Академический Документы

Профессиональный Документы

Культура Документы

AISSMS College of Engineering, Pune. M.E Mechanical (Automotive Engineering) 1

Загружено:

Shrishant Patil0 оценок0% нашли этот документ полезным (0 голосов)

95 просмотров18 страницDtsi

Оригинальное название

Main Report

Авторское право

© © All Rights Reserved

Доступные форматы

DOCX, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документDtsi

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOCX, PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

95 просмотров18 страницAISSMS College of Engineering, Pune. M.E Mechanical (Automotive Engineering) 1

Загружено:

Shrishant PatilDtsi

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOCX, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 18

AISSMS College of Engineering, Pune. M.

E Mechanical (Automotive Engineering)

1

ABSTRACT

One of the requirements of an efficient engine is the correct amount of heat shock,

delivered at the right time. This requirement is the responsibility of the ignition

system. Digital ignition system is same as an electronic ignition system in which

spark timing is controlled by a computer that continuously adjust ignition timing to

obtain optimum combustion.

The digital spark ignition is the best alternative for conventional ignition system.

Computerized control gives accurate timing for all operating conditions. At the same

time use of two spark plugs improves thermodynamic efficiency and power available.

It is also good solution to reduce pollution since it minimizes emission levels. Also it

is flexible enough in mounting location. This is important because todays smaller

engine compartment.

Thus it is better in all areas like power, speed, efficiency and clean emission and

hence it has brought a new evaluation in automobile industry.

AISSMS College of Engineering, Pune. M.E Mechanical (Automotive Engineering)

2

1. INTRODUCTION

1.1 Purpose of Ignition System

For each cylinder in an engine, the ignition system has three main jobs:

1. It must generate an electrical spark they have enough heat to ignite the air fuel

mixture in the combustion chamber.

2. It must maintain the spark long enough to allow for the combustion of all the

air-fuel mixture in the cylinder.

3. It must deliver the spark to each cylinder so combustion can begin at the right

time during the compression stroke to each cylinder.

When the combustion process is completed, a very high pressure is exerted against

top of the piston. This pressure pushes the piston down on its power stroke and is the

force that gives the engine power. For an engine to produce maximum power it can,

the maximum pressure from combustion should be present when the piston is at 10 to

23 degrees after the top dead centre. Because combustion of air-fuel mixture within

the cylinder takes short period of time, usually in milliseconds, the combustion

process must begin before the piston is on its power stroke. Therefore, the delivery of

the spark must be timed to arrive at some time before the piston reaches the top dead

centre.

1.2 Conventional Single Spark Plug Ignited Four-Stroke Engine

The orthodox single cylinder, four-stroke, spark ignition engine is generally equipped

with a single spark plug. The fresh charge (air fuel mixture) that entered the cylinder

during the suction stroke is compressed during the compression stroke resulting in the

increase of pressure and temperature of the charge. The spark plug, usually situated at

one end of the combustion chamber, ignites the air-fuel mixture and the ensuing flame

spreads like a slowly inflating balloon. There is an inevitable delay for this inflating

balloon to reach the furthest part of the combustion chamber. So, there are pockets of

poor combustion within the chamber and, overall, the combustion is slow and

AISSMS College of Engineering, Pune. M.E Mechanical (Automotive Engineering)

3

inefficient. But there are some problems that single spark flame propagation cannot

give optimal combustion hence DTSi system is invented and Patented by Bajaj Auto.

1.3 Digital Twin Spark System

The Digital Twin Spark Ignition technology, patented by Bajaj Auto, takes care of

this slower combustion problem in a simple way. The cylinder head is equipped with

two spark plugs, instead of the usual one. By generating two sparks at either ends of

the combustion chamber, (approximately 90 to the valve axis) the air-fuel mixture

gets ignited in a way that creates two flame fronts and, therefore, a reduction in flame

travel of the order of 40 per cent is achieved. A fast rate of combustion is achieved

leading to faster rise in pressure. The obvious outcome of this is more torque, better

fuel efficiency and lower emissions. An electronic device (microprocessor) controls

the firing order of these twin spark plugs. The fresh charge that entered the cylinder

during the suction stroke is compressed during the compression stroke. Then a spark

will be ignited by one of the twin spark plugs and the flame front begins to expand

like an inflating balloon. In the mean while another spark will be ignited by another

spark plug as per controls of the microprocessor. The flame front also begins to

expand like an inflating balloon. Therefore the areas that are not covered by the first

flame front will be covered by second flame front resulting in the complete & rapid

combustion of the fuel. This technology is incorporated in Bajaj bikes since 2003, in

series of Pulsar and Discover.

