Академический Документы

Профессиональный Документы

Культура Документы

Best Choice: Benson Boiler

Загружено:

Vaibhav Sarin0 оценок0% нашли этот документ полезным (0 голосов)

98 просмотров5 страницThe Benson boiler is the most widely used type of once-through boiler due to its high capacity and excellent operating characteristics. It can operate at steam pressures up to 350 bar and temperatures over 600°C. About a quarter operate at supercritical pressures. Benson boilers are highly efficient and can undergo rapid load changes. They have proven performance with over 1,000 units installed worldwide, making them popular in Europe, Japan, and South Africa. The document discusses the boiler's design capabilities and flexibility to use various fuels.

Исходное описание:

Benson Boiler

Оригинальное название

Best Choice

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документThe Benson boiler is the most widely used type of once-through boiler due to its high capacity and excellent operating characteristics. It can operate at steam pressures up to 350 bar and temperatures over 600°C. About a quarter operate at supercritical pressures. Benson boilers are highly efficient and can undergo rapid load changes. They have proven performance with over 1,000 units installed worldwide, making them popular in Europe, Japan, and South Africa. The document discusses the boiler's design capabilities and flexibility to use various fuels.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

98 просмотров5 страницBest Choice: Benson Boiler

Загружено:

Vaibhav SarinThe Benson boiler is the most widely used type of once-through boiler due to its high capacity and excellent operating characteristics. It can operate at steam pressures up to 350 bar and temperatures over 600°C. About a quarter operate at supercritical pressures. Benson boilers are highly efficient and can undergo rapid load changes. They have proven performance with over 1,000 units installed worldwide, making them popular in Europe, Japan, and South Africa. The document discusses the boiler's design capabilities and flexibility to use various fuels.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 5

Best Choice

Steam Turbines & Power Plants

by JOACHIM FRANKE and RUDOLF KRAL

BENSON BOILER

Power for generations

Excellent performance features make the Benson boiler the most widely used type

of once-through boiler

1 of 4 Siemens power journal online, October 2001

With a total of more than 1,000 units

having established a proven track record

over many years in the power generation

industry, the Benson boiler is the most

commonly used type of once-through

boiler. It operates at power levels of up to

1300 MW, steam pressures of up to 350 bar

and steam temperatures of up to more

than 600C. About a quarter of the units

operate at supercritical pressures.

Given its performance features and op-

erating characteristics, it is no surprise

that Benson technology has been success-

ful. Up to now, its use has been most wide-

spread in central Europe, Japan and South

Africa, but numerous countries are show-

ing growing interest in this technology.

Convincing Technology

Steam generators using the Benson de-

signone pass through the evaporator

section and variable endpoints of evapora-

tionincorporate features which are criti-

cal to economic success in todays compet-

itive power markets. These features in-

clude

a highly efficient steam/water cycle as a

result of supercritical pressures and high

steam temperatures,

ability to undergo rapid load changes

due to a design that allows unconstrained

thermal expansion and a variable-pres-

sure operating mode in the part-load

range,

BENSON BOILER

Best Choice

High capacity and excellent

operating characteristics are main

features of the Benson boiler,

making it the most widely used

type of once-through boiler

by Dr. JOACHIM FRANKE,

expert on Benson boiler technology, in charge of

licensing and continued development of this

steam generator type, Siemens Power Generation

and RUDOLF KRAL,

expert for steam generator technology in the

engineering sector and technical consultant to

Benson licensees, Siemens Power Generation

insensitivity of steam out-

put and superheated steam

temperature to fluctuating

fuel properties.

Benson boilers are equally

well suited for both subcritical

and supercritical pressures;

steam pressure is limited al-

most solely by the properties

of the materials used. Due to a

design that allows uncon-

strained thermal expansion

no drum, low storage mass-

esBenson boilers are ideal

for use in the mid- and peak-

load operating ranges. The

variable-pressure operating

mode prevents stressing of the

steam turbine materials due

to changes in temperature.

Environmental protection

also benefits due to the low

specific exhaust gas emissions

achieved as the result of high

efficiencies, as well as through

the use of low-NO

x

combus-

tion methods and proven,

powerful flue-gas cleaning

processes.

