Академический Документы

Профессиональный Документы

Культура Документы

Rotor Creep and Speed Detector: Applications

Загружено:

Balu MОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Rotor Creep and Speed Detector: Applications

Загружено:

Balu MАвторское право:

Доступные форматы

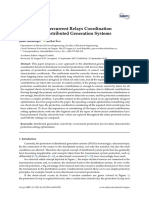

DCC-631 Signal Conditioner

SIDE VIEW

Coaxial

Integral cable

50 cm (19.68 ft)

Stator

Core

Rotor Pole

Rotor

Pole

Extension

triaxial cable

10 m (32.8 ft)

30 m (98.4 ft)

lead

1 pulse pole

Primary relay contact

Rotor Status

Indicator (LEDs)

Creep relay

contact output

DMV-100

Creep & Speed Monitor Unit

Programmable

tachometer with

real-time display

of RPM

4-20 mA proportional

RPM output

19" rackmount

VM 3.1 air gap

sensor glued

onto stator

laminations TOP VIEW

A

i

r

G

a

p

DMV

TM

-100

Rotor Creep and Speed Detector

Diagram

Applications

Detection of rotor motion and RPM on generators

and large electric motors with salient poles

Notify automation system when the machine reaches

standstill, safeguard against unexpected rotor motion

Provide RPM output to external instrumentation

Features

Comprizes:

- VM 3.1 Air Gap

Capacitive Sensor

(noncontact, extended range:

550 mm / 196.81968.5 mils)

- Fixed-length extension cable (10 m / 32.8 ft)

- DCC-631 Signal Conditioner

(built-in primary relay and 1/pole pulse outputs)

- 30 m (98.4 ft) cable link

- DMV

TM

-100 Monitor (2U rack-mount unit,

built-in main power relay for creep detection and,

digital tachometer)

Triggering incident:

- non-changing air gap for a period of 25 seconds

(i.e. rotor not in motion) energizes relay,

- 1/2 pole motion instantly de-energizes relay

( 5 mm (196.8 mils)

Front-panel display of rotor status (LEDs Rotation vs.

Stop) and real-time rotational speed (5-digit meter)

Outputs of creep detection (main power relay

NO and NC contacts available) to SCADA or

annunciation device and proportional 4-20 mA signal

of RPM to external metering or monitoring devices

Description

The DMV

TM

-100 Rotor Creep and Speed Detector has two

purposes: to detect and annunciate slow rotor motion (creep)

and to measure rotational speed (RPM). It notifies when

machine is at standstill, safeguards against unexpected rotor

motion, and provides RPM to external devices.

It consists of a VM 3.1

Capacitive Sensor, a 10 m (32.8 ft)

extension cable, a DCC-631 Signal Conditioner, a 30 m

(98.4 ft) power and output cable, and a DMV

TM

-100 Monitor

(rack-mount unit).

The noncontact sensor detects rotor motion by sensing air

gap variations as poles pass by. While machine operates, the

conditioner produces a 1/pole pulse. Its primary relay

activates when gap variation stops for over 25 seconds.

A 1/2 pole motion instantly de-energizes relay

( 5 mm (196.8 mils). The monitor displays rotor status

(LEDs) and activates the main power relay for connection

to automation system or annunciation devices. The pulse

signal is processed by a programmable tachometer which

displays real-time RPM and provides a proportional 4-20 mA

output to external device.

DCC-631 Main Specifications

Operation

Matching Sensor VM 3.1

Detection Range Extended to 5 to 50 mm

(196.8 to 1968.5 mils)

Output Signal

- System Stopped 0VDC

- Machine in Rotation 0VDC

- Machine Stopped +24VDC, 60 mA max

Accuracy <5% of reading

Repeatability 0.6% of reading

Interchangeability 5% of reading

Frequency Response

Min. DC to 1 kHz (-3 dB)

Typical DC to 1.2 kHz (-3 dB)

Temperature Drift <500 ppm/

o

C

Power Requirement

Voltage +24VDC 15%

Consumption 90 mA typical (+24VDC)

Protection auto-reset fuse

Connection

Cable from Sensor SMA connector (female)

and grounding screw

Power & Output Cable M12 male connector

Environmental

Temperature:

- Operation 0C to 55C (32F to 131F)

- Storage 0C to 85C (32F to 185F)

Humidity Up to 95% non condensing

Physical Characteristics

Module Body Die-cast aluminium

Dimensions

- A- Height 44.5 mm (1.75 in.)

