Академический Документы

Профессиональный Документы

Культура Документы

Forest Products and Trade

Загружено:

Austin OliverОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Forest Products and Trade

Загружено:

Austin OliverАвторское право:

Доступные форматы

1

CHAPTER 1. INTRODUCTION

The forest products industry is one of the worlds largest industrial sectors, with reported annual sales of

US$950 billion and a gross value-added estimated at about US$354 billion. World trade in forest

products is valued at approximately US$200 billion, and has quadrupled over the last three decades.

The forest products industry makes an important contribution to the standard of living in developed and

developing countries alike. Employing over 13 million people in nearly 200 nations, the forest products

industry is an economic engine and a vital part of the global environmental and social fabric. In many

developing (and developed) countries, forestry and forest products processing is important for economic

development and the livelihood of rural communities. People depend on the goods produced by the

worlds forest products industry on a daily basis. The forest products sector includes products such as

wood (logs, lumber veneer, panelling and engineered wood products, flooring, decorative items, furniture

parts and accessories), and pulp and paper products (all mechanical and chemical pulp, paper and

paperboard packaging such as kraft paper and linerboard and folding boxboard, newsprint, printing and

writing paper, specialty paper, and sanitary products). Forest products are derived from one of the

worlds few renewable resources and supply the base material for a significant number of other key world

industries. Forests play an important role in the socio-economic development of a country like India.

They are rich sources of energy, housing, firewood, timber and fodder and they provide employment to a

large section of the rural population. Demand for forest products and services in the country is increasing

with rapid economic growth, industrialization and increase in population.

The recorded forest area in India is about 76.5 million ha (23% of total land mass). However, the actual

forest/tree cover is just about 19% of the total geographical area. The per capita forest area in the country

is 0.08 ha as compared to the world average of 0.64 ha. The total removal of fuelwood from forestland is

estimated at 270 million tonnes annually. During the last two decades, India has witnessed annual

depletion of forest cover at a rate of 235 km2. The consumption of fuelwood and timber in the country

was 23.5 and 40 million m3, respectively against the availability of 40 million m3 and 15 million m3

from the forests.

A study was carried out to: i) assess the status of forests in India, ii) analyse the trends in production and

consumption of forest products and iii) estimate demand and supply of forest products in future.

The results of the study reveal that the area under forests registered a decline over the period. The inter-

state distribution of forest area per capita indicates that Arunachal Pradesh state ranked first with 7.93 ha

2

of forest per person. The trend in relation to production of forest products exhibited a slower growth rate

than its consumption. The forecasts of demand and supply showed a deficit of all forest products except

for wrapping, packaging paper and paper board. Thus, there is a need for an increase in area under forest

of up to one third of total geographical area as recommended by the Indian Forest Policy to meet the

requirement of forest products as well as the protection of ecological assets.

1.1 FORESTRY IN INDIA

Dense forests once covered India. As of 2010, the Food and Agriculture Organization of the United

Nations estimates India's forest cover to be about 68 million hectares, or about 20 percent of the country's

area. In qualitative terms, however, the dense forest in almost all the major Indian states has been

reduced. Forest degradation is a matter of serious concern.

[1]

In 2002, forestry industry contributed 1.7

percent to India's GDP. In 2006, the contribution to GDP dropped to 0.9 percent, largely because of rapid

growth of Indian economy in other sectors and Indian government's decision to reform and reduce import

tariffs to let imports satisfy the growing Indian demand for wood products. India produces a range of

processed forest (wood and non-wood) products ranging from sawnwood, panel products and wood pulp

to bamboo, rattan ware and pine resin. India's paper industry produces over 3 million tonnes annually

from more than 400 mills, which unlike their international counterparts, mostly uses the more sustainable

non-wood fiber as the raw material. Furniture and craft industry is another consumer of wood.

India's wood-based processing industries consumed about 30 million cubic meters of industrial wood in

2002. An additional 270 million cubic meters of small timber and fuelwood was consumed in India.

Some believe the causes for suboptimal wood use include government subsidies on wood raw materials,

poorly crafted regulations, and lack of competitive options for the rural and urban Indian consumer. India

is the world's largest consumer of fuelwood. India's consumption of fuelwood is about five times higher

than what can be sustainably removed from forests. However, a large percentage of this fuelwood is

grown as biomass remaining from agriculture, and is managed outside forests. Fuelwood meets about 40

percent of the energy needs of the country. Around 80 percent of rural people and 48 percent of urban

people use fuelwood. Unless India makes major, rapid and sustained effort to expand electricity

generation and power plants, the rural and urban poor in India will continue to meet their energy needs

through unsustainable destruction of forests and fuel wood consumption.

India's dependence of fuelwood and forestry products as a primary energy source not only is

environmentally unsustainable, it is claimed to be the primary cause of India's near-permanent haze and

air pollution. Forestry in India is more than just about wood and fuel. India has a thriving non-wood

3

forest products industry, which produces latex, gums, resins, essential oils, flavours, fragrances and

aroma chemicals, incense sticks, handicrafts, thatching materials and medicinal plants. About 60 percent

of non-wood forest products production is consumed locally. About 50 percent of the total revenue from

the forestry industry in India is in non-wood forest products category. In 2002, non-wood forest products

were a source of significant supplemental income to over 100 million people in India, mostly rural.

1.2 RECENT DEVELOPMENTS IN INDIAN FORESTRY

Over the last 20 years, India has reversed the deforestation trend. Specialists of the United Nations report

India's forest as well as woodland cover has increased. A 2010 study by the Food and Agriculture

4

Organization ranks India amongst the 10 countries with the largest forest area coverage in the world (the

other nine being Russian Federation, Brazil, Canada, United States of America, China, Democratic

Republic of the Congo, Australia, Indonesia and Sudan).

[5]

India is also one the top 10 countries with the

largest primary forest coverage in the world, according to this study.

From 1990 to 2000, FAO finds India was the fifth largest gainer in forest coverage in the world; while

from 2000 to 2010, FAO considers India as the third largest gainer in forest coverage.

[5]

Some 500,000 square kilometres, about 17 percent of India's land area, were regarded as Forest Area in

the early 1990s. In FY 1987, however, actual forest cover was 640,000 square kilometres. Some claim,

that because more than 50 percent of this land was barren or bushland, the area under productive forest

was actually less than 350,000 square kilometres, or approximately 10 percent of the country's land area.

India's 0.6 percent average annual rate of deforestation for agricultural and non-lumbering land uses in

the decade beginning in 1981 was one of the lowest in the world and on a par with Brazil.

1.3 DISTRIBUTION OF FORESTS IN INDIA

India is a large and diverse country. Its land area includes regions with some of the world's highest

rainfall to very dry deserts, coast line to alpine regions, river deltas to tropical islands. The variety and

distribution of forest vegetation is large: there are 600 species of hardwoods, including sal (Shorea

robusta). India is one of the 12 mega biodiverse regions of the world.

Indian forests types include tropical evergreens, tropical deciduous, swamps, mangroves, sub-tropical,

montane, scrub, sub-alpine and alpine forests. These forests support a variety of ecosystems with diverse

flora and fauna.

1.4 FOREST PRODUCE

Forest Produce is defined under section 2(4) of the Indian Forest Act, 1927. Its legal definition includes

timber, charcoal, caoutchouc, catechu, wood-oil, resin, natural varnish, bark, lac, myrobalans, mahua

flowers (whether found inside or brought from a forest or not), trees and leaves, flowers and fruit, plants

(including grass, creepers, reeds and moss), wild animals, skins, tusks, horns, bones, cocoons, silk,

honey, wax, other parts or produce of animals, and also includes peat, surface soil, rocks and minerals

etc. when found inside or brought from a forest, among other things.

5

Forest produce can be divided into several categories. From the point of view of usage, forest produce

can be categorized into three types: Timber, Non Timber and Minor Minerals. Nontimber Forest Products

[NTFPs] is also known as Minor Forest Produce [MFP] or Non Wood Forest Produce [NWFP]. The

NTFP can be further categorized into Medicinal and Aromatic Plants [MAP], oil seeds, fiber & floss,

resins, edible plants, bamboo, reeds and grasses.