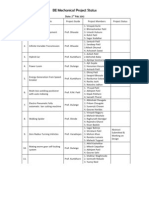

Figure 1: Conventional Single Spark & DTSi Ignition system

AISSMS College of Engineering, Pune. M.E Mechanical (Automotive Engineering)

4

2. DTSI SYSTEM: TERMINOLOGY

2.1 Ignition Timing

Ignition timing refers to the precise time spark offers and is specified by referring to

the position of the piston in relation with crank shaft rotation. Ignition timing

reference marks can be located on engine parts and on a pulley or fly wheel to

indicate the position of the piston. Vehicle manufacturer specify initial or base

ignition timing. When the marks are aligned at TDC or 0, the piston in cylinder is at

TDC of its compression stroke. Additional numbers on a scale indicates the number of

degrees of crank shaft rotation before TDC or after TDC. In majority of engines, the

initial timing is specified at a point between TDC and 20 degrees BTDC.

If optimum engine performance is to be maintained, the ignition timing of the engine

must change as the operating condition of the engine change. All the different

operating conditions affect the speed of the engine and load on the engine. All

ignition timing changes are made in reference is made to following primary factors:

2.1.1 Engine RPM:

At higher rpm, the crank shaft turns through more degrees in a given period of time. If

combustion is to be completed by 10 degrees ATDC, ignition timing must occur

sooner or advanced however, airfuel mixture turbulence increases with rpm. This

causes the mixture inside cylinder to turn faster. Increased turbulence requires that

ignition must occur slightly later or be advanced. These two factors must be balanced

for the best engine performance. Therefore, while the ignition timing must be

advanced as engine speed increases, the amount of advance must be decreased some

to compensate for the increased turbulence.

AISSMS College of Engineering, Pune. M.E Mechanical (Automotive Engineering)

5

Figure 2: Effect of speed on ignition timing (at High Speed & at Low Speed)

2.1.2 Engine Load:

The load on engine is related to the work it must do. Driving uphill or pulling extra weight

increases engine load .Under load there is resistance on the crank shaft, therefore the piston

have a harder time moving through dead strokes. This is evident by low vacuum during the

heavy loads. Under light loads and with the throttle plates partially opened, a high vacuum

exist in the intake manifold. The amount of air air-fuel mixture drawn into the manifold and

cylinder is small. On compression this thin mixture produces less combustion pressure and

combustion time is less. To complete combustion by 10 degrees ATDC, ignition time must be

advanced.

Under heavy loads when the throttle is opened fully a larger mass of air-fuel mixture can be

drawn in and the vacuum in the manifold is low .High combustion pressure and rapid burning

results. In such a case the ignition timing must be retarded to prevent complete burning from

occurring before 10 degrees ATDC.

2.2 Digital Ignition system

Digital ignition system is same as an electronic ignition system in which spark timing

is controlled by a computer that continuously adjust ignition timing to obtain optimum

combustion. The ignition system on the Twin spark is a digital system with static

spark advance and no moving parts subject to wear. It is mapped by the integrated

digital electronic control box which also handles fuel injection and valve timing. It

features two plugs per cylinder. This innovative solution, also entailing a special

AISSMS College of Engineering, Pune. M.E Mechanical (Automotive Engineering)

6

configuration of the hemispherical combustion chambers and piston heads, ensures a

fast, wide flame front when the air-fuel mixture is ignited, and therefore less ignition

advance, enabling, moreover, relatively lean mixtures to be used. This technology

provides a combination of the light weight and twice the power offered by two-stroke

engines with a significant power boost, i.e. a considerable "power-to-weight ratio"

compared to quite a few four-stroke engines. The actual picture of Bajaj Pulsar Bike

is - Moreover, such a system can adjust idling speed & even cuts off fuel feed when

the accelerator pedal is released, and meters the enrichment of the air-fuel mixture for

cold starting and accelerating purposes; if necessary, it also prevents the upper rev

limit from being exceeded. At low revs, the over boost is mostly used when

overtaking, and this is why it cuts out automatically. At higher speeds the over boost

will enhance full power delivery and will stay on as long as the driver exercises

maximum pressure on the accelerator.

