Академический Документы

Профессиональный Документы

Культура Документы

Protein Oxidation in Processed Cheese Slices Treated With Pulsed Light Technology PDF

Загружено:

huangym0 оценок0% нашли этот документ полезным (0 голосов)

47 просмотров3 страницыPulsed light technology is being studied for controlling pathogens and extending the shelf-life of ready-to-eat foods. PL is based on the application of short length light flashes of intense broad-spectrum light and a spectrophotometric DNPH assay. Protein oxidation increased along cheese storage at 4 degC, and differences among treatments remained.

Исходное описание:

Оригинальное название

Protein oxidation in processed cheese slices treated with pulsed light technology.pdf

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документPulsed light technology is being studied for controlling pathogens and extending the shelf-life of ready-to-eat foods. PL is based on the application of short length light flashes of intense broad-spectrum light and a spectrophotometric DNPH assay. Protein oxidation increased along cheese storage at 4 degC, and differences among treatments remained.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

47 просмотров3 страницыProtein Oxidation in Processed Cheese Slices Treated With Pulsed Light Technology PDF

Загружено:

huangymPulsed light technology is being studied for controlling pathogens and extending the shelf-life of ready-to-eat foods. PL is based on the application of short length light flashes of intense broad-spectrum light and a spectrophotometric DNPH assay. Protein oxidation increased along cheese storage at 4 degC, and differences among treatments remained.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 3

Short communication

Protein oxidation in processed cheese slices treated with pulsed light

technology

M. Fernndez

a,

, M. Ganan

a,b

, C. Guerra

a

, E. Hierro

a

a

Departamento de Nutricin, Bromatologa y Tecnologa de los Alimentos, Facultad de Veterinaria, Universidad Complutense, 28040 Madrid, Spain

b

CEI Campus Moncloa, UCM-UPM e INIA, Madrid, Spain

a r t i c l e i n f o

Article history:

Received 23 September 2013

Received in revised form 29 January 2014

Accepted 27 February 2014

Available online 15 March 2014

Keywords:

Pulsed light

Processed cheese

Protein oxidation

DNPH assay

Carbonyls

a b s t r a c t

The effect of pulsed light technology on protein oxidation was studied in sliced processed cheese by mea-

suring the protein-bound carbonyls with a spectrophotometric DNPH assay. Bovine serum albumin was

also tested as a protein standard. Fluences of 0.7, 2.1, 4.2, 8.4 and 11.9 J/cm

2

were applied to vacuum-

packaged cheese slices and to an aqueous solution of the protein. Treatments up to 4.2 J/cm

2

did not pro-

mote protein oxidation immediately after ashing either in cheese or in the standard. Samples treated

with 8.4 and 11.9 J/cm

2

showed signicantly higher carbonyl amounts than non-treated ones. Protein

oxidation increased along cheese storage at 4 C, and differences among treatments remained. Further

studies on the sensory properties will be needed to clarify the impact of pulsed light on processed cheese

quality.

2014 Elsevier Ltd. All rights reserved.

1. Introduction

Several non-thermal technologies are being studied for control-

ling pathogens and extending the shelf-life of ready-to-eat (RTE)

foods. Among them, pulsed light (PL) is a promising one. PL is

based on the application of short length light ashes of intense

broad-spectrum light and it has been proven to be useful to decon-

taminate surfaces. Some studies have shown that PL can inactivate

pathogenic microorganisms on the surface of various high protein

RTE foods, such as cooked meats (Hierro, Barroso, Ordez, &

Fernndez, 2011) and carpaccio (Hierro, Ganan, Barroso, & Fernn-

dez, 2012). This technology has been approved for food processing

by FDA (1996), which has established that the total cumulative

treatment must not exceed 12 J/cm

2

. PL is easy to integrate at

industrial processing lines and, once implemented, could highly re-

duce energy costs and production times (Gmez-Lpez, Regaert,

Debevere, & Devlieghere, 2007). Also, from an environmental point

of view, PL could reduce the environmental footprint of industrial

processes (Pereira & Vicente, 2010).