Timber

OFDC trade timber both in round as well as in sawn forms in different dimension from their specified

depots. Once in every month there is auction of round timbers from its each depot through general

auction.

Kendu Leaves

Orissa is the third largest producer of Kendu leaf in India. The uniqueness of kendu leaf in Orissa is

because of its specification of Color, Texture, Size and Body condition of the leaf.

Bamboo

The collection and marketing of Bamboo from the natural forest is done either by OFDC or through the

RMP (Raw Material Procurer) as per the decision of the Government to regulate the collection and trade

of Bamboo.

Sal Seed

Sal seed is a nationalized product since 1973 and is one of the important Produce obtained from Sal

(Shorea Robursta) tree, which is predominantly available in Orissa.

Honey

OFDC is involved in collection, processing and trading of honey from natural forest with an assurance of

pure and genuine in quality.

Medicinal Plants

With the financial aid of National Medicinal Plants Board, Government of India, 16 projects for

promotional activities are currently running in Orissa.

6

NTFP

Non Timber Forest Products (NTFP) refers to all biological materials other than timber extracted from

natural forests for human and animal use.

Rubber

OFDC is having rubber plantation and processing unit in Baripada & Bhubaneswar zone, since 2003.

OFDC is extracting the rubber from the matured trees and marketing it.

Pickle & Squash

OFDC is manufacturing and marketing high quality, delicious pickles such as Mango Pickle, Mixed

Pickle free from preservatives.

Plywood

The plywood industry at kuikeda near Saintala of Bolangir District was incorporated during 1983 and

started commercial production during the year 1986-87.This unit continued its operation up to 1992-93.

Cashew & Spice

OFDC Ltd. have raised cashew plantation over an area of 18704.99 ha. from 1978-79 to 1992-93 in

Bhubaneswar and Berhampur Division. Out of which pure cashew plantation over an area of 11,053.99

ha.

Biodiesel Plant

Biodiesel is the name of a clean burning alternative fuel, produced from domestic, renewable resources.

Biodiesel contains no petroleum, but it can be blended at any level with petroleum diesel to create a

biodiesel blend.

1.5 FOREST PRODUCTS TRADE AND MARKETING

The forest products industry has vigorously opened up for global trade because the prevailing business

model is built on capturing comparative advantages anywhere they abound at the right cost. Many

emerging countries possess valued forests, aspire for more processing industry and employment, and seek

7

added value to their raw materials. International investors in the forest products industry are their willing

allies but they want to ascertain predictable macroeconomic conditions, transparent fiscal incentives and

abundant labour and preferably the rule of law and a sustainable wood supply to start with. A dynamic

domestic market is nowadays becoming an important factor in attracting foreign investments, and many

emerging economies harbour bustling urban markets short of high-quality forest products.

Increasing trade in forest products has supported economic growth and eradication of poverty in a

number of emerging countries. But trading out of poverty has proven difficult and it has led to further

marginalization and events of misconduct in some countries. Safeguards must be firmly put in place to

ensure that trade is based on legal and sustainable forest use, fair labour conditions and equitable sharing

of benefits. Good governance is essential in setting the rules for sustainable production and trade.

8

CHAPTER 2. FOREST CERTIFICATION AND SUSTAINABLE FOREST

MANAGEMENT

International consensus on better management of forests and forest resources for their sustainability and

enhancement of related social and ecological benefits gave the concept and hence global commitment

towards SFM. Following, to address to the economics and market forces, certification of forests evolved

as a promising tool. Certification of forests or Forest Certification gives the consumers the right to

question the social and environmental accountability of the management practices in the forests hence

contributing towards the cause of certification. Approaches towards SFM encourage applying and

implementing best practices as well as provide trading incentives. Certification is a methodology

providing incentives for trading of forest products, and hence encouraging good practices of forest

management.

SFM for Certification: The standards pre-defined, for performance and hence management practices

of forests, provides a measuring tool for good practices.

Trade incentives: The certified forest products receive a premium in the market hence providing

incentives for management of forests.

2.1 FOREST PRODUCTS TRADE AND MARKETING

The forest products industry has vigorously opened up for global trade because the prevailing

business model is built on capturing comparative advantages anywhere they bound the right cost.

Increasing trade in forest products has supported economic growth and eradication of poverty in a

number of countries.

9

2.2 MARKETS FOR CERTIFIED PRODUCTS

Markets for certified products are strongest in Western Europe and USA, and it continues to grow. For

instance, Price Waterhouse Coopers predicts an increase in US certified forest products market by 100 to

150% per year (Dixon, 1999). These markets are led by buyer groups of forest product retailers and

traders, especially retail home improvement chains. Lowes and Home Depot in USA, and UKs B&Q,

Homebase, Sainsbury and Meyers (members of1995+ Group) are some of the most significant

members of such buyers groups. However, in comparison to American and European markets,

certification has not gained any meaningful market share in principal Asian markets such as Japan, Korea

and China. These countries are among the leading tropical timber importers (ITTO, 2004).

Although certification relies on a market-driven mechanism, with environmentally concerned consumers

sending price signals through the supply chain to the forest industries and forest managers, it is unlikely

that this consumer signal will occur in the absence of a real commitment by retailers and traders

(Kanowski et al., 1999). Therefore,

the role of retailers and traders is likely to play a key role in future development of markets for certified

products.

2.3 THE WTO AND LABELING (FOREST CERTIFICATION)

There is no official WTO position on certification or Labeling, but it is clear that in general the WTO

prefers voluntary labeling requirements above mandatory one. Any certification scheme that affects

trade is by definition a Non-Tariff Measure (NTM) in WTO terms. However, the question remains

whether it is a non-tariff barrier, and if so, whether it is permitted under WTO provisions. If a

certification scheme were to be challenged in the WTO, it would be against a member government

and might allege failure to meet obligations under the following WTO Agreements:

Government Procurement

Technical Barriers to Trade (TBT)

Subsidies and Countervailing measures

Sanitary and Phytosanitary (SPS) measures.

10

The only areas under discussion among WTO members in relation to Labeling and certification in the

lead up to the Cancun Ministerial are the TBT Agreement and the SPS Agreement. For forest

certification, the TBT Agreement is the relevant WTO Agreement (FERN, 2003). Thus, it is because of

the lack of clarity regarding Labeling and certification within the current trade regime, and because of the

push by the EU to promote environmental issues at the WTO, the last WTO Ministerial in Doha put

labeling firmly on the agenda of the 5th Ministerial in Cancun.

2.4BARRIERS TO TRADE COMMITTEE, ITS CODE OF GOOD PRACTICE AND LABELING

The Agreement on Technical Barriers to Trade tries to ensure that regulations, standards, testing and

certification procedures do not create unnecessary obstacles to trade. The agreement recognizes a

countrys right to adopt the standards it considers appropriate for example to protect human, animal or

plant life or health, for the protection of the environment, or to meet other consumer interests.

In order to prevent much diversity, the agreement encourages countries to use international standards

where these are appropriate, but it does not require them to change their levels of protection as a result.

