Академический Документы

Профессиональный Документы

Культура Документы

PIIID

Загружено:

Lionel81Исходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

PIIID

Загружено:

Lionel81Авторское право:

Доступные форматы

Logo

Home

Projects

Forum

Cytron Technologies Official Website

Navigation

open all | close all

Getting Started

rero

Buying Guides

Product Guides

Projects

Seminars & Events

News

Useful Tools / External References

Live Search

Sign In

User

Password

Remember me

Become a Member

Recover Password

Recent Comments

show plates direct on New Training Kit Coming!

ravi on Arduino Controlling MDS40A

pam on Fingerprint Reader Integrated SM630 with SM630 PC Demo GUI

Aniket on Wireless UART with Arduino and 433MHz or 434MHz module

ober on Arduino Wireless Programming (Bluetooth)

Home Getting Started Programming/Software PID for Embedded Design

Tags: Embedded, PIC Microcontroller, PID Control

PID for Embedded Design

31

Share

1

Share

Share

Share

By Kong Wai Weng

RH2T Mag, Vol.4, Mar 2010

PID control system is one of the most mature and commonly used control strategie

s in the industrial for decades thanks to its simple but effective algorithm. In

this article, we will discuss the basic concept of PID controller and how to im

plement it in the embedded system.

Introduction

Closed loop control system is an essential topic for embedded systems, bringing

together actuators and sensors with the control algorithm in software. For examp

le, motor speed can be controlled by varying the PWM duty cycle used to drive th

e motor. This is the open-loop control. However, due to the lack of feedback, th

e actual motor speed could not be verified. This is important because driving th

e motor with the same PWM duty cycle does not guarantee the motor to run at the

same speed under all circumstances. A motor will run faster in load free conditi

on than under load with the same PWM signal. In order to control the motor speed

, we need to close the loop by adding feedback of the actual motor speed to the

controller.

Besides speed control, PID control system can also be used to control other para

meters such as position, temperature, water level, stability, etc. In this artic

le, we will discuss how to implement a PID controller for position control based

on PR24.

The Problem DC Motor Position Control.

Before we begin to design a PID controller, we need to understand the problem. I

n this example, we want to move the shaft of the motor from its current position

to the target position.

motor

We want to move the output shaft of the motor from current position to target po

sition

There are a few terms commonly used to describe the PID control loops, such as:

Control Variable (CV) This is the output of the control loop. In this case, the

CV is the duty cycle of the PWM signal that drives the motor.

Process Variable (PV) This is the feedback value returned by the system to the c

ontroller. In this example, the PV is the current angle of the motor shaft.

Set Point (SP) Set point is the value that we desire for the system. In our case

, the SP is the target position of the motor shaft in angle.

Error (E) Error refers to the difference between the set point and the process v

ariable. In another words, it means how far the current position of the motor sh

aft from the target position.

The Hardware PR24

The Cytrons DIY Project Set PR24 (PID Motor Controller) is the best platform for

beginner to learn the PID algorithm. It has the following features:

PIC16F876A as the main controller.

Geared DC motor as the output.

Multi-turn variable resistor connected to the motor shaft for position feedback.

216 Character LCD for tuning and troubleshooting.

Presets for PID tuning.

Picture 049

DIY Project Set PR24 PID Motor Controller

The sample source code for the PR24 (PID Motor Controller) can be downloaded fro

m Cytrons website under the PR24 product page.

The Implementation of PID Controller

The PID controller, just like its name, comprises a proportional (P), an integra

l (I) and a derivative (D) part. The controller parts are introduced in the foll

owing sections individually and in combined operation.

Proportional Controller

When the current position of the motor shaft is still far away from the target p

osition, we want to apply more power to drive the motor towards the target posit

ion so that we can reach there faster. When the shaft is getting nearer to the t

arget position, we will reduce the power to slow it down. At the time the shaft

reaches the target position, the motor needs to be stopped. If the shaft positio

n has overshot, we need to apply negative power to the motor (reverse the motor)

to bring it back to the target position.

In short, this is called proportional controller because the power we apply to t

he motor is proportional to the error of the system.

