Академический Документы

Профессиональный Документы

Культура Документы

The constantly increasing demand in resources and energy of people and business leads to more and more bottle - necks and increasing costs in material procurement. For this reason, it is necessary to deal with materials and resources in an efficient manner for reasons of economy and sustainability. Process-Optimized These points are very important to Schmalz. Therefore the company has organized its processes to gain added value. The added-value system pursues aims such as lowest production and process costs, shortest processing times, low stocks and at the same time highest quality. The added-value system, together with the company’s modern workplaces, is the basis for efficient production and its ability to compete over the long term. At Schmalz state-of-the-art production and logistic concepts determine most of the everyday tasks in manufacturing. For example, Schmalz uses the one-piece flow concept whenever it is possible and makes sense to do so. With this concept, the vacuum speci

Загружено:

aco1970Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

The constantly increasing demand in resources and energy of people and business leads to more and more bottle - necks and increasing costs in material procurement. For this reason, it is necessary to deal with materials and resources in an efficient manner for reasons of economy and sustainability. Process-Optimized These points are very important to Schmalz. Therefore the company has organized its processes to gain added value. The added-value system pursues aims such as lowest production and process costs, shortest processing times, low stocks and at the same time highest quality. The added-value system, together with the company’s modern workplaces, is the basis for efficient production and its ability to compete over the long term. At Schmalz state-of-the-art production and logistic concepts determine most of the everyday tasks in manufacturing. For example, Schmalz uses the one-piece flow concept whenever it is possible and makes sense to do so. With this concept, the vacuum speci

Загружено:

aco1970Авторское право:

Доступные форматы

World of Vacuum Technology

J. Schmalz GmbH

Aacher Strasse 29

D-72293 Glatten

Tel. +49 (0)7443 2403 0

Fax +49 (0)7443 2403 259

schmalz@schmalz.de

www.schmalz.de

Innovative Vacuum for Automation

Vacuum Components

Catalog 2012 / 2013

V

a

c

u

u

m

C

o

m

p

o

n

e

n

t

s

C

a

t

a

l

o

g

2

0

1

2

/

2

0

1

3

Canada

Schmalz Vacuum

Technology Ltd.

Mississauga

schmalz@schmalz.ca

China

Schmalz (Shanghai) Co. Ltd.

Shanghai

schmalz@schmalz.net.cn

Finland

Oy Schmalz Ab

Vantaa

schmalz@schmalz.fi

France

Schmalz S.A.S.

Champs sur Marne

schmalz@schmalz.fr

Germany

J. Schmalz GmbH

Glatten

schmalz@schmalz.de

India

Schmalz India Pvt. Ltd.

Pune

schmalz@schmalz.co.in

Italy

Schmalz S.r.l. a Socio Unico

Novara

schmalz@schmalz.it

Japan

Schmalz K.K.

Yokohama

schmalz@schmalz.co.jp

The Netherlands

Schmalz B.V.

Hengelo

schmalz@schmalz.nl

Poland

Schmalz Sp. z o.o.

Warsaw

schmalz@schmalz.pl

Russia

Schmalz Representation

Moscow

schmalz@schmalz.ru

South Korea

Schmalz Co. Ltd.

Seoul

schmalz@schmalz.co.kr

Schmalz Worldwide

Find your local sales partner by visiting

www.schmalz.com/salesnetwork

Spain

Schmalz S.A.

Erandio (Biscay)

schmalz@schmalz.es

Switzerland

Schmalz GmbH

Nrensdorf

schmalz@schmalz.ch

Turkey

Schmalz Vakum

San. ve Tic. Ltd. ti.

Istanbul

schmalz@schmalz.com.tr

United States

Schmalz Inc.

Raleigh

schmalz@schmalz.us

Scan code to access

the digital catalog

S

c

h

m

a

l

z

,

0

9

/

1

1

I

A

r

t

i

c

l

e

N

o

.

2

9

.

0

1

.

0

3

.

0

0

6

9

7

I

S

u

b

j

e

c

t

t

o

t

e

c

h

n

i

c

a

l

c

h

a

n

g

e

s

w

i

t

h

o

u

t

n

o

t

i

c

e

I

S

c

h

m

a

l

z

i

s

a

r

e

g

i

s

t

e

r

e

d

t

r

a

d

e

m

a

r

k

Vacuum Components

Tel. +49 (0)7443 2403 102 Tel. +49 (0)7443 2403 107 Tel. +49 (0)7443 2403 108 Tel. +49 (0)7443 2403 109

Vacuum Handling Systems Vacuum Clamping Systems Vacuum Gripping Systems

Umschlag_VT_EN_2012_Umschlag_VT_GER_07.qxd 16.08.11 07:31 Seite 1

P

A

0

1

0

1

0

7

1

1

_

u

m

_

G

B

.

p

d

f

P

A

0

1

0

1

0

7

1

1

_

u

m

_

G

B

.

p

d

f

PA01010711_um_GB.pdf

PA01010711_um_GB.pdf

World of Vacuum Technology

J. Schmalz GmbH

Aacher Strasse 29

D-72293 Glatten

Tel. +49 (0)7443 2403 0

Fax +49 (0)7443 2403 259

schmalz@schmalz.de

www.schmalz.de

Innovative Vacuum for Automation

Vacuum Components

Catalog 2012 / 2013

V

a

c

u

u

m

C

o

m

p

o

n

e

n

t

s

C

a

t

a

l

o

g

2

0

1

2

/

2

0

1

3

Canada

Schmalz Vacuum

Technology Ltd.

Mississauga

schmalz@schmalz.ca

China

Schmalz (Shanghai) Co. Ltd.

Shanghai

schmalz@schmalz.net.cn

Finland

Oy Schmalz Ab

Vantaa

schmalz@schmalz.fi

France

Schmalz S.A.S.

Champs sur Marne

schmalz@schmalz.fr

Germany

J. Schmalz GmbH

Glatten

schmalz@schmalz.de

India

Schmalz India Pvt. Ltd.

Pune

schmalz@schmalz.co.in

Italy

Schmalz S.r.l. a Socio Unico

Novara

schmalz@schmalz.it

Japan

Schmalz K.K.

Yokohama

schmalz@schmalz.co.jp

The Netherlands

Schmalz B.V.

Hengelo

schmalz@schmalz.nl

Poland

Schmalz Sp. z o.o.

Warsaw

schmalz@schmalz.pl

Russia

Schmalz Representation

Moscow

schmalz@schmalz.ru

South Korea

Schmalz Co. Ltd.

Seoul

schmalz@schmalz.co.kr

Schmalz Worldwide

Find your local sales partner by visiting

www.schmalz.com/salesnetwork

Spain

Schmalz S.A.

Erandio (Biscay)

schmalz@schmalz.es

Switzerland

Schmalz GmbH

Nrensdorf

schmalz@schmalz.ch

Turkey

Schmalz Vakum

San. ve Tic. Ltd. ti.

Istanbul

schmalz@schmalz.com.tr

United States

Schmalz Inc.

