Академический Документы

Профессиональный Документы

Культура Документы

Conbextra 621: Constructive Solutions

Загружено:

Tori SmallИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Conbextra 621: Constructive Solutions

Загружено:

Tori SmallАвторское право:

Доступные форматы

constructive solutions

Page 1

Conbex t r a 621

Non-shr i nk c ement i t i ous, f r ee f l ow , pr ec i si on

gr out

Uses

Conbextra 621 is used for free flow precision grouting in wide

range of heavy duty application such as: Machine base

plates, Bridge bearings, High crane rails, Gas or Steam

Turbines, Power Generators, Presses, Anchor bolts, Milling

Machinery, and Motor Pumps.

Advant ages

Unique non-metallic dual expansion system

compensates for shrinkage in both the plastic and

hardened states.

Excellent initial flow and flow retention.

High early strength facilitates rapid installation and early

operation of plant.

High ultimate strength and low permeability ensure

durability of the hardened grout.

Hydrogen-free gaseous expansion.

Chloride free.

Suitable for pumping or pouring over a large range of

application consistencies and temperatures.

St andar ds c ompl i anc e

Conbextra 621 conforms fully to U.S. Corps of Engineers

Specification for non-shrink grout CRD-C-621-81 and ASTM

C-1107-91 (Type C).

Conbextra 621 is suitable for use in contact with potable

water. Water Bye-laws Scheme (approved product listing

number 9106511).

Desc r i pt i on

Conbextra 621 is a blend of Portland cements, graded fillers,

micro-silica and chemical additives which impart controlled

expansion in both the plastic and hardened states. The filler

grading minimises segregation and bleeding over a wide

range of application consistencies.

Conbextra 621 cementitious precision grout is supplied as a

ready to use dry powder. The addition of a controlled amount

of clean water produces a free-flowing precision grout for gap

thicknesses up to 125 mm. In addition the low water

requirement ensures high early strength and long term

durability.

Tec hni c al suppor t

Fosroc offers a comprehensive range of high quality, high

performance construction products. In addition, Fosroc

offers a world-wide technical support and on-site service to

specifiers, end-users and contractors.

Pr oper t i es

The following results were obtained at a water powder ratio

4.00 litre per 25 kg powder of (0.16) and a temperature of

25

o

C.

Test method for Typical results

Compressi ve strength

BS1881: Part 116 1983:

25 N/mm

2

at 1 day

50 N/mm

2

at 7 days

60 N/mm

2

at 14 days

65 N/mm

2

at 28 days

Flexural Strength

BS4551 1980:

2.0 N/mm

2

at 1 days

7.0 N/mm

2

at 7 days

8.0 N/mm

2

at 14 days

9.0 N/mm

2

at 28 days

Flow characteristics

(Efflux time) CRD-C Cone:

20 - 30 seconds

Setting time

BS4550 Part 3 1978:

Initial set:

Final set:

5.5 hours

7.5 hours

Time for expansion

plastic state:

Hardened state:

Start 15 minutes

Finish initial set

Start Initial set

Finish Up to 28 days

Fresh wet density: Approximately 2250 kg/m

3

depending on actual

consistency used

Youngs modulus

ASTM C-469-83:

28 kN/mm

2

Expansion

characteristics:

An expansion from 1.5-

2.0% when measured

according to ASTM C-827

overcomes plastic

settlement in the unset

material. Longer term

expansion in the hardened

state is designed to

comply with the

requirements of ASTM C-

1107-91 to compensate

for drying shrinkage

Shrinkage (CRD-C-621-81)

at 28 days:

Nil

Conbex t r a 621

Page 2

constructive solutions

Spec i f i c at i on c l auses

Performance specification

All precision grouting (specify details and areas of

application) must be carried out with a pre-packaged cement

based product, which is non-metallic and chloride-free.

It shall be mixed with clean water to the required consistency

and not exhibit bleed or segregation.

A volumetric expansion of up to 2% shall occur while the

grout is in a plastic state by means of a gaseous, hydrogen-

free system. The grout must also be compensated for

shrinkage in the hardened state.