- B- Width 82.5 mm (3.25 in.)

- C- Length 139.5 mm (5.5 in.)

Matching Triaxial Cable

Type Triaxial 100% shielded

Length

- Nominal 10 m (32.8 ft)

- Minimum 9.5 m (31.2 ft)

Connectors

- On Sensor End SMA connector (female)

and lug-terminated

grounding wire

- On Conditioner End SMA connector (male)

and lug-terminated

ground lug bolt

- Minimum Bending Radius 5 cm (2 in.)

Contact Output (Built-in Primary Relay)

Type Dry contact

SPST, normally opened

- Unit rotating Opened

- Unit stopped Closed, t stop delay >25 sec.

Sensitivity

- Stopped to rotation air gap >5 mm (197 mils),

Time to react Instantaneous

- Rotation to stopped air gap <5 mm (197 mils),

Time to react 25 sec. after stop

Pulse Output

Type NPN, open collector

1 pulse per pole

Connection

Sensor side (VM 3.12)

- Connector Female bayonet

DMV

TM

-100 Monitor side

- Connector 9-pin male CPC socket

- Cable 4-pair shielded

- Length 30 m (98 ft) lead with

female CPC socket at

one end and flying leads

at other end

Power Supply

Input Voltage +24 VDC 15% [300 mA]

Power Consumption 7 W

Fuse 0.5 A slow-blow

DMV

TM

-100 Rotor Creep and Speed Detector

A

B

C

DMV

TM

-100 Monitor Unit

Main Specifications

2U, 19" rack-mount

Creep detection relay output

Rotor status LED display (rotation/stop)

Rotational speed 5-digit display and 4-20 mA output

Overall

Connection

DCC-631 Power

and Output Removable 8-screw terminal

Relay Contact Output Removable 3-screw terminal

RPM Output Removable 3-screw terminal

Power from Main Removable 3-screw terminal

Supply

Input Voltage 85-264 VAC, 105-370 VDC

Input Frequency 47-440 Hz

System-wide Consumption 15.9 W max

Fuse Two 0.50 A, slow-blow

Environmental

Temperature Range

- Operation 0C to 50C (32F to 122F)

- Storage -20C to 65C (-5F to 150F)

Humidity Up to 90% noncondensing

Dimensions

Height 89 mm (3.5 in.)

Width 483 mm (19.0 in.)

Depth 305 mm (12.0 in.)

Weight 7.25 kg (16 lb)

Creep Detection Section

Input from DCC-631 Dry contact from

primary SPST relay

Front-panel LED Indicators

- GREEN Rotor stopped,

Relay energized

- RED Rotor moving,

Relay de-energized

Output to user equipment Dry contact, DPDT relay

Normally Opened (NO) and

Normally Closed (NC)

available, from main

power relay

State As per DCC-631 output

- System OFF Opened / De-energized

- Unit Rotating Opened / De-energized

- Unit Stopped Closed / Energized

t stop delay >25 sec.

Relay Power Requirement +24 VDC

Relay Contact Ratings Resistive load

- Limitations 10 A @ 24 VDC,

0.5 A @ 110 VDC,

5 A @ 250 VAC,

- Maximum Voltage 250 VAC/125 VDC

- Maximum Current 10 A

- Switching Capacity 1100 VA, 240 W

Rotational Speed Detection Section

Meter Digital tachometer,

front-panel display / keypad,

programmable RPM range

Input Signal 1/pole pulse, NPN-type

Input Range 0.0005 to 50,000 pulses/sec.

Accuracy @ 23C (5C) 0.006% of reading 1 digit

Internal Transfer Formula RPM = nbr pulses/sec. x

60 x ( = 1/nbr poles)

Front-panel Display 5-digit LCD, real-time RPM

Output Signal 4-20 mA, proportional to

programmed RPM range

Output Resistive Load 500 max.

DMV

TM

-100 Rotor Creep and Speed Detector

VibroSystM reserves the right to change specifications to improve products without notification.

VibroSystM, ZOOM, and AGMS are registered trademarks, DMV is a trademark of VibroSystM

Inc., Canada Patented technologies. Copyright 2010, All rights reserved.