Figure 3: Cut Section view of DTSi Engine of Pulsar 2 Valve DTSi engine

AISSMS College of Engineering, Pune. M.E Mechanical (Automotive Engineering)

7

2.2.1 Main Characteristics of DTSi System

Main characteristics of DTSi System are as follows

1. Digital electronic ignition with two plugs per cylinder and two ignition

distributors; (in case of multi cylinder TS engine )

2. Twin overhead cams with camshaft timing variation;(for 4 valve)

3. Injection fuel feed with integrated electronic twin spark ignition;

4. A high specific power;

5. Compact design and Superior balance.

2.2.2 Benefits of Twin Spark

1. Improved thermodynamic efficiency.

2. More effective combustion at yielding and low speed.

3. Considerable reduction in specific fuel consumption.

4. Reduction in exhaust emission.

5. Less chance of ignition system failure

3. DTSI SYSTEM: CONSTRUCTIONAL DETAIL

3.1 Various Components of DTSi Engine

The construction of DTSi engine (here we are considering about Bajaj Pulsar 180

DTSi model) is same as that of the conventional 4-Stroke engine. It consists of

following parts:

Piston Cylinder Crankshaft

Connecting rod Carburetor 2-sparkplug

4-valves CDI unit (ECU) TRICS III Unit

Position Sensors A/D Converter Camshaft

AISSMS College of Engineering, Pune. M.E Mechanical (Automotive Engineering)

8

Here the only change made is that the 2 sparkplug placed at the two opposite end of

the combustion chamber. The 180cc Pulsar DTSi engine sticks with the aluminum

alloy cased 4 stroke cycle engines that are clearly based on the earlier tried and tested

power plant. Its Single cylinder is air cooled % still displaces 178.6cc. Bajaj has used

its patented DTSi technology, which ensures the engines twin plugs are set to ignite

together in one instant according to need. This means the twin sparks travel to

combust mixture from opposite ends of the combustion chamber and accelerate this

process thereby delivering higher power output as improved fuel economy. The bike

also employs ExhausTEC, or a resonance chamber sitting on the silencer that helps

pack a healthy punch low in the bikes power band. This engine gives about 17.02bhp

at 8500 rpm & torque of 14.22Nm@6500.

Here we all know about the conventional mechanical parts of engine so we can skip

and go to important parts of DTSi engine system. In Pulsar 180 cc DTSi technology

based engine is used and it has the technologies called TRICS III and CDI. It works

on the DTSi technology, depending on Throttle load, Engine speed and Load, and

according sends the signal getting from position sensors.

Figure 4: CAD view of Pulsar 180cc 4valve DTSi Engine

AISSMS College of Engineering, Pune. M.E Mechanical (Automotive Engineering)

9

4. DTSI SYSTEM: WORKING

The working of DTSi engine is very similar to 4-stroke engine but here the only

modification done is we are using two spark plug at two ends of the combustion

chamber, which require less time to reach the farthest position of the combustion

chamber and optimize the combustion chamber characteristics.

There are some advance technology used in DTSi engine which makes it more

powerful than the conventional single sparkplug 4-stroke engine like

1. Tricks III technology

2. CDI technology

These above technologies are discussed below

4.1 CDI

The Intelligent Capacitor Discharge Ignition contains a microprocessor, which

continuously senses different speeds and load on engine and responds by altering

ignition timing. A Digital CDI with an 8 bit microprocessor chip handles the spark

delivery. The programmed chips memory contains an optimum Ignition timing for

any given engine rpm, thereby obtaining the best performance characteristics from the

combustion chamber. Working together with the TRICSIII system, the

microprocessor's memory provides optimum ignition timings for any given engine

rpm, thereby obtaining the best combustion performance. It improves fuel-efficiency

and reduces engine noise and vibration through smoother power delivery.

4.2 TRICS III

Throttle Responsive Ignition Control System 3rd generation. It is a means of

controlling the Ignition by operating the Throttle. Depending on the needs of the

Rider whether it be cruising, acceleration or max speed, the ignition requirements

constantly change. Based on a particular amount of Throttle opening, the Magnetic

field generated by the Magnet opens or closes the Reed switch. The Reed switch is

connected to the Digital CDI, which signals the CDI to change/switch, the desired

AISSMS College of Engineering, Pune. M.E Mechanical (Automotive Engineering)

10

Ignition Advance Timing Maps. This helps in achieving a good balance between

drivability and Optimum Ignition Spark advance, resulting in an almost perfect

Ignition Spark advance for every Throttle opening and Engine rpm. Throttle

Responsive Ignition Control System - III is an intelligent system which can quickly

adapt ignition timing to suit different riding characteristics.