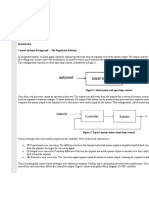

pid

The block diagram of proportional controller

From the block diagram of proportional controller, we can see that the PWM duty

cycle (output) is the result of multiplying the error with a constant, Kp.

Error = Set Point Process Variable

Control Variable = Kp * Error

Figure below shows the example of proportional loop implemented in C language.

clip_image007

Implementation of proportional loop in C language

The value of Kp needs to be chosen carefully in order to get the optimum system

response. Lower values for Kp will tend to give smoother but slower responses.

clip_image009

System response for proportional controller with low Kp

Higher values of Kp will yield much quicker response but may cause overshoot, wh

ere the output oscillates before settling.

clip_image011

System response for proportional controller with high Kp

Excessively high values of Kp may even throw the loop into an unstable state whe

re the output oscillates without ever settling at the set point.

clip_image013

System response for proportional controller with excessively high Kp

Integral Controller

As can be seen from the graph of P controller, the actual position of the motor

shaft, when settles down will not reach the target position. This is because whe

n the current position is near to the target position, the error becomes very sm

all and the computed PWM duty cycle is too small for the motor to overcome the f

riction and gravity. The small error that exists when the system has settled dow

n is called the steady state error.

Steady State Error

Steady state error due to the friction and gravity

To overcome the problem of steady state error for the P controller, I controller

is being introduced. As its name suggests, the integral is merely an accumulate

d error signals encountered since startup.

Integral = ?(Error)

This total is multiplied by a constant, Ki, and is added into the loop output. U

nlike the P controller, the I controller is rarely used alone, but mostly in com

bination with the P or PD controller. When the system has already settled down w

ith a small steady state error, the integral still continues to accumulate until

the CV is large enough to bring the PV inline with SP. The equations for PI con

troller are as follow:

Error = Set Point Process Variable

Integral = Integral + Error

Control Variable = (Kp * Error) + (Ki * Integral)

Figure below shows the example of PI controller implemented in C language.

clip_image017

Implementation of PI loop in C language

Just like the P controller, the value of Ki needs to be chosen carefully. Too lo

w the value, the steady state error is corrected very slowly; too high the value

, the system becomes unstable and oscillates.

clip_image019

System response for PI controller with no steady state error

Because the integral can grow quite large when the set point cannot be reached,

some applications stop accumulating the error when the CV is saturated.

Derivative Controller

Lets say you are driving a car, and you need to stop your car exactly 100m from y

our current position as soon as possible. If you are travelling at 10km/h, you w

ould want to accelerate your car so that you can reach the target sooner. In con

trast, if you are cruising at 100km/h, you need to start braking so that you can

stop at 100m and will not overshoot. This is where the derivative controller co

mes into play.

The derivative of any variable describes how that variable changes over time. In

a PID controller, the derivative is the rate of change of the error. In digital

form, it can be described as:

Derivative = Error Last Error

where Error is the current error value and Last Error is the error value for the

previous iteration.

Negative values of derivative indicate an improvement (reduction) in the error s

ignal. For example, if the last error was 20 and the current error is 10, the de

rivative will be -10. When these negative values are multiplied with a constant,

Kd, and are added to the output of the loop, it can slow down the system when a

pproaching the target.

Just like the I controller, the D controller is rarely used alone, but mostly in

combination with the P or PI controller. The equations for the PD controller ar

e as follow:

Last Error = Error

Error = Set Point Process Variable

Derivative = Error Last Error

Control Variable = (Kp * Error) + (Kd * Derivative)

Figure below shows the example of PD controller implemented in C language.

clip_image021

Implementation of PD loop in C language

The damping effect of the D controller allows the system to have a higher value

of Kp and/or Ki without overshooting. In consequent, this will give the system a

better response time to set point changes. However, too high the value of Kd wi

ll also have negative effect. The D controller tense to amplify the noise exists

in the feedback loop. If the Kd is too high, the system will become jerky if th

e feedback loop is noisy.

clip_image023

System response for PD controller

Joining Them Together PID Controller

By joining the P, I and D controller, we can take the advantages of the combined

benefits from each controller. We have the P controller for fast system respons

e, I controller to correct the steady state error and D controller to dampen the

system and reduce overshoot.

