Академический Документы

Профессиональный Документы

Культура Документы

Fixed Bin Replenishment in SAP

Загружено:

Mohan NaiduАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Fixed Bin Replenishment in SAP

Загружено:

Mohan NaiduАвторское право:

Доступные форматы

Fixed Bin Replenishment in SAP ECC6.

0

POSTED BY TKREDDY FEBRUARY 17, 2010 LEAVE A COMMENT

FILED UNDER FIXED BIN, REPLENISHMENT, SAP FIXED BIN REPLENISHMENT

This blog post will give you quick understanding of Fixed bin replenishment concept in terms of choosing the functionality and

required customizations along with master data maintenance.

In general you will see fixed bins for warehouses in retail distribution centers and Kit process areas where small quantitys are

more often pick from fixed bins. The storage bin in the picking area needs to be replenished so that outbound deliveries remain at

maximum efficiency.

When i am working for my clients 3.5 years back , a team member asked me about replenishment based on sales/delivery

quantity. I think we dont have that time. Now my current client is aksing this and could able to do this by Tcode LP22

Three different replenishment functions are available in SAP ECC6.0 to replenish fixed bins

1) Replenishment quantity based on current stock situation in the bin and creates a Replenishment TO during TO

Confirmation. This can be useful when you need auto TO creation when ever the min quantity for the bin reduced. But this will

not see the open pick/putaways for this bin while at TO creation.

2) LP21/ RLLNACH1 -Replenishment quantity based on current stock + open pick/putaway quantity for that bin. This will be

useful to see the forground report and supervisor can able to choose those certain bins to replenish. The required quantity will

consider the open pick/putaways for this bin.

3) LP22/RLLNACH2 -Replenishment quantity based on current stock + open pick/putaway for that bin + outbound deliveries

with pick date called planning of replenishments for fixed storage bins. This is the best option to replenish bins and quantitys

which are relevant for outbound deliveries. This can be better used for background job in the night and later can be created TO

from TRs.

For second and third cases, the system generates transfer requirements to refill the fixed storage bins with sufficient

replenishment stock for picking. It takes into account existing transfer requirements and transfer orders.

Below required steps required to run Fixed Bin Replenishment.

1) Storage type should have F as Putaway strategy

2) Storage bins need to be created under fixed Storage type

3) Extend the WM view1 and view 2 with that fixed storage type and maintain the fixed bin, minimum quantity, maximum

quantity and replenishment quantity

4) Create new replenish movt type copy from 319 movt type and if you want, enable auto TO selection and other options.

5) This step is optional i prefer to have ref.storage type search number here so that i call my own pick and putaway sequence of

storage types and maintain those in search sequence

6) Define replenishment control in the activities by maintaining the custom replenish movt type for fixed bin storage types.

7) This step is optional if you need to Create a Replenishment TO during TO Confirmation. Maintain 1 in the replenishment

method selection.

All product names are trademarks of their respective companies. The content on this site may not be reproduced or redistributed

without the express written permission of the content author.

Website help.sap.coms logos,pictures and links are trademarks or registered trademarks of SAP AG in Germany and other

countries.

Use of Mobile Data Entry into Warehouse

Management Transactions in SAP

POSTED BY TKREDDY DECEMBER 3, 2009 4 COMMENTS

FILED UNDER SAP RF SAP MOBILE DATA ENTRY

This blog post is basically for the Consultants and WM Team to

understand how SAP incorporated the use of mobile data entry into warehouse management transactions.

During my experience i used the Standard SAP RF Dynamic Cycle counting and all other processes like pick by pick sheet or

pick by ship lable was designed in custom RF program along with replenishment and pack memo printing through RF Menu..

Here i wanted to brief about the SAP RF related configurations along with features available.

Mobile data entry in the warehouse today involves the use of wireless radio frequency(RF) terminals or devices carried by the

warehouse staff to record data. The data is usually in a bar code form, either as bar code printed in Transfer orders or bar codes

that identify products, storage bins or other objects.

Standard SAP supports RF Devices and number of functions with in the Warehouse that can be executed via RF.