TRICS III helps in achieving a good balance between low-to-mid range torque and

top-end power. This helps to ride easily in different conditions like flyovers, hilly

areas, dense traffic and highway cruising

5. ADVANTAGES OF DTSI SYSTEM

5.1 Performance

There is a new feel to the power, strong yet not daunting in the least, torque and

smooth in its delivery. For 180 DTSi 0 to 80 comes up in 6.8 sec. while 0 to 100

kmph is attained in 14.66 seconds. It is not just raw speeds and times that are

impressive but the manner in which the engine just spews the forth the juices in

manner in which is thoroughly intoxicating. The pulsar 150 benefits with DTSi

technology with all round gains in acceleration and maximum speeds.

Quantity

150 cc Engine 180 cc Engine

Old DTSi Old DTSi

Power (bhp) 12 15 15 17.02

Torque (Nm) 10.8 12.5 13.20 14.72

Max Speed 100 120 107 127

Table 1: Comparison of Performance of Old & New DTSi Pulsars

AISSMS College of Engineering, Pune. M.E Mechanical (Automotive Engineering)

11

5.2 Fuel Efficiency:

Due to DTSi system it is possible to combine strong performance and fuel efficiency.

The improved engine efficiency modes have also resulted in lowered fuel

consumption. Taking the 180 pulsar first, fuel consumption in city was averaged 43.3

kmph. However she went better in steady speed 80 kmph highway mode she recorded

46 km/l as company noted. Pulsar delivers shattering performance and high levels of

actual on road fuel efficiency but that both bikes meet the Government of Indias

emission norms for 2005 right now itself without use of any secondary devices.

Figure 5: Comparison of Power of Old Pulsar 180 & New DTSi Pulsar 180

For the number crunches the power output and torque outputs have increased. The

graph shows the comparison between original pulsar & pulsar DTSi. The gains are not

just in peak power and torque but also in lowering the torque peak and torque spread

even better across the rev range. What the DTSi system does is to overcome the

problem on a small capacity four stroke engines in a very elegant manner with the use

of two spark plugs placed diametrically opposite to each other in the combustion

chamber, normal to the valve plane. The initiation of two flame fronts, invoked

instantaneously combustion, reduced the required flame travel length required to burn

the charge.

The Coefficient of variance of indicated mean effective pressure at part throttle has

improved by 50%. For a given fuel ratio when running in part throttle condition the

indicated mean effective pressure has gone up by 15% in the Pulsar 180.

AISSMS College of Engineering, Pune. M.E Mechanical (Automotive Engineering)

12

This further helped the Bajaj bowfins to mote run the high compression ratio 9.6:1 of

the original but with a leaner air furl mixture which its reward in enhanced fuel

efficiency without stunting the power & torque produced. Data supplied by Bajaj auto

(indicating BSFC- brake specific fuel consumption being reduced by 10% in 150cc &

1.7% in 180cc) & experienced in our tests on both road & track confirmed the

enhanced efficiency fuel bits & also bring a smile to the faces of those who forever

revel in wringing the throttle wide open. Add to that the virtual absence of knock &

one has an engine which many would kill for just to put their names plates on.

At last we can enlist these advantages as follows:

1. Less vibrations and noise

2. Long life of the engine parts such as piston rings and valve stem.

3. Decrease in the specific fuel consumption

4. No over heating & better work output

5. Increase the Thermal Efficiency of the Engine & even bear high loads on it.

6. Better starting of engine even in winter season & cold climatic conditions or at

very low temperatures because of increased Compression ratio.

7. Because of twin Sparks the diameter of the flame increases rapidly that would

result in instantaneous burning of fuels. Thus force exerted on the piston would

increase leading to better work output.

8. Twin ignition tends to improve the engines fuel consumption under part load

operating conditions.

9. Twin ignition helps the ignition advance timing to be somewhat retarded which

tends to improve the engines smoothness and response.

AISSMS College of Engineering, Pune. M.E Mechanical (Automotive Engineering)

13

5.3 Statistics

The following are the various statistics showing the advantages of application of DTSi

& its derived technologies i.e. the comparison of various aspects of 150 cc category

and 125 cc category bikes.