clip_image025

The block diagram of PID controller

From the block diagram of PID controller, we can see that the output of the loop

is merely the sum of output from P, I and D controller. The equations for the P

ID loop are illustrated below:

Last Error = Error

Error = Set Point Process Variable

Integral = Integral + Error

Derivative = Error Last Error

Control Variable = (Kp * Error) + (Ki * Integral) + (Kd * Derivative)

Figure below shows the example of PID controller implemented in C language.

clip_image027

Implementation of PID loop in C language

clip_image029

System response for the correctly tuned PID controller

Summary

PID controller is a simple yet effective control system widely used in industria

l. However, to implement the PID controller is simple, but not the tuning. The p

rocess of tuning the PID parameters (Kp, Ki and Kd) is a continuous trial and er

ror process. There is no exact way to calculate the value for the parameters unl

ess the whole system is mathematically modeled and simulated. Experience is an i

mportant factor to get the optimum PID parameters based on the observation of th

e system behavior during the tuning process. If you have inquiry, feel free to d

iscuss in our technical forum.

References:

Dennis Clark and Michael Owings: Building Robot Drive Trains.

Thomas Braunl: Embedded Robotics Mobile Robot Design and Applications with Embed

ded Systems.

http://en.wikipedia.org/wiki/PID_controller

http://www.expertune.com/tutor.html

http://www.newportus.com/products/techncal/techncal.htm

http://www.dprg.org/tutorials/2003-10a/motorcontrol.pdf

31

1

1

You may also like:

SIEMENS TC35 GSM Development Board, GSM-TC35

G15 Cube Servo on Mobile Robot

CIKU + LCD Keypad Shield

Controlling MD10C with Arduino

CIKU + Mifare Reader/Writer CR038

Low cost DC supply solution, 3.7V 1100mAh Li-Ion Battery (LI-3.7-1100

Related Posts:

How RC Servo Works?How RC Servo Works?

How does Stepper Motor Works Part 1How does Stepper Motor Works Part 1

Configure the Operation Mode (Closed Loop or Open Loop) of BLD04AConfigure the O

peration Mode (Closed Loop or Open Loop) of

How Does Stepper Motor Works Part 2How Does Stepper Motor Works Part 2

Published by: ober on June 22, 2012.

2 Responses to PID for Embedded Design

vamsi krishna says:

July 25, 2013 at 1:27 am

nice tutorial . is there any tutorial for implementing the fuzzy logic in microc

ontroller for motor control

tinku jangid says:

August 24, 2014 at 5:33 pm

can u tell me how much we will generate in relate to get a fixed or set point fr

equency

Leave a Reply

Name (required)

Mail (will not be published) (required)

Website

.

Help us improve the wiki Send Your Comments

2012 Tutorial by Cytron | Powered By Wordpress

Вам также может понравиться

- PID Control ArdunioДокумент8 страницPID Control ArdunioSyed Abdul Haseeb AhmedОценок пока нет

- MX009 - Proportional Integral Derivative Control PDFДокумент5 страницMX009 - Proportional Integral Derivative Control PDFjorgemdp5Оценок пока нет

- The Working Principle of A PID Controller For BeginnersДокумент15 страницThe Working Principle of A PID Controller For BeginnersSaber AbdelaalОценок пока нет

- PID ControllersДокумент6 страницPID ControllersNguyễn HảiОценок пока нет

- Implementing a simple PID controller without advanced mathДокумент14 страницImplementing a simple PID controller without advanced mathGiovanni Eliezer100% (2)

- PID Controller Working Principle Explained For BeginnersДокумент6 страницPID Controller Working Principle Explained For BeginnersPramillaОценок пока нет

- Unit 3 PLC PDFДокумент15 страницUnit 3 PLC PDFMahesh ShendeОценок пока нет

- Proportional Integral Derivative (PID)Документ27 страницProportional Integral Derivative (PID)GilagidkidОценок пока нет

- EVMS Full Notes PDFДокумент78 страницEVMS Full Notes PDFNaveen DhanurajОценок пока нет