Performance Features

Highest Steam Pressures and

Temperatures

Supercritical steam pres-

sures were already being used

in central Europe in the 1960s,

while superheated steam tem-

peratures remained in the

540C/560C range until the

mid-1990s. The 550-MW Unit 5

Steam Turbines & Power Plants

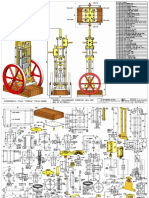

Furnace of a 930-MW lignite-

fired unit under construction

2 of 4 Siemens power journal online, October 2001

at the Staudinger power plant in Germany

is representative of this level of technolo-

gy with supercritical steam pressure at

full load and outlet temperatures of 545C

(with HP superheater) or 562C (with re-

heater). Other features of this unit include

variable-pressure operation and a net effi-

ciency of 43%.

At these steam temperatures, well-

proven and cost-effective ferritic materi-

als are adequate for the end stages of the

high-pressure and reheater heat-ex-

change surfaces. At higher temperatures,

more advanced ferritic chromium steels

are required for the thick-walled compo-

nents, while austenitic materials are re-

quired for the final superheater heat-ex-

change surfaces. The value of such materi-

als has been proven over many years of

service in the Benson boilers of the Danish

Nordjyllandsvaerket and Skaerbekvaerket

power plants, for example, at steam tem-

peratures of 580C. Operating experience

at 600C has to date been gained only

from boilers in Japan.

Today, state-of-the-art developments in

materials permit steam temperatures of

up to 600C (with HP superheater) or

620C (with reheater).

Variable Designs

Depending on plant-specific require-

ments, Benson boilers are of single- or

double-pass design.

The single-pass steam generator has

clear operational advantages when coals

with a high ash content or severely corro-

sive ash are used, since there is no reversal

of the flue gases and thus no additional

ash concentration in the vicinity of the

heat-exchange surfaces. All modern Euro-

pean lignite-fired steam generators are

therefore of the single-pass design. Other

advantages of this type of steam genera-

tor include single-wall design with its fa-

vorable unconstrained thermal expansion

characteristic.

The double-pass steam generator is

characterized by its low height and a com-

pact combustion chamber which, along

with the two separate flue-gas paths, pro-

vides advantages in terms of installation

options. Moreover, the separate cross sec-

tions of the second pass and combustion

chamber make it possible to optimize the

configuration of the convective heat-ex-

change surfaces, and thus also their size. A

typical example of the double-pass design

is the hard-coal-fired steam generator at

the Hemweg power plant in The Nether-

lands.

Flexible Use of Fuel

Since Benson boilers can be designed to

accommodate a wide range of coal types,

plant operators are able to use the lowest-

priced coal available. The combustion

chamber size and shape, the firing system

and the thermodynamics of the boiler are

then matched to the combustion proper-

ties of the range of fuels in question. Due

to the variable endpoint of evaporation,

the combustion chamber can be dimen-

Steam Turbines & Power Plants

Staudinger plant, Unit 5

550 MW

el

; hard-coal-fired

417 kg/s main steam

285 bar, 545C/562C

Germany

Nordjyllandsvaerket plant

410 MW

el

; imported coal

270 kg/s main steam

310 bar, 582C/580C

Denmark

Hemweg plant

660 MW

el

; imported coal

530 kg/s main steam

261 bar, 540C/540C

The Netherlands

sioned solely in accordance with the corre-

sponding firing characteristics.

One advantage of Benson boiler opera-

tion is that the required steam output and

main steam temperature are always

achieved, even if the properties of the coal

are highly variable. A prime example is

the Benson boiler at the Staudinger power

plant, which is capable of firing a wide

range of coalsfrom highly volatile hard

coals up to and including anthracitein

its amply dimensioned combustion cham-

bers with opposed firing.

Benson boilers can be outfitted with

various types of firing systems. In addi-

tion to conventional pulverized-coal fir-

ing, systems with liquid-ash separation,

with circulating fluidized beds, for exam-

ple, as well as systems for firing biomass

can be used. Examples are the boiler with

liquid-ash removal at the 660-MW Ibben-

bren power plant that has two slag-tap

furnaces with a common gas radiation

chamber, as well as the boiler with circu-

lating fluidized-bed firing at the 100-MW

Moabit power plant. At the Moabit plant

the fluidized-bed coolers, in addition to

the walls of the combustion chambers

and the ash cyclone, are also utilized as

evaporators.

