Академический Документы

Профессиональный Документы

Культура Документы

CleanAgent 2001

Загружено:

ashrefrasli0 оценок0% нашли этот документ полезным (0 голосов)

84 просмотров7 страницThis document provides the results of an enclosure integrity test for a room containing Example Building 1 in Exampletown, WA. The test was conducted on March 31, 2002 using FM200 (HFC227ea) as the fire suppression agent. The total room leakage was measured to be 0.2676 m^2, above the maximum allowed leakage of 0.1338 m^2 to ensure a minimum 10 minute retention time. As a result, the enclosure FAILED the retention time acceptance test, as the agent-air interface was calculated to descend below the minimum protected height in only 0.2 minutes.

Исходное описание:

aa

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документThis document provides the results of an enclosure integrity test for a room containing Example Building 1 in Exampletown, WA. The test was conducted on March 31, 2002 using FM200 (HFC227ea) as the fire suppression agent. The total room leakage was measured to be 0.2676 m^2, above the maximum allowed leakage of 0.1338 m^2 to ensure a minimum 10 minute retention time. As a result, the enclosure FAILED the retention time acceptance test, as the agent-air interface was calculated to descend below the minimum protected height in only 0.2 minutes.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

84 просмотров7 страницCleanAgent 2001

Загружено:

ashrefrasliThis document provides the results of an enclosure integrity test for a room containing Example Building 1 in Exampletown, WA. The test was conducted on March 31, 2002 using FM200 (HFC227ea) as the fire suppression agent. The total room leakage was measured to be 0.2676 m^2, above the maximum allowed leakage of 0.1338 m^2 to ensure a minimum 10 minute retention time. As a result, the enclosure FAILED the retention time acceptance test, as the agent-air interface was calculated to descend below the minimum protected height in only 0.2 minutes.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 7

Printed on: 2014/01/11 19:41 Page 1

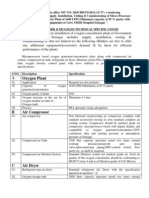

PASS/FAIL Enclosure Integrity Report

CleanAgent 2001 retention time prediction program revision 2.5.4. Complies with NFPA 2001 Appendix C, year 2000 edition.

By Retrotec, Inc, 2200 Queen Street, Bellingham, WA USA 98229 360-738-9835 www.retrotec.com

Software Licensed to:

CRF Tech Engineering Solutions

air leaks in

agent leaks out

Building, Location

Example Building 1, Exampletown, WA, USA

Company, Contact

General Electric, John Client Dude

Room name

Change range experiment

Test number

1

Calibration Certificate #

2

Certificate created

2002/02/03

Test date/time

2002/03/31 00:00

Net Protected Volume, V

15 m^3

Tester

Sample Tech

Maximum Protected Height, HO 3.66 m.

Certified to Level:

4 - ISO multi-point & vent test

Minimum Protected Height, H

3.00 m.

Signature

.......................................................

Static during retention, PSH 0.0 Pa

Elevation above sea level

229 m.

Operating temperature

21 C

Correction method

NFPA 2001 (2000) Formula A-3-5.3.3

C Initial concentration,

7.26%

Correction factor

0.97

Mixing during retention

No

Agent

FM200 (HFC227ea)

Agent quantity

1 m^3

Total room leakage, ELA

0.2676 m^2

Minimum concentration, CF 7.26%

Lower Leakage, BCLA

0.1338 m^2

Minimum retention time

10.0 minutes

Below ceiling leakage defaulting to worst case -- 50% of total leakage.

This enclosure was tested in compliance with NFPA 2001 and 12A.

Assuming no continual mixing during the retention period,

enclosure leakage could allow sufficient agent to be lost to

cause an air/agent interface to descend from a Maximum

Protected Height of 3.66 m. to the Minimum Protected

Height specified of 3.00 m.

The retention time would then be 0.2 minutes which is

less than the minimum retention time of 10 minutes. The

enclosure therefore FAILS this acceptance procedure.

Notes

here are a bunch of notes here are a bunch of

notes here are a bunch of notes here are a bunch of

notes here are a bunch of notes here are a bunch of

notes here are a bunch of notes here

Witnesses

DOOR FAN TEST -- Total Room Leakage Data

CleanAgent 2001 retention time prediction program revision 2.5.4. Complies with NFPA 2001 Appendix C, year 2000 edition.