Published: 00.02.07 Revised: 10.08.27

VibroSystM Inc.

2727 Jacques-Cartier E. Blvd, Longueuil (Quebec) J4N 1L7 Canada

Phone: 450 646-2157 1-800-663-8379 (U.S. toll free) Fax: 450 646-2164

vibrosystm.com

Вам также может понравиться

- Analog Circuit Design: A Tutorial Guide to Applications and SolutionsОт EverandAnalog Circuit Design: A Tutorial Guide to Applications and SolutionsРейтинг: 3.5 из 5 звезд3.5/5 (6)

- Microprocessor Engine/Generator Controller: Model MEC 2Документ12 страницMicroprocessor Engine/Generator Controller: Model MEC 2Andres Huertas100% (1)

- 110 Waveform Generator Projects for the Home ConstructorОт Everand110 Waveform Generator Projects for the Home ConstructorРейтинг: 4 из 5 звезд4/5 (1)

- Microprocessor Engine/Generator Controller: Model MEC 20Документ4 страницыMicroprocessor Engine/Generator Controller: Model MEC 20Gerardo OrtizОценок пока нет

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2От EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Оценок пока нет

- Danfoss MCD3000 BrosuraДокумент2 страницыDanfoss MCD3000 BrosurazvekoslavОценок пока нет

- CMZ 700 SeriesДокумент1 страницаCMZ 700 SeriesborisgolodenkoОценок пока нет

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1От EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Рейтинг: 2.5 из 5 звезд2.5/5 (3)

- CMCP 575Документ3 страницыCMCP 575Venkat Subramanyam.CОценок пока нет

- MKC - PKCДокумент12 страницMKC - PKCTymbark MaspexОценок пока нет

- Description Power Range: Analog Servo DriveДокумент8 страницDescription Power Range: Analog Servo DriveElectromateОценок пока нет

- Description Power Range: Analog Servo DriveДокумент7 страницDescription Power Range: Analog Servo DriveElectromateОценок пока нет

- Description Power Range: Analog Servo DriveДокумент7 страницDescription Power Range: Analog Servo DriveElectromateОценок пока нет

- Description Power Range: Analog Servo DriveДокумент7 страницDescription Power Range: Analog Servo DriveElectromateОценок пока нет

- Description Power Range: Analog Servo DriveДокумент7 страницDescription Power Range: Analog Servo DriveElectromateОценок пока нет

- Description Power Range: Analog Servo DriveДокумент8 страницDescription Power Range: Analog Servo DriveElectromateОценок пока нет

- Tech Characteristic VEGAДокумент16 страницTech Characteristic VEGADark _Оценок пока нет

- Analog Servo Drive: Description Power RangeДокумент13 страницAnalog Servo Drive: Description Power RangeElectromateОценок пока нет

- Transmitter QuadratureДокумент4 страницыTransmitter QuadratureJose LunaОценок пока нет

- Airpax PDFДокумент46 страницAirpax PDFvjОценок пока нет

- Drive Systems A500 Series: Your Partner in Industrial Automation SystemsДокумент4 страницыDrive Systems A500 Series: Your Partner in Industrial Automation SystemsFranklin DannyОценок пока нет

- Trivector MeterДокумент2 страницыTrivector MeterTarun AhujaОценок пока нет

- Axor CD180 PDFДокумент10 страницAxor CD180 PDFClaudiuMaxmiucОценок пока нет

- E Tended Environment: Analog Servo DriveДокумент8 страницE Tended Environment: Analog Servo DriveElectromateОценок пока нет

- M/V™ Series Servo Drive: Description Power RangeДокумент11 страницM/V™ Series Servo Drive: Description Power RangeElectromateОценок пока нет

- Phase & Residual Overcurrent: Protection RelaysДокумент6 страницPhase & Residual Overcurrent: Protection RelaysEric Espinoza BenturaОценок пока нет

- Manual MaxthermoДокумент8 страницManual Maxthermolfrago6Оценок пока нет

- Easy Gen 3000Документ56 страницEasy Gen 3000Permata Dewa100% (3)

- Relay NM 10Документ8 страницRelay NM 10Ayahnya Rizla Atha RayyanОценок пока нет

- Description Power Range: Analog Servo DriveДокумент8 страницDescription Power Range: Analog Servo DriveElectromateОценок пока нет