Raleigh

schmalz@schmalz.us

Scan code to access

the digital catalog

S

c

h

m

a

l

z

,

0

9

/

1

1

I

A

r

t

i

c

l

e

N

o

.

2

9

.

0

1

.

0

3

.

0

0

6

9

7

I

S

u

b

j

e

c

t

t

o

t

e

c

h

n

i

c

a

l

c

h

a

n

g

e

s

w

i

t

h

o

u

t

n

o

t

i

c

e

I

S

c

h

m

a

l

z

i

s

a

r

e

g

i

s

t

e

r

e

d

t

r

a

d

e

m

a

r

k

Vacuum Components

Tel. +49 (0)7443 2403 102 Tel. +49 (0)7443 2403 107 Tel. +49 (0)7443 2403 108 Tel. +49 (0)7443 2403 109

Vacuum Handling Systems Vacuum Clamping Systems Vacuum Gripping Systems

Umschlag_VT_EN_2012_Umschlag_VT_GER_07.qxd 16.08.11 07:31 Seite 1

P

A

0

1

0

1

0

7

1

1

_

u

m

_

G

B

.

p

d

f

P

A

0

1

0

1

0

7

1

1

_

u

m

_

G

B

.

p

d

f

PA01010711_um_GB.pdf

PA01010711_um_GB.pdf

fuer_PDF_einzelseiten.indd 3 26.08.11 15:31

Schmalz Online Shop

www.schmalz.com

Complete product range

Easy and secure ordering

Comprehensive services

Your personal online shop account

Quick checking of prices and availability

Order history all orders visible at a glance,

complete with status

Simple and fast follow-up and spare-part ordering

Tracking see where your order is at any time

Umschlag_VT_EN_2012_Umschlag_VT_GER_07.qxd 16.08.11 07:31 Seite 2

P

A

0

1

0

1

0

7

1

1

_

u

m

_

G

B

.

p

d

f

P

A

0

1

0

1

0

7

1

1

_

u

m

_

G

B

.

p

d

f

PA01010711_um_GB.pdf

PA01010711_um_GB.pdf

fuer_PDF_einzelseiten.indd 4 26.08.11 15:31

S

c

h

m

a

l

z

T

h

e

C

o

m

p

a

n

y

V

a

c

u

u

m

K

n

o

w

l

e

d

g

e

V

a

c

u

u

m

S

u

c

t

i

o

n

P

a

d

s

S

p

e

c

i

a

l

G

r

i

p

p

e

r

s

M

o

u

n

t

i

n

g

E

l

e

m

e

n

t

s

V

a

c

u

u

m

G

e

n

e

r

a

t

o

r

s

V

a

l

v

e

T

e

c

h

n

o

l

o

g

y

S

w

i

t

c

h

e

s

a

n

d

M

o

n

i

t

o

r

i

n

g

F

i

l

t

e

r

s

a

n

d

C

o

n

n

e

c

t

i

o

n

s

V

a

c

u

u

m

G

r

i

p

-

p

i

n

g

S

y

s

t

e

m

s

S

e

r

v

i

c

e

s

C

o

n

t

a

c

t

I

n

d

e

x

o

f

P

r

o

d

u

c

t

s

Contents

Page

Company Profile | Efficiency and Sustainability |

Business Areas | Industry Solutions

Vacuum System and its Components | System Design |

Units and Conversion Tables | Vacuum Glossary

Universal Suction Pads (Flat, Bellows) | Suction Pads for

Special Applications (Metal, Wood, Packaging etc.)

Floating Suction Pads | Magnetic Grippers |

Needle Grippers | Wafer Grippers | Composite Grippers

End Effectors | Jointed Mountings |

Spring Plungers | Holders | Sections and Connectors

Ejectors | Vacuum Units |

Pumps | Blowers

Solenoid Valves | Check Valves |

Sensing Valves | Non-Return Valves | Manual Valves

Vacuum Switches | Pressure Switches |

Measurings and Control Devices | Warning Devices

Vacuum Filters | Distributors |

Hoses and Connectors | Accessories

Large-Area Gripping Systems | Layer Gripping Systems |

Suction Spiders

Services | Test Center |

Set of Test | Schmalz Academy

Schmalz Worldwide |

Imprint

Products Sorted Alphabetically |

Products Sorted by Industry

Schmalz - The Company

Vacuum Knowledge

Special Grippers

Mounting Elements

Vacuum Generators

Valve Technology

Switches and System Monitoring

Filters and Connections

Vacuum Gripping Systems

Services

Contact

Index of Products

Vacuum Suction Pads

4

17

62

268

308

382

514

556

620

666

691

701

709

Page

Service

1_Kap_VT_Un!en_040811_EN_US_La#o"! 1 08.08.11 18:32 Sei!e 3

P

A

0

1

0

1

0

7

1

1

_

E

N

_

o

p

t

.

p

d

f

P

A

0

1

0

1

0

7

1

1

_

E

N

_

o

p

t

.

p

d

f

PA01010711_EN_opt.pdf

PA01010711_EN_opt.pdf

Consistent customer orientation and groundbreaking innovations,

excellent quality and comprehensive consulting competence make

Schmalz the world's leading partner for vacuum technology in

automation, handling and clamping applications.

4

S

c

h

m

a

l

z

T

h

e

C

o

m

p

a

n

y

V

a

c

u

u

m

K

n

o

w

l

e

d

g

e

V

a

c

u

u

m

S

u

c

t

i

o

n

P

a

d

s

S

p

e

c

i

a

l

G

r

i

p

p

e

r

s

M

o

u

n

t

i

n

g

E

l

e

m

e

n

t

s

V

a

c

u

u

m

G

e

n

e

r

a

t

o

r

s

V

a

l

v

e

T

e

c

h

n

o

l

o

g

y

S

w

i

t

c

h

e

s

a

n

d

M

o

n

i

t

o

r

i

n

g

F

i

l

t

e

r

s

a

n

d

C

o

n

n

e

c

t

i

o

n

s

V

a

c

u

u

m

G

r

i

p

-

p

i

n

g

S

y

s

t

e

m

s

S

e

r

v

i

c

e

s

C

o

n

t

a

c

t

I

n

d

e

x

o

f

P

r

o

d

u

c

t

s

1_Kap_VT_Un!en_040811_EN_US_La#o"! 1 08.08.11 18:32 Sei!e 4

P

A

0

1

0

1

0

7

1

1

_

E

N

_

o

p

t

.

p

d

f

P

A

0

1

0

1

0

7

1

1

_

E

N

_

o

p

t

.

p

d

f

PA01010711_EN_opt.pdf

PA01010711_EN_opt.pdf

5

S

c

h

m

a

l

z

T

h

e

C

o

m

p

a

n

y

V

a

c

u

u

m

K

n

o

w

l

e

d

g

e

V

a

c

u

u

m

S

u

c

t

i

o

n

P

a

d

s

S

p

e

c

i

a

l

G

r

i

p

p

e

r

s

M

o

u

n

t

i

n

g

E

l

e

m

e

n

t

s

V

a

c

u

u

m

G

e

n

e

r

a

t

o

r

s

V

a

l

v

e

T

e

c

h

n

o

l

o

g

y

S

w

i

t

c

h

e

s

a

n

d

M

o

n

i

t

o

r

i

n

g

F

i

l

t

e

r

s

a

n

d

C

o

n

n

e

c

t

i

o

n

s

V

a

c

u

u

m

G

r

i

p

-

p

i

n

g

S

y

s

t

e

m

s

S

e

r

v

i

c

e

s

C

o

n

t

a

c

t

I

n

d

e

x

o

f

P

r

o

d

u

c

t

s

We are committed to maintaining a fair partnership with

our customers and suppliers: one that is beneficial for all parties.

