Академический Документы

Профессиональный Документы

Культура Документы

Turnning

Загружено:

Ibraheem KhressИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Turnning

Загружено:

Ibraheem KhressАвторское право:

Доступные форматы

Objectives:

To determine the effect of the following parameters on the tool forces, that is

in the orthogonal metal cutting; tool feed rate, cutting speed and depth of cut.

Also, to calculate the specific cutting pressure and power consumed at the

cutting edge.

Equipments:

1. lathe machine

2. Cutting tool

3. Material for cooling the work piece and the cutting tool and it consist of

water and oils.

Theory:

1- Cutting speed (V): its the relative surface speed between the tool

and the job. Its given as:

min) / (

1000

m

DN

V

Where:

D: Diameter in mm of work piece

N: rev/min of work piece

V: cutting speed of work piece in m/min

2- Feed: its small movement per cycle of the cutting tool, relative to the

work piece in such direction. It's expressed in (mm/rev).

3- Depth of cut: its the thickness of the layer of metal removed in one

cut, or pass, measured in a direction perpendicular to the machined

surface. the depth of cut (W) is given as:

) (

2

2 1

mm

D D

W

Where:

2 , 1

D D Is the initial and final diameter of the work piece

4- Total force :

F = F

c

+ F

f

+ F

r

F

c

: cutting force , it is the largest force , it act in the direction of cutting

velocity .

Feed force , it is in the direction of the tool feed , 50 % of F

c

: F

f

F

t

: thrust force , it is perpendicular to the machined surface.

Procedure:

1. put the work piece and make sure that every thing is set .

2. turn on the machine and set the depth of cut that you need.

3. turn on the automatically cut and it will cut the work piece.

4. we can read the forces ( radial ( thrust ) , feed , cutting ) from the display that is

on the top of the cart that have the cutting tool .

Analysis:

Result (1): constant cutting speed (v) and feed rate(f), with a variable

depth of cut (w).

D=21.00 mm N=950rpm f=0.200 mm/rev

Radial force (f

r

)

(N)

Axial force (f

f

)

(N)

Tangential force (f

c

)

(N)

Depth of cut (w)

mm

10 19 39 0.5

17 39 72 1

37 71 126 1.5

41 78 150 2.0

When the depth of cut increase; then the tangential force increase, and the

Axial and radial force also increase. And it is clear that F

c

has the greatest

magnitude, because it is the largest force that need the most amount of power

to do the cutting process.

0

20

40

60

80

100

120

140

160

0 0.5 1 1.5 2 2.5

f

o

r

c

e

s

N

depth of cut mm

Relation between the cutting forces and the

depth of cut

Tangential force (fc) (N)

Axial force (ff) (N)

Radial force (ft) (N)

Result (2): constant feed rate (f) and depth of cut (w), with a variable

constant speed (v)

D=20.60mm w=0.5mm f=0.25 mm/rev

Radial force (f

r

)

(N)

Axial force (f

f

)

(N)

Tangential force

(f

c

) (N)

cutting speed

(V)

N (rev/min)

29 55 124 46 710

38 57 118 55 850

36 54 110 75 1160

29 51 108 82.2 1270

increasing the cutting speed will lead to increasing in cutting forces, when the

cutting velocity increase, then the tool life reduced, and it is clear that the short life

of the cutting tool happens because the cutting forces is larger with the higher speed,

and when the speed is increase, this means that it is wanted to remove a larger

amount of metal in less time, so the cutting force have to be larger

0

20

40

60

80

100

120

140

0 20 40 60 80 100

f

o

r

c

e

s

N

cutting speed m/min

Relation between the cutting forces and the

cutting speed

Tangential force (fc) (N)

Axial force (ff) (N)

Radial force (fr) (N)

Result (3): constant cutting speed (v) and depth of cut(w), with a variable

feed rate (f).