In Demand Worldwide

In Germany, hard-coal-fired Benson

boilers in the 800-MW to 1000-MW out-

put range have been operating successful-

ly and at high availability levels for several

years. The two 930-MW units at the Lip-

pendorf power plant achieved this same

output using lignite, a much more prob-

lematic fuel. A steam generator of the

same capacity is also installed at the Box-

dorf power plant. These Benson boilers are

among the largest in the world, with a

combustion chamber cross section of

2424 m and a boiler height of more than

160 m.

As early as the 1950s and 1960s, a num-

ber of power plants built in the U.S. were

operating at supercritical steam pressure.

Since the boilers used at that time were

only marginally suitable for variable-pres-

sure operation, American manufacturers

today are also setting their sights on mod-

ern Benson boiler technology. Although

the American market has seen almost no

new plants built since the mid-1980s, this

technology is being used successfully for

export.

In Japan, the development trend in re-

cent years has been toward very high

steam pressures and temperatures. Since

1980, once-through boilers have been es-

sentially the only type used in power

plants in Japan, about half of them Ben-

son boilers operating at supercritical pres-

sures. Steam generators operating super-

heated steam temperatures of 600C and

with capacities of up to 1000 MW have al-

ready been in operation for many years. In

Japan, traditional preference has been giv-

en to the double-pass design, such as that

used at the Hekinan power plant. Due to

the low ash content of the coals used, the

operational advantages of the single-pass

design with regard to wear and tear of the

heat-exchange surfaces would not be sig-

nificant.

Steam Turbines & Power Plants

Ibbenbren plant

750 MW

el

; anthracite

600 kg/s main steam

220 bar, 530C/530C

Germany

Hekinan plant

700 MW

el

; imported coal

639 kg/s main steam

255 bar, 543C/569C

Japan

Lippendorf plant

930 MW

el

; lignite

672 kg/s main steam

285 bar, 554C/583C

Germany

3 of 4 Siemens power journal online, October 2001

Steam Turbines & Power Plants

4 of 4 Siemens power journal online, October 2001

At the beginning of the 1970s, South

Africa recognized the advantages of Ben-

son boiler technology. Since that time,

twenty-four large units with ratings be-

tween 500 and 730 MW have been outfit-

ted with Benson boilers. The single-pass

design is preferred due to the high ash

content of the coal in that region.

In China, both drum-type and once-

through boilers are used for unit ratings of

up to 300 MW. In the future, plants in the

700/900-MW class will be designed only

for supercritical steam pressures and tem-

peratures. A supercritical, hard-coal-fired,

double-pass Benson boiler is currently be-

ing designed for the 700-MW Taishan

plant.

Outlook on Further Development

Worldwide use of the Benson boiler is

in no small measure the result of ongoing

efforts at Siemens Power Generation to

further develop this technology. The ex-

panded knowledge base obtained

through detailed studies, particularly of

the heat transfer mechanisms within the

combustion chamber tubes, has made an

important contribution to this effort.

New evaporator designs with vertical

tubing will continue to improve operating

behavior and make manufacture of the

boilers more cost-effective. An initial ref-

erence boiler that employs this new evap-

orator design is already under develop-

ment for refurbishment of a coal-fired

300-MW steam generator in China.

The Benson boiler is also ideally suited

for even higher steam pressures and tem-

peratures (designs for temperatures of

700C with plant efficiencies of more than

50% are being studied as part of the EUs

THERMIE project) due to its variable, freely

expandable construction and high operat-

ing flexibility. I

Licensees for Benson Boiler Manufacture

FLS milj (Burmeister & Wain)

Babcock-Hitachi

Kawasaki Heavy Industries

Babcock Borsig Power

(Deutsche Babcock, Steinmller)

Mitsui Babcock Energy

BHEL

Ansaldo

Babcock & Wilcox

Foster Wheeler

Austrian Energy & Environment

Denmark

Japan

Germany

England

India

Italy

USA

Austria

Leading manufactur-

ers around the world

are marketing the

advantages of Ben-

son boiler technolo-

gy through licensing

agreements. At

Siemens, activities

related to the Ben-

son boiler include

boiler design, ther-

modynamic and hy-

draulic design, start-

up systems, control

concepts and oper-

ating principles.

