Академический Документы

Профессиональный Документы

Культура Документы

Sem II 2010-2011

Загружено:

shamsulaliff94Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Sem II 2010-2011

Загружено:

shamsulaliff94Авторское право:

Доступные форматы

I

a

I

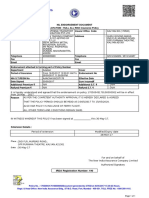

CONFIDENTIAL

UNIVERSITI TUN HUSSEIN ONN MALAYSIA

FIIIAL EXAMINATIONI

SEMESTER II

SESSTON 20r0t2011

COTJRSE NAME

COURSE CODE

PROGRAMME

E)L{MINATION DATE

DIJRATION

INSTRUCTION

CIVIL ENGINEERING I\4ATERIAL

BFCr0s02

I BFF

APRIL lMAY 2OII

2HOURS

ANSWER ALL

QUESTION

IN PART

A AND THREE (3)

QUESTIONS

IN

PART B.

ATTACH THE APPENDIXIN YOUR

ANSWER SCRIPT.

THrS

pApER

CONSTSTS OF TWELVE (r2) PAGES

COI{FIDENTIAL

BFC 10502

PART A

Ql

You are assigned to complete the laboratory experiment. The first objective is to complete

the mix design form according to DOE method. Before doing the concrete mix" you need to

carry out the sieve analysis in determining the percentage passing of 600pm.

Given,

i. Characteristic compressive strength,32 N/mm2 at 28 days with a l0%

defective rate

ft:

1.28)

ii. Ordinary Portland cement

iii. Slump requiled, l0

-

30 mm

iv. Maximum crushed aggregate size,20mm,

v. Relative density of crushed aggegate (SSD), 2700kglm3

vii. Standard deviation is 8 N/mm'

viii. Trial mix (cube size) is l00mm x l00mm x l00mm

(a) List Five (5) process involved in sieve analysis test for fine aggregate.

(5 marks)

(b) Table

Ql

show the result of sieve analysis for fine aggregate. Complete the table.

(14 marks)

(d)

(c)

(e)

Use the result of percentage passing 600pm obtained in Table

el

to complete the

Design Mix Form.

(12 marks)

The second objective of experiment is to determine the compressive strength of

cubes in 3 days, 7 days, 14 days and 28 days. The total ofcubes used is 12 cubes.

Refening to the complete of Design Mix Form, determine the new mass of water,

cement fine aggregate and coarse aggregate.

(4 marks)

The third objective of experiment is to use the recycled aggregate in concrete mix.

The percentage

of recycled aggregate used to replace the coarse aggregate is 0%o,

l$yo, 20%, 30Yo and 40%. Refening to the new mass of coarse aggregate that

obtained in

Ql

(d), determine the mass of recycled aggregate and coarse aggregate

used in this experiment.

(5 marks)

BFC 10502

;

PARTB

Q2

(a) Give the definition, the usage and the chemical composition of the cement.

(6 marks)

(b) Name Two (2) types of Portland Cement. Explain each of it.

(6 marks)

(c) List five (5) tests can be conducted on cement.

(5 marks)

(d) What is the cement hydration? Give One (l) example.

(3 marks)

Q3

(a) List three (3) types of clay used in brick manufacturer.

(3 marks)

(b) A severe weathering clay brick were tested for water absorption and saturation

coefiicient according to ASTM c67 procedure. The folowing data;

Dry mass specimen = l.822kg

Safurated mass after 24 hour submersion in cold water: 2.044kg

Saturated mass after 5 hour submersion in boiling water = 2.060kg

i. Calculate the water absorption after24 hour submersion in cold water.

(3 marks)

ii. Calculate the water absorption after5 hour submersion in boiling water.

(3 marks)

iii. Calculate the saturation coefficient.

(3 marks)

iv. The maximum saturation coefficient for ASTM requirement is 0.9. Does the

result satisfr the ASTM requirement?

(l mark)

(c) Name Three (3) advantages of the bricks if it fulfills the ASTM requirement.