D=20.60 mm N= 1150 rpm w=0.25mm

Radial force (f

r

)

(N)

Axial force (f

f

)

(N)

Tangential force (f

c

)

(N)

feed (f) (mm/rev)

20 36 66 0.200

26 55 94 0.315

45 85 118 0.400

40 78 130 0.500

When the feed increase, this means that the amount of metal removed is larger, and

to remove a larger amount of metal; a larger force is needed, so, increasing the feed

rate will lead to an increase in the cutting forces.

0.5, 130

0.5, 78

0.5, 40

0

20

40

60

80

100

120

140

0 0.1 0.2 0.3 0.4 0.5 0.6

f

o

r

c

e

s

N

feed rate mm/rev

Relation between the cutting forces and the

feed rate

Tangential force (fc) (N)

Axial force (ff) (N)

Radial force (fr) (N)

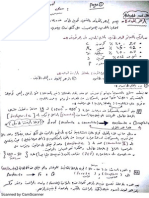

Sample calculation:

Part(1)

Specific cutting pressure (S.C.P) =

Power consumed (P) =

Part (2)

Specific cutting pressure (S.C.P) =

Power consumed (P) =

Part (3)

Specific cutting pressure (S.C.P) =

Power consumed (P) =

Conclusion:

We conclude from this experiment that the cutting speed ( v ) increase by

increasing ( N ) or ( D ) and when we increase the cutting speed and the

revolution ( N ) it will cause increase in the energy that is coming from the

cutting tool .

We conclude that the specific cutting pressure was maximum at the lowest

depth of cut and feed rate.

We conclude that the Power was maximum at the highest cutting speed.

Вам также может понравиться

- Adult Survivors Act Summons Against Mayor Eric AdamsДокумент3 страницыAdult Survivors Act Summons Against Mayor Eric AdamsCity & State New York100% (1)

- Welding Strength CalculationsДокумент20 страницWelding Strength CalculationsVikash Yadav100% (1)

- Mechanics of Metal CuttingДокумент33 страницыMechanics of Metal Cuttingnyilmaz72411Оценок пока нет

- ME - 32021 Chapter (I) Machining Processes and Machine Tools - PPTX (Repaired)Документ23 страницыME - 32021 Chapter (I) Machining Processes and Machine Tools - PPTX (Repaired)WILYОценок пока нет

- Ch-2 Force & Power in Metal CuttingДокумент43 страницыCh-2 Force & Power in Metal CuttingNimish JoshiОценок пока нет

- Mechanical Engineering DepartmentДокумент2 страницыMechanical Engineering DepartmentArjit Goswami100% (1)

- 3.1 Metal RemovalДокумент40 страниц3.1 Metal RemovalMichael Kearney50% (2)

- Mechanics of Metal CuttingДокумент24 страницыMechanics of Metal CuttingSreehari ViswanathanОценок пока нет

- Fundamentals of MachiningДокумент39 страницFundamentals of Machiningpassion481100% (1)

- Machines ElementsДокумент72 страницыMachines ElementsAref ManicheОценок пока нет

- Example For Milling CalculationДокумент3 страницыExample For Milling CalculationAbd Muhaimin AmmsОценок пока нет

- Lec 5Документ16 страницLec 5Omar AlyОценок пока нет

- 15 Technical Catalog Casting Steel eДокумент52 страницы15 Technical Catalog Casting Steel elbo330% (1)

- Metal Cutting OperationsДокумент6 страницMetal Cutting OperationsNikhil SinghОценок пока нет

- Lecture No. 7 Turning ParametersДокумент29 страницLecture No. 7 Turning ParametersMuhammad IrfanОценок пока нет

- Answer SheetsДокумент7 страницAnswer Sheetsgirma workuОценок пока нет

- Cutting Speed May BeДокумент14 страницCutting Speed May BeJibin Jose100% (1)

- Lecture 5Документ11 страницLecture 5Shakeel AhmadОценок пока нет

- Tool Engg Notes by DVSHIRBHATEДокумент148 страницTool Engg Notes by DVSHIRBHATEDIPAK VINAYAK SHIRBHATE100% (2)