Figure 6: Comparison of various aspects in 150cc category

Figure 8: Comparison of various aspects in 125cc category

AISSMS College of Engineering, Pune. M.E Mechanical (Automotive Engineering)

14

6. DISADVANTAGES OF DTSI ENGINES

The disadvantages are listed below

There is high NOx emission

If one spark plug get damaged then we have to replace both

The cost is relatively more

You spend double the amount on spark plugs when it is time to replace them.

The engine tends to overheat and loose power at higher speeds as compared to

a single plug engine.

In case the Engine is kept unused for a long time soiling of spark plugs occur.

Twin Spark system helps to reduce this problem.

It does not deliver any better mileage and acceleration than that derived from a

single spark plug.

7. LATEST DEVELOPMENT IN DTSI ENGINES

DTS-i.e. Engine can be further tuned to deliver exhilarating performance or

exceptional mileage. The further advances of DTS-I technologies are

Digital Twin Spark Swirl Induction (DTS - Si)

Digital Twin Spark Fuel Injection (DTS - Fi)

Digital Triple Spark ignition

7.1 Digital Twin Spark Swirl Induction (DTS - Si)

The DTS-I technology is the parent technology for this latest DTS-Si technology

(Used in Bajaj XCD 125, XCD 135). Even though a faster rate of combustion is

achieved by incorporating the DTS-I technology, there is a chance for further of

improvement of rapid combustion process at lighter loads. When there is a sufficient

or heavy load on the engine, the 4 stroke cycle completes at a faster rate resulting in

AISSMS College of Engineering, Pune. M.E Mechanical (Automotive Engineering)

15

the faster combustion because of the twin sparks produced by the twin plugs. But

when there exists a lighter load on the engine, the 4 stroke cycle will not complete at

a faster rate. Therefore even the incorporation of twin spark plugs cannot aid the

faster combustion i.e. still a better rate of combustion can be achieved at lighter loads.

Combustion efficiency in lean Air-Fuel mixture conditions can be further improved

by generating high turbulence in the combustion chamber. Combustion chambers

having low turbulence give rise to propagation of a flame front, which is akin to that

of a gradually expanding balloon. This results in a slower rate of combustion and thus

slower rate of pressure rise. End result is lower efficiency. When high turbulence is

generated and combustion takes place, the surface of the ballooning flame front

fragments itself, with projection like fingers, which increases its surface area, thereby

improving combustion further. Here comes the Swirl Induction concept, which is

meant for producing higher turbulence in the combustion chamber. Swirl Induction is

nothing but imparting a swirling motion to the fresh charge that enters the combustion

chamber. This can be done by making slight modifications in the ports positioning of

engine.

The DTS-Si engine will have two spark plugs but it differs from the parent DTS-I

engine in the design of position of the ports. The straight ports used in conventional

engines have limitations in generating high swirl values due to their geometry. One of

the ways to generate more swirl is to have a port configuration that promotes this

phenomena. An offset port configuration was arrived upon and optimized to generate

the required swirl numbers. Incorporated in the new engine, this results in a swirling

motion of the incoming charge, which decays itself into turbulence as the piston

moves in the Induction and Compression strokes. This results in the Air-Fuel mixture

being more thoroughly mixed and spread around the combustion chamber. Sparks

provided by the twin spark plugs ignite this highly turbulent and compressed Air-Fuel

mixture, leading to a flame front with high surface area, resulting in a rapid rise of

pressure due to rapid combustion. The values of turbulence achieved now, are

substantially higher than that of a straight port cylinder head, such as in DTS-i. A

combination of DTS-i and Swirl induction thus provides extremely rapid combustion,

resulting in high efficiency.

AISSMS College of Engineering, Pune. M.E Mechanical (Automotive Engineering)

16

7.2 Digital Twin Spark Fuel Injection (DTS - Fi)

DTS Fi is another advancement of the parent DTS i technology. This technology

is the combination of both DTS i and fuel injection. This technology is meant for

increasing the fuel efficiency in power bikes. Generally in conventional 4-stroke

engines, which use petrol as fuel, makes use of carburetor, which mixes the fuel and

fresh air in required ratio and supplies the same to the combustion chamber. The

process is similar for all loads. But the fuel consumption will be more when there is a

heavy load on the engine and it is less when there is a light load on the engine. It is

impossible for a conventional carburetor to take care of the fuel supply for these

varying loads. Therefore there is a need for some intelligent device that controls the

fuel supply according to the varying loads. That so wanted intelligent device is

nothing but the Electronic Control Unit (ECU). The Electronic Control Unit is a

microprocessor based system and can be regarded as the brain of the fuel injection

system. It processes information sent by various sensors and instantly determines

optimum fueling and spark timing for various engine-operating conditions. The ECU

contains detailed information of the engine's characteristics from which it picks the

necessary data for commanding both fueling & sparks timing.

