Академический Документы

Профессиональный Документы

Культура Документы

Assignment 2

Загружено:

Siva Kumar0 оценок0% нашли этот документ полезным (0 голосов)

10 просмотров3 страницыassignment

Авторское право

© © All Rights Reserved

Доступные форматы

DOC, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документassignment

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOC, PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

10 просмотров3 страницыAssignment 2

Загружено:

Siva Kumarassignment

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOC, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 3

UNIVERSITY OF PETROLEUM & ENERGY STUDIES

CENTRE FOR CONTINUING EDUCATION

EXECUTIVE MBA

(OIL & GAS MANAGEMENT)

SEMESTER I

YEAR: 2014 SESSION: JULY

ASSIGNMENT 2

FOR

Understanding Oi &

Gas !"siness

#MDSO $%&D'

#TO BE FILLED BY THE STUDENT'

NAME( )))))))))))))))))))))))

SAP NO*REGN NO( )))))))))))))))))))))))

Section A (20 Marks)

Write short notes on any four of the following

1. Properties and the characteristics of natural gas

2. Basic process schematics of important processes used in a refinery

3. Optimization of Refinery Operations

4. eedstoc! to Products in Petrochemical "ndustry

#. $ealth and en%ironment hazards in%ol%ed in the oil and gas industry

Section B (30 marks)

(Attempt any three)

1. &lucidate the '() *ycle.

2. $ighlight the %arious refinery configurations.

3. +iscuss the ,asics of Polymerization.

4. +escri,e in detail the method of storage of petroleum and its products in li-uid and

gaseous form.

Section C (50 marks)

(Attempt all questions. Eery question carries !0 marks)

Read the case .)as Processing at ''*. and answer the following -uestions/

Case Stu"y# $as %rocessin& at ''C

'ea! "maging0 ''* performed a lea! detection sur%ey using an optical gas imaging camera for a

company in &ast 1e2as at one of their gas processing facilities. 1he company was aware of the

new regulations coming and wanted to see what it would entail and what they should do to

prepare for it since they ha%e ne%er had any lea! detection program in place. 1he results were

amazing.

1he gas processing facility was less than a year old and we were assured that there were no gas

lea!s to ,e found. 1he field superintendent e2plained how all the e-uipment at the location was

new0 properly installed and no wearing of the e-uipment would ha%e ta!en place in this short

period of time. 3t the time of the study0 this facility was processing gas at a spot rate of 120#44

mcf per day. 3fter processing the natural gas0 the daily production %olume ,eing deli%ered to

mar!et was appro2imately 5#60 with #6 accounted for as line loss and7or fuel use.

"n less than 34 minutes0 the first lea! was detected with se%eral more following. "n all0 8 lea!s

were detected which were ine2pensi%ely rectified. 9sing the criteria and emissions factors from

the &P30 they were losing 244 mcf a day in gas. 1he worst lea! detected was coming from the

storage tan!s where the %al%e was constantly malfunctioning and releasing gas from the %ent

stac!.

3fter the repairs were made0 the company ,egan seeing an e2tra :8447day ;:21504447year< at

today=s gas prices which they were losing at >ust one facility.

1he lea! detection study >ust goes to show that the industry=s acceptance of #6 for line loss and

fuel use >ust turned the corner with new technology. 'ine loss doesn=t necessarily tell the whole

story. "t doesn=t matter whether a facility is old or new there is always the possi,ility for fugiti%e

gas lea!s and the potential to increase re%enues.

(uestions#

1. What lea! detection sur%ey did the ''* perform?

2. $ighlight the field superintendent=s analysis.

3. +iscuss the strong points of such a sur%ey ,eing conducted to find out any such lea!ages

present.

4. &%aluate the situation if the lea! detection had a failure and was not a,le to detect the

defects in the pipelines.

#. 3nalyse the case and suggest some more effecti%e measures to chec! for defects0 if any.