The compressive strength of the grout must exceed 50

N/mm

2

at 7 days and 65 N/mm

2

at 28 days.

The grout shall fully conform to the requirements of US Army

Corps of Engineers Specification for non-shrink grout CRD-

C-621-81 or ASTM C-1107-91.

The storage, handling and placement of the grout must be in

strict accordance with the manufacturers instructions.

Supplier specification

All precision grouting (specify details and areas of

application) must be carried out using Conbextra 621

manufactured by Fosroc and used in accordance with the

manufacturers data sheet.

Appl i c at i on i nst r uc t i ons

Preparation

Foundation surface

The substrate surface must be free from oil, grease or any

loosely adherent material. If the concrete surface is defective

or has laitance, it must be cut back to a sound base. Bolt

holes or fixing pockets must be blown clean of any dirt or

debris.

Pre-soaking

Several hours prior to grouting, the area of cleaned

foundation should be flooded with fresh water. Immediately

before grouting takes place, any free water should be

removed. Particular care should be taken to blow out all bolt

holes and pockets.

Base plate

It is essential that this is clean and free from oil, grease or

scale. Air pressure relief holes should be provided to allow

venting of any isolated high spots.

Levelling shims

If these are to be removed after the grout has hardened,

they should be treated with a thin layer of grease.

Formwork

The formwork should be constructed to be leak proof as

Conbextra 621 is a free flowing grout. This can be achieved

by using foam rubber strip or mastic sealant beneath the

constructed formwork and between joints. In some cases it

is practical to use a sacrificial semi-dry sand and cement

formwork. The formwork should include outlets of the pre-

soaking water.

The unrestrained surface area of the grout must be kept to

a minimum. Generally the gap width between the perimeter

formwork and the plate edge should not exceed 150 mm on

the pouring side and 50 mm on the opposite side. Gap at

the flank sides should be kept to a minimum.

Mixing

For best results a mechanically powered grout mixer should

be used. For quantities up to 50 kg a slow speed drill fitted

with a high shear paddle is suitable. Larger quantities will

require a high shear vane mixer. Do not use a colloidal

impeller mixer.

It is essential that machine mixing capacity and labour

availability is adequate to enable the grouting operation to

be carried out continuously. This may require the use of a

holding tank with provision for gentle agitation to maintain

fluidity.

The selected water content should be accurately measured

(as per the selected consistency) into the mixer. Slowly add

the total contents of the Conbextra 621 bag, mix

continuously for 5 minutes, ensuring a smooth, even

consistency is obtained.

Consistency of mixed grout

To achieve the consistencies which are defined in CRD

C-621-81, the amount of clean water that is added to a 25

kg bag at 25

o

C is (4.00 litre).

Flowable: 4.00 litres

Fluid: 4.25 litres

Maximum flow distance at 20

o

C

Minimum flow distance in mm

Grout

Consistency

Gap depth

mm

100 mm

head

250 mm

head

Flowable:

10

20

30

40

50

360

950

1500

2200

3000

1200

2600

3000

3000+

3000+

Fluid:

10

20

30

40

900

1900

3000

3000+

2500

3000

3000+

3000+

Conbex t r a 621

Page 3

constructive solutions

Placing

Place the grout within 15 minutes of mixing to gain the full

benefit of the expansion process.

Conbextra 621 can be placed in thicknesses up to 125 mm in

a single pour.

Any bolt pockets must be grouted prior to grouting between

the substrate and the base plate.

Continuous grout flow is essential.

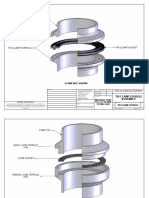

Figure (1) Typical hopper system

Removable hopper: For larger pours the grout may be

hand placed or pumped into a removable hopper (trough).

Sufficient grout must be available prior to starting and the

time taken to pour a batch must be regulated to the time

taken to prepare the next one.

