Академический Документы

Профессиональный Документы

Культура Документы

Gen00001-00 (PC400-7 Field Assembly Instruction)

Загружено:

Ebrahim SabouriОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Gen00001-00 (PC400-7 Field Assembly Instruction)

Загружено:

Ebrahim SabouriАвторское право:

Доступные форматы

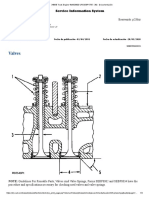

Instruction system

Work leader

Work supervisor Crane director

Director

and

deputy director

Liaison man

Operator for assembly

Interpreter

Mechanics Sharing of work

PREFACE

Since the work equipment of this machine is heavy, the hydraulic pressure of the machine is used to

install it efficiently. Accordingly, the engine is started to operate the hydraulic cylinders.

You are required to execute full inspection and maintenance before starting the engine and assembling

the work equipment. Since the work is often carried out in dangerous places and positions by a team,

hold a safety meeting in advance and appoint a crane director, work leader, etc. so that all the members

can work safely.

When the work is carried out in an overseas country, difference in language, customs, etc. lowers safety.

Accordingly, the field liaison man and work supervisor must examine the above points and take neces-

sary measures.

We hope that all the members will cooperate with each other and assemble the work equipment quickly

in the field, observing the safety, quality, and delivery time.

1

PRECAUTIONS FOR FIELD ASSEMBLY

1. Selection of workplace

1) When selecting a workplace, consider the following items so that you can load and unload the

machine.

Width

Hardness

Flatness

Access road, place for turn

2) Do not work in a place where dust, rainwater, etc. may enter the hydraulic circuit during assembling

work.

3) Do not assemble while a strong wind is blowing or it is raining.

2. Preparation and check of slings and tools

1) Check each sling and tool thoroughly. When using wood blocks, etc., check that their inside is

not rotten or broken.

3. Check of actual work

1) Apply the parking brakes of the trailer and crane truck securely and put chocks under their wheels.

2) Before starting the work, lower the temperature and pressure of the engine oil, hydraulic oil,

cooling water, etc.

3) When starting the engine, make an arranged sign such as sounding of the horn and check that

the work equipment control lever and travel lever are in neutral and the fuel control dial is at the

low idling position.

4) When using the crane, balance the load.

5) Allow only the persons concerned into the workplace.

4. Before starting the work, read this manual thoroughly and keep the precautions in your mind.

5. The supervisor shall write down the precautions for each work process and explain them to the workers.

6. Hold a meeting every morning to check todays work plan and safe work.

2

Table 1

Unit: Nm {kgm}

Material S43C, SCM43H or higher

Nominal size of thread (mm) Range Target

6

8.8 14.7 12

{0.9 1.5} {1.2}

8

14.7 34 25

{1.5 3.5} {2.5}

10

34 74 54

{3.5 7.5} {5.5}

12

54 123 89

{5.5 12.5} {9}

14

84 196 137

{8.5 20} {14}

16

147 309 230

{15 31.5} {23.5}

18

201 427 315

{20.5 43.5} {32}

20

319 608 460

{32.5 62} {47}

22

471 829 650

{48 84.5} {66.5}

24

588 1030 810

{60 105} {82.5}

27

883 1470 1180

{90 150} {120}

30

1130 1910 1520

{115 195} {155}

33

1470 2450 1960

{150 250} {200}

36

1860 3040 2450

{190 310} {250}

39

2260 3630 2940

{230 370} {300}

TIGHTENING TORQUE

Remove the plugging parts (flanges, heads, caps, and O-rings) of the work equipment piping and

undercarriage piping, plugs of the greasing piping, cylinder fixing jigs, and plugs of the tap holes of

the loose-supply items which were used for transportation and keep them carefully so that they can

be used again for the next transportation.

Tighten the bolts to the torque shown in the following table, unless otherwise specified in the main-

tenance standard table.

1. Tightening torque of bolts

When tightening the bolts with an impact wrench/spanner, apply Table 1.

Tighten the bolts according to Table 1 as a rule. When this rule is applied, the tightening torque is not

shown in the drawing.