Hekinan Hemweg Staudinger Ibbenbren Lippendorf Nordjyllandsvaerket

Вам также может понравиться

- Innovation in Electric Arc Furnaces: Scientific Basis for SelectionОт EverandInnovation in Electric Arc Furnaces: Scientific Basis for SelectionОценок пока нет

- Best Choice BENSON BOILER. Excellent Performance Features Make The Benson Boiler The Most Widely Used Type of Once-Through BoilerДокумент5 страницBest Choice BENSON BOILER. Excellent Performance Features Make The Benson Boiler The Most Widely Used Type of Once-Through BoilerStefanos DiamantisОценок пока нет

- Benson BoilersДокумент20 страницBenson BoilersPrasanna Kumar100% (1)

- The Advantages of Supercritical Circulating Fluidized Bed Boiler (Posted by P.Muthu, DGM-TSX) PDFДокумент19 страницThe Advantages of Supercritical Circulating Fluidized Bed Boiler (Posted by P.Muthu, DGM-TSX) PDFRKVSK1Оценок пока нет

- Horizontal Boilers Make 700C Steam EconomicДокумент5 страницHorizontal Boilers Make 700C Steam EconomicKrishnan Santhanaraj100% (1)

- Fluidized Bed Combustion in PracticeДокумент95 страницFluidized Bed Combustion in PracticeLTE002Оценок пока нет

- Progress of The Weston Unit 4 Supercritical Project in Wisconsin PDFДокумент6 страницProgress of The Weston Unit 4 Supercritical Project in Wisconsin PDFktsnlОценок пока нет

- Ipsen Vacuum TechnologyДокумент6 страницIpsen Vacuum TechnologyJacques GillesОценок пока нет

- Bwe Aph-GghДокумент20 страницBwe Aph-GghDaniellzhangОценок пока нет

- Cesc 6Документ64 страницыCesc 6Tinku ChoudhuryОценок пока нет

- BoilerДокумент29 страницBoilerMadhan RajОценок пока нет

- Alstom BoilerДокумент15 страницAlstom BoilertuyencntnОценок пока нет

- Alstom CFBДокумент7 страницAlstom CFBCoalhouse Walker JuniorОценок пока нет

- SORG Glas - Melting TechnologyДокумент27 страницSORG Glas - Melting Technologymetalman_m100% (2)

- STF Industrial BoilersДокумент20 страницSTF Industrial BoilersDaniellzhangОценок пока нет

- Pulverized Coal TechnologyДокумент7 страницPulverized Coal TechnologyRi KoОценок пока нет

- L&T ManualДокумент60 страницL&T ManualDineshОценок пока нет

- 2.2 Melting Techniques: 2.2.1 Regenerative FurnacesДокумент7 страниц2.2 Melting Techniques: 2.2.1 Regenerative FurnacesRicardo VelozОценок пока нет

- Katalog Per-Eko enДокумент13 страницKatalog Per-Eko enapi-246705026Оценок пока нет

- Ipsen Atmosphere TechnologyДокумент5 страницIpsen Atmosphere TechnologyCarlos SartoriОценок пока нет

- Boiler Circulation 2Документ20 страницBoiler Circulation 2Siva SubramaniyanОценок пока нет

- Amec Foster Wheeler Industrial BrochureДокумент12 страницAmec Foster Wheeler Industrial BrochureArual PerezОценок пока нет

- Equipment Design - BOILERSДокумент24 страницыEquipment Design - BOILERSEmyu ClaridadОценок пока нет

- SuperCritical Boiler 1Документ45 страницSuperCritical Boiler 1swatantar17100% (1)

- Valuable Energy!: Engine Manufacturers. Genset IntegratorsДокумент2 страницыValuable Energy!: Engine Manufacturers. Genset IntegratorsJeff LangleyОценок пока нет

- 460 Mwe Supercritical Otu CFB Boiler: Łagisza Power Plant PolandДокумент8 страниц460 Mwe Supercritical Otu CFB Boiler: Łagisza Power Plant PolanddhmbasОценок пока нет

- Industrial BoilersДокумент11 страницIndustrial Boilerstesfayregs gebretsadikОценок пока нет

- Micro 248Документ9 страницMicro 248Huyentrang NguyenОценок пока нет

- Industrial Boiler PlantsДокумент12 страницIndustrial Boiler Plantsanon_411130333Оценок пока нет