The agreement sets out a Code of Good

Practice for the preparation, adoption and application of standards by central government bodies,

which is applicable to WTO members and open to all non-state standardizing bodies. The Code of

Good Practice requirements include: avoiding duplication, making every effort to achieve national

consensus and (wherever appropriate) requiring performance-based standards. Discussions on Labeling

have been held frequently within the TBT Committee. Switzerland, Canada, the EU, Japan and the US

have all submitted papers calling for clarification of the implications of the TBT Agreement for product-

Labeling standards (FERN, 2003). For Canada, the situation is clear; it believes that the TBT rules are

clear and that the TBT or SPS Agreements cover all Labeling requirements. Canada aims to come out

with a non-paper identifying the key elements of the debate in order to contribute to a structured and

productive discussion of labeling concerns. For Japan the situation is less clear. It wants to deepen the

discussion. Its submission states that there is a gap in WTO requirements for those non-governmental

bodies that have not accepted the TBT Code of Good Practice, and therefore do not conform to Article 2

of the TBT Agreement, the Agreement that deals with preparation, adoption and application of technical

regulations by government bodies. According to Japan, all bodies that develop standards should accept

the Code of Good Practice. Furthermore, Japan highlights the TBT provision spelt out in the Code of

Good Practice to specify standards on the basis of performance characteristics, and asks for adoption of

performance-based Labeling requirements (FERN, 2003). It is important to note that in its final report to

11

the Cancun meeting the CTE Committee also stressed the importance of the TBT Agreements Code of

Good Practice. Moreover it was recalled that the TBT Committees decision on the principles for the

development of standards provided useful guidance. These principles include: transparency,

inclusiveness or openness (that all stakeholders be involved in the development of the standard),

impartiality and consensus, effectiveness and relevance, coherence and whenever possible responsiveness

to the needs and interests of developing countries.

2.5 CERTIFICATION OF NTFPs

Certification is the process of evaluating and labelling products against accepted standards of good

management. A new development in the certification movement is the certification of Non Timber Forest

Products (NTFPs). NTFPs may be certified based on standards for fair trade, organic production, and

forest stewardship. A wide variety of organisations have developed standards for certification. One main

objective of these schemes is to ensure NTFPs policies and guidelines for assessment and implementation

of certification. The other objective is to promote the certification of NTFPs by a means to achieve better

forest management. To ensure the objectivity of certification, a reputable independent third party

conducts the evaluation. Once certified, a business may promote their business and products as certified,

which is often done by using the distinctive logo of the standards setting organisation. Certification of

NTFPs has been possible under variety of schemes. The more important is FSC system doing well for a

couple of years and its accredited certifiers are carrying out assessments on NTFP operations worldwide.

The most active certifiers in this regard has been SmartWood (www.smartwood.org), based in the United

States, which has developed an NTFP certification addendum to their regular forest management

standards. These standards have been used as the basis for developing product specific standards. While

certification of NTFPs require adherence to the complete set of management standards, and also include a

number of specific references to NTFPs. These include:

The need for development of NTFP management standards to be included in any joint forest

management.

The forest is managed to produce a variety of non-timber forest products compatible with site

conditions and local economic objectives for strengthening the local economy.

Where the manager harvests or has the ability to control the harvest of NTFPs, the rate of harvest

reflects best available inventory and productivity data and provides for sustainable production.

12

Further, the certification programmes associated with NTFPs is also the most expensive certification

programme to implement. In addition, these systems are difficult to apply to informal community-based

NTFP operations that constitute the vast majority of NTFP harvesting. In this regard, this, FSC

certification is probably still most appropriate for large-scale industrial NTFP operations or for operations

where timber extraction is the primary focus of the forest management plan.

India is home to an amazing diversity of plants, with over 46 000 plant species recorded to occur there.

Many of these species are used for medicinal purposes, with approximately 760 known to be harvested

from the wild for use by India's large herbal medicine industry. There is concern, however, that collection

methods for many, if not most, of these species are destructive and wild populations declining as a result.

Despite various regulations aimed at protecting plant resources, the destructive and unsustainable

collection, use and trade of Medicinal and Aromatic Plants (MAPs) pose a major threat to several

important medicinal plant species in the country. In this regards, it is imperative to look for alternative

approach to securing the sustainable use of countrys medicinal plant resources. The use of forest

certification as a tool to promote sustainable harvest and trade in medicinal plants could be one

alternative approach for sustainable MAP resource availability (Jain, 2004). Many medicinal plant

species in India occur in forest areas and along with other non-timber forest products (NTFP), fall within

the scope of certification schemes aimed at "sustainable forest management". Other prominent types of

certification scheme relevant to medicinal plants relate to ensuring organic, fair trade and quality

standards and could be applied both to raw materials and production methods. While some independent

certification exist for fair trade and organic standards for medicinal plants in India, but these are largely

restricted to teas and other plant products more usually associated with the mainstream food and beverage

industry. The schemes exploring certification options for sustainable forest management were found to be

underway in India. However, no independent, third-party process for certifying the sustainability of

medicinal plant production exists in India. A review of the wider certification climate in India provides

important lessons for the future application of certification to medicinal plants and other NTFP. Some

independent certification schemes are taking root in India, notably in the context of "fair trade",

particularly with regard to certain exported items, such as tea, and rugs. FLO has certified 23 companies

in India as operating in accordance with its Fair Trade Standards and IFAT has several member

companies in India. Similarly, IFOAM has 29 members and eight associates in India certifying

production according to organic standards. As in the case of "fair trade", organic certification appears to

be geared primarily toward export markets. (Jain, 2004). Assessments of current practices for medicinal

plant harvests and trade, which derive from a long tradition within India, indicate that, even if the market

conditions were ripe for third party certification, the complex, informal and often opportunistic nature of

13

the trade would not be conducive to it. Comparison of practices for collection and trade of medicinal

plants in India with NTFP management requirements according to Criteria of internationally recognized

schemes have a wide gap between current management approaches, harvest and trade. Several

government certification schemes focusing on product quality, environmentally friendly and organic

production exist in India with over 1100 products certified for product quality standards by the Bureau of

Indian Standards and 16000 licenses issued to companies meeting these standards.

Certification for quality management and environmental management according to ISO has also been

adopted. The Bureau of Indian Standards has adopted the ISO 14000 series as national standards for

environmental management as voluntary environmental standards. In 1991, the Government launched the

'Eco-mark' scheme aimed at certifying and awarding a special product label to goods meeting specific

environmental standards. But participation of the companies and recognition by the consumers for this

environmental initiative has been very less.

14

CHAPTER 3. NATIONAL FOREST PRODUCTS STATISTICS

The importance of Forestry Statistics in India was realised in a meeting of The Board of Forestry at

Dehradun in 1925 where it was decided that all provinces would conduct an economic survey of Forest

Resources. Formats for collection of information were designed and circulated and the resulting

information was sent to the Forest Research Institute (FRI) in Dehradun for compilation of an all India

view. Until 1946/47, The British India Government collected only limited forestry information, however,

after independence coverage was gradually extended to include forests located in the former princely

states.

In 1958/59, the Directorate of Economics and Statistics (DES) in the Ministry of Agriculture and

Irrigation standardised state forestry statistics collection formats and began compiling national level data.

However, the accuracy of data and the timeliness of its collection and compilation were limited by

inadequate mechanisms and checking and analysis was minimal. To overcome these difficulties it was

felt necessary to form a central body to collect and compile forestry information.

In 1965, a Central Forestry Commission (CFC) was set up in the Ministry of Agriculture with the

objective of collecting, compiling and publishing standardised forestry statistics. In 1967 the CFC revised

the standard DES formats and, following comments from the states and other experts in the field, began

collecting standardised statistics. There was, however, still insufficient organisation for prompt

collection, compilation and analysis.

Following creation of the Ministry of Environment and Forests (MOEF), the CFC was reconstituted into

separate Statistics and Utilisation Divisions. During this period the FRI collected basic timber price

information through its Forest Utilisation wing, and also compiled limited forestry statistics, published

through the MOEF as Indias Forests. These activities were discontinued, however, after the post of

Forest Utilisation Officer in FRI was abolished.

Previously, data on different aspects of forestry were collected and stored by different agencies in India

but were not held in any single place which created difficulties in projecting a complete picture of

forestry and ecosystem management in India. To centralise information, the Indian Council of Forestry

Research and Education (ICFRE) organised a directorate of statistics in January 1995, under the Forestry

Research, Extension and Education Project (FREEP). The role of this directorate, now called the Division

of Statistics, is to collect, collate, process, publish and circulate covering all aspects of forestry at the

national level.