(3 marks)

(d) One unit of concrete masonry is tested according to ASTM Cl40 procedure and

produced the following result;

Mass of unit as received = 10.355 g

Saturated mass of unit

:

I l.0gg g

Oven dry mass of unit:9894 g

BFC 10502

i. Determine the perrentage ofwater absorption.

(2 marks)

ii. Determine the moisture content of the unit as a percent of total absorption.

(2 marks)

Q4

(a) List Three (3) types of hardwood and explain all.

(6 marks)

(b) Give Three (3) advantages and Three (3) disadvantages of using timber as a

consfuction material.

(6 marks)

(c) Explain briefly Four (4) types of timber heatment and curing method.

(8 marks)

Q5

(a) List Four (4) classification of steel.

(4 marks)

(b) Explain the process involved in Bessemer process and sketch the diagram of

Bessemer converter.

(8 marks)

(c) Give Two (2) differences between hardness and hardenability.

(4 marks)

(d) You are assigned to determine the hardenability of steel. As an Engineer of

euality

Assurance in steel factory, what should you do?

(4 marks)

Q6

Briefly discuss the following topics:

(a) The use of bitumen in the field ofcivil engineering

(5 marks)

(b) The advantages of Elastomer Rubber

(5 marks)

(c) The types and uses ofplastic.

(5 marks)

(d) The types and uses ofglass in industries

(5 marks)

BFC 10502

FINAL EXAMINATION

SEMESTER/SESSION

SUBJECT

2 | 20rv20rr

MATERIALS OF CIVIL

ENGINEERING

COURSE

SUBJECT CODE

BFA

BFC 10502

NAME :

STUDENT ID. NO: l/C NO or PASSPORT NO. :

LECTURER NAME:

SECTION NO. :

Table l: Result of Sieve Analysis

BS4IO

Sieve size

(mm)

Weight of

aggregate

retained

(e)

Percentage

retained

Cumulative

percentage

passing

5.00mm

2.36mm

l.l8mm

600pm

300pm

l50pm

Pan

0

35

42

45

50

34

l0

BFC 10502

STUDENT ID. NO: llC NO or PASSPORT NO. :

LECTURER NAME:

SECTION NO. :

Slllp bn

Roflnmt

qc&frton

UArr

t.2

1.3

1.4

1.5

1.6

1.1 Cfracbristic silrngilt Spaflkd

Fs3

cr

r

w

e.

Specncd

Table ZFig I

$ctfied

Standard da,btim

[faryln

Taryetmem sUergltt

CrncntsilerElt cbss

Aggcgabtner o(Etse

Aegreeetyps fte

Freewater&ennrt ratb

l/elxinwrter*tu/

cunstratio

""" """ $r?nmz

l- ....'.....,....

=

......r...r. N/mm2

4L5/52.5

@

@

I

l**hervaue

n

1.7

r.8

2 2.1

22

2.3

Stryorthbelir:

tfarimm aeg[c8pb$!e

Freeryatercsffi

Spcctred

Spqiicd

Table 3

Strnp .-...o.....................ro....... mm(flbelimg .......r...,......... S

3 3.1

32

3.3

Cement content C3

ldaxinutttcerpntcffi gecfied

|*5mmcgitwltcgiffit

Wd

,. kg/tn3

;;:;;;;;;

wnf

use 3.3 it > 3.1

ru

E

3.4 ltfodfied@rdb

4.1 Rehttoedecftyd

agrw&lssDl

Carcnbderuity

Tobl aggrcgab corfrrt

lstoil/assurned

4.2

4.3

Fis2

a

kgfinil

lg/fm3

5.1 Giadkg dfue aggreggte

5.2 Proporlkndfue4geee

5.3 Fteagr4atecoffril

l

5.4 Corsc aggr"Epts corfrnt J

c5

(----

Y

I

a....a...r..arrr.aar...aaa.ala X aaaaaaraaaaaaaaaaaaaaaaaa.aa..