- Posiflow Technology of Doosan Babcock For Supercritical BoilersДокумент12 страницPosiflow Technology of Doosan Babcock For Supercritical BoilersKarthick VelayuthamОценок пока нет

- CoalFiring HitachiДокумент20 страницCoalFiring HitachimehariiОценок пока нет

- Following The Power Demand: Modern Multistage Boiler-Feed PumpsДокумент3 страницыFollowing The Power Demand: Modern Multistage Boiler-Feed PumpsghostamirОценок пока нет

- Advanced Fire-Tube Boiler ProjectДокумент10 страницAdvanced Fire-Tube Boiler ProjectRonnieldОценок пока нет

- CFCB Bed Ash CoolerДокумент11 страницCFCB Bed Ash CoolerUdhayakumar VenkataramanОценок пока нет

- 3s Steam BoilerДокумент13 страниц3s Steam BoilertahirОценок пока нет

- Types of Boilers and Types of Hydrostatic Test: Boiler ComponentsДокумент10 страницTypes of Boilers and Types of Hydrostatic Test: Boiler ComponentsIbrahim MustafaОценок пока нет

- Steam Turbine Gas Turbine 002Документ6 страницSteam Turbine Gas Turbine 002dheerajdb99100% (1)

- PILLARD AKTUEL Progressive BurningДокумент3 страницыPILLARD AKTUEL Progressive BurningSteveih100% (1)

- 1 PDFДокумент9 страниц1 PDFAswini Kumar DashОценок пока нет

- Once ThroughДокумент6 страницOnce ThroughmikeОценок пока нет

- Alstom BFB PDFДокумент18 страницAlstom BFB PDFNaveed RabbaniОценок пока нет

- Industrial Steam Turbines Improve Energy Utilization in Thermal Power Plants by R. WicklДокумент8 страницIndustrial Steam Turbines Improve Energy Utilization in Thermal Power Plants by R. WickljnmanivannanmechОценок пока нет

- Depliant Brochure Marine en PDFДокумент9 страницDepliant Brochure Marine en PDFFadzil NorОценок пока нет

- STEAM TURBINE 3 Design and MaterialsДокумент19 страницSTEAM TURBINE 3 Design and MaterialsHandayani Kesumadewi100% (2)

- How To Increase The Efficiency of Commercial BoilersДокумент48 страницHow To Increase The Efficiency of Commercial BoilersAnas AsifОценок пока нет

- CB HRSG BrochureДокумент12 страницCB HRSG BrochuresaadounОценок пока нет

- Technical Concept StanariДокумент1 страницаTechnical Concept StanariNamik HadziibrahimovicОценок пока нет

- 1386 - C11 Burner Design PDFДокумент32 страницы1386 - C11 Burner Design PDFMartin Martin MartinОценок пока нет

- Ganapathy PDFДокумент90 страницGanapathy PDFpinenamuОценок пока нет

- Boiler StudyДокумент158 страницBoiler Studykarthikraja21100% (2)

- Lechner StephanДокумент9 страницLechner StephanleekiangyenОценок пока нет

- The Benson Boiler Turns 75Документ4 страницыThe Benson Boiler Turns 75Rio HuangОценок пока нет

- Operation of 300MW CFBC BoilerДокумент6 страницOperation of 300MW CFBC BoilerSoodamany Ponnu PandianОценок пока нет

- Different Shaft Kiln For Lime ManufacturerДокумент13 страницDifferent Shaft Kiln For Lime ManufactureranjnaОценок пока нет

- Mechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesОт EverandMechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesОценок пока нет

- Encyclopaedia Britannica, 11th Edition, Volume 8, Slice 3 "Destructors" to "Diameter"От EverandEncyclopaedia Britannica, 11th Edition, Volume 8, Slice 3 "Destructors" to "Diameter"Оценок пока нет

- Common Wealth Scholarship RequirementsДокумент10 страницCommon Wealth Scholarship RequirementsMohsin KhanОценок пока нет

- Sri LankaДокумент1 страницаSri LankaVaibhav SarinОценок пока нет

- Mantra RD Service Manual WindowsДокумент16 страницMantra RD Service Manual WindowsHeeranand ChandwaniОценок пока нет

- Insights IAS Timetable For Prelims Test Series 2018 Sheet1 PDFДокумент16 страницInsights IAS Timetable For Prelims Test Series 2018 Sheet1 PDFVishwanathSrinivasОценок пока нет