15

3.1 CURRENT FOREST PRODUCTS STATISTICAL SYSTEM

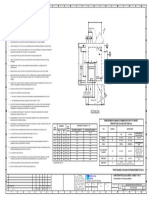

The Division of Statistics gathers data on production and trade of forest products from State Forest

Departments, IAPMA, FIPPI and the Ministry of Commerce (Figure 1). In addition to production and

trade data information is also received from the Planning Commission and MOEF, the Forest Survey of

India and the Central Statistical Organisation. At present data is received either in hard copy or

electronically via e-mail.

Data collected through State Forest Departments

Forest products information is collated by the State Forest Departments using standard formats reviewed

at the FORSTAT96 national workshop organised by the Directorate of Statistics in February 1996 at

ICFRE, Dehradun. Data from forest ranges, the lowest data collection unit, are determined through a

chain of custody system (Box 1). Information from different field offices is compiled at division level

and transmitted annually to the State Forest Department Head Quarters, where statewide statistics are

collated and consolidated. The State Forest Departments send data in standard format to ICFRE where,

after analysis and discussion with State Forest Departments, it is compiled using Microsoft Excel by the

Division of Statistics. The validity of data is checked at state level with the help of ICFRE institutions.

Figure 1. Inflow of information and data for production and trade of forest products

16

Box 1. System for Determination of Timber Production.

Production figures from State Forests Departments are collected through the following

system: (i) timber removals are based on marking book records which incorporate species

name and girth over bark at breast height; (ii) all removals are recorded in a felling register

which bears the total volume and number of pieces from each stump; (iii) transport of

removals is recorded in a transit pass register and in triplicate on transit passes; (iv)

removals are taken to Govt. depots/go downs where a copy of the transit pass is deposited

and receipt indicated on a duplicate copy; (v) in Govt. depot/go downs all incoming

material is measured piecewise and recorded in a depot/go down register; (iv) annual

arrivals at, and disposals from, depot/go downs is reported to Division/state level

authorities annually by the end of June.

Information on different aspects of national forestry is summarised and published in Forestry Statistics

India in the form of tables. To date, editions have covered 1988-94, 1995, 1996 and 2000. Forest

products information covered in Chapter 11 includes paper production (MT), plywood production by

state (m

2

), annual sawnwood production by state and saw mill (m

3

), as well as a survey of wood product

manufacturing units and information on paper industries and their raw material sources. Chapter 12

covers state wise annual production of timber (m

3

), poles, pulp and matchwood (m

3

), fuelwood (MT), sal

seeds (MT), tendu leaves (standard bags/MT), gums and resins (MT), cane and rattan (MT), bamboo

(no.), grass and fodder, drugs, spices, tannins and other NTFPs (MT).

In most states channels of information flow are not well organised and hence information flow is too

slow. As Government Forests are controlled at the state level, national agencies can only collect data with

the cooperation of State Forest Departments. Efforts are currently being made to improve the efficiency

of forestry data flow between the state and national levels. To outline the flow of information on

production and trade of forest products in India, the structure and situation in Madhya Pradesh State is

used as an example.

3.2 REVIEW OF TRADE DATA

Comparisons were made between 1990-2000 FAOSTAT forest products import and export data and

figures in the Monthly Statistics of Foreign Trade publication produced by the Directorate of Commercial

Intelligence and Statistics, Ministry of Commerce (MoC).

17

Import data

Industrial roundwood. Differences were found between FAOSTAT and MoC figures although

there was no clear trend. MoC figures are lower for 1990, 1991, 1992 and 2000 and higher

for1993 and 1999.

Fuelwood. Figures are not available in FAOSTAT for 1992 and 1998. For the years in which

comparisons could be made, MoC fuelwood import figures are lower than FAOSTAT figures.

Wood charcoal. Figures are available in FAOSTAT for 1992 and 2000 whereas MoC figures are

available for 1993 and 2000. For 2000 the MoC figure is lower.

Sawlogs and veneer logs (C and NC). Figures are not available in FAOSTAT and MoC figures

are only available for 1993.

Plywood. MoC figures not available.

Veneer sheets. FAOSTAT contains no data for 1990, 1991 and MoC figures are not available for

1994 to 1998. For 1993 and 1999 MoC figures are higher than those in FAOSTAT.

Hardboard. MoC figures not available

Fibre board and particle board. MoC figures are generally lower than those in FAOSTAT.

Export data

Forest products. Figures are available in the FAOSTAT database for 1990-2000. Country figures

are disaggregated amongst different Forest Products groups, which are under different sections of

the World Customs Organisations harmonised system of nomenclature. Therefore comparison

was not possible.

Industrial roundwood. FAOSTAT figures are only available for 1991, 1992, 1999 and 2000 in

which years MoC figures are generally higher.

Wood fuel. FAO figures are available for 1992, 1995 and 1996 whereas MoC figures are

available for 1991 and 1992 only. For 1992, the MoC figure is lower.

Wood charcoal. For the nine years where data was available for comparison, figures from

FAOSTAT are higher in all except for 1993.

18

Sawlogs and veneer logs (C and NC). Comparisons could not be made, as figures are not

available in FAOSTAT.

Plywood. FAO figures are higher than the MoC figures prior to 1993 and lower thereafter.

Veneer sheets. FAO figures are higher than MoC figures throughout the comparison period.

Fibre board. FAO export figures are rather low in comparison with the MoC figures.

Particle board. FAO figures are higher for 1990, 1991 and 1992 but considerably lower in the

latter part of the decade.

3.3 PRODUCTION AND CONSUMPTION OF FOREST PRODUCTS

3.3.1 PRODUCTION OF FOREST PRODUCTS IN INDIA

The production of fuel wood and charcoal witnessed increase at rate of 1.98 percent per annum.

The production of wood-based panels more than doubled in 1981-2010.

3.3.2 CONSUMPTION OF FOREST PRODUCTS IN INDIA

Forest products consumption in India experienced a considerable growth in last two decades. The

substantial increase in consumption of industrial roundwood indicating 47 percent in period 1981-

2000.

Fuel wood and sawnwood consumption grew at growth rate of 2.18 and 6.46 percent for the period

1970-2000, respectively.

The consumption of paper and paper wood, wrapping, packaging paper and paperboard increase

substantially over the period.

The comparison of actual production and consumption over two periods shows that growth in

consumption of most of forest products is higher than production growth creating demand -supply

imbalances

19

3.4 IMPORT AND EXPORT OF FOREST PRODUCTS

20

Comparison With Neighboring Country

21

3.5 MINOR FOREST PRODUCTS

Indian forests also supply minor forest products such as canes (rattans), gums, resins, rubber, dyes,

tannins, fibres, medicines, katha, insecticides, camphor, essential oils (e.g., rosha grasses, khas and

sandal woods), cooking oils and spices. Tendu (kendu) leaves are used as wrappers for bidis, soap-

substitutes such as ritha and shikakai, sola pith and ornamental seeds rudraksha are important

commercial products of the forests. Lac, honey, wax, tusser or moga silk are obtained from forest

22

insects. Feathers, horns, hides and ivory are also other significant forest product (obtained from forest

wild life).

For tribal people forests also provide food (tuber, roots, leaves, fruits, meat from birds and other

animals).

Export Prospects of Minor Forest Products

A new scheme called Vishesh Krishi Upaj Yojana announced under the new Foreign Trade Policy

by the Ministry of Commerce & Industry, Government of India, provides a host of incentives to boost

exports of minor forest produce and their value-added products.

USA continues to be the largest market for Indian minor forest products. However, in 2006-07,

exports to it showed a marginal decline of 0.60 per cent over the previous year when the same

dropped to Rs 681.89 crore as against Rs 686.00 crore.

How To Meet The Challenge Of Increasing Demands

The use of firewood should be discouraged to reduce pressure on more valuable natural forests. Other

sources of energy such as biogas, solar energy, etc., have to be provided to supplement practices

A ban or freeze of 15 to 20 years should be imposed on commercial tree fallings in fragile areas of

Himalayas and other hilly areas.

Environmentally sound action plans based on scientific research should be adopted.