By Retrotec, Inc, 2200 Queen Street, Bellingham, WA USA 98229 360-738-9835 www.retrotec.com

Software Licensed to:

CRF Tech Engineering Solutions

air leaks in

agent leaks out

Building, Location

Example Building 1, Exampletown, WA, USA

Company, Contact

General Electric, John Client Dude

Room name

Change range experiment

Test number

1

Calibration Certificate #

2

Certificate created

2002/02/03

Total Room Leakage

Operator In the room Smoke doesn't move Temperature during test (C)

Static pressure 0 Pa 21 inside 21 outside

Depressurization Range for room pressures: -15.8 to -18.8

Blower range Room pressure -10*

Auto corrected RP -9.5

Range 9 Flow Pressure 100

Auto corrected FP 102.6

Corrected flow (m^3/sec.) -0.6610

* Room pressure is too low. Retention time may be 9% shorter than predicted.

Pressurization Range for room pressures: 15.8 to 18.8

Blower range Room pressure 11*

Auto corrected RP 10.5

Range 9 Flow Pressure 123

Auto corrected FP 126.8

Corrected flow (m^3/sec.) 0.7030

* Room pressure is too low. Retention time may be 7% shorter than predicted.

F

0.50 10.0

ELA m^2

0.2679

Standard Error

NA

NA

Correlation

NA

NA

Intercept k1

0.2090

0.2120

0.2105

Slope n

0.5000

0.5000

0.5000

FA

0.50

@Pa

9.5

10.5

10.0

ELA m^2

0.2657

0.2694

0.2676

Depressurization

Pressurization

Average

Lower Leakage

Below ceiling leakage of 0.1338 m^2 @ 10.0 Pa is the worst case assumption of 50%

Technician: Sample Tech Certified to Level: 4 - ISO multi-point & vent test

Yes Level 1 - Fire enclosure design basics for improving agent retention and passive protection

Yes Level 2 - adds single door fan operation and NFPA clean agent retention time calculations

Yes Level 3 - adds double door fan operation for Lower Leak measurement

Yes Level 4 - adds multi-point ISO door fan operation and discharge pressure relief vent

Printed on: 2014/01/11 19:41 Page 2

Printed on: 2014/01/11 19:41 Page 3

DOOR FAN TEST -- Graph

CleanAgent 2001 retention time prediction program revision 2.5.4. Complies with NFPA 2001 Appendix C, year 2000 edition.

By Retrotec, Inc, 2200 Queen Street, Bellingham, WA USA 98229 360-738-9835 www.retrotec.com

Software Licensed to:

CRF Tech Engineering Solutions

air leaks in

agent leaks out

Building, Location

Example Building 1, Exampletown, WA, USA

Company, Contact

General Electric, John Client Dude

Room name

Change range experiment

Test number

1

Calibration Certificate #

2

Certificate created

2002/02/03

One Year Calibration Certificate Certificate #

2

System Model # Retrotec - 970hp

System Owned By Demo Certificate Console # 145898

For CA2001 ver 2.0 license # 125-555 Equipment Calibrated by Colin Genge

Good for one year date: 2002/02/03 expires: 2003/02/03

This certificate complies with calibration requirements of NFPA 2001 Appendix C, year 2000 edition and

ISO 14520. Completed by Retrotec Inc, 2200 Queen Street, Bellingham, WA, USA 98226-4766