Schmalz is a family-run company, and we focus on long-term objectives. Our company

philosophy is based on the principle of sustainability: economic success combined with

ecological and social engagement. This ensures that we remain self-sufficient and

affords us the necessary creative freedom.

Our sustainability principle as well as our lean and efficient processes keep us

perma nently competitive and reassure our customers that we are the right choice for

a long-term partnership. Our customers associate Schmalz with innovative products

and services, advanced technology that is available worldwide, as well as unsurpassed

application knowledge.

Convincing customers requires enthusiastic employees, who develop excellent inno -

vative products and market these in accordance with customers requirements and

profitability. The Schmalz employees derive their motivation for their above-average

efforts and loyalty from a modern corporate culture and share in the economic success

of our company.

Our companys readiness and capacity for change is important to us personally. We have,

for example, already positioned ourselves successfully for the future by founding our

own subsidiary companies in the most important international growth markets.

You will profit from a partnership which ensures long-term and real advantages over

your competitors rely on Schmalzs world of vacuum technology.

Dr. Dipl.-Ing. Kurt Schmalz

Managing Director

Dipl.-Ing. Wolfgang Schmalz

Managing Director

Our Purpose

Dipl.-Ing. Wolfgang Schmalz Dr. Dipl.-Ing. Kurt Schmalz

1_Kap_VT_Un!en_040811_EN_US_La#o"! 1 08.08.11 18:32 Sei!e 5

P

A

0

1

0

1

0

7

1

1

_

E

N

_

o

p

t

.

p

d

f

P

A

0

1

0

1

0

7

1

1

_

E

N

_

o

p

t

.

p

d

f

PA01010711_EN_opt.pdf

PA01010711_EN_opt.pdf

6

S

c

h

m

a

l

z

T

h

e

C

o

m

p

a

n

y

V

a

c

u

u

m

K

n

o

w

l

e

d

g

e

V

a

c

u

u

m

S

u

c

t

i

o

n

P

a

d

s

S

p

e

c

i

a

l

G

r

i

p

p

e

r

s

M

o

u

n

t

i

n

g

E

l

e

m

e

n

t

s

V

a

c

u

u

m

G

e

n

e

r

a

t

o

r

s

V

a

l

v

e

T

e

c

h

n

o

l

o

g

y

S

w

i

t

c

h

e

s

a

n

d

M

o

n

i

t

o

r

i

n

g

F

i

l

t

e

r

s

a

n

d

C

o

n

n

e

c

t

i

o

n

s

V

a

c

u

u

m

G

r

i

p

-

p

i

n

g

S

y

s

t

e

m

s

S

e

r

v

i

c

e

s

C

o

n

t

a

c

t

I

n

d

e

x

o

f

P

r

o

d

u

c

t

s

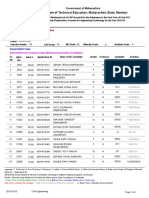

Dynamic Growth is our Passion

Founded: 1910 by Johannes Schmalz

Market importance: Leading global supplier of vacuum technology in the

areas of automation, handling and clamping technology

Business areas: Vacuum components

Vacuum gripping systems

Vacuum handling systems

Vacuum clamping systems

Employees: More than 650 worldwide, 13% trainees (DE)

Innovation indicators: About 350 industrial rights chartered and granted

7% of turnover spent on research and development

Subsidiaries abroad: In 15 countries worldwide

Sales partners: In over 40 countries worldwide

Turnover quota: Around 50% Germany

Around 50% International

Certifications: DIN ISO 9001 (quality management) since 1994

DIN ISO 14001 (environmental management) since 1997

1_Kap_VT_Un!en_040811_EN_US_La#o"! 1 08.08.11 18:32 Sei!e 6

P

A

0

1

0

1

0

7

1

1

_

E

N

_

o

p

t

.

p

d

f

P

A

0

1

0

1

0

7

1

1

_

E

N

_

o

p

t

.

p

d

f

PA01010711_EN_opt.pdf

PA01010711_EN_opt.pdf

7

S

c

h

m

a

l

z

T

h

e

C

o

m

p

a

n

y

V

a

c

u

u

m

K

n

o

w

l

e

d

g

e

V

a

c

u

u

m

S

u

c

t

i

o

n

P

a

d

s

S

p

e

c

i

a

l

G

r

i

p

p

e

r

s

M

o

u

n

t

i

n

g

E

l

e

m

e

n

t

s

V

a

c

u

u

m

G

e

n

e

r

a

t

o

r

s

V

a

l

v

e

T

e

c

h

n

o

l

o

g

y

S

w

i

t

c

h

e

s

a

n

d

M

o

n

i

t

o

r

i

n

g

F

i

l

t

e

r

s

a

n

d

C

o

n

n

e

c

t

i

o

n

s

V

a

c

u

u

m

G

r

i

p

-

p

i

n

g

S

y

s

t

e

m

s

S

e

r

v

i

c

e

s

C

o

n

t

a

c

t

I

n

d

e

x

o

f

P

r

o

d

u

c

t

s

Canada

Schmalz Vacuum Technology Ltd.

17-3190 Ridgeway Drive

ON L5L 5S8 Mississauga

Ontario

Tel +1 905 569 9520

Fax +1 905 569 8256

schmalz@schmalz.ca

China

Schmalz (Shanghai) Co. Ltd.

1F Building No.1

Jinhai Rd 1000

Jinlin Industrial Park

201206 Pudong, Shanghai

Tel +86 (0)21 510999 33

Fax +86 (0)21 503988 82

schmalz@schmalz.net.cn

Finland

Oy Schmalz Ab

Hakkilankaari 2

01380 VANTAA

Tel +358 (0)9 85746 92

Fax +358 (0)9 85746 94

schmalz@schmalz.fi

France

Schmalz S.A.S.

Le Promthe

65 Avenue du Gnral de Gaulle

77420 Champs sur Marne

Tel +33 (0)1 6473 1730

Fax +33 (0)1 6006 6371

schmalz@schmalz.fr

Germany

J. Schmalz GmbH

Aacher Strae 29

72293 Glatten

Tel +49 (0)7443 2403 0

Fax +49 (0)7443 2403 259

schmalz@schmalz.de

India

Schmalz India Pvt. Ltd.