- Cutting Data Corrax EngДокумент5 страницCutting Data Corrax Engstanalina00Оценок пока нет

- Cutting Data Corrax EngДокумент5 страницCutting Data Corrax EngPardeep Kumar100% (1)

- Effect of Coated and Uncoated Carbide Inserts On The Cutting Forces in Turning OperationsДокумент56 страницEffect of Coated and Uncoated Carbide Inserts On The Cutting Forces in Turning Operationselectronics98wordОценок пока нет

- Connection Design SheetДокумент47 страницConnection Design SheetStephen James100% (1)

- Turning: ATMH1283 CNC and Workshop Technology Machining Operation Calculation (Turning)Документ4 страницыTurning: ATMH1283 CNC and Workshop Technology Machining Operation Calculation (Turning)Shan PinОценок пока нет

- Chapter Three: FUNDAMENTALS OF CUTTING PROCESS: The Common Feature Is The Use of A Cutting Tool To FormДокумент12 страницChapter Three: FUNDAMENTALS OF CUTTING PROCESS: The Common Feature Is The Use of A Cutting Tool To FormkidusОценок пока нет

- EMMU 7244-Machine Tool Vibrations and Cutting Dynamics-Exam July 2016Документ4 страницыEMMU 7244-Machine Tool Vibrations and Cutting Dynamics-Exam July 2016Charles OndiekiОценок пока нет

- EMMU 7244-Machine Tool Vibrations and Cutting Dynamics-Exam July 2016Документ4 страницыEMMU 7244-Machine Tool Vibrations and Cutting Dynamics-Exam July 2016Charles OndiekiОценок пока нет

- Chapter Twenty TwoДокумент16 страницChapter Twenty Twoabdullaammar090Оценок пока нет

- Calculation Manufacturing ProcessДокумент18 страницCalculation Manufacturing ProcessEncik MaaОценок пока нет

- Solution To Taylors Tool Life ProblemsДокумент1 страницаSolution To Taylors Tool Life Problems19G133 VASANTH B100% (1)

- M14ME2005 Machining Process: Unit - 1Документ24 страницыM14ME2005 Machining Process: Unit - 1Prabhu RubeshОценок пока нет

- Metal CuttingДокумент45 страницMetal CuttingVarun SinghОценок пока нет

- ENS6134-Equation Sheet For Final ExaminationДокумент4 страницыENS6134-Equation Sheet For Final ExaminationDhaval PatelОценок пока нет

- Mechanics of Metal Cutting PDFДокумент24 страницыMechanics of Metal Cutting PDFEd Doloriel MoralesОценок пока нет

- Metal Cutting Theory and MechanismДокумент75 страницMetal Cutting Theory and Mechanismnishantdubey1183Оценок пока нет

- Unit 2.1 Kinimatic Motion and Chip FormationДокумент94 страницыUnit 2.1 Kinimatic Motion and Chip FormationHABTAMU FEKADUОценок пока нет

- S11-Cutting Forcess & MCDДокумент37 страницS11-Cutting Forcess & MCDBenita PrinceОценок пока нет

- Machine Operation CalculationsДокумент9 страницMachine Operation CalculationsGangadhar NavnageОценок пока нет

- 10.1.1.138.410 Modelling of Cutting ForcesДокумент8 страниц10.1.1.138.410 Modelling of Cutting ForcesVijayakumarBaskarОценок пока нет

- Theory of Metal MachiningДокумент45 страницTheory of Metal MachiningRakesh PandeyОценок пока нет

- Theory of Metal Cutting: Submitted To MR. GURPREET SINGH Submitted byДокумент39 страницTheory of Metal Cutting: Submitted To MR. GURPREET SINGH Submitted byamitОценок пока нет

- Assignment: Q.N.1. in A Turning Operation, It Was Observed That The Tool Life Was 150 Minutes When The CuttingДокумент7 страницAssignment: Q.N.1. in A Turning Operation, It Was Observed That The Tool Life Was 150 Minutes When The CuttingAnkesh KapilОценок пока нет

