Академический Документы

Профессиональный Документы

Культура Документы

Static and Dynamic Spargers

Загружено:

tinhtt2001Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Static and Dynamic Spargers

Загружено:

tinhtt2001Авторское право:

Доступные форматы

Sparging with GKN SIKA porous metal:

- uniform flow through whole construction

- uniform small bubbles for effective gas transfer

- long residence time of bubbles in liquid

- high contact area gas / liquid

- reduced dissolving time for gas in liquid

- reduced gas quantities for equal results (e.g. drilled pipes)

- 100% seamless construction for best corrosion resistance

- easiest installation

GKN spargers are available in several stainless steel alloys (standard

is AISI 316L) as well as in nickel based alloys or titanium.

Pore sizes from 0.1 - 200 m are available.

All spargers come together with customer designed connection, ready

to be installed.

GKN serves

- Food and beverage industry

- Pharmaceutical industry

- Chemical & industrial industry

- Pulp and paper industry

- Petrochemical industry

With applications like:

- Aeration

- Agitation

- Bioremediation

- Carbonation

- Chlorine bleaching

- Column flotation

- Dewatering

- Fermentation

- Gas/liquid reactions

- Hydrogenation

- Oil flotation

- Oxygen

- Oxygen stripping

- Oxygenation

- Ozonation

- pH control

- Steam

- Volatiles stripping

Dynamic (in-line) spargers

Working principle: gas is pumped through a porous SIKA IS tube direct in to the pipeline.

Using the velocity and turbulence of the flowing liquid, dynamic sparging is one of the

cheapest and most efficient sparging systems. Due to the shear effect, extremely small

gas bubbles are separated from the porous tube wall.

For additional improvement of gas dissolving manifold construction (similar to cross flow

filtration units) are possible.

Static (tank) spargers

Static sparging is usually used in batch productions and / or lower quantities of liquids. Designs with only one sparger as

well as christmas tree shaped manifold designs are possible.

GKN offers also the new seamless bended tube down to 400 mm diameter! Therefore also areas close to tank walls can be

sparged efficient.

Example with one sparger Example with three spargers

(christmas tree)

Example with a bended tube

(close to tank walls)

Pressure drop [psi]

90

75

50

45

30

15

0

0 100 200 300 400 500 600

1500

1200

900

600

300

0

0 1.5 3.0 4.5 6.0 9.0 7.5

Pressure drop [mbar]

F

l

o

w

r

a

t

e

[

m

3

/

h

.

m

2

]

F

l

o

w

r

a

t

e

[

f

t

3

/

m

i

n

.

f

t

2

]

S

I

K

A

-

R

1

0

I

S

S

I

K

A

-

R

8

I

S

S

I

K

A

-

R

5

I

S

S

IK

A

-

R

3

IS

SIKA-R 1 IS

SIKA-R 0,5 IS

1 5 10 20 40

3000

1

Pore size [m]

B

u

b

b

l

e

s

i

z

e

[

m

]

G

a

s

t

r

a

n

s

f

e

r

i

n

l

i

q

u

i

d

[

m

g

/

l

]

Coming soon:

- relation pore size / bubble size

- gas transfer to liquid

Filter connection at customers option

(weldet together with the seamless filter cartridge)

}

The advantage of GKN spargers:

- solid porous

- porous - porous

= no corrosion!

= no cracks!

Example: beer brewery

Static And Dynamic Spargers Static And Dynamic Spargers

one piece tube design

The advantage: seamless construction!

Solid connector sintered to porous body. No welding - solid porous = no chance for corrosion

Examples of different thread connectors

Flow rate

No welding

Sparging with GKN SIKA porous metal:

- uniform flow through whole construction

- uniform small bubbles for effective gas transfer

- long residence time of bubbles in liquid

- high contact area gas / liquid

- reduced dissolving time for gas in liquid

- reduced gas quantities for equal results (e.g. drilled pipes)

- 100% seamless construction for best corrosion resistance

- easiest installation

GKN spargers are available in several stainless steel alloys (standard

is AISI 316L) as well as in nickel based alloys or titanium.

Pore sizes from 0.1 - 200 m are available.

All spargers come together with customer designed connection, ready

to be installed.