EL 38 J Block MIDC

Bhosari

411026 Pune

Tel +91 (0)20 4072 5500

Fax +91 (0)20 4072 5588

schmalz@schmalz.co.in

Italy

Schmalz S.r.l. a Socio Unico

Via delle Americhe 1

28100 Novara

Tel +39 0321 621 510

Fax +39 0321 621 714

schmalz@schmalz.it

Japan

Schmalz K.K.

3595 Ikonobe-cho

Tsuzuki-ku

224-0053 Yokohama

Tel +81 (0)45 308-9940

Fax +81 (0)45 308-9941

schmalz@schmalz.co.jp

Netherlands

Schmalz B.V.

Lansinkesweg 4

7553 AE Hengelo

Tel +31 (0)74 25557 57

Fax +31 (0)74 25557 58

schmalz@schmalz.nl

Poland

Schmalz Sp. z o.o.

Al. Jerozolimskie 202

02-486 Warszawa

Tel +48 (0)22 4604970

Fax +48 (0)22 8740062

schmalz@schmalz.pl

Russia

Schmalz Reprsentanz

ul. 26 Bakinskikh Komissarov, 9

Office 109

119571, Moscow

Tel +7 495 96712 48

Fax +7 495 96712 49

schmalz@schmalz.ru

South Korea

Schmalz Co. Ltd.

Room 728,

775-1 Janghang 2-dong

IlsandongGu

GoyangCity KyungkiDo

Tel +82 (0)31 816 2403

Fax +82 (0)31 816 2404

schmalz@schmalz.co.kr

Spain

Schmalz S.A.

Avda. Ribera de Axpe. 49

P.A.E. UDONDO-Edificio B-Nave 2

48950 Erandio (Vizcaya)

Tel +34 94 480 5585

Fax +34 94 480 7264

schmalz@schmalz.es

Switzerland

Schmalz GmbH

Eigentalstrae 1

8309 Nrensdorf

Tel +41 (0)44 88875 25

Fax +41 (0)44 88875 29

schmalz@schmalz.ch

Turkey

S#'a&1 Va%-'

Sa(. ." T$. L,!. 6,$.

Y"($ Y)& S)%a%

C"a(&a* 57'"*%"1$ N): 20/2-3

34718 A3ba!"' 2 Ka!3%40 2

5STANBUL

T"& +90 (0)216 34001 21

Fa/ +90 (0)216 34001 24

+#'a&1@+#'a&1.)'.,*

United States

Schmalz Inc.

5200 Atlantic Avenue

Raleigh, NC 27616

Tel +1 919 71308 80

Fax +1 919 71308 83

schmalz@schmalz.us

Schmalz Subsidiaries

Together with customers, the Schmalz system consultants design an appropriate vacuum system for the individual

application. Whether you are looking for a vacuum solution for automation technology, handling technology or

clamping technology, Schmalz is the right partner.

The sales network, with local field representatives, international subsidiaries and trade partners, ensures quick

and competent information and advice.

International Sales Network

Expertise in 50 countries

1_Kap_VT_Un!en_040811_EN_US_La#o"! 1 08.08.11 18:32 Sei!e 7

P

A

0

1

0

1

0

7

1

1

_

E

N

_

o

p

t

.

p

d

f

P

A

0

1

0

1

0

7

1

1

_

E

N

_

o

p

t

.

p

d

f

PA01010711_EN_opt.pdf

PA01010711_EN_opt.pdf

8

S

c

h

m

a

l

z

T

h

e

C

o

m

p

a

n

y

V

a

c

u

u

m

K

n

o

w

l

e

d

g

e

V

a

c

u

u

m

S

u

c

t

i

o

n

P

a

d

s

S

p

e

c

i

a

l

G

r

i

p

p

e

r

s

M

o

u

n

t

i

n

g

E

l

e

m

e

n

t

s

V

a

c

u

u

m

G

e

n

e

r

a

t

o

r

s

V

a

l

v

e

T

e

c

h

n

o

l

o

g

y

S

w

i

t

c

h

e

s

a

n

d

M

o

n

i

t

o

r

i

n

g

F

i

l

t

e

r

s

a

n

d

C

o

n

n

e

c

t

i

o

n

s

V

a

c

u

u

m

G

r

i

p

-

p

i

n

g

S

y

s

t

e

m

s

S

e

r

v

i

c

e

s

C

o

n

t

a

c

t

I

n

d

e

x

o

f

P

r

o

d

u

c

t

s

The constantly increasing demand in resources and energy of people and business leads to more and more bottle -

necks and increasing costs in material procurement. For this reason, it is necessary to deal with materials and

resources in an efficient manner for reasons of economy and sustainability.

Process-Optimized

These points are very important to Schmalz. Therefore the company has organized its processes to gain added value.

The added-value system pursues aims such as lowest production and process costs, shortest processing times, low

stocks and at the same time highest quality. The added-value system, together with the companys modern

workplaces, is the basis for efficient production and its ability to compete over the long term.

At Schmalz state-of-the-art production and logistic concepts determine most of the everyday tasks in manufactu-

ring. For example, Schmalz uses the one-piece flow concept whenever it is possible and makes sense to do so.

With this concept, the vacuum specialist can avoid large lot sizes, thus saving material and warehouse space.

The manufacturing processes were changed over to piece-by-piece assembly. A second product is not manufactured

until the first product is completely assembled and tested.

The milk run concept in conjunction with kanban warehousing makes material available to the employees as

required and at the right time. Both of these systems ensure that material is refilled only in the quantity in which

it was consumed.

These innovative process optimizations provide lean processes and economical materials handling.

Quality Management

At Schmalz, the customer stands at the center. The goal is to meet the customers demands and deliver products in

a quality, that it is expected by the customer.

The processes and procedures at Schmalz are based on the extensive know-how, many years of experience, most

modern concepts and international standards. Since 1994 the quality management system of the vacuum specialist

has regularly been certified to DIN ISO 9001.

Computer Aided Quality (CAQ) software informs the employees of the company constantly on the current quality

level, so that Schmalz can react quickly to changes. Modern manufacturing concepts provide for early fault detection

and troubleshooting. "Continuous improvement" is part in everyday life and develops employees, companies and

products continuously. This reduces the company's level of error in longterm.