{

t.........

auuilcr

Ccrnrt

|r3t

trlrr Flprtltetrb

fi3rtrrrl fiff

CorrryrtrgrrlFgl

iat;rit'' dtmm

"fo'iil;

petrn3brrctskg,

pertid

mil d.. o........r.....,... rf

DEirllr.tfr

E*IrD!.rfl hsdi|rtt

AtE-.t|'|taFrdhf.ltl/|rd. f il,|||f- t Xyd- r nri- rfrq Ar-0d.,

ntti!ilatb:nlsddrdtr|a'!'

rtsblll/rabftcbdftEd.thnlnrotsldrr.tirrEdrotr,0l|[dE

SsD-b.tart srnl|rrhat Gafrr

BFC 10502

FINAL EXAMINATION

SEMESTER/SESSION : 2l20lG20ll COLJRSE : BFA

SUBJECT

: MATERIALS OF CIUL SUBJECT CODE : BFC 10502

ENGINEERING

Iable 2: Approximate compressive

strengths of concrete made with a free

water/cement ratio of 0.5 according to the DOE Method

Figure 1: Relationship betrveen cube compressive strength and free water/cement ratio

Type of

cement

Gement

strength

class

Type of

coarse

aggregate

Compressive strength* (M Pa(psi))

at the age of (days)

3 7 28 91

Ordinary

Portland

(Type l)

Sulfate-

resisting

Portfand

(Type V)

42.5

Uncrushed

Crushed

22 (3200)

27 (3e00)

30 (3200)

36 (5200)

42 (6100)

4e (7100)

4e (7100)

56 (8100)

Rapid-

hardening

Portland

(Type f ll)

52.5

Uncrushed

Crushed

2e (4200)

u (4e00)

37 (il00)

43 (6200)

48 (7000)

55 (8000)

54 (7800)

61 (8e00)

3

E

E

=E

(t

c

ct

g,

ID

tt

o

.D

o

E

o

(J

l0

BFC 10502

FINAL D(AMINATION

SEMESTER/SESSION

SUBJECT

2 | 20lG20t I

MATERIALS OF CIVIL

ENGINEERING

COURSE

SUBJECT

: BFA

CODE : BFC IO5O2

sflrylrrnl

(}-ro

1(F30 3$0 60!-1g0

htr_ryp$ :13 .6-13.

3-G 0-g

ilarhnrnCze

of

rysrugiilc

Typoof

lrrnl

aglrggab

l0 Uncrushed

Crushed

r50

r80

1&) 2(F

205 2n

225

2W

20 Uncrwhed

Crushed

135

170

160 180 195

r90 zla 225

n Uncrushed

Crushed

115

155

140 160 175

r75 190 2t5

bb: When cqanre and frre aggregptes d diftrent types ze used, Ute freerrater

content is e$ined

ry

tre agressbn:

?IW+tAV/.-

whore

ad

W =

frue+rahr csrbntapprcprirrc b type of frre aggregab

wn

=fteetnter

cdrterfiappropqiaE to type d coase

*greg&.

!|

E

e

.x

.5

E

o,

?

q)

\t

q,

q

()

r.)

aa-

o

H

.-

vt

c

iD

'15

-tll

<_

2500

2400

2300

2rOO

160 180 20c,

Frea-water content Ik tnj l

roo

Figure 2: Estimate wet den of fuf com concrete

ll

BFC 10502

FINAL EXAMINATION

SEMESTER/SESSION : 2l20lGl20ll COLTRSE : BFA

SLJBJECT

: MATERIALS OF CIUL SLJBJECT CODE : BFC 10502

ENGINEERJNG

Figure 3: Proportions of fine aggegates for gradin gzones 1,2,3,4

Maximurn aggregate she: 20mrn

Slump: O-1Omm

Vebe time: >12s

10-3Omm

6-12s

3G6Omm

3-6s

60-18Omrn

O-3s

s

c)

co

o)

@

(f)

(t,

(o

c)

g

o

c

.9

o

o-

o

(L

70

60

50

40

30

2a)

I

l

10i

o.