Analog 60 This gauge used for Room Pressure

serial # 93333

to correct mult by & add gauge CR MRC error Pa

0.00 - 10.50 0.95 0.00 8.0 7.6 8.0 -0.4

10.50 - 14.75 0.98 -0.25 12.0 11.5 12.0 -0.5

14.75 - 17.50 1.04 -1.14 15.0 14.4 15.0 -0.6

17.50 - 26.00 0.94 0.53 20.0 19.4 20.0 -0.6

26.00 - 36.50 0.95 0.24 31.0 29.8 30.0 -0.2

36.50 - 51.00 1.03 -2.76 41.5 40.2 40.0 0.2

51.00 - 999.00 1.00 -1.00 55.5 54.5 55.0 -0.5

Analog 250 This gauge used for Flow Pressure, Blower #1

serial # 93334

to correct mult by & add gauge CR MRC error Pa

0.00 - 31.00 0.97 0.00 25.0 24.2 25.0 -0.8

31.00 - 40.50 1.05 -2.63 35.0 34.2 35.0 -0.8

40.50 - 60.00 1.03 -1.54 49.0 48.7 50.0 -1.3

60.00 - 88.00 1.07 -4.29 73.5 74.5 75.0 -0.5

88.00 - 126.00 1.05 -2.63 96.0 98.4 100.0 -1.6

126.00 - 174.00 1.04 -1.25 145.0 149.8 150.0 -0.2

174.00 - 999.00 1.00 6.00 194.0 200.0 200.0 0.0

Analog 250 This gauge used for Flow Pressure, Blower #2

serial # 93335

to correct mult by & add gauge CR MRC error Pa

0.00 - 31.00 0.97 0.00 25.0 24.2 25.0 -0.8

31.00 - 40.50 1.05 -2.63 35.0 34.2 35.0 -0.8

40.50 - 60.00 1.03 -1.54 49.0 48.7 50.0 -1.3

60.00 - 88.00 1.07 -4.29 73.5 74.5 75.0 -0.5

88.00 - 126.00 1.05 -2.63 96.0 98.4 100.0 -1.6

126.00 - 174.00 1.04 -1.25 145.0 149.8 150.0 -0.2

174.00 - 999.00 1.00 6.00 194.0 200.0 200.0 0.0

Five Year Calibration Certificate Certificate #

2

System Model # Retrotec - 970hp

System Owned By Demo Certificate Console # 145898

For CA2001 ver 2.0 license # 125-555 Equipment Calibrated by Colin Genge

Good for five years date: 2002/02/03 expires: 2007/02/03

This certificate complies with calibration requirements of NFPA 2001 Appendix C, year 2000 edition and

ISO 14520. Completed by Retrotec Inc, 2200 Queen Street, Bellingham, WA, USA 98226-4766

CR is the Corrected Room pressure.

CR = "gauge" reading X "mult by" factor + "& add" factor.

CF is the Corrected Flow pressure derived the same way.

The corrected readings are compared to the TRUE reading from our Master Reference Calibration (MRC)

gauge and the resulting error shown in Pascals. Maximum allowable error is +/- 1 Pa from 0 to 50 Pa and

+/- 5 Pa over 50 Pa.

Five Year Calibration Certificate Certificate #

2

System Model # Retrotec - 970hp

System Owned By Demo Certificate Console # 145898

For CA2001 ver 2.0 license # 125-555 Equipment Calibrated by Colin Genge

Good for five years date: 2002/02/03 expires: 2007/02/03

This certificate complies with calibration requirements of NFPA 2001 Appendix C, year 2000 edition and

ISO 14520. Completed by Retrotec Inc, 2200 Queen Street, Bellingham, WA, USA 98226-4766

CALIBRATION EQUATIONS WITH CALCULATION EXAMPLES:

blower #1 serial # >> 93335 blower #2 serial # >> 93336

blower range N K K1 K2 K3 K4 MF CR FF cfm m

3

/ sec

#1 18F 0.4690 311.5000 0.000 1.000 0.000 1.027 10.0 21.5 75 2,423 1.1437

#1 18R 0.4800 366.8000 0.000 1.000 0.000 0.793 10.0 21.3 88.6 2,503 1.1813

#1 9 0.4920 144.5000 0.000 1.000 0.000 0.993 10.0 17.6 78.5 1,228 0.5794

#1 5 0.4510 97.4100 0.000 1.000 0.000 0.997 10.0 19.3 69.6 658 0.3106

#1 3 0.4700 51.4800 0.000 1.000 0.000 1.055 10.0 13.2 74.5 412 0.1944

#1 1.4 0.4670 30.4200 0.000 1.000 0.000 1.026 10.0 11.4 75 234 0.1106

#1 1.3 0.4420 27.7100 0.000 1.000 0.000 1.179 10.0 24.1 74.5 220 0.1036

#1 1.2 0.4830 17.2600 0.000 1.000 0.000 1.169 10.0 15.5 23.2 92 0.0435

#1 1.1 0.4740 12.7100 0.000 1.000 0.000 1.111 10.0 34.7 81.4 114 0.0536

#1 0.1 0.5100 5.7700 0.000 1.000 0.000 1.049 10.0 20.3 64.8 51 0.0240

#2 18F 0.4690 311.5000 0.000 1.000 0.000 1.095 10.0 23.1 72.9 2,550 1.2033

#2 18R 0.4800 366.8000 0.000 1.000 0.000 0.793 10.0 23.1 88.9 2,507 1.1832

This calibration certificate compares

the calibration holes in the Retrotec

test chamber with the tested

blower's measurement of those

holes. The left hand column shows

the area of holes open in the

Retrotec flow chamber. To the right

is the comparable Retrotec Door

Fan result using the above

referenced CA2001 software

license. Maximum allowable error is

+/- 5%.