Efficiency and Sustainability

Schmalz value creation

1_Kap_VT_Un!en_040811_EN_US_La#o"! 1 08.08.11 18:32 Sei!e 8

P

A

0

1

0

1

0

7

1

1

_

E

N

_

o

p

t

.

p

d

f

P

A

0

1

0

1

0

7

1

1

_

E

N

_

o

p

t

.

p

d

f

PA01010711_EN_opt.pdf

PA01010711_EN_opt.pdf

9

S

c

h

m

a

l

z

T

h

e

C

o

m

p

a

n

y

V

a

c

u

u

m

K

n

o

w

l

e

d

g

e

V

a

c

u

u

m

S

u

c

t

i

o

n

P

a

d

s

S

p

e

c

i

a

l

G

r

i

p

p

e

r

s

M

o

u

n

t

i

n

g

E

l

e

m

e

n

t

s

V

a

c

u

u

m

G

e

n

e

r

a

t

o

r

s

V

a

l

v

e

T

e

c

h

n

o

l

o

g

y

S

w

i

t

c

h

e

s

a

n

d

M

o

n

i

t

o

r

i

n

g

F

i

l

t

e

r

s

a

n

d

C

o

n

n

e

c

t

i

o

n

s

V

a

c

u

u

m

G

r

i

p

-

p

i

n

g

S

y

s

t

e

m

s

S

e

r

v

i

c

e

s

C

o

n

t

a

c

t

I

n

d

e

x

o

f

P

r

o

d

u

c

t

s

Suppliers are also an important part of the overall system. Schmalz demands the same quality standard from suppliers

as it demands of itself. Continuous supplier development contributes to the overall success of the company.

Efficient Products

In the development and manufacturing of its products, Schmalz puts great emphasis on efficiency in terms of energy

consumption and recyclability. Apart from the functionality, aspects such as a long service life, high efficiency and

good recyclability are taken into consideration. Therefore Schmalz has developed vacuum generators with an

integrated air-saving function, lifting devices with a wireless remote control and suction pads with separable

elastomer part and nipple, just to name a few.

Sustainability in Practice

Schmalz has made the principle of sustainable development one of its corporate objectives. Only sustainable

growth allows Schmalz to protect its corporate interests. Since Schmalz is thinking in the long-term, the company

aligns its corporate strategy in such a way that economics, ecology and social commitment complete each other.

This means Schmalz is able to finance its own growth in order to ensure secure jobs and actively realize our social

and ecological responsibility.

The special importance of sustainability is reflected in the corporate principles. The company management and

employees are required to think and practice business with environmental awareness. As a positive energy com -

pany, Schmalz generates more energy from renewable sources then the company consumes itself. It is the firm

opinion of the vacuum specialist that economic success goes hand-in-hand with the awareness of ecological and

social responsibility.

Schmalz exceptional dedication has gained wide recognition and has been rewarded with numerous awards.

1_Kap_VT_Un!en_040811_EN_US_La#o"! 1 08.08.11 18:32 Sei!e 9

P

A

0

1

0

1

0

7

1

1

_

E

N

_

o

p

t

.

p

d

f

P

A

0

1

0

1

0

7

1

1

_

E

N

_

o

p

t

.

p

d

f

PA01010711_EN_opt.pdf

PA01010711_EN_opt.pdf

Vacuum Components and Gripping Systems

Vacuum components and vacuum gripping systems from Schmalz permit decisive

productivity improvements in automated processes. Be it in mechanical engineering

or in the robot industry Schmalz customers in all areas of automation technology

profit from our qualified system consultancy services and our groundbreaking,

innovative solutions. The range of workpieces which can be handled with vacuum

extends from easily damaged, small parts such as electronic chips or CDs to furniture

elements or heavy sheets of steel.

Our specialists expertise guarantees efficient and economical solutions for the

automation of a process; from the individual components, to the complex gripping

system, all the way through to the particular customer-specific application.

Vacuum Components

Vacuum suction pads

Special grippers

Mounting elements

Vacuum generators

Valve technology

Switches and system monitoring

Filters and connections

Vacuum Gripping Systems

Fully configured systems for industrial

robots and portals, delivered ready for

connection

10

S

c

h

m

a

l

z

T

h

e

C

o

m

p

a

n

y

V

a

c

u

u

m

K

n

o

w

l

e

d

g

e

V

a

c

u

u

m

S

u

c

t

i

o

n

P

a

d

s

S

p

e

c

i

a

l

G

r

i

p

p

e

r

s

M

o

u

n

t

i

n

g

E

l

e

m

e

n

t

s

V

a

c

u

u

m

G

e

n

e

r

a

t

o

r

s

V

a

l

v

e

T

e

c

h

n

o

l

o

g

y

S

w

i

t

c

h

e

s

a

n

d

M

o

n

i

t

o

r

i

n

g

F

i

l

t

e

r

s

a

n

d

C

o

n

n

e

c

t

i

o

n

s

V

a

c

u

u

m

G

r

i

p

-

p

i

n

g

S

y

s

t

e

m

s

S

e

r

v

i

c

e

s

C

o

n

t

a

c

t

I

n

d

e

x

o

f

P

r

o

d

u

c

t

s

Business Areas

1_Kap_VT_Un!en_040811_EN_US_La#o"! 1 08.08.11 18:32 Sei!e 10

P

A

0

1

0

1

0

7

1

1

_

E

N

_

o

p

t

.

p

d

f

P

A

0

1

0

1

0

7

1

1

_

E

N

_

o

p

t

.

p

d

f

PA01010711_EN_opt.pdf

PA01010711_EN_opt.pdf

11

S

c

h

m

a

l

z

T

h

e

C

o

m

p

a

n

y

V

a

c

u

u

m

K

n

o

w

l

e

d

g

e

V

a

c

u

u

m

S

u

c

t

i

o

n

P

a

d

s

S

p

e

c

i

a

l

G

r

i

p

p

e

r

s

M

o

u

n

t

i

n

g

E

l

e

m

e

n

t

s

V

a

c

u

u

m

G

e

n

e

r

a

t

o

r

s

V

a

l

v

e

T

e

c

h

n

o

l

o

g

y

S

w

i

t

c

h

e

s

a

n

d

M

o

n

i

t

o

r

i

n

g

F

i

l

t

e

r

s

a

n

d

C

o

n

n

e

c

t

i

o

n

s

V

a

c

u

u

m

G

r

i

p

-

p

i

n

g

S

y

s

t

e

m

s

S

e

r

v

i

c

e

s

C

o

n

t

a

c

t

I

n

d

e

x

o

f

P

r

o

d

u

c

t

s

Vacuum Handling Systems

Business Areas

Vacuum handling systems from Schmalz rationalize and simplify production processes by facilitating easy and

efficient workpiece handling. They feature functionality, safety and ergonomic operation in processes such as

the loading and unloading of machines.

Vacuum Tube Lifter Jumbo

Vacuum tube lifters Jumbo are ideal for the frequent

and rapid lifting and moving of cardboard boxes, sacks,

barrels, and numerous other applications weighing up

to 300 kg.

Vacuum Lifting Devices VacuMaster

Vacuum lifting devices VacuMaster are the ideal tool

for the ergonomic and safe handling of loads weighing

up to several tons.

Cranes and Crane Systems

Various working ranges, load classes and aluminum

or steel crane rails facilitate their use in a variety of

applications.

Workshop Equipment

Workshop equipment provides invaluable support in

trade and industrial production processes; in the wood

and solar energy industries, for example.