GKN serves

- Food and beverage industry

- Pharmaceutical industry

- Chemical & industrial industry

- Pulp and paper industry

- Petrochemical industry

With applications like:

- Aeration

- Agitation

- Bioremediation

- Carbonation

- Chlorine bleaching

- Column flotation

- Dewatering

- Fermentation

- Gas/liquid reactions

- Hydrogenation

- Oil flotation

- Oxygen

- Oxygen stripping

- Oxygenation

- Ozonation

- pH control

- Steam

- Volatiles stripping

Dynamic (in-line) spargers

Working principle: gas is pumped through a porous SIKA IS tube direct in to the pipeline.

Using the velocity and turbulence of the flowing liquid, dynamic sparging is one of the

cheapest and most efficient sparging systems. Due to the shear effect, extremely small

gas bubbles are separated from the porous tube wall.

For additional improvement of gas dissolving manifold construction (similar to cross flow

filtration units) are possible.

Static (tank) spargers

Static sparging is usually used in batch productions and / or lower quantities of liquids. Designs with only one sparger as

well as christmas tree shaped manifold designs are possible.

GKN offers also the new seamless bended tube down to 400 mm diameter! Therefore also areas close to tank walls can be

sparged efficient.

Example with one sparger Example with three spargers

(christmas tree)

Example with a bended tube

(close to tank walls)

Pressure drop [psi]

90

75

50

45

30

15

0

0 100 200 300 400 500 600

1500

1200

900

600

300

0

0 1.5 3.0 4.5 6.0 9.0 7.5

Pressure drop [mbar]

F

l

o

w

r

a

t

e

[

m

3

/

h

.

m

2

]

F

l

o

w

r

a

t

e

[

f

t

3

/

m

i

n

.

f

t

2

]

S

I

K

A

-

R

1

0

I

S

S

I

K

A

-

R

8

I

S

S

I

K

A

-

R

5

I

S

S

IK

A

-

R

3

IS

SIKA-R 1 IS

SIKA-R 0,5 IS

1 5 10 20 40

3000

1

Pore size [m]

B

u

b

b

l

e

s

i

z

e

[

m

]

G

a

s

t

r

a

n

s

f

e

r

i

n

l

i

q

u

i

d

[

m

g

/

l

]

Coming soon:

- relation pore size / bubble size

- gas transfer to liquid

Filter connection at customers option

(weldet together with the seamless filter cartridge)

}

The advantage of GKN spargers:

- solid porous

- porous - porous

= no corrosion!

= no cracks!

Example: beer brewery

Static And Dynamic Spargers Static And Dynamic Spargers

one piece tube design

The advantage: seamless construction!

Solid connector sintered to porous body. No welding - solid porous = no chance for corrosion

Examples of different thread connectors

Flow rate

No welding

Materials and products

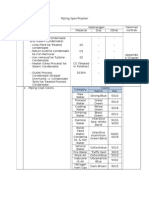

Material Name Wst-No Sika- Fe Cr Ni C Mo Miscellany Max. Temperature C Keyword

R... FIL B in weight- % Reducing Ocidizing

AISI 304 L

AISI 316 L

AISI 904

AISI 310

FeCrAl

HasteloyC22

HasteloyC276

HasteloyX

Inconet 600

Inconet 625

Monel 400

CuSn 12

Ti

IS AX AS

1.4306

1.4404

1.4539

1.4841

1.4767

Mod.

2.4602

2.4819

2.4665

2.4816

2.4856

2.4360

2.1052

-

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

Bal.

Bal.

Bal.

Bal.

Bal.

2.0-6.0

4.0-7.0

17.0-20.0

6.0-10.0

<=5.00

<2.0

-

-

18.0-20.0

16.0-18.0

19.0-21.0

24.0-26.0

19.0-22.0

20.0-22.5

14.0-16.0

20.5-23.0

14.0-17.0

20.0-23.0

-

-

-

8.0-12.0

10.0-14.0

24.0-26.0

19.0-22.0

-

Bal.

Bal.

Bal.