Вам также может понравиться

- Helium Leak Testing Procedure-Turbine Condenser Negative Pressure PartsДокумент4 страницыHelium Leak Testing Procedure-Turbine Condenser Negative Pressure PartsNAITIKОценок пока нет

- Structural Design Offshore - Lecture 1 IntroДокумент26 страницStructural Design Offshore - Lecture 1 IntrobaharmarineОценок пока нет

- Non Alcholic Perfume From Kashmiri Roses: Nawab Shabir Nayab Dutt Khalid Muzzafar Zubair Bhat Ravish RahejaДокумент15 страницNon Alcholic Perfume From Kashmiri Roses: Nawab Shabir Nayab Dutt Khalid Muzzafar Zubair Bhat Ravish RahejaNeed IsolationОценок пока нет

- TABEL EQUIVALENT Chart Oli-OliДокумент1 страницаTABEL EQUIVALENT Chart Oli-OliZainal L SijaОценок пока нет

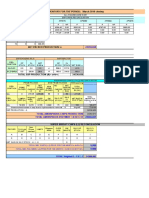

- INVENTORY FOR THE PERIOD: March 2016 ClosingДокумент4 страницыINVENTORY FOR THE PERIOD: March 2016 ClosingSiva KumarОценок пока нет

- Advanced Well CompletionДокумент25 страницAdvanced Well CompletionM.c. Tim LimОценок пока нет

- BP Case BPMДокумент20 страницBP Case BPMkiller dramaОценок пока нет

- Gas Turb Optimum Operation Lm2500Документ109 страницGas Turb Optimum Operation Lm2500Samir Benabdallah100% (1)

- Risk Assessment Oils & Fats PDFДокумент9 страницRisk Assessment Oils & Fats PDFFlutura NurediniОценок пока нет

- HAZOP STUDY Report (Kutch Chemical Industries Limited)Документ82 страницыHAZOP STUDY Report (Kutch Chemical Industries Limited)kanakarao173% (11)

- 2009 Front End Conceptual Estimating YearbookДокумент470 страниц2009 Front End Conceptual Estimating YearbookGerardo Delgado100% (4)

- Career Episode Report1Документ9 страницCareer Episode Report1Amber BookerОценок пока нет

- Project Report Battery Manufacturing PlantДокумент14 страницProject Report Battery Manufacturing PlantVasim Shaikh50% (4)

- Risk Based Inspection and Maintenance Procedures For European IndustryДокумент25 страницRisk Based Inspection and Maintenance Procedures For European IndustryDia Putranto HarmayОценок пока нет

- PVT DaneshДокумент202 страницыPVT Daneshegv2000Оценок пока нет

- FEMS ReportДокумент11 страницFEMS ReportMohammad GouseОценок пока нет

- Environment Audit Report Format - GPCBДокумент8 страницEnvironment Audit Report Format - GPCBmaikalrОценок пока нет

- Audit Check List - Investment Casting FoundryДокумент15 страницAudit Check List - Investment Casting FoundryManivannanMudhaliarОценок пока нет

- Fuel Gas Efficiency BMP - Efficient Use of Fuel Gas in Engines (Module 7) PDFДокумент76 страницFuel Gas Efficiency BMP - Efficient Use of Fuel Gas in Engines (Module 7) PDFKopi BrisbaneОценок пока нет

- Industrial Piping and Equipment Estimating ManualОт EverandIndustrial Piping and Equipment Estimating ManualРейтинг: 5 из 5 звезд5/5 (7)

- PerformanceTest Updated9octДокумент38 страницPerformanceTest Updated9octHossein100% (1)

- Oxygen From Air by Pressure Swing Adsorption PDFДокумент162 страницыOxygen From Air by Pressure Swing Adsorption PDFkalai0% (1)

- Service Buletin ZV 4048Документ156 страницService Buletin ZV 4048pendik kuswoyoОценок пока нет

- AICHE Coal Gasification ReportДокумент23 страницыAICHE Coal Gasification ReportMuzzy VoraОценок пока нет

- PC 1 FlowAssurance PDFДокумент21 страницаPC 1 FlowAssurance PDFAlvaro VelardeОценок пока нет

- Final Project Report Plastic Bottle ManufactureДокумент101 страницаFinal Project Report Plastic Bottle Manufactureaskaridumbo82% (33)

- A Refinery Approach To Address Corrosion Under Insulation & External CorrosionДокумент35 страницA Refinery Approach To Address Corrosion Under Insulation & External CorrosionIshan ShahОценок пока нет

- Turbines Paper Ray BeebeДокумент9 страницTurbines Paper Ray Beebealiscribd46Оценок пока нет

- Gas PlantДокумент44 страницыGas PlantabbutalibbОценок пока нет

- Project Experiences - Gunawan MuktiwibowoДокумент29 страницProject Experiences - Gunawan MuktiwibowoGunawan Raharjo100% (1)

- Hydraulic Fracture ModelsДокумент177 страницHydraulic Fracture ModelsAdrian Cardasol75% (4)