Similarly to other RTE foods, processed cheese can be contami-

nated with microorganisms after pasteurization, particularly dur-

ing slicing and packaging. PL technology could offer an adequate

treatment for surface decontamination, once the product is

packaged. In this sense, previous studies have shown that PL can

easily penetrate packaging lms (Fernndez, Manzano, de la Hoz,

Ordez, & Hierro, 2009; Keklik, Demirci, & Puri, 2010). However,

exposure to light may promote physicochemical changes in food

components, such as oxidation. While oxidative reactions of lipids

have been deeply studied in foods, less attention has been paid to

protein oxidation, which has been shown to change functionality

(Lund, Lametsch, Hviid, Jensen, & Skibsted, 2007; Martins & Netto,

2006; Xiong & Decker, 1995), to lower digestibility (Morzel,

Gatellier, Sayd, Renerre, & Laville, 2006), and to induce the

formation of unpleasant odors (Dalsgaard et al., 2010; Mortensen,

Bertelsen, Mortensen, & Stapelfeldt, 2004).

Semi-hard, hard, and processed cheeses are considered to be

readily oxidised by light exposure (Mortensen et al., 2004), but

studies on the oxidation of proteins are scarce. Elmnasser et al.

(2008) investigated the effect of PL on the conformational structure

and amino acid composition of milk proteins. Scheidegger, Pecora,

Radic, and Kivatinitz (2010) studied protein-bound carbonyls in

milk along storage at 4 C under UV and uorescent light. The

aimof our study was to evaluate the effect of PL technology on pro-

tein oxidation in processed cheese, at the uences that could be

used for decontamination purposes.

2. Materials and methods

2.1. Samples

Cheese slices (80 80 2 mm thick) were purchased in a local

supermarket. Once in the laboratory, slices were individually vac-

uum-packaged in plastic bags (Cryovac Sealed Air, Barcelona,

http://dx.doi.org/10.1016/j.foodchem.2014.02.165

0308-8146/ 2014 Elsevier Ltd. All rights reserved.

Corresponding author. Tel.: +34 913943946.

E-mail address: manuela@vet.ucm.es (M. Fernndez).

Food Chemistry 159 (2014) 388390

Contents lists available at ScienceDirect

Food Chemistry

j our nal homepage: www. el sevi er . com/ l ocat e/ f oodchem

Spain) made of 48 lm polyamide/polyethylethylene/vinyl acetate,

and kept at 4 C until experiments were performed. This lm was

selected on the basis of previous investigations which indicated

that PL could easily penetrate it (Fernndez et al., 2009). In these

experiments, the inactivation of Listeria monocytogenes was tested

on supercially inoculated agar plates wrapped with different

packaging polymers, and the reduction achieved (5.5 log cfu/cm

2

)

was the same as that obtained in unwrapped plates using the same

uence (0.35 J/cm

2

).

2.2. Pulsed light treatment

PL treatment was applied using a desktop Steribeam SBSXeMat-

ic-2L-A device (Steribeam Systems, Kehl am Rhein, Germany). The

apparatus consists of a metal housing surrounding a treatment

chamber made of polished stainless steel (20 cm wide 14 cm

deep 12 cm high) and equipped with two (upper and lower) xe-

non lamps and a quartz table located in the centre. The spectral

output of the lamps corresponds to 30% UV light (12% UV-C, 10%

UV-B and 8% UV-A), 30% infrared radiation and 40% visible light.

Each pulse is delivered in 250 ls and corresponds to a uence of

0.7 J/cm

2

at the level of the quartz table. The uence was measured

with a Laserpoint A-2-D12-BBF energy meter coupled to a 4p read-

out unit (Laserpoint, Milano, Italy). A vacuum pump was connected

to the chamber purge to extract the ozone produced by the lamps.

Samples were placed on the quartz table and received different

uences: 0.7, 2.1, 4.2, 8.4 and 11.9 J/cm

2

. These uences were se-

lected on the basis of previous studies on microbial decontamina-

tion carried out in our laboratory. Untreated control samples were

also analysed. The temperature of the samples was monitored dur-

ing the PL treatment using a Testo720 thermocouple equipped

with a needle-type probe (Testo AG, Lenzkirch, Germany). A tem-

perature increase of approximately 2.5 C per pulse was recorded.

Pulsed and non-pulsed samples were stored at 4 C in the dark.

Analyses were performed immediately after treatment and at days

15 and 30 of cold storage. Results are the mean of two independent

experiments.