>=72.0

>=58.0

>=63.0

-

-

<=0.03

<=0.03

<=0.02

<=0.25

<0.10

<0.02

<0.02

<0.15

<0.15

<0.10

<0.30

-

-

0.5

2.0-3.0

4.0-5.0

-

-

12.0-14.5

15.0-17.0

8.0-10.0

-

8.0-10.0

-

-

-

N<=0.1

N<=0.1

N<=0.15

Cu 1.2-2.0

-

Al 5.0-6.5

with rare earth

elements

W 2.0-3.5, Co 2.5

W 3.0-4.5

Co 0.5-2.5

W 0.2-1.0

-

Nb 3.15-4.15

Cu 28.0-34.0

Cu 89 Sn 11

Ti > 99%

540

540

600

800

unfit

650

650

930

700

650

500

300

500

400

400

500

600

1000

650

650

800

700

650

500

250

500

Standard for foot application

Resistant against sulphuric acid,

phosphoric and hydrochloric acid

Heat resistant

Corrosion resistant with various

agressive media. Duration appli-

cation at > 400C possible

Resistant against Cl-containing

media

Typically used for hydraulic &

pneumatic

Medicine, acid, electrolysis

H

i

g

h

a

l

l

o

y

e

d

m

a

t

e

r

i

a

l

N

i

c

k

e

l

b

a

s

e

d

a

l

l

o

y

s

*

O

t

h

e

r

T

i

t

a

n

*

*

B

r

o

n

z

e

Other materials on request

* Nickel based AX-products only after consultation. Not all dimensions producible. **Not all raw materials are in stock.

Typical Iron or Nickel elements e.g. Si, Mn, P, S according to the literature.

SIKA-R...IS

Made from sintered metal powder (A variety of

alloys are used, depending upon requirement)

Filter grades from 0.5 - 200m

The opportunity to use different alloys allows

for use up to 950 C

Seamless up to 1500 mm in length and up to

300 mm in diameter

.

.

.

.

SIKA-R...AX

Axial pressed filters made of metal powder

(A variety of alloys are used, depending upon

requirement)

Filter grades between 0.5 and 200 m

Employed mainly in gas and liquid filtration

SIKA...AS

Asymmetric designed powder / powder compo-

site, consisting of a course support and a thin

filter active layer of the SAME alloy

Developed for surface filtration (up to four times

higher flow rates with improved backflushing

performance)

Employed in catalyst recovery and cross flow

application

SIKA-R...IS

Produced from stainless steel fibers

60 - 90 % porosity

Filter grades from 1 - 100 m

Employed mainly in gas filtration with high gas

velocities

SIKA-R...B

Gravity sintered filters made of bronze

Filter grades between 8 and 200 m

Employed mainly in pneumatic - hydraulic

application and polymer filtration

Best for comples shapes

SIKA- Modules

Customer designed elements with fitting

Possible for guaranteed flow or pressure drop

Employed mainly for sensor protection and flow

resistors

Welding constructions

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

GKN Sinter Metals Filters GmbH

Dahlienstrasse 43

D-42477 Radevormwald

Phone: +49 (0) 2195-609-0

Fax: +49 (0) 2195-609-48

E-mail: info@gkn-filters.com

www.gkn-filters.com

GKN Sinter Metals Filters

1765 H Cortland

Ct Addison, IL 60101 - USA

Phone: +1-630-495-2240

Toll free: +1-800-426-0977

Fax: +1-630-495-2214

E-mail: filtersales@sinter.gknplc.com

www.gkn-filters.com

Copyright by GKN Sinter Metals Filters GmbH, Radevormwald

Printed in Germany

ISO 9001 Certified

Вам также может понравиться

- Computer Laboratory Maintenance Plan and ScheduleДокумент5 страницComputer Laboratory Maintenance Plan and ScheduleJm Valiente100% (3)

- 33cpa S 25w 45w 70w PDFДокумент6 страниц33cpa S 25w 45w 70w PDFdanielstancu883296Оценок пока нет

- 2012 D61ex-15e0Документ1 239 страниц2012 D61ex-15e0Alex San Tana100% (3)

- Bell Desk-2Документ96 страницBell Desk-2Arrow PrasadОценок пока нет

- Deepwater Horizon Accident Investigation Report Appendices ABFGHДокумент37 страницDeepwater Horizon Accident Investigation Report Appendices ABFGHBren-RОценок пока нет