Environmentally sound action plans based on scientific research should be adopted.

Masses and voluntary agencies should be involved in the task of tree planting.

23

CHAPTER 4. TRADE OF FOREST PRODUCTS

4.1 GLOBAL

Forest-based products are divided into (i) wood and wood-based products and (ii) non wood/ timber

forest products (NWFP or NTFPs). The value of global trade may be estimated at $ 155 billion in 2003 of

which non-wood products could account for about 7% depending on their definition (FAO, 2005). The

figure does not include the value of traded services such as forest-based ecotourism which is a growing

industry and is becoming a significant source of revenue in many countries. Wood-based products are

traded as (a) roundwood (or chips), (b) primary processed products (sawnwood, wood-based panels, pulp

and paper), or (c) further processed value-added products (builders woodwork, wooden furniture,

converted paper and paperboard products, etc.). Not more than 15% of the global roundwood production

enters international trade as the balance is used domestically. The share, however, varies by product and

region and it tends to increase as a function of product unit value. Trade has shown a visible change over

the last few decades with a decline in the exports of roundwood (mainly due to physical supply

limitations, bans and restrictions on exports, etc.) relative to the trade in processed products. World

roundwood production in 2003 reached 3,342 million m

3

, about 1.2 per cent above the level of the

preceding year. The greater part of global wood production is burned as fuel. Of total roundwood

production in 2003, 53 percent was woodfuel and the remaining 47 percent available for industrial

roundwood. The vast majority of wood burning occurs in developing countries, where wood is often the

most important source of energy. On the other hand, the larger part of industrial roundwood production

continues to be accounted for by the developed countries, which provide more than 70 percent of the

total. As most industrial roundwood is consumed and processed domestically, the proportion reaching

international markets is small.

The developing countries accounted for 2,000 million m

3

or 60 percent, of total roundwood production in

2002. Almost 80 percent of roundwood production consists of woodfuel, the production of which has

been stable in recent years.

Total roundwood production in the developed countries, following a significant decline in the early

1990s, is still well below the peak levels of 1989-90. Industrial roundwood

accounts for 87 percent of production, whereas woodfuel is of relatively marginal importance. The value

of international trade in forest products increased rapidly from the mid-1980s to the mid-1990s to reach

$155 billion in 2003. Europe, Asia and North & Central America account for the major share of the value

of world forest product imports. In 2003, imports of forest products reached a maximum value of $76

billion in Europe and $43 billion in Asia, the second-largest importing region. Exports of forest products

24

increased remarkably in Europe in recent years and topped at $83 billion in 2003, accounting for more

than half of the world's total forest product exports. The second-largest exporting region is North and

Central America (FAO, 2005). Europe earns higher trade value both within and outside the region

because many countries manufacture value-added products. The region accounts for 55 percent of world

export value, although its roundwood production rests at only 30 percent of the world total. Countries in

South America, Africa and Oceania mainly trade in raw material, earning 4, 2 and 2 percent, respectively,

of world export value while accounting for 10, 4 and 3 percent of total roundwood production. World

trade volume (exports plus imports) continued improving in 2004 when it surged by 10.3%, up sharply

from 5.4% in 2003 and well above the average growth over the past decade and during the 1980s. Trade

growth slowed in 2005, but still expanded by a solid 7%. World trade growth is projected to accelerate to

7.4% in 2006. Both developed and, particularly, developing countries contributed to the surge in trade

growth in 2004, with both exports and imports expanding. The deceleration in world trade in 2005 was

likewise due to lower trade volumes by both developed and developing countries. Average non-fuel

primary commodity prices (US$) climbed by 18.5% in 2004, due mostly to the depreciation of the US

dollar and buoyant global demand, particularly in China. Average non-fuel primary commodity prices

rose a further 8.6% in 2005. However, the average price of these commodities is projected to contract by

2.1% in 2006 in anticipation of slowing global growth, particularly in China. After remaining almost flat

or declining slightly from the mid-1990s to 2001, average primary commodity prices appear set to

resume a gradual long-term downward trend despite the strong surge in 2003-2005 (ITTO, 2005).

4.2 INDIA

4.2.1 Trade of Wood

Indias roundwood production in 2006 was estimated to about 300 million m

3

, of which 225

million m

3

(85 per cent) is the estimated share of fuelwood and 70-80 million m3

industrial roundwood, including poles and small lumber for rural households (ITTO, 2006). Compared

with 1991, roundwood production in 2001 registered an increase of about 20%. Supply from Indian

natural forests (including temperate hardwood and softwood species) is about 12 million m

3

(about half

of it from tropical forest areas). The estimated share of industrial roundwood for industry coming from

farm forestry and other trees outside forests is 31 million m

3

. Official imports of timber count for just

over 3 million m

3

in 2006, mostly in form of logs. Hence there is a gap between consumption and supply

of timber of about 25 million m

3

. It is possible that a considerable part of this gap is coming from

unregistered sources, such as homegardens and small timber logs and poles. A major player to fill up this

gap is the production of timber from Non-Forest areas, the high potential of which has not been recorded

25

at the National level. The incidents of some theft from forest areas, tantamount to illegal felling, are not

ruled out. A considerable share of demand for industrial roundwood is coming from the pulp and paper

industry. This industry mostly sources its raw material in India, not through imports of pulp. Wood (47%)

and bamboo (24%) count to about 5.9 million m3 roundwood equivalent of the total production of 5.3

million metric tonnes. Eucalypts (47%), Casuarina equisetifolia (26%) and Leucaena leucocephala (20%)

are the main wood species demanded. The main suppliers of the pulp and paper industry are farm forestry

28%, the open market (29%) and government sources (39%). ITC Ltd. Bhadracgalam Unit in Andra

Pradesh for example obtains 83% of its wood from farm forestry, JK paper in Orissa obtains nearly 90%

from farm forestry. India is a net importer of forest products. In 2001, the largest share of import bill

went for logs for feeding the processing units, followed by paper and paperboards. The total value of

imports of primary forest-based products in 2001 was US$ 942 million, compared to US$94 million for

such exports. Logs made up about 42% of the total forest products import bill. The import volume was

about 2.1 million m3 in 2004 and is projected to increase significantly to meet the growing gap between

supply and demand, especially of quality tropical hardwoods. As such, 95% of all wood imports to India

are logs, mainly from tropical countries. With Indonesia and Papua New Guinea no longer in the arena,

Myanmar and Malaysia remain the major countries for tropical log imports. Several African and Latin

American countries are joining the log and other forest product exporters to India, notably Benin, Costa

Rica, Cote d Ivoire, Ecuador, Gabon, Ghana, Nigeria, Tanzania and Togo, and even Cameroon, Guyana

and Panama. Log imports are supported by a favourable tariff regime of 5% compared with 25% for

imported sawnwood and 34.4% for plywood.

4.2.2 Trade of NTFP

India has a rich resource base of NTFP that includes 3,000 species of plants, 1800 medicinal plants, 250

essential oil yielding plants, 100 tans and dye yielding plants and 120 gums and resin yielding plants. The

quantity, price and thus value of both imports and exports of NWFP has increased. The increase is more

in exports than imports and is a good sign for the country. Benefit of such increase will be still more if

these benefits trickle down to the local people. This is very important especially when a large section of

people living near to forests derive economic support form these products. Nearly 60 percent of all the

recorded forest revenue in India comes from NTFP. Most of India's 50 million tribal people receive a

substantial proportion of their cash and in-kind income from NTFP (NTFP are estimated to generate 70

percent of all employment in the Indian forestry sector), while about 200 to 300 million village people

depend on products from forests to varying degrees (Shiva 1995). The forestry sector, with 23 percent of

the country's geographical area, provides 2.3 million person-years of employment. Of this total, 1.6

million person-years are related to NTFP. Most NTFP often provide employment during only part of the

26

year because the processing of NTFP is still poorly developed (Gupta 1994). Therefore production and

trade in NTFPs receives attention in successive forest policy statements because NTFPs are so important

in the forest-dependent rural and tribal economy. The Constitutional Amendments of 1993 provided for

transfer of ownership of NTFPs from the State governments to Gram Sabhas/ Panchayats (village

assemblies) in States having sizeable tribal populations. Many States have specific regulations about

NTFP production and trade. The prime objective of the State Minor Forest Produce (Trade and

Development) Co-operative Federation is to save the tribal people who are engaged in collection of

minor forest products (= NTFPs) from inequitable trading with urban-based middlemen, to ensure fair

wages and benefits, to rationalize marketing of products, to empower the community in managing their

own affairs through appropriate institutional arrangements, and to ensure that the resources are

sustainably managed.