2.3. Protein oxidation

The protein-bound carbonyl content is the most commonly

used marker of protein oxidation (Dalle-Donne, Rossi, Giustarini,

Milzani, & Colombo, 2003). In this study, carbonyls were measured

by spectrophotometric quantication of the acid hydrazones

formed by reaction with 2,4-dinitrophenylhydrazine (DNPH),

according to Oliver, Ahn, Moerman, Goldstein, and Stadtman

(1987).

Previously to studies in cheese, bovine serum albumin (BSA)

was used as protein model to evaluate oxidation caused by PL in

a simple system. A standard solution of BSA 1:1 (w/v) (Sigma-Al-

drich, Saint Louis, MO) was placed on a quartz dish and PL treated.

Two aliquots of BSA per uence applied were taken and precipi-

tated with trichloroacetic acid (TCA, 10% nal concentration).

One aliquot was added with 0.2% (w/v) DNPH in 2 N HCl and the

other, used as blank, was only added with 2 N HCl. Both samples

were incubated at 30 C for 1 h and stirred every 10 min. Then,

samples were reprecipitated with TCA and centrifuged at 2000g

for 10 min. The supernatants were discarded and the pellets were

again precipitated with TCA and washed twice with ethanol:ethyl

acetate (1:1, v/v) to remove free DNPH. Pellets were then resus-

pended in 6 M guanidine HCl with 20 mM sodium phosphate buf-

fer (pH 6.5), followed by 10 min stirring. The amount of hydrazone

formed was determined by measuring absorbance at 370 nm.

Results were expressed as nmol carbonyls/mg protein, using a mo-

lar extinction coefcient of 21.0 mM

1

cm

1

. Protein concentration

of cheese was calculated by spectrophotometry at 280 nm using

BSA as standard.

For the determination of carbonyl content in processed cheese

slices, a previous step of protein extraction was followed. A cheese

homogenate, containing approximately 1.2 mg protein/mL, was

prepared by mixing 0.1 g of cheese in 10 mL of 0.15 M KCl for

3 min using a Polytron PT 1035 GT probe (Kinematica, Lucerne,

Switzerland) in a glass vessel immersed in an ice bath. TCA 10% (-

nal concentration) was added to precipitate proteins, and samples

were centrifuged at 2000g for 10 min to obtain the pellets. Two ali-

quots were taken for each PL condition, and carbonyls were deter-

mined following the procedure previously detailed for BSA.

2.4. Statistical analysis

A one-way ANOVA was conducted to compare the results of the

different batches, using Statgraphics Centurion XVI.I (Statpoint

Technologies, Warrenton, VA). Statistical signicance was identi-

ed at 95% condence level. Duncans multiple range test was used

to assess differences between means.

3. Results and discussion

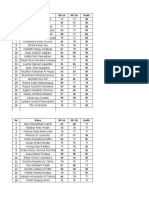

The effect of PL on BSA oxidation is shown in Fig. 1. The car-

bonyl content signicantly increased (p < 0.05) when uences of

8.4 and 11.9 J/cm

2

were used. In cheese, the amount of carbonyls

detected immediately after PL treatment ranged between 3.8 and

5.4 nmol/mg protein (Fig. 2). Only the highest uences showed sig-

nicant differences (p < 0.05) with the control samples. Carbonyl

content increased during storage, and differences among treat-

ments remained.

Light-induced oxidation of proteins is mainly caused by wave-

lengths of the UV region, although other bands of the spectrum

can also be involved (Hollsy, 2002; Scheidegger et al., 2010). PL

ashes generally range between 200 and 1000 nm, and UV repre-

sents about 30% of the total radiation. Therefore, a certain degree

of protein oxidation due to PL could be expected. In this study, this

effect was observed at the highest uences tested and was more

noticeable in BSA. The higher carbonyl values recorded for the pro-

tein standard in comparison to those of cheese slices could be ex-

plained by the penetration depth of PL. While BSA was a

transparent solution, light fails in penetrating the opaque surface

of cheese and then, oxidative changes are restricted to the surface.

Protein oxidation may occur by a direct mechanism through the

absorption of UV light by amino acids, but also by an indirect via

with the involvement of photosensitizers (Mortensen et al.,

2004). The direct mechanism would be responsible for BSA

oxidation. This protein has a maximum absorbance at 280 nm

(Mortensen et al., 2004), that is also the wavelength at which

a

a

b b

b

b

0

2

4

6

8

10

12

0 0.7 2.1 4.2 8.4 11.9

n

m

o

l

c

a

r

b

o

n

y

l

s

/

m

g

B

S

A

Fluence (J/cm

2

)

Fig. 1. Protein-bound carbonyl content of a BSA solution treated with different

uences of pulsed light. Bars show standard deviation.