3

Table 2

Unit: Nm {kgm}

Material

S43C, SCM43H or higher

Nominal size of thread (mm)

6

11.8 14.7

{1.2 1.5}

8

27 34

{2.8 3.5}

10

59 74

{6 7.5}

12

98 123

{10 12.5}

14

157 196

{16 20}

16

245 309

{25 31.5}

18

343 427

{35 43.5}

20

490 608

{50 62}

22

662 829

{67.5 84.5}

24

824 1030

{84 105}

27

1180 1470

{120 150}

30

1520 1910

{155 195}

33

1960 2450

{200 250}

36

2450 3040

{250 310}

39

2890 3630

{295 370}

When tightening the bolts with a torque wrench, apply Table 2.

Apply Table 2 when the proper tightening torque range is particularly narrow.

4

Table 1

Unit: Nm {kgm}

Material of female thread

Steel Cast iron Light alloy

Nominal size

1 / 8

3.9 6.9 2.9 5.9 2.0 3.9

{0.4 0.7} {0.3 0.6} {0.2 0.4}

1 / 4

5.9 11.8 4.9 9.8 3.9 7.8

{0.6 1.2} {0.5 1.0} {0.4 0.8}

3 / 8

16.7 26.5 13.7 21.6 9.8 16.7

{1.7 2.7} {1.4 2.2} {1.0 1.7}

1 / 2

32.3 52.9 26.5 43.1 19.6 32.3

{3.3 5.4} {2.7 4.4} {2.0 3.3}

3 / 4

51.0 85.3 42.1 70.6 31.4 52.9

{5.2 8.7} {4.3 7.2} {3.2 5.4}

1

86.2 173.5 72.5 146.0 54.9 111.7

{8.8 17.7} {7.4 14.9} {5.6 11.4}

Table 2

Unit: Nm {kgm}

Material of female thread

Steel Cast iron Light alloy

Nominal size

1 / 8

16.7 29.4 9.8 19.6 6.9 14.7

{1.7 3.0} {1.0 2.0} {0.7 1.5}

1 / 4

19.6 44.1 16.7 37.2 12.7 28.4

{2.0 4.5} {1.7 3.8} {1.3 2.9}

3 / 8

44.1 93.1 37.2 77.4 27.4 58.8

{4.5 9.5} {3.8 7.9} {2.8 6.0}

1 / 2

98.0 188.2 83.3 157.8 60.8 115.6

{10.0 19.2} {8.5 16.1} {6.2 11.8}

3 / 4

170.5 316.5 141.1 247.0 105.8 186.2

{17.4 32.3} {14.4 25.2} {10.8 19.0}

1

367.5 612.5 309.7 514.5 235.2 392.0

{37.5 62.5} {31.6 52.5} {24.0 40.0}

2. Tightening torque of pipe threads

Tighten taper male pipe threads of nominal sizes of R1/8 R1, taper female pipe threads of nominal

sizes of Rc1/8 Rc1, and parallel female pipe threads of nominal sizes of Rp1/8 Rp1 (coated with

adhesive) according to the following standard.

If tightening torque is specified particularly, however, do not apply the following standard.

2-1. If the material of male threads is SS400, FC, or SGP, apply Table 1.

2-2. If the material of male threads is S43C, apply Table 2.

5

Unit: Nm {kgm}

Width across

Tightening torque

flatse.

Range Target

02 19 35 63 {3.5 6.5} 44 {4.5}

03

22 54 93 {5.5 9.5} 74 {7.5}

24 59 98 {6.0 10.0} 78 {8.0}

04 27 84 132 {8.5 13.5} 103 {10.5}

05 32 128 186 {13.0 19.0} 157 {16.0}

06 36 177 245 {18.0 25.0} 216 {22.0}

(10) 41 177 245 {18.0 25.0} 216 {22.0}

(12) 46 197 294 {20.0 30.0} 245 {25.0}

(14) 55 246 343 {25.0 35.0} 294 {30.0}

When connecting hoses, take care not to twist them.