- Digital Controller R35Документ12 страницDigital Controller R35Takagi PhạmОценок пока нет

- Description Power Range: Analog Servo DriveДокумент8 страницDescription Power Range: Analog Servo DriveElectromateОценок пока нет

- Telemecanique Altivar 16 ATV16U72N4Документ33 страницыTelemecanique Altivar 16 ATV16U72N4Tezontepec De Aldama HidalgoОценок пока нет

- Honeywell DC1000 ShortДокумент5 страницHoneywell DC1000 ShortSi NiОценок пока нет

- Continuous Level Measurement - Ultrasonic ControllersДокумент8 страницContinuous Level Measurement - Ultrasonic ControllersknchnОценок пока нет

- Generator Protection M 3425AДокумент38 страницGenerator Protection M 3425AFelixAvila100% (1)

- Description Power Range: Analog Servo DriveДокумент7 страницDescription Power Range: Analog Servo DriveElectromateОценок пока нет

- M/V™ Series Servo Drive: Description Power RangeДокумент11 страницM/V™ Series Servo Drive: Description Power RangeElectromateОценок пока нет

- Commander SE: Simple and EasyДокумент8 страницCommander SE: Simple and EasyRitesh SharmaОценок пока нет

- Data Sheet Compact ControllerДокумент12 страницData Sheet Compact ControllerRizqy LuthfiantoОценок пока нет

- MS4600 Datasheet en 201507 F266I-E-01Документ7 страницMS4600 Datasheet en 201507 F266I-E-01Eliezer DominguezОценок пока нет

- High Performances in Small Dimensions: InverterДокумент19 страницHigh Performances in Small Dimensions: InverterСДММ ГЕВГЕЛИЈАОценок пока нет

- I G5Документ16 страницI G5MoustaffaОценок пока нет

- Samsung AC Servo System 2009 4Документ40 страницSamsung AC Servo System 2009 4Frank M C100% (1)

- E Tended Environment: Analog Servo DriveДокумент8 страницE Tended Environment: Analog Servo DriveElectromateОценок пока нет

- Description Power Range: Analog Servo DriveДокумент8 страницDescription Power Range: Analog Servo DriveElectromateОценок пока нет

- Analog Servo Drive: Description Power RangeДокумент9 страницAnalog Servo Drive: Description Power RangeElectromateОценок пока нет

- Analog Servo Drive: Description Power RangeДокумент11 страницAnalog Servo Drive: Description Power RangeElectromateОценок пока нет

- Beckwith M 3425AДокумент482 страницыBeckwith M 3425AJohnLT092Оценок пока нет

- Description Power Range: Analog Servo DriveДокумент8 страницDescription Power Range: Analog Servo DriveElectromateОценок пока нет

- 10 A 8 DDДокумент7 страниц10 A 8 DDElectromateОценок пока нет

- Smartstep 2 Servo Drive DatasheetДокумент12 страницSmartstep 2 Servo Drive DatasheetTio_louis32Оценок пока нет

- Analog Servo Drive: Description Power RangeДокумент9 страницAnalog Servo Drive: Description Power RangeElectromateОценок пока нет

- Ieocr Mme en 1007Документ24 страницыIeocr Mme en 1007SaptCahbaguzОценок пока нет

- Beckwith M-3425 Prot GeneradorДокумент34 страницыBeckwith M-3425 Prot Generadorgusfaj100% (1)

- Maxon 145391Документ2 страницыMaxon 145391Mathieu BrasseurОценок пока нет

- Analog Servo Drive: Description Power RangeДокумент9 страницAnalog Servo Drive: Description Power RangeElectromateОценок пока нет

- Azbh 12 A 8Документ8 страницAzbh 12 A 8ElectromateОценок пока нет

- Capability Chart of A Doubly Fed Induction Generation Based On Its Ratings and Stability MarginДокумент6 страницCapability Chart of A Doubly Fed Induction Generation Based On Its Ratings and Stability MarginBalu MОценок пока нет

- Back Up Protection SystemsДокумент21 страницаBack Up Protection SystemsBalu MОценок пока нет

- Research On Inverter Integrated Reactive Power Control Strategy in The Grid-Connected PV SystemsДокумент22 страницыResearch On Inverter Integrated Reactive Power Control Strategy in The Grid-Connected PV SystemsBalu MОценок пока нет