7.3 Digital Triple Spark Ignition

At the heart of the new Pulsar is its cutting-edge engine which sets new benchmarks

in performance, emission and incidentally also fuel efficiency. The DTS-i (Digital

Twin Spark-ignition) technology launched in 2003 marked a unique first in the history

of Indian Motoring. The new Pulsar takes this technology altogether to another level

with a SOHC 4-valve Triple Spark engine controlled by an advanced Electronic

Control Unit for an absolutely unmatched performance. To support this exhilarating

heart-pumping performance the bike comes with liquid cooling and a six speed gear

box. The Pulsar 200NS chassis comprises a pressed steel perimeter frame and a

Rectangular tube section swing arm delivering over three times the lateral stiffness of

a P220 frame. These deliver outstanding high speed handling and cornering stability.

The centrally located muffler and the unique gas filled Nitrox mono suspension

further improve the ride and handling of the bike due to low & centralized CG

position. The Pulsar design character has evolved with the performance & dynamics.

AISSMS College of Engineering, Pune. M.E Mechanical (Automotive Engineering)

17

It's become stronger, more aggressive with a street fighter stance. The look just begs

you to ride it. Once astride, the sporty Speedo console, triple-tree clip-ons, the

signature clips and the illuminated switches evoke the design, fit and finish so far

exclusively reserved for much more expensive super sports bikes. The new 200cc

Pulsar is probably the most stunning sports bike in its class oozing raw muscular

appeal. To make use of 3 spark plugs, the pulsar engine houses a pent roof

combustion chamber which in turn allows housing 3 spark plugs in the engine

chamber. Out of the three plugs, the primary plug is the center one and is mounted in

an angle and enters the chamber at the top-center. The other two secondary plugs are

mounted below, each opposite each other and one of them being vertically underneath

the primary plug. The secondary plugs fires a bit after the primary one has fired and

the timings are controlled by the ECU depending on various parameters like throttle

position, engine revs, load on engine and much other stuff. According to Bajaj, these

plugs gain an advantage in low-rev riding condition where it extracts the best

economy.

8. SUMMARY

Hence it can be concluded that the application of this technology in the present day

automobiles will give the present generation what they want i.e. power bikes with fuel

efficiency. Since these technologies also minimize the fuel consumption and harmful

emission levels, they can also be considered as one of the solutions for increasing fuel

costs and increasing effect of global warming. The use of these technologies ensures

rapid combustion of the fuel in the combustion chamber, lower emissions and thereby

an increase in the fuel efficiency. Better low end torque, Lower fuel delivery and

optimization of spark timing, improved cold start, quick warm up and excellent

response to the sudden acceleration, Lower emission levels, Self detection and

communication of fuel system malfunctioning if any are also some of the important

advantages of these technologies. We can hope for still better technologies, which can

achieve still better results because there is no end for innovation.

AISSMS College of Engineering, Pune. M.E Mechanical (Automotive Engineering)

18

Reference Books

Dr. Kirpal Singh, Automobile Engineering. Vol.2, Standard Publishers

Distributors, 2009 Pg. No 516 to 607 Engine specifications

John b. Heywood, Internal Combustion Engine Fundamentals, McGraw-Hill

Book Co., New Delhi, 2001.

Papers from Journals or Transaction/s

Recent trends in Four-Stroke Internal Combustion Engines of Two-Wheelers

Syed Moizuddin1, Naved Ahmad2, Mohammad (IOSR Journal of Mechanical

and Civil Engineering (IOSR-JMCE) e-ISSN: 2278-1684, p-ISSN: 2320-334X

PP 37-41)

Digital Twin Spark Ignition Using Mechatronics by Dattatrey Zambre1,

Gaurav Shintre2, Bhagyashri Patil (IOSR Journal of Mechanical and Civil

Engineering (IOSR-JMCE) e-ISSN: 2278-1684, p-ISSN: 2320-334X PP 73-

78)

Comparative study of performance of dual plug and single plug SI engine at

different compression ratios By Narasimha Bailkeri1, Krishna Prasad,

Shrinivasa Rao (International Journal of Advanced Research in engineering

technology Volume 4, Issue 5, July August 2013, pp. 188-197)

Reports, Handbooks etc.

