Академический Документы

Профессиональный Документы

Культура Документы

3M - Scotchcast - LV Hazard Area-Brochure

Загружено:

Muhammad AlshafiОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

3M - Scotchcast - LV Hazard Area-Brochure

Загружено:

Muhammad AlshafiАвторское право:

Доступные форматы

3M Electrical Markets Division

3M

Scotchcast

Hazardous Area Cable Joints

Speed

Safety

Reliability

3M

Scotchcast

Hazardous Area LV Cable Joints

Speed

Safety

Reliability

3M

Electrical Markets Division

The success of 3M

is founded on listening to the customers

needs and applying technology to offer a solution. With

hundreds of technology platforms 3M has an ongoing

commitment to research and development.

Within the Electrical Markets Division this method of working

has not only led to the development of the rst ever vinyl

insulation tape, but also the conception of many resin

jointing techniques as we know them today through the

introduction of 3M

Scotchcast

Resin Bags & Joints more

than 35 years ago. Our commitment to innovation in this

area has now led to the development of a new generation

of LV resin jointing products that are unique in the electrical

contracting sector. These products are designed to make

the installation process simpler and safer; saving time and

money for the contractor while maintaining the level of

quality and reliability our customers have come to expect

from 3M. We strive to be the chosen supplier not only

because of our innovative and efcient products, but also

our commitment to service and support for your business.

3M

Hazardous Area Cable Joint

Our design is based around a high quality BS EN 50393

compliant product, conventional re-insulation techniques

using self amalgamating tapes, and specialist resin

encapsulation.

Once the joint has been completed electrically it is

surrounded within a specialised joint shell which is ame

retardant, hydrocarbon resistant, and halogen free. The joint

is then lled with a polyurethane resin (3M ref 1402FR)

which has been highly modied by the inclusion of various

chemical additives. These additives make the resin

ame retardant, halogen free, and virtually unaffected by

immersion in either hydro-carbons or chemical solvents.

3M have been supplying cable accessories and resin for

use in hazardous areas for in excess of 25 years and have

carried out extensive research into the effects of hydro-

carbons and chemical solvents on resin encapsulants.

Earthing Method

To avoid awkward manipulation of armour

wires while trying to t worm drive clips

over support rings, we have chosen to use

constant force springs as our preferred

earthing method - a quick and easy solution

requiring the minimum of fuss and no extra

tooling.

3M

1402FR high quality, highly

modied polyurethane resin

Resin is fully compliant with the

latest European legislation

(Reach & RoHS)

Kit Type Resin Resin Mould Power Instrumentation and control

Hazard Area #1402FR Translucent

Hazardous Area Range

Designed for specialist applications where hydrocarbons are present.

Hydrocarbon Resistant Resin

Due to their chemical formulation, Cold Pour Electrical resins can decay in the presence

of hydro-carbons or chemical solvents.

The polymer chain backbone of the resin is attacked and, once broken by hydro-

carbon or chemical solvents, the resin will revert back to its original liquid components.

Our test results show how different resin types are affected when immersed in either

petrol/diesel or a highly aggressive combination of chemical solvents.

Rapid deterioration is most clearly pronounced in low cost, standard PUR resin. Epoxy

resins offer better performance over these low cost resins, but can also be adversely

affected when exposed to some of the test liquids.

3M 1402FR high quality, highly modied polyurethane resin, demonstrates superior

performance above all the other resin types. It is for this reason that 1402FR resin is

supplied in the range of 3M hazardous area cable joints covering instrumentation, control

cables and power cables rated up to 3.3kV.

Joint shell and Resin is

ame retardant;

hydrocarbon resistant and

halogen free

3M

Scotchcast

LV Resin Bags

Our innovative new resin bag is designed to eliminate almost any chance of skin contact and reduce vapour inhalation from the resin itself.

Furthermore, it gives the user superb control over the resin mixing and pouring process; avoiding unnecessary spills and wastage.

Our Resin Range

It is the quality of our resins for which we are best known and the foundation on which many of our customers keep choosing 3M time and time

again. When it comes to peace of mind and condence in a job well done then second best just isnt enough. Alongside the development of a new

resin delivery system, we have also re-developed our resin compounds to comply with EU environmental and user safety regulation changes.

3

3M Electrical Markets Division

3M United Kingdom plc

3M Centre,

Cain Road, Bracknell,

Berkshire RG12 8HT

3M Ireland Limited

The Iveagh Building

The Park

Carrickmines

Dublin 18

For more information on 3M

Electrical Products

please call our information line

(0870) 609 4639 UK

(1800) 812 732 Ireland

or email 3Melectrouk@mmm.com

Quote Ref: LVHA

www.3M.co.uk/electrical

How the new resin bags work

30 seconds

2 minutes

Open the foil outer pack

Ensure all resin is freed

from the corners

Pull apart the partition seal

Mix thoroughly again

Mix the 2 resins thoroughly

Activate nozzle and pour resin

2-part resin bag

Activation nozzle

# 1402FR

Hydrocarbon

Resistant

Type Polyetherurethane

Form 2 Part

Density (g/cm) 1.6

Viscosity at 23C (Pas) 2.5

Hardness (Shore D) 75

Elongation at break (%) 2

Pot life at 23C (min) 20

Dielectric strength (kV/mm) 20

Exotherme Reaction (C) - Temp 40C 65

Helping Contractors Make the Change

Product Training and Demonstration

We take training seriously and have a long track record of

working closely with our customers to give them the best 3M

product training possible. Of course, the design of our products

helps to ensure consistently high installation quality. We

recognise that the right installation techniques mean that work is

carried out more accurately, safely and quickly. Most importantly,

training helps joints and terminations to last longer with reduced

failure risk, giving you a better return on your investment.