RF Devices:

SAP Transactions can be executed on RF devices that are handheld or forklift mounted. No Middle ware software required to

connect the devices to SAP. There are two Standard RF devices that can be used with SAP, which are

1) GUI devices- uses a Microsoft Windows-based OS

2) Character based devices- uses uses terminal emulation.

I got experienced to work with Character based RF devices only.

These RF device is not connected directly to SAP but communicates via an interface called SAPConsole. There are two industry

standards for screen sizes are supported by SAP

1) RF devices for forklifts: 8 lines by 40 characters

2) Portable RF devices: 16 lines by 20 characters

In ECC 6.0 many transactions are defined as mobile data entry and available for use with RF devices. These includes

Goods receipt

Goods issue

Material putaway

Material picking

Packing and unpacking

Physical inventory

Loading and unloading

Serial number capture

Stock overview

Bar code support in SAP: SAP reads bar codes for identification and verification. The items that can be identified include Storage

bin, Material, Storage unit, Handling unit, Quantity, Delivery, Staging area, Shipment, Pick wave. It is possible to scan items for

verification purposes and these fields includes Storage unit, Storage bin, Material, Quantity.. SAP may increase few more fields

in future.

Some configuration steps in SAP Mobile Data Entry are as follows

Configuration for Bar codes: Verification profile is a set of fields that can be verified by the user.

Path: IMG>Logistics Execution>Mobile Data Entry> Verification control> Define Profiles

Vefification profile can be assigned to movt types used in warehouses that will be subject to bar code scanning.

Path: IMG>Logistics Execution>Mobile Data Entry> Verification control> Assign Verification Profiles to Goods

Movements.

Define bar codes for warehouse

Path: IMG>Logistics Execution>Mobile Data Entry>Bar Code> Assign Bar Code Types to Warehouses.

Maintaining Bar code specifications

Path: IMG>Logistics Execution>Mobile Data Entry>Bar Code> Maintain Bar Code Specification.

Defining the Radio Frequency Queue: To assign a range of activities to certain users, functionality called the RF Queue

Management must be defined

Path: IMG>Logistics Execution>Mobile Data Entry>Rf Queue Management.

The queues are easily identifiable for picking, putaway, and goods receipt. The queues then can be assigned to the relevant areas

Adding a User for mobile data entry using Transaction code LRFMD

Logging on to Mobile Data Entry using Transaction code LM00

Accessing the RF monitor using Transaction code LRF1

The use of RF devices for data collection and transaction processing in warehouse management has been increasing over a

number SAP releases.

All product names are trademarks of their respective companies. The content on this site may not be reproduced or redistributed

without the express written permission of the content author.

Website help.sap.coms logos,pictures and links are trademarks or registered trademarks of SAP AG in Germany and other

countries.

Вам также может понравиться

- SAP S/4HANA Retail: Processes, Functions, CustomisingОт EverandSAP S/4HANA Retail: Processes, Functions, CustomisingРейтинг: 5 из 5 звезд5/5 (1)

- Interview Questions With Answers in SAP WMДокумент3 страницыInterview Questions With Answers in SAP WMmunaffОценок пока нет

- ReplenishmentДокумент2 страницыReplenishmentRAMAKRISHNA.GОценок пока нет

- The Up & Away Advisors’ Guide to Implementing and Executing Sap’s Vehicle Management SystemОт EverandThe Up & Away Advisors’ Guide to Implementing and Executing Sap’s Vehicle Management SystemОценок пока нет

- SAP PR Release Strategy Concept and Configuration Guide: A Case StudyОт EverandSAP PR Release Strategy Concept and Configuration Guide: A Case StudyРейтинг: 4 из 5 звезд4/5 (6)

- SAP IS-Retail Interview Questions, Answers, and ExplanationsОт EverandSAP IS-Retail Interview Questions, Answers, and ExplanationsРейтинг: 3 из 5 звезд3/5 (11)

- Automatic Replenishment - Warehouse Management (WM) in SAPДокумент3 страницыAutomatic Replenishment - Warehouse Management (WM) in SAPnikОценок пока нет

- Material Staging Components WM HUMДокумент4 страницыMaterial Staging Components WM HUMBLОценок пока нет