The mixed grout should be poured only from one side of the

void to eliminate the entrapment of air or surplus pre-soaking

water. This is best achieved by pouring the grout across the

shortest distance of travel. Use of straps or chain may aid

grout flow in wide applications.

Where large volumes have to be placed Conbextra 621 may

be pumped. A heavy-duty diaphragm pump is recommended

for this purpose. Screw feed and piston pump may also be

suitable.

For sections thicker than 125 mm, it is necessary to fill out

the Conbextra 621 with graded 10 mm silt free aggregate to

minimise temperature rise. The quantity of aggregate should

not exceed 1 part aggregate to 1 part Conbextra 621 by

weight.

Curing

On completion of the grouting operation, exposed areas

should be thoroughly cured. This should be done by the

use of Concure Curing Membrane, continuous application of

water and/or wet hessian.

Cleaning

Conbextra 621 should be removed from tools and

equipment with clean water immediately after use. Cured

material can be removed mechanically, or with Fosroc Acid

Etch.

Li mi t at i ons

Low temperature working

When the air or contact surface temperatures are 5

o

C or

below on a falling thermometer, warm water (30 - 40

o

C) is

recommended to accelerate strength development.

For ambient temperatures below 10

o

C the grout consistency

should be flowable and the formwork should be maintained

in place for at least 36 hours.

Normal precautions for winter working with cementitious

materials should then be adopted.

High temperature working

At ambient temperatures above 35

o

C the mixed grout

should be stored in the shade Cool water (below 20

o

C)

should be used for mixing the grout.

Est i mat i ng

Supply

Conbextra 621 is supplied in 25 kg bags

Yield

Allowance should be made for wastage when estimating

quantities required. The approximate yield per 25 kg bag

for different consistencies is:

Consistency Flowable Fluid

Yield (litres) 12.90 13.00

St or age

Conbextra 621 has a shelf life of 12 months if kept in a dry

store in sealed bags. If stored in high temperature and high

humidity locations the shelf life may be reduced.

Fosam Company Li mi t ed

Head Office

Post Box 11081

J eddah 21453

Saudi Arabia

w w w .f osr oc .c om

Telephone: +966 2 637 5345 Fax: +966 2 637 5891 email: fosam@fosroc.com

Regi onal Of f i c es

J eddah Sales Office Tel: (02) 608 0999 Fax: (02) 638 0693 Yanbu Tel: (04) 322 4280 Fax: (04) 391 2980

J eddah Showroom Tel: (02) 665 0187 Fax: (02) 667 4844 Makkah Tel: (02) 542 0869 Fax: (02) 542 0869

Riyadh Tel: (01) 482 9303 Fax: (01) 482 7562 Medinah Tel: (04) 855 0091 Fax: (04) 855 0047

Dammam Tel: (03) 814 1282 Fax: (03) 814 1581 J ubail Tel: (03) 362 3904 Fax: (03) 362 3875

Khamis Mushayt Tel: (07) 250 0469 Fax: (07) 250 0469 CSD Tel: (02) 608 0999 Fax: (02) 638 0693

Registered Office: Industrial Area, Phase 4, Road No. 414, Street No. 407

Page 4

Conbex t r a 621

FO SA/CONBEXTRA 621/05/09/D

Important note:

Fosroc products are guaranteed against defective materials and manufacture and are sold subject to its standard Conditions

for the Supply of Goods and Services, copies of which may be obtained on request. Whilst Fosroc endeavours to ensure that

any advice, recommendation, specification of information it may give is accurate and correct, it cannot, because it has no direct

or continuous control over where or how its products are applied, accept any liability either directly or indirectly arising from the

use of its products, whether or not in accordance with any advice, specification, recommendation of information given by it.

Pr ec aut i ons

Health and safety

Conbextra 621 is alkaline and should not come into contact

with skin and eyes. Avoid inhalation of dust during mixing.

Gloves, goggles and dust mask should be worn.

If contact with skin occurs, wash with water. Splashes to

eyes should be washed immediately with plenty of clean

water and medical advice sought.

Fire

Conbextra 621 is non-flammable.