- How Does A PID Controller Work - Structure & Tuning MethodsДокумент12 страницHow Does A PID Controller Work - Structure & Tuning Methodsmurugan1984Оценок пока нет

- PID Speed Control of DC Motor Using MicrocontrollerДокумент7 страницPID Speed Control of DC Motor Using MicrocontrollerGias NawariОценок пока нет

- PID ControllerДокумент5 страницPID ControllerAbhilash MallikarjunaОценок пока нет

- Drive Unit 4 Closed Loop Control of DC DriveДокумент22 страницыDrive Unit 4 Closed Loop Control of DC DriveswamОценок пока нет

- Control Systems Background - The Regulation ProblemДокумент19 страницControl Systems Background - The Regulation ProblemHilmy Pramuditya FhansuriОценок пока нет

- Implementing A PID Controller Using A PICДокумент15 страницImplementing A PID Controller Using A PICJavier CharrezОценок пока нет

- 21 THДокумент32 страницы21 THujjwal kumarОценок пока нет

- Pid MSP PDFДокумент6 страницPid MSP PDFAlberto Corona MartinezОценок пока нет

- Lab 4: Positional Servo Using P.I.D Control Positional Servo Using P.I.D ControlДокумент9 страницLab 4: Positional Servo Using P.I.D Control Positional Servo Using P.I.D ControlEugene Jin LeowОценок пока нет

- PID CONTROLLER LECTURE ON AUTOMATION AND ROBOTICSДокумент31 страницаPID CONTROLLER LECTURE ON AUTOMATION AND ROBOTICSAndré GomesОценок пока нет

- PID CONTROLLER EXPERIMENTДокумент13 страницPID CONTROLLER EXPERIMENTMohd KhairiОценок пока нет

- Project 2: DC Motor ControlДокумент7 страницProject 2: DC Motor ControlhunnbajajОценок пока нет

- PIDДокумент21 страницаPIDMukesh JainОценок пока нет

- PID Controllers Explained: Jacques Smuts, PH.DДокумент4 страницыPID Controllers Explained: Jacques Smuts, PH.Djenix105Оценок пока нет

- Products Home Rapid Order Services The Company Contact Us My ThorlabsДокумент2 страницыProducts Home Rapid Order Services The Company Contact Us My Thorlabsअमरेश झाОценок пока нет

- Vpat 10Документ10 страницVpat 10Xavier DannyОценок пока нет

- Mizan Tepi Campus Lab Report Speed Control of DC MotorДокумент16 страницMizan Tepi Campus Lab Report Speed Control of DC MotorMelaku DinkuОценок пока нет

- Group 4 Lab 5Документ16 страницGroup 4 Lab 5Melaku DinkuОценок пока нет

- Pid ExplainedДокумент4 страницыPid ExplainedShiva Sai BuraОценок пока нет

- Implementing A PID Control System On A Microcontroller: Using The Example of A Microchip PIC 18F4550Документ12 страницImplementing A PID Control System On A Microcontroller: Using The Example of A Microchip PIC 18F4550Venkatesan SundaramОценок пока нет

- Special Nonlinear PID ControllersДокумент25 страницSpecial Nonlinear PID ControllersawalmeidaОценок пока нет

- Design and applications of fuzzy logic PID controllerДокумент19 страницDesign and applications of fuzzy logic PID controllerPriya BhardwajОценок пока нет

- IoT2x Module 4 PID ActivityДокумент5 страницIoT2x Module 4 PID Activityvanishree raОценок пока нет

- EE402 RecitationДокумент64 страницыEE402 Recitationvignesh0617Оценок пока нет

- PID ControllerДокумент22 страницыPID ControllerFoo He XuanОценок пока нет

- A Simple Method For Servo Motor Tuning - National InstrumentsДокумент5 страницA Simple Method For Servo Motor Tuning - National InstrumentsSan BanОценок пока нет

- DC Motor Speed Control Part I: Open-Loop CommandДокумент5 страницDC Motor Speed Control Part I: Open-Loop CommandEbd RahmanОценок пока нет

- Control SystemsДокумент18 страницControl Systemsgayatri jaltareОценок пока нет

- PID Controller Explained - PID ExplainedДокумент10 страницPID Controller Explained - PID ExplainedShahid AnwarОценок пока нет