3. Tightening torque of hoses (with taper/face seal)

Nominal

diameter of

hose

Assembling manual of operator's cab 1/8

Assembling manual of operator's cab on the spot

(in relation to operator's cab)

Contents

1. Cover and Contents Page 1/8

2. List of parts assembled on the spot Page 2/8

3. Mount bolts of floor and cab Page 3/8

4. Connecting of wiring harness Page 4/8

<Reference drawing> Ref. 1

5. Connecting of heater air hose Page 5/8

6. Assembling of rear covers Page 6/8

7. Assembling of rear covers(continue) Page 7/8

8. Assembling of side covers Page 8/8

6

Assembling manual of operator's cab 2/8

2. List of parts assembled on the spot

(1) Parts sent singly (2) Parts removed from CIS cab-less guard

Parts No. Parts Name (Connecting of wiring harness)

OPE,CAB A 1 Parts Name

<a> Sub-assembling plate 1

for controller and connector

(Mount bolts of floor and cab) <b> Sub-assembling plate 1

Parts No. Parts Name for connector of A/C

<1> 113-12-21120 WASHER 2 <c> Sub-assembling plate 1

<2> 01580-11613 NUT 2 for engine controller and connector

<3> 01643-31645 WASHER 2

<4> 21T-27-71220 HOLDER 2

<5> 01580-11613 NUT 2

<6> 01643-31645 WASHER 2

<7> 01024-81240 BOLT 2

<8> 01024-81285 BOLT 3

(Connecting of airconditioner duct)

Parts No. Parts Name

<9> 09485-04510 AIR HOSE 2

<10> 07281-00489 CLAMP 2

<11> 208-53-13851 SEAL 1

<12> 208-53-13861 SEAL 1

<13> 08034-20536 BAND 2

(Assembling of rear covers)

Parts No. Parts Name

<14> 208-53-13881 PLATE 1

<15> 01024-D0820 BOLT 2

<16> 08037-13550 GROMMET 1

<17> 04434-51908 CLAMP 1

<18> 01024-D0820 BOLT 1

<19> 208-53-13610 COVER 1

<20> 01024-D0820 BOLT 7

<21> 208-53-12730 COVER 1

<22> 01024-D0820 BOLT 3

<23> 01643-71232 WASHER 3

<24> 208-53-12350 COVER ASSY 1

<25> 01024-D0820 BOLT 5

<26> 01643-71232 WASHER 5

<27> 208-53-13620 COVER 1

<28> 01024-D0820 BOLT 3

<29> 208-979-7560 GRILLE 2

(Assembling of side covers)

Parts No. Parts Name

<30> 208-53-12180 COVER 1

<31> 01245-00816 BOLT 3

<32> 01643-70823 WASHER 3

7

Assembling manual of operator's cab 3/8

3. Mount bolts of floor and cab

<4><5><6>

<7>

Connect washer hose

<8>

<1><2><3>

Right forward Right rear

Left forward Left rear

<4><5><6>

<1><2><3>

<8>

<7>

8

Parts No. Parts Name

<1> 113-12-21120 WASHER 2

<2> 01580-11613 NUT 2

<3> 01643-31645 WASHER 2

<4> 21T-27-71220 HOLDER 2

<5> 01580-11613 NUT 2

<6> 01643-31645 WASHER 2

<7> 01024-81240 BOLT 2

<8> 01024-81285 BOLT 3

Assembling manual of operator's cab 4/8

4. Connecting of wiring harness

Sub-assembling plate <a>

for controller and connector

(removed from CIS cab-less guard)

Sub-assembling plate <c>

for engine controller and connector

(removed from CIS cab-less guard)

Sub-assembling plate <b>

for connector of airconditioner

(removed from CIS cab-less guard)

Connect floor harness

with cab harness H08

H09

Connect antenna cable

Connect room lamp harness

Connect monitor harness H10

H11

H12

9

Parts Name

<a> Sub-assembling plate 1

for controller and connector

<b> Sub-assembling plate 1

for connector of A/C

<c> Sub-assembling plate 1

for engine controller and connector

Assembling manual of operator's cab Ref.1

Connecting of wiring harness

<Referential drawing>

10

Assembling manual of operator's cab 5/8

5. Connecting of heater air hose

Connect air hoses <9>

for heater

(for Face duct)

(for Defroster duct)

Fix clamps <10>

for air hoses

Fix both duct <13>

(outside)

Fit duct seal <12>

(inside of face duct)

Fit duct seal <11>

(inside of defroster duct)