Plant-based medicines for which the knowledge is traditional and inherited in tribal communities ought to

confer intellectual property rights on the producer communities. It is unclear if India has the appropriate

legislation to permit the registration of such knowledge (as prior art), which can be used to advantage

by the communities if the private sector (or government) attempts to domesticate or patent the plant

genomes or their products. The situation is complicated by the long period for which the phytochemical

survey of India has been running well over a century so the traditional knowledge may have been

placed in the public domain before intellectual property rights were deemed to be commercial for

indigenous and traditional people.

4.2.3 Contribution Of Forest Sector To Gross Domestic Product (GDP)

It is a direct measure of contribution of forestry sector to national economy and can be used to estimate

its multiplier effects on other sectors of economy. It provides one of the basis for allocation of resources

in Indian national planning system and thus availability of monetary resources for forest development.

Since it measures unduplicated value-added, the Gross Domestic Product (GDP) may be considered more

useful to measure economic contribution than revenue or employment. Forestrys contribution to GDP

fell from about 2.9% in 1981 to 1.7% in 1991 and around 1.1% in 2005 and 0.9% in 2006 (CSO, 2006).

This figure excludes the contributions of forest-based industries (which are counted under

manufacturing), as well as the vast amount of products such as fuelwood and fodder, the use of which is

unrecorded. The figure also ignores the contribution of environmental services such as water and soil

conservation. About 7.5 million people, mostly in rural and tribal settings, are in forest-related

employment. The declining trend in national income and the absence of reliable estimates of removals

and value of forest products calls for detailed study to find out actual estimates and to identify causes of

decline and revise the estimates if necessary.

27

CHAPTER 5. EXPORT PROSPECTS OF MINOR FOREST PRODUCTS

Minor forest products (MFPs), also known as non-timber forest products, non-wood forest products or

special forest products, are obtained from various species such as fruits, seeds, leaves, barks, roots,

flowers and grasses, including entire plants of medicinal herbs/ shrubs. These products are used by rural

communities as medicine and food. The rural communities earn substantial income, especially during

non-agriculture season, through their collection and sales. In India, the MFPs over the years have been

playing an important role in the viability and survival of tribal households because of the importance of

forests in their social, cultural and economic survival. Women are the primary players in the collection,

processing and marketing of MFPs who gather bulk of forest produce. A major share of MFPs in India

originates from the states of Maharashtra, Madhya Pradesh, Bihar, Orissa and Andhra Pradesh.

India over the years has been exporting a wide range of MFPs. Some of the major ones inter alia include

guargum and guargum-based products, oleoresins of spices, flowers, leaves, a wide variety of lacs and

gums, saps and extracts of plants and leaves, bidi wrappers (tendu leaves), betel leaves, sandalwood

powder and bamboo-based products. Guar gum enjoys preeminent position in the exports of minor forest

products. India exports guar gum in various forms to all parts of the globe. More than 80 per cent of

exports of minor forest products are accounted for by guar gum.

Guar or cluster beans is a legume crop that is grown best in the semi-arid regions in the country. In India,

guar is grown primarily in Rajasthan. It is also grown in Haryana, Punjab, Gujarat and Madhya Pradesh.

While guar is seen as a vegetable in the South, in the North it is primarily seen as a raw material to

28

produce guar gum. Guar gum is used as a thickening agent and additive in food products such as instant

soups, sauces, processed meat products, baked goods, milk and cheese products, yoghurt and ice creams.

It is also used in industrial applications such as paper and textile sectors, explosive manufacture and

fracturing of gas and oil formations. India is one of the major producers of guar seed and gum,

accounting for 80 to 85 per cent of the total global supply.

The Indian Institute of Natural Resins and Gums is a nodal institute at national level for conducting

research and development on all aspects of lac and other natural gums and resins, such as harvesting,

tapping, processing, product development, training, information repository and technology dissemination.

Another government body Shellac Export Promotion Council (set up by the Ministry of Commerce,

Government of India), recently renamed as Shellac and Forest Products Export Promotion Council

(SHEFEXIL), has been looking after export promotion of minor forest products. Besides, to pay specific

attention to the marketing requirements of the tribal forest and agricultural produce, the government of

India has set up another body called the Tribal Cooperative Marketing Development Federation of India

(TRIFED).

5.1 RECENT DEVELOPMENTS

EU notification on guar gum. The government of India, Department of Commerce, has decided that

wide sampling of the entire chain of guar gum needs to be done to find out presence of dioxins and

pentacholorophenol (PCP) in food-grade guar gum exported from India, at the instance of alert cautioned

by the European Commission. The step has been initiated as a sequel to EU notification on presence of

dioxins and pentacholorophenol.

The EU Rapid Alert System for Food and Feed (RTASFF) has informed all member states that in certain

batches of guar gum from India, the contamination levels were very high. At present, there is no system

to establish presence of dioxins in guar gum which was being exported.

Boosting exports of bamboo- based products. Shellac and Forest Products Export Promotion Council

(SHEFEXIL) has recently taken up a project to boost exports of bamboo-based products in Mizoram and

Tripura under the Backward Region Grant Fund (BRGF) scheme of the Government of India. The main

objectives of the project are to raise Indias exports of value-added bamboo items to Rs 15 crore by 2011

from the current Rs 96 lakh, and providing employment to the rural folk. The council would assist in both

product manufacturing and competency development by way of training, providing implements and

facilities for mat weaving. It would also be working for technology support with agencies such as the

Guwahati-based Cane and Bamboo Technology Centre and private players.

29

R&D

project. The Ministry of Commerce, Government of India, has recently approved a project on R&D

proposed by Shellac and Forest Products Export Promotion Council in order to develop high-yielding,

quality seeds for enhancing Indias guar gum exports under the Market Access Initiative Scheme (MAI).

The project is set to increase exports of guar gum in a big way. A strategic objective of R&D project

is to maximise arid land utilisation by bringing them under guar cultivation.

Vishesh Krishi Upaj Yojana. A new scheme called Vishesh Krishi Upaj Yojana announced under the

new Foreign Trade Policy by the Ministry of Commerce & Industry, Gov ernment of India, provides a

host of incentives to boost exports of minor forest produce and their valueadded products. These inter

alia include duty-free import of capital goods under the Export Promotion Capital Goods (EPCG)

scheme and duty credit scrip equivalent to 5 per cent of the f.o.b. value of exports.

The entitlement is freely transferable and can be used for import of a variety of inputs and goods. The

special scheme has been announced to uplift the economic status of tribal population who largely depend

on forest products for their livelihood. Procedural guidelines for the scheme have also been notified and

the exporter has been given the flexibility to obtain duty credit certificates in split form that will make

utilisation of the licences easier.

Minor Forest Produce I nformation Centre. The Shellac and Forest Products Export Promotion Council

(SHEFEXIL) has recently set up a Minor Forest Produce Information Centrea one-step cell for

providing all information related to MFPs to the concerned interests in the trade and industry.

Portal on MFPs. The SHEFEXIL has recently launched its online international businessto- business

marketplace. The portal is a onestop sourcing point for foreign importers and the major players are the

dynamic Indian exporters with proven track record.

National Bamboo Mission. Against the backdrop of tapping tremendous potential of bamboo and

bamboo-based products, the Government of India has recently launched a special scheme to integrate the

production, post-felling management, value addition and market aspects related to bamboo and bamboo-

based products. It targets to cover a total area of 6 million hectares under bamboo cultivation during the

Tenth and the Eleventh Plans.