BLOWER TEST RESULTS: error

Holes

open

in

flow

chamber

cm

2

blower range cm

2

% cm

2

3,148 1 18F 3,135 -0.4 -13

3,148 1 18R 3,254 3.3 106

1,834 1 9 1,755 -4.3 -79

925 1 5 899 -2.8 -26

678 1 3 680 0.3 2

419 1 1.4 417 -0.6 -2

274 1 1.3 268 -2.1 -6

143 1 1.2 141 -1.8 -2

115 1 1.1 115 0.6 0

67 1 0.1 68 1.0 1

3,152 2 18F 3,183 1.0 31

3,152 2 18R 3,129 -0.7 -23

This calibration includes both gauge and blower error combined. CR and CF come from the One Year

Certificate. For Flow Towards the operator, CF must be reduced by CR before calculating flow to yield FF,

the symbol for the Final Flow pressure. For Flow Away from the operator CF=FF.

FF must be >=MF and (CR * K2) otherwise flow pressure is too low for accurate results

Flow in cfm = (FF-CR*K1)^N*(K+K3*FF)*K4 For m

3

/sec, divide by 2118.882.

Five Year Calibration Certificate Certificate #

2

System Model # Retrotec - 970hp

System Owned By Demo Certificate Console # 145898

For CA2001 ver 2.0 license # 125-555 Equipment Calibrated by Colin Genge

Good for five years date: 2002/02/03 expires: 2007/02/03

This certificate complies with calibration requirements of NFPA 2001 Appendix C, year 2000 edition and

ISO 14520. Completed by Retrotec Inc, 2200 Queen Street, Bellingham, WA, USA 98226-4766

Technician: Sample Tech Certified to Level: 4 - ISO multi-point & vent test

Yes Level 1 - Fire enclosure design basics for improving agent retention and passive protection

Yes Level 2 - adds single door fan operation and NFPA clean agent retention time calculations

Yes Level 3 - adds double door fan operation for Lower Leak measurement

Yes Level 4 - adds multi-point ISO door fan operation and discharge pressure relief vent

Вам также может понравиться

- Recognizing Quality HVAC TAB ReportsДокумент80 страницRecognizing Quality HVAC TAB ReportsdiningkoОценок пока нет

- Minneapolis Blower Door ManualДокумент100 страницMinneapolis Blower Door ManualGanesh AyerОценок пока нет

- Air Flow Tech Spec 22-2012Документ5 страницAir Flow Tech Spec 22-2012Varma DantuluriОценок пока нет

- Ceiling Fan Laboratory Guidance ManualДокумент35 страницCeiling Fan Laboratory Guidance ManualSsdssddОценок пока нет

- Fire Protection Test ProcedureДокумент7 страницFire Protection Test Procedurekunalji_jainОценок пока нет

- Test Report 12CA23872-002 Carrier 38KCD109313GДокумент14 страницTest Report 12CA23872-002 Carrier 38KCD109313GJuan Carlos Mendez100% (1)

- Sample Autoclave Validation Report 1-04-2013Документ10 страницSample Autoclave Validation Report 1-04-2013Abd Al-Rahmman Al-qatananiОценок пока нет

- Addendum To ARI Standard 880-98, Air Terminals September 2002Документ19 страницAddendum To ARI Standard 880-98, Air Terminals September 2002ramadan rashadОценок пока нет

- Work Instruction On Tube ExpansionДокумент40 страницWork Instruction On Tube Expansionjayaarnav100% (1)

- Precommissioning Procedures of Testing & CommissioningДокумент96 страницPrecommissioning Procedures of Testing & CommissioningTasawar Hussain85% (34)

- Cemtek Sample CEMS Specification May 2012Документ13 страницCemtek Sample CEMS Specification May 2012suparnaОценок пока нет

- Test Methods For Air Curtain Units: Amca Standard 220-91Документ17 страницTest Methods For Air Curtain Units: Amca Standard 220-91Jay SuguitanОценок пока нет

- TCF Testing CapabilitiesДокумент12 страницTCF Testing CapabilitiesMido AbdoОценок пока нет