M. Fernndez et al. / Food Chemistry 159 (2014) 388390 389

aromatic amino acids (phenylalanine, tyrosine and tryptophan),

and also histidine and cysteine, absorb light (Hollsy, 2002).

Approximately 18% of the BSA chain corresponds to these amino

acid residues (Hirayama, Akashi, Furuya, & Fukuhara, 1990).

In relation to the results obtained in cheese, in principle, the

indirect mechanism of protein oxidation could also be relevant

due to the presence of riboavin, which is an efcient photosensi-

tizer (Mortensen et al., 2004). This compound, due to its conju-

gated double bond system, absorbs visible light apart from UV

(Choe, Huang, & Min, 2005), both components of PL ashes, as pre-

viously stated. When irradiated, riboavin can produce reactive

oxygen species, such as singlet oxygen or hydroxyl radical, in the

presence of oxygen. However, this mechanism can be balanced

by b-carotene, which also absorbs a signicant fraction of light,

protecting riboavin (Li, King, & Min, 2000; Mortensen et al.,

2004). The protein-bound carbonyl content reported in the litera-

ture ranges from 1.5 to 4.5 nmol/mg protein for different cheese

varieties (Fedele & Bergamo, 2001; Balestrieri et al., 2002).

Although in our study the PL treatment with the highest uences

signicantly increased (p < 0.05) protein oxidation, the values ob-

tained immediately after ashing can be considered as normal

for cheese, taking into account the thermal treatment applied for

the manufacture of processed cheese. On the other hand, it is pos-

sible that vacuum-packaging and the low penetration of light in

the samples had contributed to control light-induced oxidation.

4. Conclusion

In this preliminary study, PL treatment up to 4.2 J/cm

2

did not

increase protein oxidation in processed cheese slices, while higher

uences signicantly enhanced oxidation. Further studies on the

sensory attributes will be the next step to evaluate the real impact

of these changes on cheese quality.

Acknowledgements

This work has been supported by Project AGL2011-29325

(Ministerio de Educacin y Ciencia, Government of Spain) and

UCM Group 920276. Dr. Ganan was the recipient of a postdoctoral

contract from the International Program of Talent Recruitment

from the Campus of International Excellence, University Complu-

tense of Madrid.

References

Balestrieri, M., Spagnuolo, M. S., Cigliano, L., Stori, G., Ferrara, L., Abrescia, P., &

Fedele, E. (2002). Evaluation of oxidative damage in mozzarella cheese

produced from bovine or water buffalo milk. Food Chemistry, 77, 293299.

Choe, E., Huang, R., & Min, D. B. (2005). Chemical reactions and stability of riboavin

in foods. Journal of Food Science, 70, 2836.

Dalle-Donne, I., Rossi, R., Giustarini, D., Milzani, A., & Colombo, R. (2003). Protein

carbonyl groups as biomarkers of oxidative stress. Clinica Chimica Acta, 329,

2338.

Dalsgaard, T. K., Srensen, J., Bakman, M., Voghsen, L., Nebesl, C., Albrechtsen, R., &

Nielsen, J. (2010). Light-induced protein and lipid oxidation in cheese:

Dependence on fat content and packaging conditions. Dairy Science and

Technology, 90, 565577.

Elmnasser, N., Dalgalarrondo, M., Orange, N., Bakhrouf, A., Haertl, T., Federighi, M.,

& Chobert, J. M. (2008). Effect of pulsed-light treatment on milk proteins and

lipids. Journal of Agricultural and Food Chemistry, 56, 19841991.

FDA (1996). Code of Federal Regulations. 21CFR179.41. Title 21, Volume 3. Revised

as of April 1, 2003.

Fedele, E., & Bergamo, P. (2001). Protein and lipid oxidative stresses during cheese

manufacture. Journal of Food Science, 66, 932935.

Fernndez, M., Manzano, S., de la Hoz, L., Ordez, J. A., & Hierro, E. (2009). Pulsed

light inactivation of Listeria monocytogenes through different plastic lms.

Foodborne Pathogens and Disease, 6, 12651267.