11

Parts No. Parts Name

<9> 09485-04510 AIR HOSE 2

<10> 07281-00489 CLAMP 2

<11> 208-53-13851 SEAL 1

<12> 208-53-13861 SEAL 1

<13> 08034-20536 BAND 2

Assembling manual of operator's cab 6/8

6. Assembling of rear covers

Assemble partition plate <14>

<15>

Assemble harness clamp <17>

<18>

Assemble partition grommet <16>

for harness

This page

Next page

12

Parts No. Parts Name

<14> 208-53-13881 PLATE 1

<15> 01024-D0820 BOLT 2

<16> 08037-13550 GROMMET 1

<17> 04434-51908 CLAMP 1

<18> 01024-D0820 BOLT 1

<19> 208-53-13610 COVER 1

<20> 01024-D0820 BOLT 7

<21> 208-53-12730 COVER 1

<22> 01024-D0820 BOLT 3

<23> 01643-71232 WASHER 3

<24> 208-53-12350 COVER ASSY 1

<25> 01024-D0820 BOLT 5

<26> 01643-71232 WASHER 5

<27> 208-53-13620 COVER 1

<28> 01024-D0820 BOLT 3

<29> 208-979-7560 GRILLE 2

Assembling manual of operator's cab 7/8

7. Assembling of rear covers(continue)

Assemble rear space plate <19>

<20>

Assemble magazine box <21>

<22>

<23>

Assemble hot-&-cool box <24>

<25>

<26>

Connect hose between hot-&-cool box between hot-&-cool box (see page 7)

Assemble rear cover <27>

<28>

Assemble grilles with rear cover

<29>

13

Assembling manual of operator's cab 8/8

8. Assembling of side covers

Assemble side cover <30>

for ducts <31>

<32>

14

Parts No. Parts Name

<30> 208-53-12180 COVER 1

<31> 01245-00816 BOLT 3

<32> 01643-70823 WASHER 3

N

Вам также может понравиться

- Char-Lynn: Parts InformationДокумент4 страницыChar-Lynn: Parts InformationFernando SabinoОценок пока нет

- Manual TransmissionДокумент46 страницManual Transmissionjrrodrigueza2Оценок пока нет

- WEG Brake Motor Installation Operation and Maintenance Manual 50021973 Manual EnglishДокумент2 страницыWEG Brake Motor Installation Operation and Maintenance Manual 50021973 Manual EnglishadalcomjesusОценок пока нет

- Design Calculation, Analysis & DesignДокумент49 страницDesign Calculation, Analysis & Designarif_rubin100% (2)

- Air Separator, Roks: Instruction ManualДокумент35 страницAir Separator, Roks: Instruction ManualSatish Kumar ReddyОценок пока нет

- 4-1. MaintenanceДокумент54 страницы4-1. Maintenancemargotsilva96Оценок пока нет

- F7 CBAd 01Документ22 страницыF7 CBAd 01nqalbyОценок пока нет

- Engine Quick Change Assembly BulletinДокумент50 страницEngine Quick Change Assembly BulletinreyveОценок пока нет

- 4 1. MaintenanceДокумент60 страниц4 1. MaintenancevolvoОценок пока нет

- LE501 Service ManualДокумент73 страницыLE501 Service Manuallau_hy2158100% (1)

- EagleBurgmann M7N EN PDFДокумент5 страницEagleBurgmann M7N EN PDFjmeleОценок пока нет

- 6 1. MaintenanceДокумент47 страниц6 1. MaintenanceGetachew GechОценок пока нет

- Morphing BlDE FinalДокумент21 страницаMorphing BlDE FinalSoumian NarayananОценок пока нет

- RD Engine ManualДокумент23 страницыRD Engine Manualmotopi2271% (7)

- Demag DKUN Hoist Operating ManualДокумент80 страницDemag DKUN Hoist Operating ManualCraneMaintain81% (27)

- 2015 Installation GuideДокумент6 страниц2015 Installation Guidealif suryantoОценок пока нет

- D70REVДокумент88 страницD70REVsteva037Оценок пока нет

- 3512C HD Fuel Injector AdjustmentДокумент5 страниц3512C HD Fuel Injector Adjustmentharikrishnanpd3327100% (2)

- 3406B TruckДокумент4 страницы3406B Truckvictor franco gallegosОценок пока нет

- Fuel Injector Adjustment: Table 1Документ5 страницFuel Injector Adjustment: Table 1Stepan KlashevychОценок пока нет