Product

Demonstrations

Fully demonstrate and

install 3M products into

pre-prepared cables

3M product installation

training and cable

preparation requirements

We can recommend

the correct company for

training

Product

Installation

Training

Utility Approved

Product

Installation

Training

P

l

e

a

s

e

r

e

c

y

c

l

e

.

P

r

i

n

t

e

d

i

n

t

h

e

U

n

i

t

e

d

K

i

n

g

d

o

m

.

3

M

2

0

1

1

.

A

l

l

r

i

g

h

t

s

r

e

s

e

r

v

e

d

.

Вам также может понравиться

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Special Penal LawsДокумент14 страницSpecial Penal LawsBrenna ColinaОценок пока нет

- 240 Marilag v. MartinezДокумент21 страница240 Marilag v. Martinezdos2reqjОценок пока нет

- Persephone and The PomegranateДокумент3 страницыPersephone and The PomegranateLíviaОценок пока нет

- Gogo ProjectДокумент39 страницGogo ProjectLoyd J RexxОценок пока нет

- Utilitarianism Bentham: PPT 6 Hedonic Act UtilitarianismДокумент9 страницUtilitarianism Bentham: PPT 6 Hedonic Act UtilitarianismPepedОценок пока нет

- 1 PDFДокумент176 страниц1 PDFDigna Bettin CuelloОценок пока нет

- EN 12953-8-2001 - enДокумент10 страницEN 12953-8-2001 - enעקיבא אסОценок пока нет

- The Nobel Peace Prize 2018Документ4 страницыThe Nobel Peace Prize 2018khkhОценок пока нет

- PoetryДокумент5 страницPoetryKhalika JaspiОценок пока нет

- Objectivity in HistoryДокумент32 страницыObjectivity in HistoryNeelab UnkaОценок пока нет

- Solar - Bhanu Solar - Company ProfileДокумент9 страницSolar - Bhanu Solar - Company ProfileRaja Gopal Rao VishnudasОценок пока нет

- Part I Chapter 1 Marketing Channel NOTESДокумент25 страницPart I Chapter 1 Marketing Channel NOTESEriberto100% (1)

- Yahoo Tabs AbbДокумент85 страницYahoo Tabs AbbKelli R. GrantОценок пока нет

- Urban Transportation System Design and Feasibility Analysis A Case Study of Lagos Mega-CityДокумент8 страницUrban Transportation System Design and Feasibility Analysis A Case Study of Lagos Mega-CityKaren EstradaОценок пока нет

- Computer Engineering Project TopicsДокумент5 страницComputer Engineering Project Topicskelvin carterОценок пока нет

- Usaid/Oas Caribbean Disaster Mitigation Project: Planning To Mitigate The Impacts of Natural Hazards in The CaribbeanДокумент40 страницUsaid/Oas Caribbean Disaster Mitigation Project: Planning To Mitigate The Impacts of Natural Hazards in The CaribbeanKevin Nyasongo NamandaОценок пока нет

- Discussion: Functions, Advantages and Disadvantages of BIOPOT Cassava Peel and Husk CharcoalДокумент4 страницыDiscussion: Functions, Advantages and Disadvantages of BIOPOT Cassava Peel and Husk CharcoalAhmad BurhanudinОценок пока нет

- The Overseas Chinese of South East Asia: Ian Rae and Morgen WitzelДокумент178 страницThe Overseas Chinese of South East Asia: Ian Rae and Morgen WitzelShukwai ChristineОценок пока нет

- Daftar Ebook-Ebook Manajemen Bisnis MantapДокумент3 страницыDaftar Ebook-Ebook Manajemen Bisnis MantapMohamad Zaenudin Zanno AkilОценок пока нет

- Cases in Political Law Review (2nd Batch)Документ1 страницаCases in Political Law Review (2nd Batch)Michael Angelo LabradorОценок пока нет

- Cantorme Vs Ducasin 57 Phil 23Документ3 страницыCantorme Vs Ducasin 57 Phil 23Christine CaddauanОценок пока нет

- 1 Summative Test in Empowerment Technology Name: - Date: - Year & Section: - ScoreДокумент2 страницы1 Summative Test in Empowerment Technology Name: - Date: - Year & Section: - ScoreShelene CathlynОценок пока нет

- Deed OfAdjudication Cresencio Abuluyan BasilioДокумент4 страницыDeed OfAdjudication Cresencio Abuluyan BasilioJose BonifacioОценок пока нет

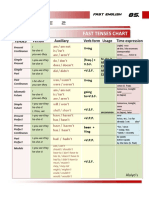

- Table 2: Fast Tenses ChartДокумент5 страницTable 2: Fast Tenses ChartAngel Julian HernandezОценок пока нет

- 26candao Vs People of The Philipines, 664 SCRA 769, G.R. No. 186659-710, February 1, 2012Документ5 страниц26candao Vs People of The Philipines, 664 SCRA 769, G.R. No. 186659-710, February 1, 2012Gi NoОценок пока нет

- Louis I Kahn Trophy 2021-22 BriefДокумент7 страницLouis I Kahn Trophy 2021-22 BriefMadhav D NairОценок пока нет

- Executive Summary: College of EngineeringДокумент17 страницExecutive Summary: College of Engineeringjoel c. herreraОценок пока нет

- Muhammad Naseem KhanДокумент2 страницыMuhammad Naseem KhanNasim KhanОценок пока нет

- Selection Letter Abhishek TodkarДокумент1 страницаSelection Letter Abhishek TodkarDipak GiteОценок пока нет

- Land Laws (MOHD AQIB SF)Документ18 страницLand Laws (MOHD AQIB SF)Mohd AqibОценок пока нет