- Bond Strand 5000 eДокумент8 страницBond Strand 5000 eUmar KidaОценок пока нет

- DeZURIK KCG Knife Gate ValvesДокумент12 страницDeZURIK KCG Knife Gate ValvesKithkarnonОценок пока нет

- ThyssenKrupp - PASДокумент3 страницыThyssenKrupp - PASWalter AcostaОценок пока нет

- Tubular Products From Special MetalsДокумент26 страницTubular Products From Special Metalskaveh-bahiraeeОценок пока нет

- Series 5000C Fiberglass Fiberlgass Pipe and Fittin PDFДокумент8 страницSeries 5000C Fiberglass Fiberlgass Pipe and Fittin PDFsandbadbahriОценок пока нет

- Series M Knife Gate ValveДокумент11 страницSeries M Knife Gate ValveRicardo MoralesОценок пока нет

- Seal Ball ValvesДокумент45 страницSeal Ball Valvesmetasoniko2014Оценок пока нет

- Sika-B V4Документ16 страницSika-B V4Didier MarneffeОценок пока нет

- Valves Pipe Fittings DimensionsДокумент37 страницValves Pipe Fittings DimensionstsoheilОценок пока нет

- STP CatalogueДокумент37 страницSTP CataloguemmkattaОценок пока нет

- CRДокумент8 страницCRErfan EffendyОценок пока нет

- Gasno Zavarivanje UputstvoДокумент15 страницGasno Zavarivanje UputstvoRadivojevic SasaОценок пока нет

- Aeroterma ATLASДокумент4 страницыAeroterma ATLASLaura Daniela GavrilasОценок пока нет

- Technical Catalogue: Pipes Tubes Fittings FlangesДокумент121 страницаTechnical Catalogue: Pipes Tubes Fittings FlangesDANIELVENZUELAAОценок пока нет

- Block & Bleed Valve: High Technology Valve & Fitting SeriesДокумент20 страницBlock & Bleed Valve: High Technology Valve & Fitting SeriesMayur PatelОценок пока нет

- En ArpolДокумент44 страницыEn ArpoldenemeuserОценок пока нет

- Mineral Wook Data SheetДокумент2 страницыMineral Wook Data SheetjasonkkzОценок пока нет

- Swagelok WLD Fittings SAF 2507 Super DuplexДокумент8 страницSwagelok WLD Fittings SAF 2507 Super DuplextotcsabОценок пока нет

- Spirax Sarco PDFДокумент4 страницыSpirax Sarco PDFandresaroОценок пока нет

- Swagelok Tubing SpecificationsДокумент8 страницSwagelok Tubing SpecificationsAugustine Owo UkpongОценок пока нет

- Av Catalogo Completo 2005Документ20 страницAv Catalogo Completo 2005Marin LaurentiuОценок пока нет

- Top Guide Control ValveДокумент32 страницыTop Guide Control Valveachari_swapnilОценок пока нет

- Gaugeable SAF 2507™ Super Duplex Tube Fittings, (MS-01-174, R5)Документ12 страницGaugeable SAF 2507™ Super Duplex Tube Fittings, (MS-01-174, R5)김윤식Оценок пока нет

- Ameron PSXJFДокумент4 страницыAmeron PSXJFmohammadazraiОценок пока нет

- SteelДокумент38 страницSteelArdeela IlezОценок пока нет

- Stainless SteelДокумент6 страницStainless SteelNiko NištićОценок пока нет

- ISC Series: The Seals Nnovative Tandard ArtridgeДокумент4 страницыISC Series: The Seals Nnovative Tandard ArtridgeJosé Fernando TerronesОценок пока нет

- 2205 InfoДокумент6 страниц2205 InfoMave75Оценок пока нет

- Stainless EnstainlessДокумент27 страницStainless EnstainlessVinaya Almane DattathreyaОценок пока нет

- Piping SpecificationДокумент5 страницPiping SpecificationShandi Hasnul FarizalОценок пока нет

- Kaiser Aluminum Soft Alloy Tube PDFДокумент31 страницаKaiser Aluminum Soft Alloy Tube PDFgerrzen64Оценок пока нет