- CourseДокумент16 страницCourseVaibhav SarinОценок пока нет

- Startup Purge Credit Benefits Combined Cycle OperationsДокумент13 страницStartup Purge Credit Benefits Combined Cycle OperationsVaibhav SarinОценок пока нет

- Planning Bus Driver Rosters: Marta Mesquita, Margarida Moz, Ana Paias and Margarida PatoДокумент6 страницPlanning Bus Driver Rosters: Marta Mesquita, Margarida Moz, Ana Paias and Margarida PatoVaibhav SarinОценок пока нет

- Senior Bus Routes 2019-20-NewДокумент11 страницSenior Bus Routes 2019-20-NewVaibhav SarinОценок пока нет

- Commonwealth Scholarships For Developing CountriesДокумент5 страницCommonwealth Scholarships For Developing CountriesVaibhav SarinОценок пока нет

- Dream 11 IPL 2020 Match Schedule UAE PDFДокумент2 страницыDream 11 IPL 2020 Match Schedule UAE PDFAadhi RøckzŹźОценок пока нет

- Scheduled Maintenance PracticesДокумент5 страницScheduled Maintenance PracticesVaibhav SarinОценок пока нет

- 2019 ERP Candidate GuideДокумент24 страницы2019 ERP Candidate GuideVaibhav SarinОценок пока нет

- 5ab601ba 366430 4Документ1 страница5ab601ba 366430 4Vaibhav SarinОценок пока нет

- Dream 11 IPL 2020 Match Schedule UAE PDFДокумент2 страницыDream 11 IPL 2020 Match Schedule UAE PDFAadhi RøckzŹźОценок пока нет

- Placement ReportДокумент35 страницPlacement ReportVaibhav SarinОценок пока нет

- CFA Level I 2019 - 2020 Curriculum Changes: Subjects 2019 Reading No Reading NameДокумент20 страницCFA Level I 2019 - 2020 Curriculum Changes: Subjects 2019 Reading No Reading NameVaibhav SarinОценок пока нет

- Vodafone 4G Data Plans 4G Net Pack Price List For Prepaid - 24th September, 2020Документ1 страницаVodafone 4G Data Plans 4G Net Pack Price List For Prepaid - 24th September, 2020Vaibhav SarinОценок пока нет

- CourseДокумент16 страницCourseVaibhav SarinОценок пока нет

- Quant 700 To 800 Level QuestionsДокумент87 страницQuant 700 To 800 Level QuestionsBakayoko VaflalyОценок пока нет

- Vodafone 4G Data Plans 4G Net Pack Price List For Prepaid - 24th September, 2020Документ1 страницаVodafone 4G Data Plans 4G Net Pack Price List For Prepaid - 24th September, 2020Vaibhav SarinОценок пока нет

- 3 Pressure Losses During Fluid Flow Through Straight Pipes and Local ResistancesДокумент8 страниц3 Pressure Losses During Fluid Flow Through Straight Pipes and Local ResistancesVaibhav SarinОценок пока нет

- 2019 ERP Candidate GuideДокумент24 страницы2019 ERP Candidate GuideVaibhav SarinОценок пока нет

- Commonwealth Scholarships For Developing CountriesДокумент5 страницCommonwealth Scholarships For Developing CountriesVaibhav SarinОценок пока нет

- Vodafone Idea Latest Plans After Rate Hike New Packs, Data, Validity ExplainedДокумент1 страницаVodafone Idea Latest Plans After Rate Hike New Packs, Data, Validity ExplainedVaibhav SarinОценок пока нет

- Level of Difficulty Ethical and Professional StandardsДокумент6 страницLevel of Difficulty Ethical and Professional StandardsVaibhav SarinОценок пока нет

- Commonwealth Scholarships For Developing CountriesДокумент5 страницCommonwealth Scholarships For Developing CountriesVaibhav SarinОценок пока нет

- Yojana April 2013Документ57 страницYojana April 2013Vaibhav SarinОценок пока нет

- Far EastДокумент108 страницFar EastVaibhav SarinОценок пока нет

- Mechanical Engg IIДокумент9 страницMechanical Engg IIVaibhav SarinОценок пока нет