Addi t i onal i nf or mat i on

For further details about the use and selection of grouts

refer to the Fosroc Information Module entitled Precision

Grouting in the Construction Industry. In addition to grouts,

Fosroc manufactures a wide range of complementary

products including concrete repair mortars, sealants,

industrial flooring, protective coatings, concrete admixtures,

waterproofing membranes, PVC water stops, and tile

adhesives,

For further information please contact your local Fosroc

office.

Вам также может понравиться

- Topqm Infoservice New Cqi 9 4.edition 2020 v001 enДокумент6 страницTopqm Infoservice New Cqi 9 4.edition 2020 v001 enDFLQMS50% (2)

- Sikagrout 214-11 PdsДокумент2 страницыSikagrout 214-11 PdscharlessimoОценок пока нет

- Main Lab: FT-A-21226 29Y Female SelfДокумент1 страницаMain Lab: FT-A-21226 29Y Female SelfTori SmallОценок пока нет

- Imam Hussain Sermon at MinaДокумент15 страницImam Hussain Sermon at MinaTori SmallОценок пока нет

- Conbextra HFДокумент4 страницыConbextra HFUbaid Mazhar Abidi SyedОценок пока нет

- Conbextra BB80: Non-Shrink Cementitious Bridge Bearing GroutДокумент3 страницыConbextra BB80: Non-Shrink Cementitious Bridge Bearing GroutTori Small100% (1)

- Conbextra GP2Документ4 страницыConbextra GP2Sikander GirgoukarОценок пока нет

- Datasheet File - Conbextra GPДокумент3 страницыDatasheet File - Conbextra GPmuraliОценок пока нет

- Conbextra GP2 (T)Документ4 страницыConbextra GP2 (T)Vikas Singh ChandelОценок пока нет

- Conbextra GP 1011Документ4 страницыConbextra GP 1011Srinivasan ReddyОценок пока нет

- Fosroc Conbextra GP2Документ4 страницыFosroc Conbextra GP2awsdhnjkklmОценок пока нет

- Conbextra GP TDSДокумент4 страницыConbextra GP TDSMoataz MedhatОценок пока нет

- Conbextra GPIДокумент4 страницыConbextra GPIVenkata Raju KalidindiОценок пока нет

- Cebex Cable Grout - FosrocДокумент4 страницыCebex Cable Grout - FosrocIrshadYasinОценок пока нет

- Conbextra Cable GroutДокумент4 страницыConbextra Cable GroutVenkata RaoОценок пока нет

- Conbextra HTДокумент3 страницыConbextra HTTori SmallОценок пока нет

- Renderoc LA80Документ4 страницыRenderoc LA80Balasubramanian AnanthОценок пока нет

- TDS - Masterflow 928 TДокумент4 страницыTDS - Masterflow 928 TVenkata RaoОценок пока нет

- CONBEXTRA GP - JordanДокумент4 страницыCONBEXTRA GP - JordanShabbir HussainОценок пока нет

- Method Statement Cementitious GroutingДокумент3 страницыMethod Statement Cementitious Groutingmahmoud husseinОценок пока нет

- SikaGrout212 PdsДокумент4 страницыSikaGrout212 PdsdidbeauОценок пока нет

- Masterflow 928T PDFДокумент5 страницMasterflow 928T PDFChristian D. OrbeОценок пока нет

- Flo-Grout BP800Документ26 страницFlo-Grout BP800qasim078100% (1)

- TDS DC High Grout 210Документ4 страницыTDS DC High Grout 2104919404Оценок пока нет

- (PDS) Conbextra EP300Документ4 страницы(PDS) Conbextra EP300Faizal HaziziОценок пока нет

- Masterflow 928 TДокумент5 страницMasterflow 928 THaresh BhavnaniОценок пока нет

- Flowgrout 60 MДокумент2 страницыFlowgrout 60 Mmail2meanwar7865Оценок пока нет

- Fosroc Conbextra BB80 Antienhung - VNДокумент3 страницыFosroc Conbextra BB80 Antienhung - VNGigih M. PrayogoОценок пока нет