- The Cost of Mercury Removal in An IGCC Plant: Final Report September 2002Документ27 страницThe Cost of Mercury Removal in An IGCC Plant: Final Report September 2002Senthil NathanaОценок пока нет

- Performance Test by SEDAДокумент67 страницPerformance Test by SEDAMohd AshakriОценок пока нет

- Eor ScreeningДокумент25 страницEor ScreeningMinh LeОценок пока нет

- Oin Ops Chem 014 Recommendations of Epri WorkshopДокумент15 страницOin Ops Chem 014 Recommendations of Epri WorkshopraniОценок пока нет

- Masteroppgave PDFДокумент109 страницMasteroppgave PDFSyed ASIM motplОценок пока нет

- 2.302 Procedure For Stack Emission MonitoringДокумент3 страницы2.302 Procedure For Stack Emission Monitoringkirandevi1981Оценок пока нет

- PNABU386Документ224 страницыPNABU386Andrei HorhoianuОценок пока нет

- Objectives: Khalid Humaid Al-HasaniДокумент13 страницObjectives: Khalid Humaid Al-HasaniZenon KociubaОценок пока нет

- Data For Design of Vapor Recovery UnitsДокумент8 страницData For Design of Vapor Recovery UnitsaljamajiОценок пока нет

- Asset: Optimisation Strategies For Large TransformersДокумент4 страницыAsset: Optimisation Strategies For Large TransformersPanayiotis DemetriouОценок пока нет

- 18ael58 Ec and FM Lab ManualДокумент66 страниц18ael58 Ec and FM Lab Manualabithek03Оценок пока нет

- 27763-Ms So Sánh Thực Tế Và Mô Hình Dự Đoán EORДокумент13 страниц27763-Ms So Sánh Thực Tế Và Mô Hình Dự Đoán EORtuanleanh2599Оценок пока нет

- 065 Spe 114797Документ9 страниц065 Spe 114797mahdiОценок пока нет

- Techniques of Gas Spot SamplingДокумент5 страницTechniques of Gas Spot Samplingjuan carlosОценок пока нет

- Case Study Troubleshooting Centrifugal Compressor TripsДокумент13 страницCase Study Troubleshooting Centrifugal Compressor TripsiJordanScribdОценок пока нет

- Scale Effects in Open Water Test Results For Performance of Conventional and Unconventional PropellersДокумент35 страницScale Effects in Open Water Test Results For Performance of Conventional and Unconventional PropellersJUNIOR JAVIER OLIVO FARRERAОценок пока нет

- Optimization MassMin04 FinalДокумент12 страницOptimization MassMin04 FinalColleen CallahanОценок пока нет

- SPE 181142 MS Successful Application of Root Cause Analysis On ProgressiveДокумент21 страницаSPE 181142 MS Successful Application of Root Cause Analysis On Progressivejainrakeshj4987Оценок пока нет

- SPE 39754 "Survival of The Fittest" An Optimised Well Location Algorithm For Reservoir SimulationДокумент7 страницSPE 39754 "Survival of The Fittest" An Optimised Well Location Algorithm For Reservoir SimulationNana Silvana AgustiniОценок пока нет

- 100690-MEC-QW-E-2006: Site QA/QC ManagerДокумент6 страниц100690-MEC-QW-E-2006: Site QA/QC ManagerAhmed GamalОценок пока нет

- Multiphase Meter CheckДокумент24 страницыMultiphase Meter CheckmuralisunОценок пока нет

- p1m6150 Well Control Policy ManualДокумент92 страницыp1m6150 Well Control Policy Manualfisco4ril100% (1)

- Tarea 26 00069434 (1) - 21 MayoДокумент7 страницTarea 26 00069434 (1) - 21 MayodanonninoОценок пока нет

- Iptc 21821 MsДокумент17 страницIptc 21821 MssariОценок пока нет

- Esl Ie 81 04 02Документ4 страницыEsl Ie 81 04 02majmor-1Оценок пока нет

- Engro'S Experience: in The Construction and Start Up of A Jumbo-Scale PlantДокумент43 страницыEngro'S Experience: in The Construction and Start Up of A Jumbo-Scale PlantAjay SastryОценок пока нет

- Year 4 Course Brief SPFДокумент4 страницыYear 4 Course Brief SPFMichel IsereОценок пока нет

- Research Paper Petroleum EngineeringДокумент7 страницResearch Paper Petroleum Engineeringgvzcrpym100% (1)