- Capability Chart of A Doubly Fed Induction Generation Based On Its Ratings and Stability MarginДокумент6 страницCapability Chart of A Doubly Fed Induction Generation Based On Its Ratings and Stability MarginBalu MОценок пока нет

- New JSME Standard S008 Performance Conversion MethДокумент11 страницNew JSME Standard S008 Performance Conversion MethBalu MОценок пока нет

- Generator Protection - CalculationДокумент4 страницыGenerator Protection - CalculationBalu MОценок пока нет

- Numerical and Experimental Investigation of The 4-Quadrant Behavior of Different Mixed Flow Diffuser PumpsДокумент18 страницNumerical and Experimental Investigation of The 4-Quadrant Behavior of Different Mixed Flow Diffuser PumpsBalu MОценок пока нет

- Research On The Automatic Generation Control (AGC) Coordinated Control Modes Between Provincial Dispatching and Regional Dispatching in Yunnan Power GridДокумент7 страницResearch On The Automatic Generation Control (AGC) Coordinated Control Modes Between Provincial Dispatching and Regional Dispatching in Yunnan Power GridBalu MОценок пока нет

- Motor ClasstyДокумент128 страницMotor Classtywatep_08Оценок пока нет

- N 2 XfgbyДокумент3 страницыN 2 XfgbyBalu MОценок пока нет

- Sensors 17 00872Документ16 страницSensors 17 00872Waris KhanОценок пока нет

- N 2 XcyДокумент4 страницыN 2 XcyBalu MОценок пока нет

- Ocpem 2019 20 BДокумент7 страницOcpem 2019 20 BBalu MОценок пока нет

- Hawker Batteries: HandbookДокумент0 страницHawker Batteries: Handbookrajpre1213Оценок пока нет

- HITACHIДокумент8 страницHITACHIBalu MОценок пока нет

- Top Five Causes of Switchgear FailureДокумент3 страницыTop Five Causes of Switchgear FailureGlenn Adalia Bonita75% (4)

- Generator Hipot TestingДокумент30 страницGenerator Hipot TestingBalu MОценок пока нет

- Internal 2013Документ246 страницInternal 2013eekamalesh100% (1)

- Top Five Causes of Switchgear FailureДокумент3 страницыTop Five Causes of Switchgear FailureGlenn Adalia Bonita75% (4)

- Energies: Directional Overcurrent Relays Coordination Problems in Distributed Generation SystemsДокумент17 страницEnergies: Directional Overcurrent Relays Coordination Problems in Distributed Generation SystemsBalu MОценок пока нет

- Paper 1Документ33 страницыPaper 1Balu MОценок пока нет

- Iec Electric Motors - Insulation Class Explanation: 150°C Ptcs SettingДокумент1 страницаIec Electric Motors - Insulation Class Explanation: 150°C Ptcs Settingmr_badihiОценок пока нет

- Pumped Storage Hydro-Plant Models For System Transient and Long-Term Dynamic StudiesДокумент8 страницPumped Storage Hydro-Plant Models For System Transient and Long-Term Dynamic Studiesmunagala balasubramanyamОценок пока нет

- Last 50 Years of Hydro Energy-A Bibliographic Survey: KeywordsДокумент7 страницLast 50 Years of Hydro Energy-A Bibliographic Survey: KeywordsBalu MОценок пока нет

- Distance Protection Testing in An IEC 61850 Environment: Jan Ciechanowicz, Waldemar RebizantДокумент5 страницDistance Protection Testing in An IEC 61850 Environment: Jan Ciechanowicz, Waldemar RebizantBalu MОценок пока нет

- Hydro NasselqvistДокумент19 страницHydro NasselqvistBalu MОценок пока нет

- Transient Behavior of Variable Speed Pump-Turbine UnitsДокумент14 страницTransient Behavior of Variable Speed Pump-Turbine UnitsSuresh CОценок пока нет

- C - Connecting Water To WireДокумент24 страницыC - Connecting Water To WireBalu MОценок пока нет

- Among Us Hack Mod Menu Mod AlwaysДокумент4 страницыAmong Us Hack Mod Menu Mod AlwaysC JОценок пока нет