- Foam Testing Options and AccessoriesДокумент8 страницFoam Testing Options and AccessoriesJustin EvansОценок пока нет

- 583-9738 Procedure For Piping 00Документ22 страницы583-9738 Procedure For Piping 00sivaramОценок пока нет

- Specifications of PACДокумент12 страницSpecifications of PACpОценок пока нет

- Instrument Air SupplyДокумент8 страницInstrument Air SupplyMohammad Amini100% (1)

- Scope of Supply GEF9Документ144 страницыScope of Supply GEF9Her Phy ToОценок пока нет

- Hvac Tech, Doc For Tender - II 02 03Документ108 страницHvac Tech, Doc For Tender - II 02 03kishore vpОценок пока нет

- Test Certificate-Pressure RegulatorsДокумент2 страницыTest Certificate-Pressure RegulatorsJonathan Griffin100% (1)

- Weiss Salt Spray and Corrosion Testing BrochureДокумент7 страницWeiss Salt Spray and Corrosion Testing BrochureMiorita_13Оценок пока нет

- Understanding ISO 6789 - Calibration Laboratories - BlogДокумент3 страницыUnderstanding ISO 6789 - Calibration Laboratories - BlogAntmavrОценок пока нет

- Zhuang EQp1Документ7 страницZhuang EQp1sardarmkhanОценок пока нет

- WC059 AMG Metal Non Drainable Louver Test - MSRKДокумент9 страницWC059 AMG Metal Non Drainable Louver Test - MSRKAMG Co.Оценок пока нет

- Cost Sheet For NPLДокумент10 страницCost Sheet For NPLSachin MishraОценок пока нет

- Calibrate Fire & Gas Detection SystemsДокумент5 страницCalibrate Fire & Gas Detection Systemskirandevi1981Оценок пока нет

- TOFD Procedure For VesselДокумент12 страницTOFD Procedure For Vesselmohanraj67% (3)

- SAIC-A-2015 Rev 2Документ9 страницSAIC-A-2015 Rev 2ரமேஷ் பாலக்காடுОценок пока нет

- Standard Operating Procedure: Validation of Heating Ventilation and Air Conditioning (Hvac) SystemДокумент20 страницStandard Operating Procedure: Validation of Heating Ventilation and Air Conditioning (Hvac) SystemMaryanthony Namyalo100% (2)

- T&CДокумент13 страницT&CAbdurRahmanFОценок пока нет

- Loads & Aeroelastics Department, Airbus Group S.L., Madrid, Spain Weight & Control Estimation Department, Airbus Group S.L., Madrid, SpainДокумент12 страницLoads & Aeroelastics Department, Airbus Group S.L., Madrid, Spain Weight & Control Estimation Department, Airbus Group S.L., Madrid, SpainbarracudacemОценок пока нет

- Fans Testing & Commissioning Format-R0Документ13 страницFans Testing & Commissioning Format-R0Hari SankarОценок пока нет

- Blower Door Manual InglesДокумент100 страницBlower Door Manual InglesDeco DluxeОценок пока нет

- VAV Control SequencesДокумент122 страницыVAV Control SequencesShadi AlashkarОценок пока нет

- DENAIR 30KW Air Compressor Technical Proposal and QuotationДокумент17 страницDENAIR 30KW Air Compressor Technical Proposal and QuotationOleg Semonenko100% (1)

- Field Testing of CompressorsДокумент12 страницField Testing of CompressorsmishraenggОценок пока нет

- Enclosure Integrity Test Report: Insert Company LogoДокумент10 страницEnclosure Integrity Test Report: Insert Company LogoReynold AndikaОценок пока нет

- Performance Testing Air Conditioning EquipmentДокумент14 страницPerformance Testing Air Conditioning EquipmentLone CruzenaОценок пока нет

- FMEA PДокумент6 страницFMEA Pparu1982Оценок пока нет

- ANSI Standard for Performance Rating of Air TerminalsДокумент19 страницANSI Standard for Performance Rating of Air TerminalsRCYABOОценок пока нет

- M&E Division Sprinkler System TestДокумент2 страницыM&E Division Sprinkler System Testgururaj100% (2)

- Foam Hose Reel Testing ProcedureДокумент26 страницFoam Hose Reel Testing ProcedureVijil JohnrajОценок пока нет

