assessment Study On Stator Bars, After 40 Years of OperationДокумент4 страницыCondition Assessment Study On Stator Bars, After 40 Years of Operationnir205Оценок пока нет

- Strain Gauges Are Used To Measure The Strain of A MaterialДокумент7 страницStrain Gauges Are Used To Measure The Strain of A MaterialThinesh Rau KrishnamurtyОценок пока нет

- Lecture 005Документ30 страницLecture 005guddu guptaОценок пока нет

- Guidelines For The Installation of Cable in Cable Trays PDFДокумент7 страницGuidelines For The Installation of Cable in Cable Trays PDFStefanos DiamantisОценок пока нет

- Power Transformer Design, Manufacturing and TestingДокумент19 страницPower Transformer Design, Manufacturing and TestingAbd ALRahmanОценок пока нет

- Nexans CableДокумент8 страницNexans CableQwerty1992ABCОценок пока нет

- Non-Destructive Electrical Test Methods For Evaluating High-Voltage Stator InsulationДокумент9 страницNon-Destructive Electrical Test Methods For Evaluating High-Voltage Stator InsulationHendi AfriyanОценок пока нет

- Strain GaugeДокумент7 страницStrain GaugeNicholas Fok0% (5)

- The Strain Gage Pressure TransducerДокумент7 страницThe Strain Gage Pressure TransducertbmariОценок пока нет

- Bending Fatigue Tests On Stays Cables: Figure 1: Fred Hartman BridgeДокумент10 страницBending Fatigue Tests On Stays Cables: Figure 1: Fred Hartman BridgediegoОценок пока нет

- EDOC-Technology & Testing of Interphase SpacersДокумент27 страницEDOC-Technology & Testing of Interphase SpacersEl Comedor BenedictОценок пока нет

- Name: Mohamed Abdelaleem Abdelsamea Mostafa Section: 3Документ20 страницName: Mohamed Abdelaleem Abdelsamea Mostafa Section: 3IslamОценок пока нет

- Efect of Sag On Transmission LineДокумент4 страницыEfect of Sag On Transmission LineGabriel Barriga JaqueОценок пока нет

- Piezoresistive Sensors: Strain GaugesДокумент17 страницPiezoresistive Sensors: Strain GaugesAjinkya DeshmukhОценок пока нет

- BRIDON BAC TechnicalДокумент25 страницBRIDON BAC TechnicalMohamed SidateОценок пока нет

- Effect of Sag On Transmission LineДокумент4 страницыEffect of Sag On Transmission LineMohan ManickamОценок пока нет

- Ybco Superconductor Characterization Under Shear StrainДокумент4 страницыYbco Superconductor Characterization Under Shear StrainRiddhesh PatelОценок пока нет

- Effect of Sag On TLДокумент4 страницыEffect of Sag On TLsubashini_jaganathanОценок пока нет

- Experimental Stress Analysis 03Документ19 страницExperimental Stress Analysis 03ayadОценок пока нет

- A Novel Flexural Strain Measurement Frame For BeamsДокумент21 страницаA Novel Flexural Strain Measurement Frame For BeamsPaki TurgutОценок пока нет

- CMT Lesson 3Документ6 страницCMT Lesson 3April Jhen BenavidezОценок пока нет

- Special Applications of Chemical GroutsДокумент14 страницSpecial Applications of Chemical GroutsHồ ThắngОценок пока нет

- Dke78 FMДокумент19 страницDke78 FMHồ ThắngОценок пока нет

- Berlin Tie-Back WallДокумент21 страницаBerlin Tie-Back WallmayldaОценок пока нет

- Dke78 Ch19Документ30 страницDke78 Ch19Hồ ThắngОценок пока нет

- Dke78 Ch19Документ30 страницDke78 Ch19Hồ ThắngОценок пока нет

- Dke78 Ch18Документ26 страницDke78 Ch18Hồ ThắngОценок пока нет

- Specifications, Supervision, and InspectionДокумент23 страницыSpecifications, Supervision, and InspectionHồ ThắngОценок пока нет

- Dke78 Ch10Документ30 страницDke78 Ch10Hồ ThắngОценок пока нет

- Dke78 Ch1Документ13 страницDke78 Ch1Hồ ThắngОценок пока нет

- Grouting To Shut Off SeepageДокумент25 страницGrouting To Shut Off SeepageHồ ThắngОценок пока нет

- Dke78 Ch13Документ39 страницDke78 Ch13Hồ ThắngОценок пока нет

- Field Procedures and TestsДокумент18 страницField Procedures and TestsHồ ThắngОценок пока нет

- Grout Curtains: Chap. 11Документ30 страницGrout Curtains: Chap. 11Hồ ThắngОценок пока нет

- Dke78 Ch11Документ78 страницDke78 Ch11Hồ ThắngОценок пока нет

- Dke78 Ch12Документ8 страницDke78 Ch12Hồ ThắngОценок пока нет

- Dke78 Ch8Документ6 страницDke78 Ch8Hồ ThắngОценок пока нет

- Dke78 Ch9Документ21 страницаDke78 Ch9Hồ ThắngОценок пока нет

- Dke78 Ch3Документ26 страницDke78 Ch3Hồ ThắngОценок пока нет

- Piling, Nailing, and MixingДокумент10 страницPiling, Nailing, and MixingHồ ThắngОценок пока нет