- Steam ProblemsДокумент10 страницSteam ProblemsCaro Kan LopezОценок пока нет

- Experiment No. 1 Measurement of Heating Surface of A Firetube BoilerДокумент16 страницExperiment No. 1 Measurement of Heating Surface of A Firetube BoilerAli Requiso MahmudОценок пока нет

- Boiler: For The Limp Bizkit Song, SeeДокумент12 страницBoiler: For The Limp Bizkit Song, SeeMahesh G RajuОценок пока нет

- High Silica After Overhaul of Fouled TurbineДокумент3 страницыHigh Silica After Overhaul of Fouled Turbineak_thimiriОценок пока нет

- Punch List Ss RFCC Qc-2015!09!21Документ2 страницыPunch List Ss RFCC Qc-2015!09!21sinambeladavidОценок пока нет

- What Are Boiler AccessoriesДокумент7 страницWhat Are Boiler AccessoriesTHEOPHILUS ATO FLETCHERОценок пока нет

- 13 RDM 181185Документ13 страниц13 RDM 181185orangelanaya-1Оценок пока нет

- Sample QuestionsДокумент3 страницыSample QuestionsRAJKUMARОценок пока нет

- Boiler 2Документ25 страницBoiler 2Aashid PsОценок пока нет

- Notes - Thermal Power PlantДокумент51 страницаNotes - Thermal Power Planteddula ganeshОценок пока нет

- Maquina 34 PDFДокумент3 страницыMaquina 34 PDFEstefannyОценок пока нет

- Steam Powered TrainДокумент8 страницSteam Powered Trainapi-340237311Оценок пока нет

- Attachment #2 Marked-Up P&id PDFДокумент17 страницAttachment #2 Marked-Up P&id PDFzhangОценок пока нет

- Enroll 64 65 66 68 75 EmeДокумент114 страницEnroll 64 65 66 68 75 EmeHarsh PatelОценок пока нет

- Dual Pressure (Double Evaporation) Boilers: Secondary DrumДокумент3 страницыDual Pressure (Double Evaporation) Boilers: Secondary DrumMeghanath AdkonkarОценок пока нет

- Its Generation and Use, by Babcock & Wilcox Co. 1Документ225 страницIts Generation and Use, by Babcock & Wilcox Co. 1rapasconОценок пока нет

- Railwaylocomotiv 36 NewyuoftДокумент426 страницRailwaylocomotiv 36 NewyuoftKrishna VamsiОценок пока нет

- Basics Steam BoilersДокумент29 страницBasics Steam BoilersZia Ul HassanОценок пока нет

- Garden Rail - N°284 - 2018-04Документ64 страницыGarden Rail - N°284 - 2018-04Valery GagichОценок пока нет

- Example 1: Bar 035 - 0 at 2 Bar 42 at 1Документ3 страницыExample 1: Bar 035 - 0 at 2 Bar 42 at 1CantalicioОценок пока нет

- AQC Integral Pipe Support Inspection - HPДокумент2 страницыAQC Integral Pipe Support Inspection - HPGoutam HotaОценок пока нет

- BC 1.1 000213 PhoenixДокумент8 страницBC 1.1 000213 PhoenixGIrindera ChoirusmanОценок пока нет

- Bme ExperimentДокумент4 страницыBme Experimentmspiso2000Оценок пока нет

- Steam Generators or Boilers: Chapter-2 Steam Generator (25 Marks) 5 Sem Mechanical EnggДокумент12 страницSteam Generators or Boilers: Chapter-2 Steam Generator (25 Marks) 5 Sem Mechanical EnggDarklightОценок пока нет

- Flow Sheet Eh-500fk 1000-030-9846Документ1 страницаFlow Sheet Eh-500fk 1000-030-9846thanh thien nguyenОценок пока нет

- Alarm Trip Setting List 3Документ35 страницAlarm Trip Setting List 3Vraja KisoriОценок пока нет

- Thermal Power PlantДокумент13 страницThermal Power PlantSanat KumarОценок пока нет

- BoilersДокумент38 страницBoilersAshlin Augusty92% (24)

- HRSG DeaeratorДокумент2 страницыHRSG DeaeratorTripoli2010Оценок пока нет

- HRSG Steam Blow (Load 20 MW) PDFДокумент2 страницыHRSG Steam Blow (Load 20 MW) PDFKanzanah PettaraniОценок пока нет