1_Kap_VT_Un!en_040811_EN_US_La#o"! 1 08.08.11 18:32 Sei!e 11

P

A

0

1

0

1

0

7

1

1

_

E

N

_

o

p

t

.

p

d

f

P

A

0

1

0

1

0

7

1

1

_

E

N

_

o

p

t

.

p

d

f

PA01010711_EN_opt.pdf

PA01010711_EN_opt.pdf

Vacuum Clamping Systems

Schmalz vacuum clamping technology enhances the efficiency in production processes for CNC machine tools.

Innovative ideas, numerous national and international trade mark rights, system diversity and customer focus

have made Schmalz to the world market leader in the area of vacuum clamping technology.

We are the system supplier to the internationally leading manufacturers, who equip their CNC machining centres

as standard with Schmalz clamping systems, thus ensuring maximum productivity for their customers.

Clamping Solutions for the Wood Industry

Profitability through shorten set-up times

Clamping Solutions for the Metal Industry

Precise and secure

Modernising

Retrofitting for consisting machines

Set-up reduced by up to 80 percent

12

S

c

h

m

a

l

z

T

h

e

C

o

m

p

a

n

y

V

a

c

u

u

m

K

n

o

w

l

e

d

g

e

V

a

c

u

u

m

S

u

c

t

i

o

n

P

a

d

s

S

p

e

c

i

a

l

G

r

i

p

p

e

r

s

M

o

u

n

t

i

n

g

E

l

e

m

e

n

t

s

V

a

c

u

u

m

G

e

n

e

r

a

t

o

r

s

V

a

l

v

e

T

e

c

h

n

o

l

o

g

y

S

w

i

t

c

h

e

s

a

n

d

M

o

n

i

t

o

r

i

n

g

F

i

l

t

e

r

s

a

n

d

C

o

n

n

e

c

t

i

o

n

s

V

a

c

u

u

m

G

r

i

p

-

p

i

n

g

S

y

s

t

e

m

s

S

e

r

v

i

c

e

s

C

o

n

t

a

c

t

I

n

d

e

x

o

f

P

r

o

d

u

c

t

s

Business Areas

1_Kap_VT_Un!en_040811_EN_US_La#o"! 1 08.08.11 18:32 Sei!e 12

P

A

0

1

0

1

0

7

1

1

_

E

N

_

o

p

t

.

p

d

f

P

A

0

1

0

1

0

7

1

1

_

E

N

_

o

p

t

.

p

d

f

PA01010711_EN_opt.pdf

PA01010711_EN_opt.pdf

Industry Solutions

In all areas of automation technology, Schmalz customers benefit from expert systems consulting and ground-

breaking, innovative solutions. Schmalz vacuum components include everything they need to develop a fully

operational vacuum system.

The wide product range of vacuum components corresponds to the specific requirements of a wide variety of

industry sectors. The focus is on the industries described below. In the catalog, the industry-specific suitability

of each product is indicated using symbols. The index at the end of the catalog can assist in finding appropriate

items for your industry sector.

Wood

Handling of workpieces with a variety of surfaces under

difficult operating conditions

Suction pads for handling and separating workpieces

the suck-through effect

Comprehensive range of filters for protecting vacuum

systems from contamination

Large area vacuum gripping systems for moving wooden

sheets, furniture parts, pallets or entire layers of boards

13

S

c

h

m

a

l

z

T

h

e

C

o

m

p

a

n

y

V

a

c

u

u

m

K

n

o

w

l

e

d

g

e

V

a

c

u

u

m

S

u

c

t

i

o

n

P

a

d

s

S

p

e

c

i

a

l

G

r

i

p

p

e

r

s

M

o

u

n

t

i

n

g

E

l

e

m

e

n

t

s

V

a

c

u

u

m

G

e

n

e

r

a

t

o

r

s

V

a

l

v

e

T

e

c

h

n

o

l

o

g

y

S

w

i

t

c

h

e

s

a

n

d

M

o

n

i

t

o

r

i

n

g

F

i

l

t

e

r

s

a

n

d

C

o

n

n

e

c

t

i

o

n

s

V

a

c

u

u

m

G

r

i

p

-

p

i

n

g

S

y

s

t

e

m

s

S

e

r

v

i

c

e

s

C

o

n

t

a

c

t

I

n

d

e

x

o

f

P

r

o

d

u

c

t

s

Metal sheets /automotive

Fast cycle times and high operational reliability

Special suction pads for highly dynamic metal sheet

handling, even with oiled metal sheets or fragile

components

Vacuum generator with integrated system monitoring,

condition monitoring and IO-Link technology for

increasing process reliability and improving energy

efficiency

Optimized mounting elements for the requirements

of the automotive industry

Worldwide at home in many industries

1_Kap_VT_Un!en_040811_EN_US_La#o"! 1 08.08.11 18:32 Sei!e 13

P

A

0

1

0

1

0

7

1

1

_

E

N

_

o

p

t

.

p

d

f

P

A

0

1

0

1

0

7

1

1

_

E

N

_

o

p

t

.

p

d

f

PA01010711_EN_opt.pdf

PA01010711_EN_opt.pdf

14

S

c

h

m

a

l

z

T

h

e

C

o

m

p

a

n

y

V

a

c

u

u

m

K

n

o

w

l

e

d

g

e

V

a

c

u

u

m

S

u

c

t

i

o

n

P

a

d

s

S

p

e

c

i

a

l

G

r

i

p

p

e

r

s

M

o

u

n

t

i

n

g

E

l

e

m

e

n

t

s

V

a

c

u

u

m

G

e

n

e

r

a

t

o

r

s

V

a

l

v

e

T

e

c

h

n

o

l

o

g

y

S

w

i

t

c

h

e

s

a

n

d

M

o

n

i

t

o

r

i

n

g

F

i

l

t

e

r

s

a

n

d

C

o

n

n

e

c

t

i

o

n

s

V

a

c

u

u

m

G

r

i

p

-

p

i

n

g

S

y

s

t

e

m

s

S

e

r

v

i

c

e

s

C

o

n

t

a

c

t

I

n

d

e

x

o

f

P

r

o

d

u

c

t

s

Packaging

Packaging of goods and handling of packaged products with minimal cycle times

Complete suction pad offering with a large variety of materials and geometries for a wide range of packaging

and products

Large range of vacuum generators for various process requirements

Modular system VEE for quick and cost-efficient assembly of vacuum end effectors

Vacuum layer gripping systems for palletizing and order picking of packaged products

Plastics

Removal of hot plastic parts

leaving very few marks

Special materials of the

suction pads with tempe-

rature resistance require-

ments, requirements

relating to the ability to

paint or varnish the work-

piece and requirements

that very few marks be

left on the workpiece

Vacuum generator mini -

mized in size for highly

dynamic handling

Solar

Extremely fast, accurate and gentle handling

Wafer grippers for careful, fast and accurate

handling of photovoltaic components

Suction pads in various materials and geometries

Special grippers for low-contact and gentle handling

1_Kap_VT_Un!en_040811_EN_US_La#o"! 1 08.08.11 18:32 Sei!e 14

P

A

0

1

0

1

0

7

1

1

_

E

N

_

o

p

t

.