- PIOGA MSC TENORM Study Responses DEP StudyДокумент15 страницPIOGA MSC TENORM Study Responses DEP StudyDory HippaufОценок пока нет

- Emission Estimation Technique Manual: Mineral Sands Mining and ProcessingДокумент70 страницEmission Estimation Technique Manual: Mineral Sands Mining and ProcessingAbhishek JainОценок пока нет

- CV - Nainish Sahare Oil and GasДокумент5 страницCV - Nainish Sahare Oil and GasNitai DuraisamiОценок пока нет

- TSD Ethanol 02 0408Документ6 страницTSD Ethanol 02 0408Tin Aung KyiОценок пока нет

- Spe 191176 MSДокумент7 страницSpe 191176 MSnandani sudamaОценок пока нет

- Opportunity For Improvement (OFI) : 3600 MW TPP, Chhattisgarh, IndiaДокумент13 страницOpportunity For Improvement (OFI) : 3600 MW TPP, Chhattisgarh, Indiapramod_nandaОценок пока нет

- Oisd RP 233 DraftДокумент66 страницOisd RP 233 DraftVenkatesh NatlaОценок пока нет

- Tutorial - DGA AnalysisДокумент17 страницTutorial - DGA Analysisw automationОценок пока нет

- Process Control in Wet ProcessingДокумент23 страницыProcess Control in Wet ProcessingKirti Nagda75% (4)

- ApplicationofRCMforachipping AndsawingmillДокумент25 страницApplicationofRCMforachipping AndsawingmillflavianosamelОценок пока нет

- InventoryДокумент4 страницыInventorySiva KumarОценок пока нет

- Unit ConversionДокумент1 страницаUnit ConversionSiva KumarОценок пока нет

- Intrument Range ListДокумент5 страницIntrument Range ListSiva KumarОценок пока нет

- FileДокумент2 страницыFileSiva KumarОценок пока нет

- Planned Order TemplateДокумент1 страницаPlanned Order TemplateSiva KumarОценок пока нет

- Daily Production Report December - 2019 (24.12.19)Документ51 страницаDaily Production Report December - 2019 (24.12.19)Siva KumarОценок пока нет

- InventoryДокумент4 страницыInventorySiva KumarОценок пока нет

- SSP Pending Jobs SL No Points Responsible Target DateДокумент2 страницыSSP Pending Jobs SL No Points Responsible Target DateSiva KumarОценок пока нет

- AMP Color Testing MethodДокумент1 страницаAMP Color Testing MethodSiva KumarОценок пока нет

- SDS For Water Column OverheadДокумент11 страницSDS For Water Column OverheadSiva KumarОценок пока нет

- Technical Specifications: 50Hz Powered by Perkins SeriesДокумент4 страницыTechnical Specifications: 50Hz Powered by Perkins SeriesSiva KumarОценок пока нет

- Storage location-SCM: SL No Department Material Type Storage Location NameДокумент3 страницыStorage location-SCM: SL No Department Material Type Storage Location NameSiva KumarОценок пока нет

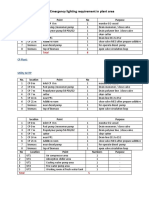

- Additional Emergency Lighting Requirement in Plant Area: No. Location Point No PurposeДокумент2 страницыAdditional Emergency Lighting Requirement in Plant Area: No. Location Point No PurposeSiva KumarОценок пока нет

- School FormДокумент3 страницыSchool FormSiva KumarОценок пока нет

- Pet Polycondensation Side ReactionsДокумент6 страницPet Polycondensation Side ReactionsGeorge MarkasОценок пока нет

- Plant Capacity 220 Heater Design DataДокумент4 страницыPlant Capacity 220 Heater Design DataSiva KumarОценок пока нет

- Insane ProjectДокумент220 страницInsane ProjectsurajphilipsОценок пока нет

- 1 Solid State Polymerization of Poly Ethylene Terephthalate I Experimental Study of The Reaction Kinetics and Properties PDFДокумент16 страниц1 Solid State Polymerization of Poly Ethylene Terephthalate I Experimental Study of The Reaction Kinetics and Properties PDFSiva KumarОценок пока нет

- C4054 Uif PR 1010 FB 00001 2Документ1 страницаC4054 Uif PR 1010 FB 00001 2Siva KumarОценок пока нет