154

40'

60-

1

/

-/

-go-

-100-

o.4 0.6 0.8 o.2 a.4 0.6 0.8

Free-water/cement

ratio

1t'

I

-

1

':/

-4O-

:

=69=

-8b- -100'

15

:49^-

.60::

.1@'

z

-8,0-

/

t2

Вам также может понравиться

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Podem - Electric Chain Hoists - CLF & CLW (En)Документ8 страницPodem - Electric Chain Hoists - CLF & CLW (En)GogyОценок пока нет

- MembersДокумент79 страницMembersErik HooverОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Speeds and FeedsДокумент11 страницSpeeds and Feedszidaaan0% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Top Glove - M. O. S. Unloading & Loading of 1560kWДокумент4 страницыTop Glove - M. O. S. Unloading & Loading of 1560kWHaris IsmailОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (894)

- ALfpdfДокумент59 страницALfpdfHOSAM HUSSEINОценок пока нет

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Condition Inspection Report - RTO 27Документ4 страницыCondition Inspection Report - RTO 27Nathan EngeОценок пока нет

- Project Manager Construction Real Estate Development in Los Angeles CA Resume Rey AdalinДокумент2 страницыProject Manager Construction Real Estate Development in Los Angeles CA Resume Rey AdalinReyAdalinОценок пока нет

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- History of GarmentsДокумент2 страницыHistory of GarmentsShanto Malo EpuОценок пока нет

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Understanding and Minimizing Gas Defects in Iron CastingsДокумент2 страницыUnderstanding and Minimizing Gas Defects in Iron Castingsmecaunidos7771Оценок пока нет

- BOQ Boundary WallДокумент4 страницыBOQ Boundary WallVishal ShrivastavaОценок пока нет

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- Production Engineering by SKMondal PDFДокумент201 страницаProduction Engineering by SKMondal PDFmasterash02Оценок пока нет

- Kati List 2020Документ114 страницKati List 2020Zeeshan Ahmed80% (5)

- STOCK DATAДокумент49 страницSTOCK DATABellwetherSataraОценок пока нет

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Ryanair 09 Adrian DunneДокумент33 страницыRyanair 09 Adrian Dunneballes84Оценок пока нет

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Insurance 1Документ1 страницаInsurance 1Amar kushwahОценок пока нет

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Nescafe Supply ChainДокумент14 страницNescafe Supply ChainHassan100% (3)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Journal Airport PavementДокумент5 страницJournal Airport Pavementeqa amirОценок пока нет

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- MSC 35Документ5 страницMSC 35Bruno Avila PauloОценок пока нет

- Reading Reflection: Technological Institute of The PhilippinesДокумент3 страницыReading Reflection: Technological Institute of The PhilippinesMao TuazonОценок пока нет

- Rough Carpentry and Architectural Woodwork SectionsДокумент5 страницRough Carpentry and Architectural Woodwork SectionsAngel Mendez RoaringОценок пока нет

- CaseHard BS970-1955EN36AДокумент2 страницыCaseHard BS970-1955EN36AtechzonesОценок пока нет

- Plasma CuttingДокумент12 страницPlasma Cuttingpavi32Оценок пока нет

- Datasheet Sandvik 12c27 enДокумент4 страницыDatasheet Sandvik 12c27 enRizqi D. KurniantoОценок пока нет

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Supply Chain CaseletsДокумент16 страницSupply Chain Caseletsarun1974Оценок пока нет

- Ch.03 Aircraft Specification SASДокумент12 страницCh.03 Aircraft Specification SASAhmad Faisal Ibrahim100% (1)

- Neighborhood-Friendly Rock ExcavationДокумент8 страницNeighborhood-Friendly Rock ExcavationAgus WinarnoОценок пока нет

- Company Detail UttarakhandДокумент61 страницаCompany Detail UttarakhandAdtiya Devgun100% (3)

- Chopra 03 ChapterДокумент56 страницChopra 03 ChapterRashadafanehОценок пока нет

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Career Test Result - Free Career Test Taking Online at 123testДокумент5 страницCareer Test Result - Free Career Test Taking Online at 123testapi-266265727Оценок пока нет

- Foundry LabДокумент24 страницыFoundry LabthodatisampathОценок пока нет