p

d

f

P

A

0

1

0

1

0

7

1

1

_

E

N

_

o

p

t

.

p

d

f

PA01010711_EN_opt.pdf

PA01010711_EN_opt.pdf

15

S

c

h

m

a

l

z

T

h

e

C

o

m

p

a

n

y

V

a

c

u

u

m

K

n

o

w

l

e

d

g

e

V

a

c

u

u

m

S

u

c

t

i

o

n

P

a

d

s

S

p

e

c

i

a

l

G

r

i

p

p

e

r

s

M

o

u

n

t

i

n

g

E

l

e

m

e

n

t

s

V

a

c

u

u

m

G

e

n

e

r

a

t

o

r

s

V

a

l

v

e

T

e

c

h

n

o

l

o

g

y

S

w

i

t

c

h

e

s

a

n

d

M

o

n

i

t

o

r

i

n

g

F

i

l

t

e

r

s

a

n

d

C

o

n

n

e

c

t

i

o

n

s

V

a

c

u

u

m

G

r

i

p

-

p

i

n

g

S

y

s

t

e

m

s

S

e

r

v

i

c

e

s

C

o

n

t

a

c

t

I

n

d

e

x

o

f

P

r

o

d

u

c

t

s

Composite

Handling of porous composite materials

Special grippers with integrated vacuum generation

and high volume flow for secure gripping even in

case of porous materials such as carbon composites

Various suction pad geometries and materials provide

for adjustment to a variety of applications

Needle grippers for handling of bending and unstable

materials, as well materials to which it is difficult to

apply suction

Battery

Handling of electrodes, separators and battery cells

without causing any damage

Special grippers for lithium ion batteries

Ideal marking behavior confirmed in contamination

tests of the FRAUNHOFER IPA

Careful, fast and accurate handling of battery

components and cells

CD/ DVD

Clean and flexible vacuum handling

Complete suction pad range in a wide variety of materials for all processing steps

in CD/DVD production

Vacuum generator with integrated system monitoring for increasing process reliability

Small vacuum components minimized in size for highly dynamic handling

Glass

Mark-free and secure gripping

Suction pads especially for handling flat, smooth

and thin workpieces

Special suction plates made from special materials

for use in areas with high UV and ozone levels

1_Kap_VT_Un!en_040811_EN_US_La#o"! 1 08.08.11 18:32 Sei!e 15

P

A

0

1

0

1

0

7

1

1

_

E

N

_

o

p

t

.

p

d

f

P

A

0

1

0

1

0

7

1

1

_

E

N

_

o

p

t

.

p

d

f

PA01010711_EN_opt.pdf

PA01010711_EN_opt.pdf

16

S

c

h

m

a

l

z

T

h

e

C

o

m

p

a

n

y

V

a

c

u

u

m

K

n

o

w

l

e

d

g

e

V

a

c

u

u

m

S

u

c

t

i

o

n

P

a

d

s

S

p

e

c

i

a

l

G

r

i

p

p

e

r

s

M

o

u

n

t

i

n

g

E

l

e

m

e

n

t

s

V

a

c

u

u

m

G

e

n

e

r

a

t

o

r

s

V

a

l

v

e

T

e

c

h

n

o

l

o

g

y

S

w

i

t

c

h

e

s

a

n

d

M

o

n

i

t

o

r

i

n

g

F

i

l

t

e

r

s

a

n

d

C

o

n

n

e

c

t

i

o

n

s

V

a

c

u

u

m

G

r

i

p

-

p

i

n

g

S

y

s

t

e

m

s

S

e

r

v

i

c

e

s

C

o

n

t

a

c

t

I

n

d

e

x

o

f

P

r

o

d

u

c

t

s

2_Kap_VT_040811_EN_K2_DE V2 08.08.11 18:33 Seite 1

P

A

0

1

0

1

0

7

1

1

_

E

N

_

o

p

t

.

p

d

f

P

A

0

1

0

1

0

7

1

1

_

E

N

_

o

p

t

.

p

d

f

PA01010711_EN_opt.pdf

PA01010711_EN_opt.pdf

Vacuum Knowledge

Overview of Section 2

17

S

c

h

m

a

l

z

T

h

e

C

o

m

p

a

n

y

V

a

c

u

u

m

K

n

o

w

l

e

d

g

e

V

a

c

u

u

m

S

u

c

t

i

o

n

P

a

d

s

S

p

e

c

i

a

l

G

r

i

p

p

e

r

s

M

o

u

n

t

i

n

g

E

l

e

m

e

n

t

s

V

a

c

u

u

m

G

e

n

e

r

a

t

o

r

s

V

a

l

v

e

T

e

c

h

n

o

l

o

g

y

S

w

i

t

c

h

e

s

a

n

d

M

o

n

i

t

o

r

i

n

g

F

i

l

t

e

r

s

a

n

d

C

o

n

n

e

c

t

i

o

n

s

V

a

c

u

u

m

G

r

i

p

-

p

i

n

g

S

y

s

t

e

m

s

S

e

r

v

i

c

e

s

C

o

n

t

a

c

t

I

n

d

e

x

o

f

P

r

o

d

u

c

t

s

The Vacuum System and its Components

Basic Vacuum Knowledge and Vacuum Terminology

Page

Overview of a Vacuum System

Vacuum Suction Pads

Special Grippers

Mounting Elements

Vacuum Generators

Valve Technology

Switches and System Monitoring

Filters and Connectors

44

System Design Calculation Example 47

Symbols in Vacuum Technology 56

Units and Conversion Tables 57

Vacuum Glossary 59

Seminars and training

19

20

27

30

32

37

39

42

Schmalz offers customized training, seminars and courses at the Schmalz Academy. Customers benefit from our comprehensive

expertise and all our years of experience as vacuum specialists.

You will find more details in the chapter Services.

2_Kap_VT_040811_EN_K2_DE V2 08.08.11 18:34 Seite 17

P

A

0

1

0

1

0

7

1

1

_

E

N

_

o

p

t

.

p

d

f

P

A

0

1

0

1

0

7

1

1

_

E

N

_

o

p

t

.

p

d

f

PA01010711_EN_opt.pdf

PA01010711_EN_opt.pdf

18

S

c

h

m

a

l

z

T

h

e

C

o

m

p

a

n

y

V

a

c

u

u

m

K

n

o

w

l

e

d

g

e

V

a

c

u

u

m

S

u

c

t

i

o

n

P

a

d

s

S

p

e

c

i

a

l

G

r

i

p

p

e

r

s

M

o

u

n

t

i

n

g

E

l

e

m

e

n

t

s

V

a

c

u

u

m

G

e

n

e

r

a

t

o

r

s

V

a

l

v

e

T

e

c

h

n

o

l

o

g

y

S

w

i

t

c

h

e

s

a

n

d

M

o

n

i

t

o

r

i

n

g

F

i

l

t

e

r

s

a

n

d

C

o

n

n

e

c

t

i

o

n

s

V

a

c

u

u

m

G

r

i

p

-

p

i

n

g

S

y

s

t

e

m

s

S

e

r

v

i

c

e

s

C

o

n

t

a

c

t

I

n

d

e

x

o

f

P

r

o

d

u

c

t

s

2_Kap_VT_040811_EN_K2_DE V2 08.08.11 18:34 Seite 18

P

A

0

1

0

1

0

7

1

1

_

E

N

_

o

p

t

.