- Haccp 06 PDFДокумент13 страницHaccp 06 PDFSiva KumarОценок пока нет

- New Doc 2018-02-27 - 1 PDFДокумент1 страницаNew Doc 2018-02-27 - 1 PDFSiva KumarОценок пока нет

- Pet Polycondensation Side ReactionsДокумент6 страницPet Polycondensation Side ReactionsGeorge MarkasОценок пока нет

- C4054 UIF PR 1010 DB 00006 0 OM V1 6 Schedule For Pre CommissioningДокумент1 страницаC4054 UIF PR 1010 DB 00006 0 OM V1 6 Schedule For Pre CommissioningSiva KumarОценок пока нет

- c4054 Uif PR 1015 DB 00001 0 Om V2a 05 CPC Sts PreparationДокумент13 страницc4054 Uif PR 1015 DB 00001 0 Om V2a 05 CPC Sts PreparationSiva KumarОценок пока нет

- DEG TankДокумент2 страницыDEG TankSiva KumarОценок пока нет

- C4054 UIF PR 1010 DB 00001 0 General Process DescriptionДокумент64 страницыC4054 UIF PR 1010 DB 00001 0 General Process DescriptionSiva Kumar100% (1)

- C4054 UIF PR 1010 DB 00001 0 General Process DescriptionДокумент64 страницыC4054 UIF PR 1010 DB 00001 0 General Process DescriptionSiva Kumar100% (1)

- Cutting Defect FormatДокумент1 страницаCutting Defect FormatSiva KumarОценок пока нет

- Gold Not Oil InflationДокумент8 страницGold Not Oil Inflationpderby1Оценок пока нет

- 8.5 - Coal and PetroleumДокумент12 страниц8.5 - Coal and PetroleumSayantan Pahari CreationsОценок пока нет

- Praguer U Truth About ClimateДокумент62 страницыPraguer U Truth About ClimatePepe GarciaОценок пока нет

- Formulation of Water-Based Drilling Fluid Using Local MaterialsДокумент8 страницFormulation of Water-Based Drilling Fluid Using Local MaterialsDavid IsuОценок пока нет

- Algeria Country ProfileДокумент36 страницAlgeria Country ProfileAnurita GhoshОценок пока нет

- Progress Report IIДокумент19 страницProgress Report IIAkashahZakariaОценок пока нет

- Allocated ProductionДокумент55 страницAllocated ProductionVanVietRoanОценок пока нет

- Fuels CLRДокумент6 страницFuels CLRZohaib Anis KundaОценок пока нет

- Oil, Gas & Consumable Fuels: NBCFM ResearchДокумент26 страницOil, Gas & Consumable Fuels: NBCFM ResearchForexliveОценок пока нет

- RE: Vapour Pressure Specification Update #2Документ9 страницRE: Vapour Pressure Specification Update #2nedian_2006Оценок пока нет

- MODEC Brochure EN PDFДокумент15 страницMODEC Brochure EN PDFAshish WadeОценок пока нет

- SPE-185398-MS Radial Jet Drilling in Mature Fields of Oil India Limited-An Experimental ApproachДокумент13 страницSPE-185398-MS Radial Jet Drilling in Mature Fields of Oil India Limited-An Experimental Approachdiego rodriguezОценок пока нет

- Abdulkader - Djellout AlgeriaДокумент59 страницAbdulkader - Djellout AlgeriasashaОценок пока нет

- Oem Sale Sheet RenaultДокумент4 страницыOem Sale Sheet RenaultDarmawan PutrantoОценок пока нет

- Buyers PDF 2Документ10 страницBuyers PDF 2Ali VezasОценок пока нет

- Economy of SouthWest AsiaДокумент1 страницаEconomy of SouthWest AsiaRonald OngudaОценок пока нет

- Introduction - Module 1 PresentationДокумент23 страницыIntroduction - Module 1 Presentationkuye dejiОценок пока нет

- Curriculum Vitae: Technical SkillsДокумент5 страницCurriculum Vitae: Technical SkillsIvan StojkovОценок пока нет

- V.K. Jain Meenal SharmaДокумент39 страницV.K. Jain Meenal SharmaCharu AryaОценок пока нет

- Responding To The Dual Challenge BP PDFДокумент84 страницыResponding To The Dual Challenge BP PDFedgarmerchanОценок пока нет

- Environmental Science 14th Edition Enger Test Bank Full Chapter PDFДокумент67 страницEnvironmental Science 14th Edition Enger Test Bank Full Chapter PDFlynnnorrisqmdjptfrwi100% (11)