30

CHAPTER 6. WEAKNESSES AND CONSTRAINS IN THE FOREST PRODUCTS

STATISTICAL SYSTEM

6.1 RELIABILITY OF PRODUCTION AND TRADE DATA

There are several difficulties with ensuring the reliability of data from different sources collates by the

Division of Statistics. These are related not only to the direct providers of information, but also to the

chain of information providers from which they themselves receive data.

With respect to information collected by State Forest Departments from forest ranges and sent to the

Division of Statistics, the mechanisms involved are, at present, inadequate to ensure data accuracy and

timely submission. This is partl y because of the lack of statistical units in some State Forest Departments

and the fact that the involved staff, being already burdened with other work, may be inclined to treat

collation of information from user agencies as a secondary task. The Division of Statistics also faces

difficulties in collating information from state and central agencies as a result of differences between the

data collection formats used by the agencies and those sent by The Division of Statistics. Gaps in

information are therefore inevitable and on occasion there is considerable hesitancy in sharing data for

one reason or another.

Once information is received by the ICFRE Division of Statistics for national publication, it is considered

correct and as such no checking, even by sampling, is carried out. All precautions are taken, however,

during data compilation. Safeguards include scrutiny of data, in consultation with experienced forest

officers at Dehradun and double-checking of information with original forms once data are entered in

Microsoft Excel spreadsheets. In general, there are no great problems in analysing and disseminating

statistical information at the national level and The Division of Statistics at Dehradun discharges this duty

very efficiently.

State/UT Forest Departments do not have staff trained in collection and compilation of statistical

information and, due to a scarcity of funds, are unable to acquire the latest data processing equipment.

They also lack the funding to appoint experienced database and Internet administrators to efficiently

manage and maintain statistical systems and, in fact, very few State/UT Forest Departments are able to

access internet facilities. Without making such facilities available to the State/UT Forest Departments it

is unlikely that it will be possible to obtain accurate and timely forestry information. The main constraints

and weaknesses in forest products statistics collection are summarised in Table 1.

31

Table 1. Matrix of weaknesses and constraints in the current statistical system

Activity Weaknesses Constraints

Data

collection

Information may be inaccurate and

unreliable

Information is reported irregularly

or not at all.

Data formats used at the state and

national levels are not uniform.

There is often indifference to

sharing information.

General lack of staff and also a lack

of staff trained in relevant fields.

Lack of funds.

Responsibility for state level

reporting is not entrusted to the

Directorate of Statistics.

No single agency is responsible for

providing state level information.

Data

compilation

and analysis

Data may go unchecked or

unanalysed

Insufficient staff and electronic

equipment

Lack of a database and of database

administrators

Lack of staff trained in the use of

relevant software.

Lack of trained and experienced

staff at both state and national level.

Dissemination No priority is given to timely

collection and supply of

information by the states.

Difficulties are found in publishing

final reports on time.

Lack of funds.

Lack of an internet administrator.

States HQs have no internet

facilities

Lack of a database at the central

and state levels.

1 erstwhile Directorate of Statistics; the unit of statistics under the Directorate of Education in ICFRE.

32

ADHERENCE OF CUSTOMS STATISTICS TO THE WCO HARMONISED SYSTEM

For the assessments in this report, forest products trade statistics were taken from the March 2011 issue

of Monthly Statistics of Foreign Trade, published by the Directorate of Commercial Intelligence and

Statistics, Department of Commerce. The information contained therein conforms exactly to the World

Customs Organisation harmonised system. This is in accordance with the explanatory notes issued by the

Directorate of Publication, Custom and Central Excise, New Delhi, which includes the Harmonised

Commodity Description and Coding System. The nomenclature and codes followed for export and

import of forest products is covered in chapters 6, 12, 14 and 44 to 49. In this respect, there are no

problems with trade statistics.

33

7. RECOMMENDATIONS TO IMPROVE THE FOREST PRODUCTS

STATISTICAL SYSTEM

To improve the national forest products statistics systems state and national level data collection formats

should be harmonised to facilitate accurate and timely data reporting and compilation.

At the national level, the Division of Statistics maintains a forestry database and equivalent databases

should be set-up in all State Forest Departments. Those that do not have a statistical unit at head quarters

should create such a unit. To ensure that the unit is properly staffed, the staff should comprise one Senior

Statistical Officer, two Statistical Officers and four Research Investigators. The Division of Statistics

should post a Junior Research Fellow (JRF) to each State/UT Forest Department to assist with compiling

and sending information to the National Forest Department HQ on time. The JRFs could also help with

installing information-processing systems.

All State/UT Forest Department Head Quarters should equip their statistical units with Internet facilities

and modern data processing equipment. With such facilities available to all State/UT Forest Departments,

information flow will be much more rapid and State/UT level information could also be made available

on the Internet. A programme to improve facilities in this way would be facilitated by researchers and

funding agencies working together with the Forest Departments.

Other proposed suggestions include:

Statistical correspondents at each State Forest Department Head Quarters should be nominated.

Links should be formed through NIC with districts/divisions.

Districts should send information in standard format directly to ICFRE, either directly by e-mail

or through NIC.

Data from national level agencies should be requested in electronic form.

34

CONCLUSION

Despite overall economic growth, poverty, hunger and malnutrition persists in parts of the world and

among various sectors of population due to uneven distribution of wealth and access to resources. About

100 million forest dwellers and another 275 million people are dependents on forestland for their

livelihood. Forests do and will continue to play an important role in providing products and income for

these peoples. Competing demands for forests to continue to provide for local needs and to meet the

increasing national demands for industrial forest products, which will be stimulated by rising income

levels, may well intensify. The combined effect of economic growth and increasing population size on

demand for fore.

35

BIBLIOGRAPHY

India & World Trade Organization (WTO):

http://commerce.nic.in/trade/international_trade_tig_nama_sectorals_w64.asp

Forestry in India: http://en.wikipedia.org/wiki/Forestry_in_India

Forest produce: http://en.wikipedia.org/wiki/Forest_produce

Forest products trade and marketing: http://www.fao.org/forestry/trade/en/

National forest products statistics, India:

http://www.fao.org/docrep/005/ac778e/AC778E10.htm

Вам также может понравиться

- Jackson V AEGLive - May 10 Transcripts, of Karen Faye-Michael Jackson - Make-up/HairДокумент65 страницJackson V AEGLive - May 10 Transcripts, of Karen Faye-Michael Jackson - Make-up/HairTeamMichael100% (2)

- The RBG Blueprint For Black Power Study Cell GuidebookДокумент8 страницThe RBG Blueprint For Black Power Study Cell GuidebookAra SparkmanОценок пока нет

- TimberДокумент93 страницыTimberHarshita MittalОценок пока нет

- Offshore Financial CentreДокумент39 страницOffshore Financial CentreAustin OliverОценок пока нет

- (En) PDFДокумент95 страниц(En) PDFNguyen Hien100% (1)

- Selected Current Issues in The Forest Sector: P Ii SДокумент18 страницSelected Current Issues in The Forest Sector: P Ii SrajeshdhomaneОценок пока нет

- Current & Future Uses With Hunting As A Focus Current & Future Uses With Hunting As A FocusДокумент16 страницCurrent & Future Uses With Hunting As A Focus Current & Future Uses With Hunting As A FocushuntmstrОценок пока нет

- Assistant Cook Learner Manual EnglishДокумент152 страницыAssistant Cook Learner Manual EnglishSang Putu Arsana67% (3)

- Building Services Planning Manual-2007Документ122 страницыBuilding Services Planning Manual-2007razanmrm90% (10)

- Supply Chain Mapping For The Forest Products Industry - HaartvДокумент30 страницSupply Chain Mapping For The Forest Products Industry - HaartvTharun SebastianОценок пока нет

- Forestry in PakistanДокумент6 страницForestry in Pakistanmurtazee0% (1)