- Optimize PID Controller Tuning for Process Control SystemsДокумент62 страницыOptimize PID Controller Tuning for Process Control SystemsHuy Nguyen LuongОценок пока нет

- PID control of mechanical systemДокумент12 страницPID control of mechanical systemanagha joshiОценок пока нет

- PID CONTROLLER DESIGN AND TUNING GAINS PresentationДокумент22 страницыPID CONTROLLER DESIGN AND TUNING GAINS PresentationHassan AliОценок пока нет

- AVR221 Discrete PID ControllerДокумент10 страницAVR221 Discrete PID ControllerSadık KorkmazОценок пока нет

- Speed Control of DC Motor Using Pid Controller BasedДокумент16 страницSpeed Control of DC Motor Using Pid Controller Basedayesha amjadОценок пока нет

- Chapter 2: Optimum Controller Chapter 2: Optimum Controller Settings Settings GGДокумент5 страницChapter 2: Optimum Controller Chapter 2: Optimum Controller Settings Settings GGLakshmiОценок пока нет

- PID Controller Block Diagram and ComponentsДокумент4 страницыPID Controller Block Diagram and ComponentsSmakshi ChoudharyОценок пока нет

- PID ControlДокумент32 страницыPID ControlSyamil RahmanОценок пока нет

- Lab 5 ReportДокумент12 страницLab 5 ReportMelaku DinkuОценок пока нет

- Apc Term PaperДокумент9 страницApc Term PaperDarshan MalaniОценок пока нет

- Controllers and Thier Tuningclo2Документ31 страницаControllers and Thier Tuningclo2AreeshaОценок пока нет

- What Is A PID ControllerДокумент11 страницWhat Is A PID ControllerANRG Batch 11Оценок пока нет

- PID Without A PHDДокумент16 страницPID Without A PHDirfanexpertОценок пока нет

- PID Controller DesignДокумент14 страницPID Controller DesignWashington Luiz Leite SousaОценок пока нет

- Contro EngineeringДокумент29 страницContro EngineeringNor AshimyОценок пока нет

- Pid Control TheoryДокумент8 страницPid Control TheorySonu SinghОценок пока нет

- Control of DC Motor Using Different Control StrategiesОт EverandControl of DC Motor Using Different Control StrategiesОценок пока нет

- PLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsОт EverandPLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsОценок пока нет

- Hacks To Crush Plc Program Fast & Efficiently Everytime... : Coding, Simulating & Testing Programmable Logic Controller With ExamplesОт EverandHacks To Crush Plc Program Fast & Efficiently Everytime... : Coding, Simulating & Testing Programmable Logic Controller With ExamplesРейтинг: 5 из 5 звезд5/5 (1)

- Projects With Microcontrollers And PICCОт EverandProjects With Microcontrollers And PICCРейтинг: 5 из 5 звезд5/5 (1)

- Advanced Techniques and Technology of Computer-Aided Feedback ControlОт EverandAdvanced Techniques and Technology of Computer-Aided Feedback ControlОценок пока нет

- Logo HomeДокумент5 страницLogo HomeLionel81Оценок пока нет

- Logo HomeДокумент5 страницLogo HomeLionel81Оценок пока нет

- Logo HomeДокумент6 страницLogo HomeLionel81Оценок пока нет

- KUUTДокумент6 страницKUUTLionel81Оценок пока нет

- Logo HomeДокумент6 страницLogo HomeLionel81Оценок пока нет

- KTTДокумент1 страницаKTTLionel81Оценок пока нет

- TTKДокумент1 страницаTTKLionel81Оценок пока нет

- Catalog FIRE 08.2011 054581.G0 EnglishДокумент303 страницыCatalog FIRE 08.2011 054581.G0 EnglishCostin VictorОценок пока нет

- Securing Containerized Environments: 10 Best PracticesДокумент25 страницSecuring Containerized Environments: 10 Best PracticesJackОценок пока нет

- Create An Ebook Table of Contents in Microsoft WordДокумент9 страницCreate An Ebook Table of Contents in Microsoft WordDion ShawОценок пока нет