- High-Efficiency Gas/liquid Contacting.: CorporationДокумент8 страницHigh-Efficiency Gas/liquid Contacting.: Corporationgkdora574Оценок пока нет

- ValvesДокумент8 страницValvespravin_2011Оценок пока нет

- Tuberia Fibra de VidrioДокумент0 страницTuberia Fibra de VidrioFernando Reyes GomezОценок пока нет

- Hot Dip GalvanizingДокумент24 страницыHot Dip GalvanizingKarthikeyan MuniaswamyОценок пока нет

- Technical DataДокумент17 страницTechnical Datat_syamprasadОценок пока нет

- JIS10K FlangeДокумент1 страницаJIS10K Flangeamanogho.adidiОценок пока нет

- Silencers CatalogДокумент14 страницSilencers CatalogpalindapcОценок пока нет

- b3311 722-2Документ7 страницb3311 722-2Arnaldo BenitezОценок пока нет

- Silencers For HVACДокумент12 страницSilencers For HVACZaw Moe KhineОценок пока нет

- Data SAF2205 04Документ8 страницData SAF2205 04il_yoo_1Оценок пока нет

- New Storage Tanks Design GuidelinesДокумент6 страницNew Storage Tanks Design GuidelinespaaryОценок пока нет

- Rigid Pipe Covering (K450) : With Extr A Rig IDДокумент6 страницRigid Pipe Covering (K450) : With Extr A Rig IDraguhvacind4620Оценок пока нет

- A Casa SaddleДокумент2 страницыA Casa SaddlesalamrefighОценок пока нет

- Industeel Tableau Nuances Special Carbon and Low AlloyДокумент1 страницаIndusteel Tableau Nuances Special Carbon and Low AlloyPravin VisputeОценок пока нет

- CIRCOR D-Series Technical BrochureДокумент12 страницCIRCOR D-Series Technical BrochureJAYОценок пока нет

- Goulds 3186: High-temperature/Pressure Paper Stock/ Process PumpsДокумент8 страницGoulds 3186: High-temperature/Pressure Paper Stock/ Process PumpsGorea AndreiОценок пока нет

- Valvula Agua 1000 WOGДокумент2 страницыValvula Agua 1000 WOGRauloxz100% (1)

- Lagerlistan 080424 TryckklarДокумент16 страницLagerlistan 080424 TryckklarAymeeenОценок пока нет

- Gaseous Hydrogen Piping SpecificationДокумент5 страницGaseous Hydrogen Piping SpecificationAndri DoemeriОценок пока нет

- A Brief Overview of Plasma Cutting: Figure 1 - Temperature DifferencesДокумент8 страницA Brief Overview of Plasma Cutting: Figure 1 - Temperature DifferencesAdibah BiagiОценок пока нет

- Microsoft Word - DELTA Moisture SeparatorsДокумент3 страницыMicrosoft Word - DELTA Moisture SeparatorsKRUNALОценок пока нет

- Alfa CondДокумент2 страницыAlfa CondKillol ShahОценок пока нет

- Cilindros e Servo CilindrosДокумент16 страницCilindros e Servo CilindrosluisbottonОценок пока нет

- Carbon Steels (1 000, 11 00, 1 200, and 1500 Series)Документ18 страницCarbon Steels (1 000, 11 00, 1 200, and 1500 Series)Kerem Cengiz KılıçОценок пока нет

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonОт EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonОценок пока нет

- Van Buggenhout S. Data Based Mechanistic Modelling Approach To Determine The Age of Air in A Ventilated Space 2006Документ11 страницVan Buggenhout S. Data Based Mechanistic Modelling Approach To Determine The Age of Air in A Ventilated Space 2006tinhtt2001Оценок пока нет

- Turbulence in Micro-ChannelsДокумент8 страницTurbulence in Micro-Channelstinhtt2001Оценок пока нет

- ICAAT RMP Tran AbstractДокумент2 страницыICAAT RMP Tran Abstracttinhtt2001Оценок пока нет

- Cavitation Bubble DynamicsДокумент11 страницCavitation Bubble Dynamicstinhtt2001Оценок пока нет