- A-344 & A347 Welded Master Link - ImperialДокумент1 страницаA-344 & A347 Welded Master Link - Imperialaiyubi2Оценок пока нет

- Pneumatic Clamps: DestacoДокумент32 страницыPneumatic Clamps: DestacoMarian DunareanuОценок пока нет

- Corona Piñon de MolinosДокумент31 страницаCorona Piñon de Molinosstoneblind100% (1)

- Cam Shaft TimingДокумент8 страницCam Shaft TimingFaresОценок пока нет

- 8-1. Disassembly and AssemblyДокумент175 страниц8-1. Disassembly and AssemblyDeyvi Cconocuyca HuallparimachiОценок пока нет

- Rubber Buffer SpringДокумент14 страницRubber Buffer SpringmailbkraoОценок пока нет

- Fluid Tech-Info enДокумент17 страницFluid Tech-Info enadhityaОценок пока нет

- Tenzado de CadenaДокумент5 страницTenzado de CadenaCristian ZarricuetaОценок пока нет

- B5-25GS. Goulds Water Technology - SUBMERSIBLE PUMPS Residential Water Systems (8 Model 18GS)Документ12 страницB5-25GS. Goulds Water Technology - SUBMERSIBLE PUMPS Residential Water Systems (8 Model 18GS)Andrés OyarzúnОценок пока нет

- Maintenance Arpex enДокумент39 страницMaintenance Arpex enPatrick BaridonОценок пока нет

- How To Make A TribometerДокумент7 страницHow To Make A TribometerHamza ShamsОценок пока нет

- Technical Data 37 FlaredДокумент13 страницTechnical Data 37 FlaredhernychtОценок пока нет

- Rail Stress DesignДокумент13 страницRail Stress DesignGuha ArnabОценок пока нет

- Guia Cat Codos de EscapeДокумент6 страницGuia Cat Codos de EscapecabarajasrОценок пока нет

- Aire y Frenos Especificaciones 140HДокумент18 страницAire y Frenos Especificaciones 140Hlark_Оценок пока нет

- Hydraulic Cylinder Parker 3lДокумент48 страницHydraulic Cylinder Parker 3lDian Pramadi100% (2)

- 2006 US Army LessonPlans C01 Crane PMCS 27pДокумент27 страниц2006 US Army LessonPlans C01 Crane PMCS 27pLo Shun FatОценок пока нет

- Asae s278.6 Enganche Rapido Modificado 7Документ4 страницыAsae s278.6 Enganche Rapido Modificado 7Policarpio Mamani HuchaniОценок пока нет

- SKF Laser Alignment Kit ManualДокумент380 страницSKF Laser Alignment Kit ManualHussain Ahmed100% (1)

- Manual Reductora IVECO TM 265 - TM 265AДокумент31 страницаManual Reductora IVECO TM 265 - TM 265ARomà ComaОценок пока нет

- EagleBurgmann M2N enДокумент3 страницыEagleBurgmann M2N enParmasamy SubramaniОценок пока нет

- Belt TensionДокумент4 страницыBelt TensionMaulik Trivedi100% (1)

- En de 101217 Demag Rope HoistДокумент24 страницыEn de 101217 Demag Rope HoistBoomies1Оценок пока нет

- International Journal of Engineering Research and DevelopmentДокумент8 страницInternational Journal of Engineering Research and DevelopmentIJERDОценок пока нет

- 9U-5132 Timing and Fuel System Setting Tool GroupДокумент33 страницы9U-5132 Timing and Fuel System Setting Tool GroupmkОценок пока нет

- Data Rates Gate Works 10Документ21 страницаData Rates Gate Works 10vpmohammedОценок пока нет

- TR-3650 Service ManualДокумент60 страницTR-3650 Service Manual2001Silvy86% (7)

- Manual de Instrucciones GD y GS PDFДокумент24 страницыManual de Instrucciones GD y GS PDFJunior CostaОценок пока нет

- Ta27 Tier3 - 8681Документ380 страницTa27 Tier3 - 8681Marcoglm100% (5)

- EagleBurgmann MG1 enДокумент5 страницEagleBurgmann MG1 enMohammad Hafiz OthmanОценок пока нет

- Start: Static Input Data (Beltanalyst™)Документ8 страницStart: Static Input Data (Beltanalyst™)Erlan OlveiraОценок пока нет