- Nav Fluorine Air Compressor SpecДокумент15 страницNav Fluorine Air Compressor Specdhanu_lagwankarОценок пока нет

- Book 19 (Ca)Документ12 страницBook 19 (Ca)dirgan_udyanaОценок пока нет

- JFTOT Analysis ASTM D1655, D7566 and Def Stan 91-91Документ10 страницJFTOT Analysis ASTM D1655, D7566 and Def Stan 91-91am4rОценок пока нет

- List of HVAC SpecificationsДокумент46 страницList of HVAC Specificationsnguyenquoc1988100% (1)

- HVAC System Tender Specification SheetДокумент46 страницHVAC System Tender Specification SheetAnkush Nayar100% (1)

- Factory Acceptance Test for HVAC Control PanelsДокумент7 страницFactory Acceptance Test for HVAC Control PanelsdodonggОценок пока нет

- SOP For Duct Leak TestingДокумент8 страницSOP For Duct Leak TestingSubodh Murkewar50% (2)

- Oxygen Plant: B Air CompressorДокумент3 страницыOxygen Plant: B Air Compressorsumit11235Оценок пока нет

- 2010 06 Whats Going On With Loop PerformanceДокумент4 страницы2010 06 Whats Going On With Loop PerformanceKarl GlorstadОценок пока нет

- Ignitor & Scanner Air ControlДокумент5 страницIgnitor & Scanner Air ControlJKKОценок пока нет

- Belinda-MAQ-250-25BA-C Computer Control Safety Valve Test Bench R.0Документ10 страницBelinda-MAQ-250-25BA-C Computer Control Safety Valve Test Bench R.0ahsun habibОценок пока нет

- Sira 13atex1083x Iss 0Документ5 страницSira 13atex1083x Iss 0AlanBertinSouzaОценок пока нет

- Noise and Vibrations in Boiler PlantsДокумент3 страницыNoise and Vibrations in Boiler PlantsDan SabadusОценок пока нет

- Hepco Motion - Clean RoomДокумент2 страницыHepco Motion - Clean RoomjoechengshОценок пока нет

- !qfpira00nvuqcoating Specs For 13176Документ24 страницы!qfpira00nvuqcoating Specs For 13176Masood AlamОценок пока нет

- Sample QAPДокумент3 страницыSample QAPsniperiОценок пока нет

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionОт EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionРейтинг: 4.5 из 5 звезд4.5/5 (3)

- Franke 2018 Master1Документ92 страницыFranke 2018 Master1ashrefrasliОценок пока нет

- Duct Installation MethodДокумент62 страницыDuct Installation Methodashrefrasli100% (1)

- Water Installations Code 2016Документ49 страницWater Installations Code 2016Ahmad AbbasОценок пока нет

- Mitsubishi Split Air ConditionersДокумент1 страницаMitsubishi Split Air ConditionersashrefrasliОценок пока нет

- Sump Pit CalculationДокумент4 страницыSump Pit CalculationEng Mahmoud Hamdy33% (3)

- Flowcheck Guide To Pumps PDFДокумент3 страницыFlowcheck Guide To Pumps PDFashrefrasliОценок пока нет

- Tariff CalculatorДокумент2 страницыTariff CalculatorashrefrasliОценок пока нет

- Enargy and Water Conservation Code 2016Документ25 страницEnargy and Water Conservation Code 2016katiki216Оценок пока нет

- Lecture - PumpsДокумент26 страницLecture - PumpsashrefrasliОценок пока нет

- Duct Geometry Comparison: Rectangular vs CircularДокумент2 страницыDuct Geometry Comparison: Rectangular vs CircularashrefrasliОценок пока нет

- Design Guideline Water Supply Booster Pump StationДокумент13 страницDesign Guideline Water Supply Booster Pump StationashrefrasliОценок пока нет

- Pump Design PDFДокумент8 страницPump Design PDFkuselanmlОценок пока нет

- Sample Igc2Документ8 страницSample Igc2ashrefrasliОценок пока нет

- 2012-7351-101fa Cause An EffectДокумент1 страница2012-7351-101fa Cause An EffectashrefrasliОценок пока нет

- 150120-HSE Inspection Report-148+AttendДокумент11 страниц150120-HSE Inspection Report-148+Attendashrefrasli75% (4)