Gmez-Lpez, V. M., Regaert, P., Debevere, J., & Devlieghere, F. (2007). Pulsed light

for food decontamination: a review. Trends in Food Science & Technology, 18,

464473.

Hierro, E., Barroso, E., Ordez, J. A., & Fernndez, M. (2011). Efcacy of pulsed light

for shelf-life extension and inactivation of Listeria monocytogenes on ready-to-

eat cooked meat products. Innovative Food Science & Emerging Technologies, 12,

275281.

Hierro, E., Ganan, M., Barroso, E., & Fernndez, M. (2012). Pulsed light treatment for

the inactivation of selected pathogens and the shelf-life extension of beef and

tuna carpaccio. International Journal of Food Microbiology, 158, 4248.

Hirayama, K., Akashi, S., Furuya, M., & Fukuhara, K. (1990). Rapid conrmation and

revision of the primary structure of bovine serum albumin by ESIMS and

frit-FAB LC/MS. Biochemical and Biophysical Research Communications, 173,

639646.

Hollsy, F. (2002). Effects of ultraviolet radiation on plant cells. Micron, 33, 179197.

Keklik, N. M., Demirci, A., & Puri, V. M. (2010). Decontamination of unpackaged and

vacuum-packaged boneless chicken breast with pulsed ultraviolet light. Poultry

Science, 89, 570581.

Li, T. L., King, J. M., & Min, D. B. (2000). Carotenoids in riboavin photosensitized

singlet oxygen oxidation of vitamin D

2

. Journal of Food Biochemistry, 24,

477492.

Lund, M. N., Lametsch, R., Hviid, M. S., Jensen, O. N., & Skibsted, L. H. (2007). High-

oxygen packaging atmosphere inuences protein oxidation and tenderness of

porcine longissimus dorsi during chill storage. Meat Science, 77, 295303.

Martins, V. B., & Netto, F. M. (2006). Physicochemical and functional properties of

soy protein isolate as a function of water activity and storage. Food Research

International, 39, 145153.

Mortensen, G., Bertelsen, G., Mortensen, B. K., & Stapelfeldt, H. (2004). Light-

induced changes in packaged cheeses A review. International Dairy Journal, 14,

85102.

Morzel, M., Gatellier, Ph., Sayd, T., Renerre, M., & Laville, E. (2006). Chemical

oxidation decreases proteolytic susceptibility of skeletal muscle myobrillar

proteins. Meat Science, 73, 536543.

Oliver, C. N., Ahn, B. W., Moerman, E. J., Goldstein, S., & Stadtman, E. R. (1987). Aged-

related changes in oxidized proteins. The Journal of Biological Chemistry, 262,

54885491.

Pereira, R. N., & Vicente, A. A. (2010). Environmental impact of novel thermal and

non-thermal technologies in food processing. Food Research International, 43,

19361943.

Scheidegger, D., Pecora, R. P., Radic, P. M., & Kivatinitz, S. C. (2010). Protein oxidative

changes in whole and skim milk after ultraviolet or uorescent light exposure.

Journal of Dairy Science, 93, 51015109.

Xiong, Y. L., & Decker, E. A. (1995). Alterations of muscle protein functionality by

oxidative and antioxidative processes. Journal of Muscle Foods, 6, 139160.

2

3

4

5

6

7

8

0 3 5 1 0

n

m

o

l

c

a

r

b

o

n

y

l

s

/

m

g

p

r

o

t

e

i

n

Time (days)

Fig. 2. Changes in the protein-bound carbonyl content of vacuum-packaged slices

of processed cheese treated with different uences of pulsed light and stored at

4 C. Fluences: () 0, (s) 0.7, (4) 2.1, (N) 4.2, () 8.4, (h) 11.9 J/cm

2

. Bars show

standard deviation.