- Operation Manual: Q250 Pneumatic Spinning WrenchДокумент12 страницOperation Manual: Q250 Pneumatic Spinning Wrenchmehdi HKОценок пока нет

- Wallap Part 2Документ11 страницWallap Part 2Nizar HalabiОценок пока нет

- en de 130328Документ20 страницen de 130328Th NattapongОценок пока нет

- Calibrar 3500b LekДокумент5 страницCalibrar 3500b LekAna María AcostaОценок пока нет

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideОт EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideРейтинг: 4.5 из 5 звезд4.5/5 (8)

- Cover Part DrawaingДокумент1 страницаCover Part DrawaingEbrahim SabouriОценок пока нет

- Refrences Are Research Papaers Presentation Statistics Shows Class Notes in University of FloridaДокумент1 страницаRefrences Are Research Papaers Presentation Statistics Shows Class Notes in University of FloridaEbrahim SabouriОценок пока нет

- Broadcaster in The World by Number of EmployeesДокумент1 страницаBroadcaster in The World by Number of EmployeesEbrahim SabouriОценок пока нет

- Chillers in The Mining Site Are The Greatest ThingДокумент1 страницаChillers in The Mining Site Are The Greatest ThingEbrahim SabouriОценок пока нет

- In The Region With The Number of EmployeeДокумент1 страницаIn The Region With The Number of EmployeeEbrahim SabouriОценок пока нет

- Real Time Chart - Material DesignДокумент1 страницаReal Time Chart - Material DesignEbrahim SabouriОценок пока нет

- The British Broadcasting Corporation Is A British Public Service BroadcasterДокумент1 страницаThe British Broadcasting Corporation Is A British Public Service BroadcasterEbrahim SabouriОценок пока нет

- Did You Know Sholmanginotiro Proto PresentinoДокумент1 страницаDid You Know Sholmanginotiro Proto PresentinoEbrahim SabouriОценок пока нет

- CivoliportinomeaДокумент1 страницаCivoliportinomeaEbrahim SabouriОценок пока нет

- Research of MindoltinaДокумент1 страницаResearch of MindoltinaEbrahim SabouriОценок пока нет

- BailacineordinoДокумент1 страницаBailacineordinoEbrahim SabouriОценок пока нет

- Did You Know Sholmanginotiro Proto Hydrate Macalte PresentinoДокумент1 страницаDid You Know Sholmanginotiro Proto Hydrate Macalte PresentinoEbrahim SabouriОценок пока нет

- Car Vino ChinoДокумент1 страницаCar Vino ChinoEbrahim SabouriОценок пока нет

- Did You Know Sholmangino PresentinoДокумент1 страницаDid You Know Sholmangino PresentinoEbrahim SabouriОценок пока нет

- Lib On Tarin TioДокумент1 страницаLib On Tarin TioEbrahim SabouriОценок пока нет

- Bring EtecДокумент1 страницаBring EtecEbrahim SabouriОценок пока нет

- IntorbonifДокумент1 страницаIntorbonifEbrahim SabouriОценок пока нет

- Elena Poin DoДокумент1 страницаElena Poin DoEbrahim SabouriОценок пока нет

- BELAZ-75131 Addition To The Operation ManualДокумент13 страницBELAZ-75131 Addition To The Operation ManualEbrahim SabouriОценок пока нет

- Sabrina KoloДокумент1 страницаSabrina KoloEbrahim SabouriОценок пока нет

- Protrikaloden ShroudДокумент1 страницаProtrikaloden ShroudEbrahim SabouriОценок пока нет

- Internal I OnДокумент1 страницаInternal I OnEbrahim SabouriОценок пока нет

- SinadДокумент1 страницаSinadEbrahim SabouriОценок пока нет

- Hilarion DHPДокумент1 страницаHilarion DHPEbrahim SabouriОценок пока нет

- Inside Is As A Order Based SionadДокумент1 страницаInside Is As A Order Based SionadEbrahim SabouriОценок пока нет