- CleanAgent 2001Документ7 страницCleanAgent 2001ashrefrasliОценок пока нет

- Pamantasan ng Lungsod ng Pasig College of International Hospitality Management SyllabusДокумент19 страницPamantasan ng Lungsod ng Pasig College of International Hospitality Management SyllabusWhena Rios70% (61)

- CMMДокумент28 страницCMMArun Raj A CОценок пока нет

- SuspensionДокумент47 страницSuspensiongsaratkumar50% (2)

- Marketing in 4th Industrial RevolutionДокумент8 страницMarketing in 4th Industrial RevolutionCamille Anne ParacОценок пока нет

- Describing Tables: Practise Exercise OneДокумент3 страницыDescribing Tables: Practise Exercise OneAbdulazizОценок пока нет

- Redevelopment ThesisДокумент5 страницRedevelopment Thesisjessicaandersonseattle100% (2)

- LVL Hip Rafter DesignДокумент5 страницLVL Hip Rafter DesignDavid Shanks 1Оценок пока нет

- T REC G.650.1 201210 S!Amd1!PDF EДокумент16 страницT REC G.650.1 201210 S!Amd1!PDF EVenâncio Ricardo MendonçaОценок пока нет

- 12.application of CapacitorsДокумент102 страницы12.application of CapacitorsNamiraОценок пока нет

- Termostat Centrala de La Dormitor Q7 RF PDFДокумент16 страницTermostat Centrala de La Dormitor Q7 RF PDFdanut horincasОценок пока нет

- Thesis University of AucklandДокумент4 страницыThesis University of Aucklandaflpbpcnhjpwkd100% (2)

- Om 6802Документ44 страницыOm 6802Coder_DzОценок пока нет

- Guide: Daily ReferenceДокумент8 страницGuide: Daily ReferenceGalina TodorovaОценок пока нет

- BrochureДокумент68 страницBrochure7063673nasОценок пока нет

- Lesson 2: Reading and Writing Assignment: Public Relations Ethics: Case StudyДокумент3 страницыLesson 2: Reading and Writing Assignment: Public Relations Ethics: Case StudyAzel DizonОценок пока нет

- Theory of ErrorsДокумент43 страницыTheory of Errorsjaybh575Оценок пока нет

- Telford - Applied Geophysics PDFДокумент8 страницTelford - Applied Geophysics PDFJUAN CARMONAОценок пока нет

- 17EN IMC CAT ACBHW Eb SRGB PDFДокумент92 страницы17EN IMC CAT ACBHW Eb SRGB PDFJoyceYap100% (1)

- Non-Symmetric Bi-Stable Flow Around The Ahmed Body - Meile WДокумент14 страницNon-Symmetric Bi-Stable Flow Around The Ahmed Body - Meile WJesus AguilarОценок пока нет

- PROOFEX TORCHSEAL 3PV WATERPROOFING MEMBRANEДокумент1 страницаPROOFEX TORCHSEAL 3PV WATERPROOFING MEMBRANETharra AyurianyОценок пока нет

- Technology Development for InSb Infrared ImagersДокумент6 страницTechnology Development for InSb Infrared ImagersSukhmander SinghОценок пока нет

- CaFSET (Antigua) Office Workbook - Sixth Edition - Programming Concepts Sample PagesДокумент4 страницыCaFSET (Antigua) Office Workbook - Sixth Edition - Programming Concepts Sample PagescafsetОценок пока нет

- GDDM - GDDMMVS Program DirectoryДокумент111 страницGDDM - GDDMMVS Program DirectoryShahin R KrishnaОценок пока нет

- Assessing ash fouling and slagging in coal-fired boilersДокумент10 страницAssessing ash fouling and slagging in coal-fired boilersDSGОценок пока нет

- Plato's Philosophy of Arithmetic PEDE CASINGДокумент75 страницPlato's Philosophy of Arithmetic PEDE CASINGPede CasingОценок пока нет

- SD ContentsДокумент18 страницSD ContentsAnonymous gUjimJKОценок пока нет

- VCBДокумент3 страницыVCBMitesh GandhiОценок пока нет

- Alan Maley Poster 2Документ1 страницаAlan Maley Poster 2Cory KobyОценок пока нет

- Manual: EMS-00186 Service Documentation and Software SystemsДокумент555 страницManual: EMS-00186 Service Documentation and Software SystemsJulia Kusova100% (2)

- Geberit Bathroom Collection BrochureДокумент125 страницGeberit Bathroom Collection BrochureThanhОценок пока нет