- DRM Transmitter PresentationДокумент22 страницыDRM Transmitter PresentationJuan Jose PerezОценок пока нет

- Photosynthesis LabДокумент3 страницыPhotosynthesis Labapi-276121304Оценок пока нет

- Unit 16 AssignmentДокумент15 страницUnit 16 AssignmentRavi Gajenthran100% (1)

- 1.5SMC Series-1864824 PDFДокумент8 страниц1.5SMC Series-1864824 PDFRizwan RanaОценок пока нет

- Compressed Air Treatment EquipmentДокумент12 страницCompressed Air Treatment EquipmentSAUL OSPINOОценок пока нет

- Api 682Документ132 страницыApi 682Raul Gonzalez FernandezОценок пока нет

- Hadron XX ManualДокумент41 страницаHadron XX ManualEverton DenardiОценок пока нет

- DO 178 B Brief NotesДокумент18 страницDO 178 B Brief NotesMani Shankar PrasadОценок пока нет

- Seminar Report ON "Linux"Документ17 страницSeminar Report ON "Linux"Ayush BhatОценок пока нет

- TT2223 Week 12a Z-TransformДокумент39 страницTT2223 Week 12a Z-TransformAjiMaulanaОценок пока нет

- d9 VolvoДокумент57 страницd9 Volvofranklin972100% (2)

- Ecg Signal Thesis1Документ74 страницыEcg Signal Thesis1McSudul HasanОценок пока нет

- TIL 1881 Network Security TIL For Mark VI Controller Platform PDFДокумент11 страницTIL 1881 Network Security TIL For Mark VI Controller Platform PDFManuel L LombarderoОценок пока нет

- A Simplified Two-Stage Method To Estimate The Settlement and Bending Moment of Upper Tunnel Considering The Interaction of Undercrossing Twin TunnelsДокумент32 страницыA Simplified Two-Stage Method To Estimate The Settlement and Bending Moment of Upper Tunnel Considering The Interaction of Undercrossing Twin TunnelsJianfeng XueОценок пока нет

- Circuito PCB Control Pedal V3 TerminadoДокумент1 страницаCircuito PCB Control Pedal V3 TerminadoMarcelo PereiraОценок пока нет

- Problem 1-4Документ6 страницProblem 1-4Anonymous xIzzEifjPОценок пока нет

- Crisfield - Vol1 - NonLinear Finite Element Analysis of Solids and Structures EssentialsДокумент360 страницCrisfield - Vol1 - NonLinear Finite Element Analysis of Solids and Structures EssentialsAnonymous eCD5ZRОценок пока нет

- An Analysis of The Ejector-Ram-Rocket EngineДокумент9 страницAn Analysis of The Ejector-Ram-Rocket Enginefundamental_aeroОценок пока нет

- Common Inspection Training Report Kosovo (UNHCR1244)Документ51 страницаCommon Inspection Training Report Kosovo (UNHCR1244)awfahОценок пока нет

- Astm D3350-10Документ7 страницAstm D3350-10Jorge HuarcayaОценок пока нет

- Item Rate For GMCTH Jajpur Rate Acceptance For Sub Structure - Concrete, Shuttering, Reinforcement Work & Pile Chipping WorkДокумент3 страницыItem Rate For GMCTH Jajpur Rate Acceptance For Sub Structure - Concrete, Shuttering, Reinforcement Work & Pile Chipping WorkBittudubey officialОценок пока нет

- 1450 01 Air Hoists and Trolleys Atlas CopcoДокумент12 страниц1450 01 Air Hoists and Trolleys Atlas Copcomohammed shammiОценок пока нет

- 09T030 FinalДокумент14 страниц09T030 FinalKriengsak RuangdechОценок пока нет

- Cadence Short CommandsДокумент1 страницаCadence Short Commandsgetme_samОценок пока нет

- RDBMS and HTML Mock Test 1548845682056Документ18 страницRDBMS and HTML Mock Test 1548845682056sanjay bhattОценок пока нет

- Udyam Registration Certificate UDYAM-MH-26-0097771Документ3 страницыUdyam Registration Certificate UDYAM-MH-26-0097771Suresh D ChemateОценок пока нет