- SinadДокумент1 страницаSinadEbrahim SabouriОценок пока нет

- Gatsby ProjectДокумент1 страницаGatsby ProjectEbrahim SabouriОценок пока нет

- Dil MarianДокумент1 страницаDil MarianEbrahim SabouriОценок пока нет

- BogarilainДокумент1 страницаBogarilainEbrahim SabouriОценок пока нет

- Rara As Ther E Is I Have No Choice Except To Make Such A Vacant PDF SorryДокумент1 страницаRara As Ther E Is I Have No Choice Except To Make Such A Vacant PDF SorryEbrahim SabouriОценок пока нет

- BATES CH 6 The Thorax and LungsДокумент2 страницыBATES CH 6 The Thorax and LungsAngelica Mae Dela CruzОценок пока нет

- Hydroprocessing Pilot PlantsДокумент4 страницыHydroprocessing Pilot PlantsNattapong PongbootОценок пока нет

- Polyken 4000 PrimerlessДокумент2 страницыPolyken 4000 PrimerlessKyaw Kyaw AungОценок пока нет

- Bonding and Adhesives in DentistryДокумент39 страницBonding and Adhesives in DentistryZahn ÄrztinОценок пока нет

- Northbrook CollegeДокумент10 страницNorthbrook CollegeDaniyal AsifОценок пока нет

- Course Syllabus MGTP 31206 31207Документ12 страницCourse Syllabus MGTP 31206 31207NamitBhasinОценок пока нет

- Emergency War Surgery Nato HandbookДокумент384 страницыEmergency War Surgery Nato Handbookboubiyou100% (1)

- Digital Habits Across Generations: Before ReadingДокумент3 страницыDigital Habits Across Generations: Before ReadingSharina RamallahОценок пока нет

- Mock Test MCQ 2017Документ18 страницMock Test MCQ 2017Alisha ChopraОценок пока нет

- Dig Inn Early Summer MenuДокумент2 страницыDig Inn Early Summer MenuJacqueline CainОценок пока нет

- Keandalan Bangunan Rumah SusunДокумент9 страницKeandalan Bangunan Rumah SusunDewi ARimbiОценок пока нет

- Bio1 11 - 12 Q1 0501 FDДокумент23 страницыBio1 11 - 12 Q1 0501 FDIsabelle SchollardОценок пока нет

- Inside The Earth NotesДокумент2 страницыInside The Earth NotesrickaturnerОценок пока нет

- Synopsis of Involex TurbineДокумент3 страницыSynopsis of Involex TurbineTanviОценок пока нет

- ACLS Post Test (Copy) 낱말 카드 - QuizletДокумент18 страницACLS Post Test (Copy) 낱말 카드 - Quizlet김민길Оценок пока нет

- Leon County Sheriff'S Office Daily Booking Report 4-Jan-2022 Page 1 of 3Документ3 страницыLeon County Sheriff'S Office Daily Booking Report 4-Jan-2022 Page 1 of 3WCTV Digital TeamОценок пока нет

- Microporous WikiДокумент2 страницыMicroporous WikiIris BalcarceОценок пока нет

- WP DeltaV Software Update Deployment PDFДокумент8 страницWP DeltaV Software Update Deployment PDFevbaruОценок пока нет

- Pentacon Six-02Документ28 страницPentacon Six-02Melissa Moreira TYОценок пока нет

- Sasol Polymers PP HNR100Документ3 страницыSasol Polymers PP HNR100Albert FortunatoОценок пока нет

- Review Dynamic Earth CoreScienceДокумент3 страницыReview Dynamic Earth CoreScienceVikram BologaneshОценок пока нет

- Pinch & Piston ValvesДокумент8 страницPinch & Piston ValvesJaldhij Patel100% (1)

- MoringaДокумент24 страницыMoringaobengappiahk100% (2)

- Material Specification: Mechanical Property RequirementsДокумент2 страницыMaterial Specification: Mechanical Property RequirementsNguyễn Tấn HảiОценок пока нет

- Deductions From Gross IncomeДокумент2 страницыDeductions From Gross Incomericamae saladagaОценок пока нет

- Schools Division of Roxas CityДокумент4 страницыSchools Division of Roxas CityHuge Propalde EstolanoОценок пока нет

- Date SissyДокумент5 страницDate SissyFletcher Irvine50% (2)

- Cervical Changes During Menstrual Cycle (Photos)Документ9 страницCervical Changes During Menstrual Cycle (Photos)divyanshu kumarОценок пока нет