- ET275 Unit 2 - Lesson Plan - SlidesДокумент27 страницET275 Unit 2 - Lesson Plan - SlidesDonald LeedyОценок пока нет

- Dell Online - Case AnalysisДокумент5 страницDell Online - Case AnalysisMohit Agarwal0% (1)

- HTTP ProtocolДокумент16 страницHTTP ProtocolHao NguyenОценок пока нет

- Dell PowerEdge M1000e Spec SheetДокумент2 страницыDell PowerEdge M1000e Spec SheetRochdi BouzaienОценок пока нет

- Microeconomics Theory and Applications 12th Edition Browning Solutions ManualДокумент5 страницMicroeconomics Theory and Applications 12th Edition Browning Solutions Manualhauesperanzad0ybz100% (26)

- 2 - McCullough HospitalДокумент2 страницы2 - McCullough HospitalGuru Charan ChitikenaОценок пока нет

- BMR - Lab ManualДокумент23 страницыBMR - Lab ManualMohana PrasathОценок пока нет

- Azar Mukhtiar Abbasi: Arkad Engineering & ConstructionДокумент4 страницыAzar Mukhtiar Abbasi: Arkad Engineering & ConstructionAnonymous T4xDd4Оценок пока нет

- C TKP3 SMQДокумент11 страницC TKP3 SMQDavid Tovar cruzОценок пока нет

- Spark - Eastern Peripheral Road Project (Epr) Weekly Quality MeetingДокумент6 страницSpark - Eastern Peripheral Road Project (Epr) Weekly Quality Meetingengr.s.a.malik6424Оценок пока нет

- Managing Apps in Windows 10Документ29 страницManaging Apps in Windows 10CourageMarumeОценок пока нет

- OTP Protocol PharmacistsДокумент14 страницOTP Protocol PharmacistsericОценок пока нет

- IDS701Документ26 страницIDS701Juan Hidalgo100% (2)

- 2015 Paper 2 Specimen Paper PDFДокумент10 страниц2015 Paper 2 Specimen Paper PDFAhmad Osama MashalyОценок пока нет

- For Visual Studio User'S Manual: Motoplus SDKДокумент85 страницFor Visual Studio User'S Manual: Motoplus SDKMihail AvramovОценок пока нет

- Important Dates (PG Students View) Semester 1, 2022-2023 - All Campus (As of 2 October 2022)Документ4 страницыImportant Dates (PG Students View) Semester 1, 2022-2023 - All Campus (As of 2 October 2022)AFHAM JAUHARI BIN ALDI (MITI)Оценок пока нет

- Case Study ToshibaДокумент6 страницCase Study ToshibaRachelle100% (1)

- MEETING 12 - Additional CasesДокумент25 страницMEETING 12 - Additional CasesJohn Michael VidaОценок пока нет

- HCMA ZW370 6 Brochure - 02 - 22Документ24 страницыHCMA ZW370 6 Brochure - 02 - 22Carlos Arturo AcevedoОценок пока нет

- PDF 24Документ8 страницPDF 24Nandan ReddyОценок пока нет

- 20 X 70Документ102 страницы20 X 70MatAlengОценок пока нет

- MCQ (Chapter 6)Документ4 страницыMCQ (Chapter 6)trail meОценок пока нет

- Nogales V Capitol Medical CenterДокумент2 страницыNogales V Capitol Medical CenterGraceОценок пока нет

- C# Program To Print Even NumbersДокумент11 страницC# Program To Print Even NumbersNadikattu RavikishoreОценок пока нет

- 737-11 Tikona Bill Free Plan Leaflet - v2Документ1 страница737-11 Tikona Bill Free Plan Leaflet - v2alok singhОценок пока нет

- The Mechanism of Notifying and Record Keeping Three Forms Are Used For Notifying and Record KeepingДокумент6 страницThe Mechanism of Notifying and Record Keeping Three Forms Are Used For Notifying and Record KeepingRoger FernandezОценок пока нет

- Challenges Students Face in Conducting A Literature ReviewДокумент6 страницChallenges Students Face in Conducting A Literature ReviewafdtunqhoОценок пока нет

- Star - 6 ManualДокумент100 страницStar - 6 ManualOskarОценок пока нет

- c15 ldn01610 SchematicДокумент4 страницыc15 ldn01610 SchematicJacques Van Niekerk50% (2)