- Conbextra EP10TGДокумент2 страницыConbextra EP10TGBambang SasikiranaОценок пока нет

- Cmci Cmci: Epoxy Grout System For Equipment BasesДокумент2 страницыCmci Cmci: Epoxy Grout System For Equipment Basespravi3434Оценок пока нет

- Masterflow: Cementitious High Strength Non-Shrink Precision GroutДокумент3 страницыMasterflow: Cementitious High Strength Non-Shrink Precision GroutAydın VarolОценок пока нет

- Cmci Cmci: High Flow Epoxy Grout SystemДокумент2 страницыCmci Cmci: High Flow Epoxy Grout Systempravi3434Оценок пока нет

- Nitocote cm210Документ4 страницыNitocote cm210pravi3434Оценок пока нет

- Sikagrout 215 (New)Документ3 страницыSikagrout 215 (New)ArbiОценок пока нет

- Sika PDS - E - SikaGrout - 214-11 HF2 PDFДокумент4 страницыSika PDS - E - SikaGrout - 214-11 HF2 PDFlwin_oo2435Оценок пока нет

- Conbextra Cable Grout : Constructive SolutionsДокумент4 страницыConbextra Cable Grout : Constructive SolutionsAnonymous uNhWGqNzОценок пока нет

- Conbextra EP10Документ2 страницыConbextra EP10MuhammedHafis100% (1)

- Grouts & AnchorsДокумент6 страницGrouts & Anchorseng_osamahazaymehОценок пока нет

- Flo-Grout PC100 - TDSДокумент2 страницыFlo-Grout PC100 - TDSAhmed AbuoelnagaОценок пока нет

- Conbextra GP2 (T)Документ4 страницыConbextra GP2 (T)Gautam PaulОценок пока нет

- Grouting in PostДокумент7 страницGrouting in PostDeven PatleОценок пока нет

- RCT-ConGrout GPДокумент3 страницыRCT-ConGrout GPfahadОценок пока нет

- Sikagrout 215Документ2 страницыSikagrout 215Riska Anshar PramonoОценок пока нет

- Cmci Cmci: High Performance Epoxy Grout SystemДокумент2 страницыCmci Cmci: High Performance Epoxy Grout Systempravi3434Оценок пока нет

- Inspection, Good Construction Practices, Workmanship and Codal ProvisionsДокумент31 страницаInspection, Good Construction Practices, Workmanship and Codal ProvisionsThiyagarajan TiguОценок пока нет

- Conbextra HF - Grout For Tank Gaps PDFДокумент4 страницыConbextra HF - Grout For Tank Gaps PDFEngr.Mohammed KhaledОценок пока нет

- Cempatch HM: Technical Data SheetДокумент2 страницыCempatch HM: Technical Data SheetsssmouОценок пока нет

- Conbextra HES: Free Flow, High Strength, Rapid Setting, Cementitious GroutДокумент4 страницыConbextra HES: Free Flow, High Strength, Rapid Setting, Cementitious GroutVenkata Raju KalidindiОценок пока нет

- C CR90 TM Oe 0802Документ3 страницыC CR90 TM Oe 0802Jaime Patricio Chan GallardoОценок пока нет

- SikaflexPRO TdsДокумент6 страницSikaflexPRO TdsidontlikeebooksОценок пока нет

- Conbextra Ep75Документ4 страницыConbextra Ep75Sathiya SeelanОценок пока нет

- Dlc-Grout C100: General Purpose, High Strength, Non-Shrink Cementitious GroutДокумент4 страницыDlc-Grout C100: General Purpose, High Strength, Non-Shrink Cementitious Grout4919404Оценок пока нет

- Ns GroutДокумент2 страницыNs Groutpravi343450% (2)

- HK Conbextra UW PDFДокумент4 страницыHK Conbextra UW PDFtin aungtunОценок пока нет

- TDS - Bronco Cemgrout SP75Документ4 страницыTDS - Bronco Cemgrout SP75Jignessh JoshiОценок пока нет