OVERDRIVE Vol. 6, No.1, September 2003. OVERDRIVEVol. 5, No 5,

January 2003.

Pulsar DTSi Workshop manual

Auto-car India No. 509 Bajaj Pulsar 180cc DTSi Article

Internet

http://www.iosrjournals.org

http://www.bajajauto.com

http://www.wikipaedia.com/bajapulsar

Вам также может понравиться

- AISSMS College of Engineering, Pune. M.E Mechanical (Automotive Engineering) 1Документ18 страницAISSMS College of Engineering, Pune. M.E Mechanical (Automotive Engineering) 1Safalsha BabuОценок пока нет

- DTSI Techonology Seminar Report For Rite CollegeДокумент21 страницаDTSI Techonology Seminar Report For Rite Collegesurjit kumar sahoo82% (17)

- Automobile Electric IgnitionДокумент35 страницAutomobile Electric IgnitionPM50% (2)

- Timing Advance UnitДокумент9 страницTiming Advance UnitShohan Taylor50% (2)

- Chapter 9Документ50 страницChapter 9gonriОценок пока нет

- Ignition Timing: Dead Center (BTDC) - Advancing The Spark BTDC Means That The Spark Is EnergizedДокумент5 страницIgnition Timing: Dead Center (BTDC) - Advancing The Spark BTDC Means That The Spark Is Energizedmiguel angelОценок пока нет

- Dtsi TechnologyДокумент10 страницDtsi TechnologyPrabir Kumar PatiОценок пока нет

- Diesel Engines Class NotesДокумент15 страницDiesel Engines Class NotesNandakumar BasavarajОценок пока нет

- DtsiДокумент14 страницDtsiShubhad KumarОценок пока нет

- Ijmet 10 02 001 PDFДокумент9 страницIjmet 10 02 001 PDFAnonymous 2e2XE0GFwpОценок пока нет

- DTS I EngineДокумент18 страницDTS I EngineAwais AhmadОценок пока нет

- Turbocharging of Ic EnginesДокумент5 страницTurbocharging of Ic EnginesKrishna MurthyОценок пока нет

- Unit-II Two Mark QuestionsДокумент7 страницUnit-II Two Mark QuestionshariharanbookОценок пока нет

- DTSIДокумент17 страницDTSIAbhimanyuBishnoi100% (1)

- Tech Seminar - FinalДокумент22 страницыTech Seminar - FinalpreetamОценок пока нет

- Dts IДокумент20 страницDts Ishikha1609Оценок пока нет

- Transonic EngineДокумент24 страницыTransonic Enginesajumj100% (1)

- Digital Twin Spark Ignition (Dtsi)Документ13 страницDigital Twin Spark Ignition (Dtsi)ShaswathMurtuguddeОценок пока нет

- Digital Twin Spark Ignition (Dtsi)Документ16 страницDigital Twin Spark Ignition (Dtsi)Yogi BhimaniОценок пока нет

- PLUG WIRE CAPACITOR TechnologyДокумент1 страницаPLUG WIRE CAPACITOR TechnologyJavedОценок пока нет

- Spark AdvanceДокумент9 страницSpark Advanceblackmailer hackОценок пока нет

- Basic Spark Advance TableДокумент9 страницBasic Spark Advance Tablek07800702123Оценок пока нет

- All Ablut Glowplugs BERUДокумент16 страницAll Ablut Glowplugs BERURoman AdamОценок пока нет

- Fuel Metering For Diesel Engines: Mixture RequirementsДокумент6 страницFuel Metering For Diesel Engines: Mixture Requirementsallan lariosaОценок пока нет

- Fuel Metering For Diesel Engines: Mixture RequirementsДокумент6 страницFuel Metering For Diesel Engines: Mixture RequirementsSANDEEP ROYОценок пока нет

- Advance and Ignition Timing For Better Fuel EconomyДокумент9 страницAdvance and Ignition Timing For Better Fuel EconomySebastian BryceОценок пока нет

- Assignment: Advanced I.C. EnginesДокумент11 страницAssignment: Advanced I.C. EnginesMuhammed RameesОценок пока нет