- WM Interface To Inventory ManagementДокумент5 страницWM Interface To Inventory ManagementPhilip BurrowОценок пока нет

- SAP CatchweightДокумент32 страницыSAP Catchweightsanthoshinou100% (1)

- Handling UnitsДокумент8 страницHandling UnitsImmanale YamarthiОценок пока нет

- Order Confirmation ParametersДокумент14 страницOrder Confirmation ParameterskrishnaОценок пока нет

- Comparison Between SAP IM - WM - Lean WM - DWM - EWMДокумент4 страницыComparison Between SAP IM - WM - Lean WM - DWM - EWMSebastian BravoОценок пока нет

- Warehouse Management ImplementationДокумент37 страницWarehouse Management Implementationarenaali456Оценок пока нет

- WM Printing SettingsДокумент4 страницыWM Printing SettingsWaaKaaWОценок пока нет

- Post Goods Issue With HU Via Production OrderДокумент4 страницыPost Goods Issue With HU Via Production OrderBLОценок пока нет

- Bulk Storage Put Away Strategy in SAP EWMДокумент19 страницBulk Storage Put Away Strategy in SAP EWMwaseem abbasОценок пока нет

- Decentralized Ewm: Setup Reports For Configuration of Idoc CommunicationДокумент7 страницDecentralized Ewm: Setup Reports For Configuration of Idoc CommunicationkamalrajОценок пока нет

- Sap Ewm Batch Management - CustomДокумент1 страницаSap Ewm Batch Management - CustomFernando TlaxaloОценок пока нет

- 1909.EWM and QM Integration End User ManualДокумент20 страниц1909.EWM and QM Integration End User ManualSantosh KadamОценок пока нет

- SAP MM Consultant with 8+ Years ExperienceДокумент7 страницSAP MM Consultant with 8+ Years ExperiencechangingmomentsОценок пока нет

- WM Phy Inv T CodesДокумент13 страницWM Phy Inv T CodesSachin DewanganОценок пока нет

- WM Storage Location ControlДокумент4 страницыWM Storage Location ControlPradeep Kumar Reddy NaraОценок пока нет

- Wms ConfigДокумент73 страницыWms Configsujeet kumarОценок пока нет

- Material Staging Via Outbound DeliveryДокумент3 страницыMaterial Staging Via Outbound DeliveryBLОценок пока нет

- SAP WM Putaway and Removal Strategies in WMДокумент8 страницSAP WM Putaway and Removal Strategies in WMShwetha SОценок пока нет

- Sap MM Master DataДокумент19 страницSap MM Master DataImran PatelОценок пока нет

- I. Creation of Unit of MeasureДокумент7 страницI. Creation of Unit of MeasureRahul JainОценок пока нет

- Step by Step WMДокумент58 страницStep by Step WMchandra9000Оценок пока нет

- BACKFLUSH-WM MovementsДокумент5 страницBACKFLUSH-WM MovementsscribdatlantaОценок пока нет

- Configure Customer Exits for Batch NumberДокумент5 страницConfigure Customer Exits for Batch NumberSagar Goliwar100% (2)

- PPT4 Warehouse+StructureДокумент20 страницPPT4 Warehouse+StructureVKОценок пока нет

- Overview of Stock Transfer Configuration in SAP-WMДокумент11 страницOverview of Stock Transfer Configuration in SAP-WMMiguel TalaricoОценок пока нет

- Varient ConfigurationДокумент20 страницVarient ConfigurationTarunChaudharyОценок пока нет

- EWM Organizational StructureДокумент25 страницEWM Organizational Structurezak100% (1)

- SAP EWM Advanced Embedded Packaging Specification Ambikeya 1692876641Документ16 страницSAP EWM Advanced Embedded Packaging Specification Ambikeya 1692876641Amo Ofertas BrОценок пока нет

- How To Configure of Quality Management in Embedded EWMДокумент37 страницHow To Configure of Quality Management in Embedded EWMGhassan SharafОценок пока нет

- Ewm Class 40 - ScrappingДокумент8 страницEwm Class 40 - ScrappingRaviteja KanakaОценок пока нет