- en-GB - Flo-Grout 2.03012016065544 PDFДокумент2 страницыen-GB - Flo-Grout 2.03012016065544 PDFHassan SleemОценок пока нет

- Supercast PC PDFДокумент2 страницыSupercast PC PDFmilanbrasinaОценок пока нет

- PDS Sikacrete 113 PPДокумент4 страницыPDS Sikacrete 113 PPKoh HanОценок пока нет

- PlastisealДокумент4 страницыPlastisealVenkata RaoОценок пока нет

- Flogrout 60: Technical Data SheetДокумент2 страницыFlogrout 60: Technical Data SheetSanjith SadanandanОценок пока нет

- Sikacrete - 114: Free Flowing Microconcrete For Grouting and RepairДокумент3 страницыSikacrete - 114: Free Flowing Microconcrete For Grouting and RepairQazinadeemОценок пока нет

- Conbextra STDДокумент2 страницыConbextra STDPritha DasОценок пока нет

- Sewage Disposal Works: Their Design and ConstructionОт EverandSewage Disposal Works: Their Design and ConstructionОценок пока нет

- Project: JUAYMAH380/230KV BSP: SL No AДокумент4 страницыProject: JUAYMAH380/230KV BSP: SL No ATori SmallОценок пока нет

- Course Book 6Документ19 страницCourse Book 6Tori SmallОценок пока нет

- S.No Item Description Start Date Finish Date Status As On 02.04.2016 1 Walkway Around BuildingsДокумент2 страницыS.No Item Description Start Date Finish Date Status As On 02.04.2016 1 Walkway Around BuildingsTori SmallОценок пока нет

- Assets List Against File # 17920: Alfanar ConstructionДокумент1 страницаAssets List Against File # 17920: Alfanar ConstructionTori SmallОценок пока нет

- Assets List Against File # 23352: Alfanar ConstructionДокумент1 страницаAssets List Against File # 23352: Alfanar ConstructionTori SmallОценок пока нет

- I Site Progress Civil Works: A 380 KV GIS BuildingДокумент3 страницыI Site Progress Civil Works: A 380 KV GIS BuildingTori SmallОценок пока нет

- 7-2-c Form - Gen Consultant PQ Summary Rev-0Документ4 страницы7-2-c Form - Gen Consultant PQ Summary Rev-0Tori SmallОценок пока нет

- Details of Company Car Expenses (01.12.15)Документ266 страницDetails of Company Car Expenses (01.12.15)Tori SmallОценок пока нет

- 230kv Ohtl Sub - 10 Cut Over Plan Updated 29.2.16Документ10 страниц230kv Ohtl Sub - 10 Cut Over Plan Updated 29.2.16Tori SmallОценок пока нет

- Prism Online QuestionnaireДокумент2 страницыPrism Online QuestionnaireTori SmallОценок пока нет

- Acomplishment Chart 380kVДокумент8 страницAcomplishment Chart 380kVTori Small100% (1)

- Request# Status: Visitor Management SystemДокумент1 страницаRequest# Status: Visitor Management SystemTori SmallОценок пока нет

- Expense Sheet: Yasir Nisar Syed Project Engineer (Civil) Khalid AkhterДокумент4 страницыExpense Sheet: Yasir Nisar Syed Project Engineer (Civil) Khalid AkhterTori SmallОценок пока нет

- Shahrour FreedomДокумент14 страницShahrour FreedomTori SmallОценок пока нет

- CRC ChecklistДокумент1 страницаCRC ChecklistTori SmallОценок пока нет

- Design Data - T-Girder - Jan 11 - 2017 PDFДокумент1 страницаDesign Data - T-Girder - Jan 11 - 2017 PDFYirga BezabehОценок пока нет

- QC - 16 Guided Bend Test.Документ3 страницыQC - 16 Guided Bend Test.mahendra100% (1)

- Product36 - File - 0 - MCM Product Guide - Fastening Technology P - PDFДокумент50 страницProduct36 - File - 0 - MCM Product Guide - Fastening Technology P - PDFmuathОценок пока нет