- N0174147G Manufacturing ProcessesДокумент10 страницN0174147G Manufacturing Processesphillip chirongweОценок пока нет

- Theory of Metal MachiningДокумент42 страницыTheory of Metal MachiningAbdulla AlattawiОценок пока нет

- Drawing Process of Wire and BarДокумент5 страницDrawing Process of Wire and BarRajesh Bapu100% (1)

- RadovanovicM DasicP MOCM 12Документ7 страницRadovanovicM DasicP MOCM 12AlexandruTomaОценок пока нет

- ABrasive FormulasДокумент3 страницыABrasive FormulasjakimlmОценок пока нет

- Chapter Twenty ThreeДокумент11 страницChapter Twenty Threeabdullaammar090Оценок пока нет

- Design and Analysis of An Industrial, Progressive Die For Cutting and FormingДокумент35 страницDesign and Analysis of An Industrial, Progressive Die For Cutting and Formingmazen banatОценок пока нет

- Design and Analysis of An Industrial, Progressive Die For Cutting and FormingДокумент35 страницDesign and Analysis of An Industrial, Progressive Die For Cutting and FormingVineela ChОценок пока нет

- Fundamentals of Machining or Orthogonal MachiningДокумент75 страницFundamentals of Machining or Orthogonal MachiningFawad HussainОценок пока нет

- Merchant's Circle NotsДокумент5 страницMerchant's Circle NotsSaravanan MathiОценок пока нет

- CIRP Annals - Manufacturing Technology: Y. Altintas (1), M. Eynian, H. OnozukaДокумент4 страницыCIRP Annals - Manufacturing Technology: Y. Altintas (1), M. Eynian, H. OnozukafgdfsgdfОценок пока нет

- CAT I - EMMU 7241 - Machine Tool Vibrations and Cutting DynamicsДокумент2 страницыCAT I - EMMU 7241 - Machine Tool Vibrations and Cutting DynamicsCharles OndiekiОценок пока нет

- Mechanics of Metal Cutting: Tool EngineeringДокумент26 страницMechanics of Metal Cutting: Tool EngineeringChen WANYINGОценок пока нет

- Cutting Speed, Feed, Depth of CutДокумент3 страницыCutting Speed, Feed, Depth of CutHOD TD GITОценок пока нет

- Strength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresОт EverandStrength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresРейтинг: 4 из 5 звезд4/5 (1)

- 2014 SOLIDWORKS Help - Equation Driven CurvesДокумент2 страницы2014 SOLIDWORKS Help - Equation Driven CurvesIbraheem KhressОценок пока нет

- Post Info - LatheДокумент2 страницыPost Info - LatheIbraheem KhressОценок пока нет

- 111Документ1 страница111Ibraheem KhressОценок пока нет

- Fuse Blows Power Lost Motor(s) OverheatДокумент2 страницыFuse Blows Power Lost Motor(s) OverheatIbraheem KhressОценок пока нет

- 3 1 Eight Forms CorrosionДокумент20 страниц3 1 Eight Forms CorrosionIbraheem KhressОценок пока нет

- Work OrderДокумент2 страницыWork OrderIbraheem KhressОценок пока нет

- Running On Windows 64 BitДокумент8 страницRunning On Windows 64 BitIbraheem KhressОценок пока нет

- Work Package 2: DR Jüri RiivesДокумент34 страницыWork Package 2: DR Jüri RiivesIbraheem KhressОценок пока нет

- General Mech EnglishДокумент19 страницGeneral Mech EnglishIbraheem KhressОценок пока нет

- ReportДокумент6 страницReportIbraheem KhressОценок пока нет

- معادن سكندДокумент15 страницمعادن سكندIbraheem KhressОценок пока нет

- PYC 1501 Basic Psychology - PersonalityДокумент15 страницPYC 1501 Basic Psychology - Personalityektha_nankoomar91100% (3)