- Industry Snapshot PDF - Wood ProductsДокумент8 страницIndustry Snapshot PDF - Wood ProductsAnonymous IG9ScKОценок пока нет

- Timber ConversionДокумент15 страницTimber ConversionAsitha Rathnayake100% (1)

- Engineered TIMBER PRODUCTSДокумент9 страницEngineered TIMBER PRODUCTSAr Ayoushika Abrol0% (1)

- Market Outlook Russ TaylorДокумент37 страницMarket Outlook Russ TaylorjibranqqОценок пока нет

- Vietnam Wood Processing Industry - Ho Chi Minh City - Vietnam - 06-11-2020Документ8 страницVietnam Wood Processing Industry - Ho Chi Minh City - Vietnam - 06-11-2020Ngọc ĐoànОценок пока нет

- Tackling Illegal Logging and The Related TradeДокумент72 страницыTackling Illegal Logging and The Related TradeSal McGaundieОценок пока нет

- Forest ProductsДокумент30 страницForest ProductsRudy LangiОценок пока нет

- Timber or Lumber: University of Rizal System Morong, RizalДокумент6 страницTimber or Lumber: University of Rizal System Morong, RizalariannecqnОценок пока нет

- Wood Market UpdateДокумент14 страницWood Market UpdateKim BerlyОценок пока нет

- Chapter (4) Wood ProductsДокумент35 страницChapter (4) Wood ProductsMin Htet MyintОценок пока нет

- Some Market Trends of Wood Products Exports in Ghana and Their Implications For Stakeholders PDFДокумент8 страницSome Market Trends of Wood Products Exports in Ghana and Their Implications For Stakeholders PDFRichard Nkosuo AcquahОценок пока нет

- World: Wood-Based Panels - Market Report. Analysis and Forecast To 2020Документ7 страницWorld: Wood-Based Panels - Market Report. Analysis and Forecast To 2020IndexBox MarketingОценок пока нет

- Sources of Hindu LawДокумент9 страницSources of Hindu LawKrishnaKousikiОценок пока нет

- Special Woods and Wood AlternativesДокумент61 страницаSpecial Woods and Wood AlternativesnadiajmiОценок пока нет

- Meno's Paradox of Inquiry and Socrates' Theory of RecollectionДокумент10 страницMeno's Paradox of Inquiry and Socrates' Theory of RecollectionPhilip DarbyОценок пока нет

- BT5 - WoodsДокумент34 страницыBT5 - WoodsHatdugОценок пока нет

- 03 Properties of Wood and Structural Wood ProductsДокумент62 страницы03 Properties of Wood and Structural Wood ProductswalaywanОценок пока нет

- Forest ConservationДокумент33 страницыForest ConservationJay GrijaldoОценок пока нет

- Agroforestry Production For Energy Production in RwandaДокумент11 страницAgroforestry Production For Energy Production in RwandaRaymond KatabaziОценок пока нет

- Kaizen CostingДокумент21 страницаKaizen CostingAustin OliverОценок пока нет

- Veneers and LaminatesДокумент31 страницаVeneers and LaminatesVijaya Ratna MОценок пока нет

- Wood Products TreatmentДокумент24 страницыWood Products TreatmentTegha Lucas100% (1)

- Forest Resource ManagementДокумент7 страницForest Resource ManagementYusufОценок пока нет

- National Forest Policy Review - Sri LankaДокумент20 страницNational Forest Policy Review - Sri LankaSaravorn75% (4)

- MDF (Medium Density Fibreboard) Made by A Process Which Glues WoodДокумент3 страницыMDF (Medium Density Fibreboard) Made by A Process Which Glues WoodJensenОценок пока нет

- Seasoning of TimberДокумент21 страницаSeasoning of TimberJyoti Bansal100% (1)

- Competitive Exams: Forestry: ExamraceДокумент4 страницыCompetitive Exams: Forestry: ExamraceprasanthakumarОценок пока нет

- Defects in TimberДокумент17 страницDefects in TimberAasim AzmiОценок пока нет

- Wood PropertiesДокумент14 страницWood PropertieskelisianoОценок пока нет

- Forest & Wildlife ResourcesДокумент26 страницForest & Wildlife ResourcesAjith SubbuОценок пока нет

- Forest: Our Lifeline: by Abishek ThiyagarajanДокумент10 страницForest: Our Lifeline: by Abishek ThiyagarajanAbishek ThiyagarajanОценок пока нет

- Gir Forest National ParkДокумент10 страницGir Forest National ParkJatinChadhaОценок пока нет

- of Fast Growing Trees of The Region (Name - Rity Mehta, Roll 2003073) 12Документ7 страницof Fast Growing Trees of The Region (Name - Rity Mehta, Roll 2003073) 12anuj raj100% (1)

- Draft National Forest Policy 2018Документ11 страницDraft National Forest Policy 2018Byron heartОценок пока нет

- Tree TransplantingДокумент26 страницTree Transplantingnarendra chandewarОценок пока нет

- Innovations in Forestry FieldДокумент55 страницInnovations in Forestry FieldFitzgerald BillyОценок пока нет

- CONSERVATION OF PLANTS AND ANIMALS - NotesДокумент3 страницыCONSERVATION OF PLANTS AND ANIMALS - NotesNiraj SethiОценок пока нет

- Particle BoardДокумент4 страницыParticle BoardAssassin's j :uОценок пока нет

- Tashi Doma - Project ReportДокумент5 страницTashi Doma - Project ReportNivesh GurungОценок пока нет

- Melina (Gmelina Arborea) in Central AmericaДокумент22 страницыMelina (Gmelina Arborea) in Central AmericaEuclides Fornaris GómezОценок пока нет

- Hands On Training (Forest Based Industries)Документ11 страницHands On Training (Forest Based Industries)Samuel DavisОценок пока нет

- Community Forest 1Документ20 страницCommunity Forest 1Ananta ChaliseОценок пока нет

- Analyzing The Supply Potential and Demand For WoodДокумент9 страницAnalyzing The Supply Potential and Demand For Woodsiraj likiОценок пока нет

- Introduction of ForestryДокумент4 страницыIntroduction of ForestryDeepak SharmaОценок пока нет

- Carbon Sinks and Green House GasesДокумент30 страницCarbon Sinks and Green House Gasestalal_ali61Оценок пока нет

- Market Sorvey On PlywoodДокумент19 страницMarket Sorvey On PlywoodEduardo MafraОценок пока нет

- Improved WoodДокумент17 страницImproved WoodPavo33% (3)

- Urban Forestry by Nimra KhalilДокумент19 страницUrban Forestry by Nimra KhalilTOOBA KHALILОценок пока нет

- 730Документ8 страниц730ajaОценок пока нет

- Utilization NotesДокумент78 страницUtilization Notesvallala mohan50% (2)

- Tropical Natural Fibres and Their Properties: 2.1 BackgroundДокумент25 страницTropical Natural Fibres and Their Properties: 2.1 BackgroundbatazivoОценок пока нет

- Characteristics & Properties of WoodДокумент16 страницCharacteristics & Properties of WoodM Shahid100% (1)

- Brochure On Bamboo - RVSDДокумент2 страницыBrochure On Bamboo - RVSDFrank Mwarimbo100% (1)

- C. FY14 JGI Workshop Participatory Forest MGT Kigoma Uvinza Mpanda Nsimbo - 2014.08.02Документ14 страницC. FY14 JGI Workshop Participatory Forest MGT Kigoma Uvinza Mpanda Nsimbo - 2014.08.02Bilali SefuОценок пока нет

- Vegetaion of RajasthanДокумент4 страницыVegetaion of Rajasthanpoonam bhardwajОценок пока нет

- Forest Cover Measurement MethodsДокумент6 страницForest Cover Measurement Methodsshoaibansari641Оценок пока нет

- Banking Sector Reforms in India Some ReflectionsДокумент14 страницBanking Sector Reforms in India Some ReflectionsAustin OliverОценок пока нет