- Sika JointДокумент16 страницSika JointnasrulaminzubainiОценок пока нет

- General Guidelines For Successful Materials SelectionДокумент5 страницGeneral Guidelines For Successful Materials SelectionBALARAM S PATTARОценок пока нет

- (AWS A5.20 E71T-1) : Technical ReportДокумент2 страницы(AWS A5.20 E71T-1) : Technical ReportRyu RyuОценок пока нет

- Waterblocking Swellable Yarn - : Dyy5000SДокумент2 страницыWaterblocking Swellable Yarn - : Dyy5000SHomero RamosОценок пока нет

- Proses BubutДокумент46 страницProses BubutloafОценок пока нет

- V Archi of PunjabДокумент30 страницV Archi of Punjabar jain57% (7)

- Tube O.D.: Assembly Tri-Clamp FerruleДокумент12 страницTube O.D.: Assembly Tri-Clamp FerruleVasilis PolykarpidisОценок пока нет

- RДокумент161 страницаRJignesh PandyaОценок пока нет

- Mechanical Properties of Fly Ash Reinforced Aluminium 6061 CompositeДокумент5 страницMechanical Properties of Fly Ash Reinforced Aluminium 6061 CompositeLuisОценок пока нет

- Spez High Cube20Документ15 страницSpez High Cube20Bylts MFОценок пока нет

- Konsol PDFДокумент2 страницыKonsol PDFCiput MardiantoОценок пока нет

- Capral Industrial Products QLDДокумент41 страницаCapral Industrial Products QLDKevin YewОценок пока нет

- bt cad cơ bảnДокумент21 страницаbt cad cơ bảnVõ Huỳnh Hữu NghịОценок пока нет

- TDS MasterRoc SA 192 PDFДокумент3 страницыTDS MasterRoc SA 192 PDFdana setiawanОценок пока нет

- BS EN 1503-4 2002 Valves Materials For Bodies BonnetsДокумент10 страницBS EN 1503-4 2002 Valves Materials For Bodies BonnetsолегОценок пока нет

- FinetekДокумент21 страницаFinetekdenny kanaОценок пока нет

- WL100-GA - Rev 01Документ1 страницаWL100-GA - Rev 01affendy roynОценок пока нет

- Basf Mastertop 1240 Tds PDFДокумент2 страницыBasf Mastertop 1240 Tds PDFHari HaranОценок пока нет

- Saniware Catalogue2022 Compressed 220801 155910 2Документ91 страницаSaniware Catalogue2022 Compressed 220801 155910 2Tony ThooОценок пока нет

- Ch-21 Sand CastingДокумент156 страницCh-21 Sand CastingDivya SoniОценок пока нет

- ASTM D3183 10 - Standard Practice For Rubber-Preparation of Pieces For Test Purposes From ProductsДокумент2 страницыASTM D3183 10 - Standard Practice For Rubber-Preparation of Pieces For Test Purposes From ProductsAndre SpirimОценок пока нет

- Admixture Technical Sheet - ATS 12 Pumping Admixtures: 1 FunctionДокумент2 страницыAdmixture Technical Sheet - ATS 12 Pumping Admixtures: 1 FunctionDileepa DissanayakeОценок пока нет

- Plant Design Solutions Master Contents and Updates: Pds Master Catalog For Cadworx 2015Документ2 страницыPlant Design Solutions Master Contents and Updates: Pds Master Catalog For Cadworx 2015calebneltonОценок пока нет

- Studies On Ultra High Performance Concrete Incorporating Copper Slag As Fine AggregateДокумент8 страницStudies On Ultra High Performance Concrete Incorporating Copper Slag As Fine AggregatechandrasekharОценок пока нет

- Working With The Cold Box ProcessДокумент21 страницаWorking With The Cold Box ProcessAnonymous iztPUhIiОценок пока нет

- Welder Qualification ReportДокумент2 страницыWelder Qualification ReportSyed Mahmud Habibur RahmanОценок пока нет