- 07aДокумент58 страниц07aHồ ThắngОценок пока нет

- Dke78 Ch2Документ27 страницDke78 Ch2Hồ ThắngОценок пока нет

- Water Removal and WellpointingДокумент12 страницWater Removal and WellpointingHồ ThắngОценок пока нет

- 07bДокумент56 страниц07bHồ ThắngОценок пока нет

- 05aДокумент35 страниц05aHồ ThắngОценок пока нет

- 04cДокумент32 страницы04cHồ ThắngОценок пока нет

- 06aДокумент52 страницы06aHồ ThắngОценок пока нет

- 06bДокумент57 страниц06bHồ ThắngОценок пока нет

- 05cДокумент33 страницы05cHồ ThắngОценок пока нет

- 05bДокумент36 страниц05bHồ Thắng0% (1)

- 04bДокумент41 страница04bMoises Guilherme Abreu BarbosaОценок пока нет

- KIVO-CSV 4.2mmДокумент1 страницаKIVO-CSV 4.2mmRinda ManuОценок пока нет

- Chemistry Investigatory ProjectДокумент15 страницChemistry Investigatory ProjectArjit TiwariОценок пока нет

- Is 513 Amendment-1Документ2 страницыIs 513 Amendment-1sanjeev00747488Оценок пока нет

- Unit 6Документ13 страницUnit 6yuniОценок пока нет

- Liquid Diffusion MethodДокумент5 страницLiquid Diffusion MethodSUNDARAMAHALINGAM AОценок пока нет

- Recurrent Surge Oscillograph (RSO) For Rotor Winding Shorts DetectionДокумент5 страницRecurrent Surge Oscillograph (RSO) For Rotor Winding Shorts DetectionjjcanoolivaresОценок пока нет

- A Guide and Manual: Ceramic Reinforced Technologies Cerflon® and Certex™ Fluoroceramic ChemistryДокумент45 страницA Guide and Manual: Ceramic Reinforced Technologies Cerflon® and Certex™ Fluoroceramic Chemistryarmando lopezОценок пока нет

- DH31-EX Heat TreatДокумент4 страницыDH31-EX Heat TreatMichael KrummОценок пока нет

- High Silicon Infleunce of Heat Treatment AnnealingДокумент9 страницHigh Silicon Infleunce of Heat Treatment AnnealingFernando Martinez ContrerasОценок пока нет

- 252 Galvanic Corrosion Compatibilty Chart Technical InformationДокумент1 страница252 Galvanic Corrosion Compatibilty Chart Technical InformationDan CosacОценок пока нет

- ENSC 3008 Lecture Notes 2016Документ316 страницENSC 3008 Lecture Notes 2016richard4handokoОценок пока нет

- 2 Specimen PreparationДокумент5 страниц2 Specimen PreparationjanakОценок пока нет

- Common Surface Defects of Wire Rod and Steel Bar and Treatment MethodsДокумент4 страницыCommon Surface Defects of Wire Rod and Steel Bar and Treatment Methodsdofan thrimavithanaОценок пока нет

- StructurePoint Software Impact of Changes From ACI 318-14 To ACI-318-19Документ10 страницStructurePoint Software Impact of Changes From ACI 318-14 To ACI-318-19zaidg9876553Оценок пока нет

- Thermodynamics and Statistical Mechanics - Walter GreinerДокумент480 страницThermodynamics and Statistical Mechanics - Walter GreinerAldo Fernando G G92% (12)

- Planck's ConstantДокумент7 страницPlanck's ConstantAngy100% (1)

- 2011-11-09 Diana and AtenaДокумент8 страниц2011-11-09 Diana and AtenareluОценок пока нет

- Fundamentals of Coatings - Werner BlankДокумент18 страницFundamentals of Coatings - Werner Blankemac234Оценок пока нет

- Paper Summary FormatДокумент3 страницыPaper Summary FormatMohammed Salman KhanОценок пока нет

- Lyophilic and Lyophobic ColloidsДокумент7 страницLyophilic and Lyophobic Colloidsnagmaparvez111980Оценок пока нет

- Cat 1 of Finite Element Analysis and Applications OkДокумент4 страницыCat 1 of Finite Element Analysis and Applications Oknkuriza jean damasceneОценок пока нет

- Many Body Physics NotesДокумент239 страницMany Body Physics NotesAnonymous oK0EuQОценок пока нет

- Pass BДокумент9 страницPass BJoel JusayОценок пока нет

- INTERMOLECULAR VS Intramolecular ForcesДокумент4 страницыINTERMOLECULAR VS Intramolecular ForcesReeb BukhariОценок пока нет

- ME 328.3 E5 - Welding MetallurgyДокумент41 страницаME 328.3 E5 - Welding Metallurgytbmari100% (1)

- Asme Sa 199 Grade t11 TubesДокумент1 страницаAsme Sa 199 Grade t11 TubesFerroPipEОценок пока нет

- 1 s2.0 S0272884202002109 MainДокумент5 страниц1 s2.0 S0272884202002109 MainCamila ScienaОценок пока нет

- Styron 686E: High Heat Crystal PolystyreneДокумент2 страницыStyron 686E: High Heat Crystal PolystyreneMarwin PilayОценок пока нет

- Temperature SystemsДокумент10 страницTemperature SystemsrajaraghuramvarmaОценок пока нет

- Carpenter Stainless Type 430: IdentificationДокумент4 страницыCarpenter Stainless Type 430: Identificationumesh sengarОценок пока нет