- EWM CLASS 26 - Posting Changes - Stock Transfer ConfigurationДокумент7 страницEWM CLASS 26 - Posting Changes - Stock Transfer ConfigurationRaviteja KanakaОценок пока нет

- SAP WM - Uploading Opening Balances To Storage BinДокумент3 страницыSAP WM - Uploading Opening Balances To Storage BinIlmoyeteОценок пока нет

- Free Goods in SAP SDДокумент1 страницаFree Goods in SAP SDpraveennbsОценок пока нет

- Custom Nodes in SAP EWM Warehouse MonitorДокумент7 страницCustom Nodes in SAP EWM Warehouse Monitorvinodkumar.280421Оценок пока нет

- Assigning Output Type WMTA To Inbound Deliveries - SAP DocumentationДокумент2 страницыAssigning Output Type WMTA To Inbound Deliveries - SAP DocumentationlavleenlesyaОценок пока нет

- How To Create Material Master in SAP MMДокумент4 страницыHow To Create Material Master in SAP MMDebasish SahaОценок пока нет

- Sap (TSCM60)Документ12 страницSap (TSCM60)Raj Kumar0% (1)

- BC Sets Guide OverviewДокумент6 страницBC Sets Guide Overviewandy7820Оценок пока нет

- CIFДокумент5 страницCIFvijayjeoОценок пока нет

- Sap SD PDFДокумент54 страницыSap SD PDFsapsd1082012Оценок пока нет

- 2 Step Picking - Wave Management Configuration and ProcessДокумент28 страниц2 Step Picking - Wave Management Configuration and ProcessEKTA SIMARIAОценок пока нет

- Batch Management From SAP SD PointДокумент9 страницBatch Management From SAP SD PointnabigcsОценок пока нет

- Special Stock & Special Procurement in SAPДокумент17 страницSpecial Stock & Special Procurement in SAProbnunesОценок пока нет

- WM OverviewДокумент38 страницWM OverviewRahul KumarОценок пока нет

- WM Stock Upload ProcedureДокумент9 страницWM Stock Upload ProcedurejalalhussainrshОценок пока нет

- WM ScenariosДокумент6 страницWM ScenariosVishnu Kumar SОценок пока нет

- 3 SDДокумент16 страниц3 SDMiguel P BerumenОценок пока нет

- Bulk Strategy - PutawayДокумент11 страницBulk Strategy - PutawayEKTA SIMARIAОценок пока нет

- WM table namesДокумент3 страницыWM table namesjaypnarayanОценок пока нет

- Replenishment Control in SAP WMДокумент11 страницReplenishment Control in SAP WMsumitjain_25Оценок пока нет

- No Schedule Lines Due ToДокумент15 страницNo Schedule Lines Due ToBharathk KldОценок пока нет

- MM Master DataДокумент42 страницыMM Master DataMohan NaiduОценок пока нет

- Idoc 1Документ30 страницIdoc 1biltexОценок пока нет

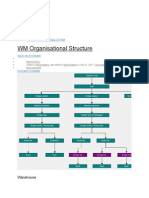

- WM Organisational Structure: WarehouseДокумент3 страницыWM Organisational Structure: WarehouseMohan NaiduОценок пока нет

- IDOCpДокумент29 страницIDOCpMohan NaiduОценок пока нет

- Handling Unit ReversalДокумент16 страницHandling Unit ReversalMohan NaiduОценок пока нет

- How To Create Sales OrderДокумент6 страницHow To Create Sales OrderMohan NaiduОценок пока нет

- Handling Unit ReversalДокумент16 страницHandling Unit ReversalMohan NaiduОценок пока нет

- Fixed Bin Replenishment in SAPДокумент5 страницFixed Bin Replenishment in SAPMohan NaiduОценок пока нет

- Configuration Company Name CreationДокумент16 страницConfiguration Company Name CreationMohan NaiduОценок пока нет

- Sap Project PreperationДокумент1 страницаSap Project PreperationMohan NaiduОценок пока нет

- Sap Project PreperationДокумент1 страницаSap Project PreperationMohan NaiduОценок пока нет

- Sap Project PreperationДокумент1 страницаSap Project PreperationMohan NaiduОценок пока нет