- 08 163 4 JPL ScheickДокумент50 страниц08 163 4 JPL ScheickSaqib Ali KhanОценок пока нет

- Chem Sba 2019-2020Документ36 страницChem Sba 2019-2020Amma MissigherОценок пока нет

- UntitledДокумент2 страницыUntitledapi-236961637Оценок пока нет

- PCB Engraver Operator Manual PDFДокумент41 страницаPCB Engraver Operator Manual PDFmyoshkeuОценок пока нет

- Anesthesia 3Документ24 страницыAnesthesia 3PM Basiloy - AloОценок пока нет

- Interactive and Comprehensive Database For Environmental Effect Data For PharmaceuticalsДокумент5 страницInteractive and Comprehensive Database For Environmental Effect Data For PharmaceuticalsRaluca RatiuОценок пока нет

- Exercise 6Документ2 страницыExercise 6Satyajeet PawarОценок пока нет

- Study On Optimization and Performance of Biological Enhanced Activated Sludge Process For Pharmaceutical Wastewater TreatmentДокумент9 страницStudy On Optimization and Performance of Biological Enhanced Activated Sludge Process For Pharmaceutical Wastewater TreatmentVijaya GosuОценок пока нет

- Schengen Certificate ExampleДокумент2 страницыSchengen Certificate ExampleGabriel Republi CanoОценок пока нет

- Revised Man As A Biological BeingДокумент8 страницRevised Man As A Biological Beingapi-3832208Оценок пока нет

- 09B Mechanical Properties of CeramicsДокумент13 страниц09B Mechanical Properties of CeramicsAhmed AliОценок пока нет

- Wax Depilation ManualДокумент17 страницWax Depilation ManualAmit Sharma100% (1)

- Variant Perception - Recessions and ShocksДокумент15 страницVariant Perception - Recessions and ShocksVariant Perception Research80% (5)

- PACKET 1 - Exercises and ActivitiesДокумент7 страницPACKET 1 - Exercises and ActivitiesPrantsir Pernes100% (2)

- DefibrillatorДокумент2 страницыDefibrillatorVasanth VasanthОценок пока нет

- Literature Review On Coconut MilkДокумент4 страницыLiterature Review On Coconut Milkea6mkqw2100% (1)

- Application of Knowledge QuestionsДокумент16 страницApplication of Knowledge QuestionsElllie TattersОценок пока нет

- 742210V01Документ2 страницы742210V01hakim_zadehОценок пока нет

- Final Plant Diversity Lab ReportДокумент6 страницFinal Plant Diversity Lab Reportapi-508660724Оценок пока нет

- GASESДокумент55 страницGASESja_QuinineОценок пока нет

- Barangay Clearance SampleДокумент1 страницаBarangay Clearance SampleBarangay Onse Malaybalay100% (3)

- Reading Test - 3 Clinical Depression Text AДокумент17 страницReading Test - 3 Clinical Depression Text AJisha JanardhanОценок пока нет

- Sathyamangalam Chennai MR Sivakumar N: Rolsun TravelsДокумент2 страницыSathyamangalam Chennai MR Sivakumar N: Rolsun TravelsGayu carita catoОценок пока нет

- Pengaruh Pembangunan Center Point of IndДокумент11 страницPengaruh Pembangunan Center Point of IndSumitro SafiuddinОценок пока нет

- 2 Avaliação Edros 2023 - 7º Ano - ProvaДокумент32 страницы2 Avaliação Edros 2023 - 7º Ano - Provaleandro costaОценок пока нет

- Biomedical EngineeringДокумент5 страницBiomedical EngineeringFranch Maverick Arellano Lorilla100% (1)

- Vulnerability of The Urban EnvironmentДокумент11 страницVulnerability of The Urban EnvironmentKin LeeОценок пока нет

- Case Diagnosis For RomanДокумент4 страницыCase Diagnosis For RomanChris Marie JuntillaОценок пока нет