390 M. Fernndez et al. / Food Chemistry 159 (2014) 388390

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Approaches To Violence in IndiaДокумент17 страницApproaches To Violence in IndiaDeepa BhatiaОценок пока нет

- Designing A Peace Building InfrastructureДокумент253 страницыDesigning A Peace Building InfrastructureAditya SinghОценок пока нет

- Simple Past TenselДокумент3 страницыSimple Past TenselPutra ViskellaОценок пока нет

- (Abhijit Champanerkar, Oliver Dasbach, Efstratia K (B-Ok - Xyz)Документ273 страницы(Abhijit Champanerkar, Oliver Dasbach, Efstratia K (B-Ok - Xyz)gogОценок пока нет

- Thesis Statement VampiresДокумент6 страницThesis Statement Vampireslaurasmithdesmoines100% (2)

- Thermal Physics Questions IB Question BankДокумент43 страницыThermal Physics Questions IB Question BankIBBhuvi Jain100% (1)

- Ancestral Healing PrayersДокумент4 страницыAncestral Healing Prayerssuperhumannz100% (13)

- Sysmex HemostasisДокумент11 страницSysmex HemostasisElyza L. de GuzmanОценок пока нет

- Layos vs. VillanuevaДокумент2 страницыLayos vs. VillanuevaLaura MangantulaoОценок пока нет

- Understanding Ui-Ux-By Harry Muksit - SДокумент109 страницUnderstanding Ui-Ux-By Harry Muksit - Sgodzalli44100% (1)

- TypeFinderReport ENFPДокумент10 страницTypeFinderReport ENFPBassant AdelОценок пока нет

- 67-Article Text-118-1-10-20181206Документ12 страниц67-Article Text-118-1-10-20181206MadelОценок пока нет

- EELE 202 Lab 6 AC Nodal and Mesh Analysis s14Документ8 страницEELE 202 Lab 6 AC Nodal and Mesh Analysis s14Nayr JTОценок пока нет

- Papadakos PHD 2013Документ203 страницыPapadakos PHD 2013Panagiotis PapadakosОценок пока нет

- 25 ConstitutionДокумент150 страниц25 ConstitutionSaddy MehmoodbuttОценок пока нет

- Statistical MethodsДокумент4 страницыStatistical MethodsYra Louisse Taroma100% (1)

- Dr. A. Aziz Bazoune: King Fahd University of Petroleum & MineralsДокумент37 страницDr. A. Aziz Bazoune: King Fahd University of Petroleum & MineralsJoe Jeba RajanОценок пока нет

- The Personal Law of The Mahommedans, According To All The Schools (1880) Ali, Syed Ameer, 1849-1928Документ454 страницыThe Personal Law of The Mahommedans, According To All The Schools (1880) Ali, Syed Ameer, 1849-1928David BaileyОценок пока нет

- Ib Physics SL - Unit 4 ReviewДокумент46 страницIb Physics SL - Unit 4 ReviewMax HudgenesОценок пока нет

- ĐỀ THI DỰ ĐOÁN 9Документ4 страницыĐỀ THI DỰ ĐOÁN 9tranvananh2041985Оценок пока нет

- TugasFilsS32019.AnthoniSulthanHarahap.450326 (Pencegahan Misconduct)Документ7 страницTugasFilsS32019.AnthoniSulthanHarahap.450326 (Pencegahan Misconduct)Anthoni SulthanОценок пока нет

- Grade 7 1ST Quarter ExamДокумент3 страницыGrade 7 1ST Quarter ExamJay Haryl PesalbonОценок пока нет

- Department of Education: Republic of The PhilippinesДокумент2 страницыDepartment of Education: Republic of The PhilippinesShailac RodelasОценок пока нет

- University of Dar Es Salaam MT 261 Tutorial 1Документ4 страницыUniversity of Dar Es Salaam MT 261 Tutorial 1Gilbert FuriaОценок пока нет

- A Lei Do Sucesso Napoleon Hill Download 2024 Full ChapterДокумент23 страницыA Lei Do Sucesso Napoleon Hill Download 2024 Full Chapterdavid.brown752100% (12)

- Graphic Organizers As A Reading Strategy: Research FindДокумент9 страницGraphic Organizers As A Reading Strategy: Research Findzwn zwnОценок пока нет

- Oda A La InmortalidadДокумент7 страницOda A La InmortalidadEmy OoTeam ClésОценок пока нет

- Sumit Kataruka Class: Bcom 3 Yr Room No. 24 Roll No. 611 Guide: Prof. Vijay Anand SahДокумент20 страницSumit Kataruka Class: Bcom 3 Yr Room No. 24 Roll No. 611 Guide: Prof. Vijay Anand SahCricket KheloОценок пока нет

- Sop 2Документ43 страницыSop 2naveengargnsОценок пока нет

- 2,3,5 Aqidah Dan QHДокумент5 страниц2,3,5 Aqidah Dan QHBang PaingОценок пока нет