p

d

f

P

A

0

1

0

1

0

7

1

1

_

E

N

_

o

p

t

.

p

d

f

PA01010711_EN_opt.pdf

PA01010711_EN_opt.pdf

S

c

h

m

a

l

z

d

a

s

U

n

t

e

r

n

e

h

m

e

n

E

i

n

f

h

r

u

n

g

V

a

k

u

u

m

-

S

a

u

g

g

r

e

i

f

e

r

S

p

e

z

i

a

l

g

r

e

i

f

e

r

B

e

f

e

s

t

i

g

u

n

g

s

-

e

l

e

m

e

n

t

e

V

a

k

u

u

m

-

E

r

z

e

u

g

e

r

V

e

n

t

i

l

t

e

c

h

n

i

k

S

c

h

a

l

t

e

r

u

n

d

b

e

r

w

a

c

h

u

n

g

F

i

l

t

e

r

u

n

d

V

e

r

b

i

n

d

u

n

g

e

n

V

a

k

u

u

m

-

G

r

e

i

f

s

y

s

t

e

m

e

S

e

r

v

i

c

e

s

K

o

n

t

a

k

t

P

r

o

d

u

k

t

i

n

d

e

x

The Vacuum System and its Components

Vacuum Knowledge

19

S

c

h

m

a

l

z

d

a

s

U

n

t

e

r

n

e

h

m

e

n

E

i

n

f

h

r

u

n

g

V

a

k

u

u

m

-

S

a

u

g

g

r

e

i

f

e

r

S

p

e

z

i

a

l

g

r

e

i

f

e

r

B

e

f

e

s

t

i

g

u

n

g

s

-

e

l

e

m

e

n

t

e

V

a

k

u

u

m

-

E

r

z

e

u

g

e

r

V

e

n

t

i

l

t

e

c

h

n

i

k

S

c

h

a

l

t

e

r

u

n

d

b

e

r

w

a

c

h

u

n

g

F

i

l

t

e

r

u

n

d

V

e

r

b

i

n

d

u

n

g

e

n

V

a

k

u

u

m

-

G

r

e

i

f

s

y

s

t

e

m

e

S

e

r

v

i

c

e

s

K

o

n

t

a

k

t

P

r

o

d

u

k

t

i

n

d

e

x

S

c

h

m

a

l

z

d

a

s

U

n

t

e

r

n

e

h

m

e

n

V

a

k

u

u

m

-

W

i

s

s

e

n

V

a

k

u

u

m

-

S

a

u

g

g

r

e

i

f

e

r

S

p

e

z

i

a

l

g

r

e

i

f

e

r

B

e

f

e

s

t

i

g

u

n

g

s

-

e

l

e

m

e

n

t

e

V

a

k

u

u

m

-

E

r

z

e

u

g

e

r

V

e

n

t

i

l

t

e

c

h

n

i

k

S

c

h

a

l

t

e

r

u

n

d

b

e

r

w

a

c

h

u

n

g

F

i

l

t

e

r

u

n

d

V

e

r

b

i

n

d

u

n

g

e

n

V

a

k

u

u

m

-

G

r

e

i

f

s

y

s

t

e

m

e

S

e

r

v

i

c

e

s

K

o

n

t

a

k

t

P

r

o

d

u

k

t

i

n

d

e

x

Overview of a Vacuum System

Vacuum systems are used as grippers in automated applications. Customers benefit from the comprehensive component program of

Schmalz, the vacuum specialist, when designing a vacuum system.

Filters and connectors

Filters protect the vacuum generator;

hoses and connectors connect the

components

Switches and system monitoring

Measuring and control components

ensure safe operation of the vacuum

system

Vacuum generators

Centralized or decentralized

vacuum generation by means of

ejectors, pumps or blowers

Mounting elements

Fast and flexible connection of

vacuum components to tooling

systems

Vacuum suction pads or special grippers

Interface between vacuum system and

workpiece

Valve technology

Valves are used to control the vacuum

as well as the compressed air

(decentralized or centralized)

Vacuum gripping systems

Complete solutions, such as large-area gripping

systems, layer grippers or vacuum spiders, are

customized to meet customer needs

S

c

h

m

a

l

z

T

h

e

C

o

m

p

a

n

y

V

a

c

u

u

m

K

n

o

w

l

e

d

g

e

V

a

c

u

u

m

S

u

c

t

i

o

n

P

a

d

s

S

p

e

c

i

a

l

G

r

i

p

p

e

r

s

M

o

u

n

t

i

n

g

E

l

e

m

e

n

t

s

V

a

c

u

u

m

G

e

n

e

r

a

t

o

r

s

V

a

l

v

e

T

e

c

h

n

o

l

o

g

y

S

w

i

t

c

h

e

s

a

n

d

M

o

n

i

t

o

r

i

n

g

F

i

l

t

e

r

s

a

n

d

C

o

n

n

e

c

t

i

o

n

s

V

a

c

u

u

m

G

r

i

p

-

p

i

n

g

S

y

s

t

e

m

s

S

e

r

v

i

c

e

s

C

o

n

t

a

c

t

I

n

d

e

x

o

f

P

r

o

d

u

c

t

s

2_Kap_VT_040811_EN_K2_DE V2 08.08.11 18:34 Seite 19

P

A

0

1

0

1

0

7

1

1

_

E

N

_

o

p

t

.

p

d

f

P

A

0

1

0

1

0

7

1

1

_

E

N

_

o

p

t

.

p

d

f

PA01010711_EN_opt.pdf

PA01010711_EN_opt.pdf

Vacuum suction pads are the link between the workpiece and

the handling system. They consist of the suction pad (elastomer

S

c

h

m

a

l

z

d

a

s

U

n

t

e

r

n

e

h

m

e

n

E

i

n

f

h

r

u

n

g

V

a

k

u

u

m

-

S

a

u

g

g

r

e

i

f

e

r

S

p

e

z

i

a

l

g

r

e

i

f

e

r

B

e

f

e

s

t

i

g

u

n

g

s

-

e

l

e

m

e

n

t

e

V

a

k

u

u

m

-

E

r

z

e

u

g

e

r

V

e

n

t

i

l

t

e

c

h

n

i

k

S

c

h

a

l

t

e

r

u

n

d

b

e

r

w

a

c

h

u

n

g

F

i

l

t

e

r

u

n

d

V

e

r

b

i

n

d

u

n

g

e

n

V

a

k

u

u

m

-

G

r

e

i

f

s

y

s

t

e

m

e

S

e

r

v

i

c

e

s

K

o

n

t

a

k