- Cds61305 LTCD NTK Lambda To Can DualДокумент3 страницыCds61305 LTCD NTK Lambda To Can DualMARIPAОценок пока нет

- M26831 - NEW - (For IGV N VSV) - 5 - 18Документ36 страницM26831 - NEW - (For IGV N VSV) - 5 - 18faisalnadimОценок пока нет

- Free-Space Path LossДокумент4 страницыFree-Space Path LossCrystalОценок пока нет

- Paging Space Management in AixДокумент14 страницPaging Space Management in Aixamshadab-1Оценок пока нет

- Terminales y ConectoresДокумент64 страницыTerminales y Conectoreswaltico2812100% (3)

- Compact Concrete Mixing Plants CP 30/CP 45 Technical DataДокумент8 страницCompact Concrete Mixing Plants CP 30/CP 45 Technical DataMunaОценок пока нет

- 2N2369Документ7 страниц2N2369Martín SayagoОценок пока нет

- FileДокумент114 страницFilevaibhav shuklaОценок пока нет

- How To Create A Custom Startup Winpe 2.X CDДокумент13 страницHow To Create A Custom Startup Winpe 2.X CDmmarrioОценок пока нет

- 6 Cylinder Head - ValveДокумент14 страниц6 Cylinder Head - ValveSaraОценок пока нет

- Turning Tool Nose Radius CompensationДокумент3 страницыTurning Tool Nose Radius Compensation123anthonyОценок пока нет

- Ec501 Practical Work 4 PDFДокумент25 страницEc501 Practical Work 4 PDFAdam DmcОценок пока нет

- General Questions on Shift Registers and CountersДокумент11 страницGeneral Questions on Shift Registers and CountersakakaОценок пока нет

- Multi Band Ceiling Mount Omni Antenna 790-960 1710-2700 MHzДокумент1 страницаMulti Band Ceiling Mount Omni Antenna 790-960 1710-2700 MHzJohannita AlvaradoОценок пока нет

- Install Computer SystemsДокумент43 страницыInstall Computer Systemsashley bendanaОценок пока нет

- Fall 2019/20 - Lecture Notes # 5: - Flag Registers and Bit FieldsДокумент10 страницFall 2019/20 - Lecture Notes # 5: - Flag Registers and Bit FieldsHifsah NasirОценок пока нет

- Image Pal Capturing DocumentДокумент11 страницImage Pal Capturing DocumentRajesh KhannaОценок пока нет

- 170 ADI 350 00 - 32 Pt. Discrete Input Module OverviewДокумент14 страниц170 ADI 350 00 - 32 Pt. Discrete Input Module OverviewGabriel ZorattiОценок пока нет

- Chapter 9: 8086/8088 Hardware SpecificationsДокумент28 страницChapter 9: 8086/8088 Hardware SpecificationsChanchan LebumfacilОценок пока нет

- Manual Bios Intel Dp35dpДокумент32 страницыManual Bios Intel Dp35dpMarcelo CheloОценок пока нет

- Photoshop CC 2017 Tutorial: Getting Started with Image EditingДокумент24 страницыPhotoshop CC 2017 Tutorial: Getting Started with Image EditingMohammadAssabiОценок пока нет

- Yamaha Fazer-Fzh150 CatalogueДокумент55 страницYamaha Fazer-Fzh150 CatalogueAnonymous KoA00wXXD69% (13)

- Datasheet P3015 - 4AA2-5002ENUCДокумент4 страницыDatasheet P3015 - 4AA2-5002ENUCdul jonnaОценок пока нет

- Tablero de Control Micro SLXДокумент4 страницыTablero de Control Micro SLXprimarioОценок пока нет

- Introduction To Robotics Lab Manual: The Islamia University of Bahawalpur Department of Computer Systems EngineeringДокумент62 страницыIntroduction To Robotics Lab Manual: The Islamia University of Bahawalpur Department of Computer Systems EngineeringEngrFawwadHassanJaskani100% (1)

- Philips AmpLightДокумент5 страницPhilips AmpLighthusnikhalilОценок пока нет

- VLSI Lab CompendiumДокумент52 страницыVLSI Lab CompendiumSaad Ali Khan SherwaniОценок пока нет