- Mce523 - IgnitionДокумент19 страницMce523 - Ignitionडॉ. इन्द्रसेन सिंहОценок пока нет

- Ignition TimingДокумент2 страницыIgnition TimingleitordОценок пока нет

- CI Engine CombustionДокумент14 страницCI Engine CombustionRahul MeenaОценок пока нет

- Lecture Notes On Advanced I.C. Engine Part-IДокумент0 страницLecture Notes On Advanced I.C. Engine Part-IJaiguru Narayanasamy0% (1)

- SEM 2 2016/2017 BETA 3573 Vehicle Powertrain Management System Tutorial 2Документ5 страницSEM 2 2016/2017 BETA 3573 Vehicle Powertrain Management System Tutorial 2uoyonoОценок пока нет

- Two Stroke NXT Generation EngineДокумент10 страницTwo Stroke NXT Generation EnginesaswatmahantyОценок пока нет

- Digital Triple Spark IgnitionДокумент20 страницDigital Triple Spark IgnitionAsifОценок пока нет

- Digital Twin Spark Ignition FinalДокумент17 страницDigital Twin Spark Ignition FinalSoumen Das100% (2)

- Final Tdi Diesel 01Документ28 страницFinal Tdi Diesel 01rschhajedОценок пока нет

- Advancing and RetardingДокумент2 страницыAdvancing and RetardingsabbirОценок пока нет

- What Is Stratified Charge Engine?Документ18 страницWhat Is Stratified Charge Engine?ÅBin PÅulОценок пока нет

- Effect of Valve ClearanceДокумент13 страницEffect of Valve Clearanceabdu0% (1)

- Advanced Ic EnginesДокумент13 страницAdvanced Ic EnginesVenkatesh MecОценок пока нет

- A Report On: Gasoline Direct Injection EngineДокумент17 страницA Report On: Gasoline Direct Injection EngineSrikanth Kabbal MОценок пока нет

- Dts-I Engine ReportДокумент13 страницDts-I Engine ReportRajesh PandaОценок пока нет

- Recent Advances in Ic Engine UNIT-5: SinghДокумент54 страницыRecent Advances in Ic Engine UNIT-5: SinghAshutosh RaiОценок пока нет

- Internal Combustion Engine - Engine KnockingДокумент11 страницInternal Combustion Engine - Engine KnockingZuhairi Iylia ZulkafliОценок пока нет

- Seminar ReportДокумент15 страницSeminar ReportSachin Igoor100% (1)

- Fat I Mad Ya A Saad Octane NumberДокумент15 страницFat I Mad Ya A Saad Octane NumberMalik HatemОценок пока нет

- What Happens If Ignition Timing Is Too AdvancedДокумент2 страницыWhat Happens If Ignition Timing Is Too Advancedayush shrotriya0% (1)

- IC Engines (Ch-III)Документ10 страницIC Engines (Ch-III)prasanthiОценок пока нет

- 218 - Valve Timing and Ignition For CNGДокумент5 страниц218 - Valve Timing and Ignition For CNGAndres Fernando Sokol UrzagasteОценок пока нет

- Diesel CycleДокумент10 страницDiesel CycleSri Ram VikasОценок пока нет

- Emissions and Fuels - HalfДокумент43 страницыEmissions and Fuels - HalfKashif UsmanОценок пока нет

- Lecture - 3 Combustion Phases of SI and CI EnginesДокумент21 страницаLecture - 3 Combustion Phases of SI and CI EnginesMuhammad SaqibОценок пока нет

- Ignition Dynamics I: Aircraft Research ReportДокумент7 страницIgnition Dynamics I: Aircraft Research ReportWilson UmpuОценок пока нет

- Specifications of The Modified Engine 1Документ24 страницыSpecifications of The Modified Engine 1Naveen DasОценок пока нет

- 10.5. Ignition Delay: 10.5.1. Definition and DiscussionДокумент14 страниц10.5. Ignition Delay: 10.5.1. Definition and DiscussionDUVAN FELIPE MUNOZ GARCIAОценок пока нет

- Thermal 2 Marks5Документ13 страницThermal 2 Marks5Kannan SubramaniОценок пока нет

- Ic-Mid Exam N SolutnДокумент9 страницIc-Mid Exam N SolutnFasilОценок пока нет

- Ic Engine: Assignment#02Документ9 страницIc Engine: Assignment#02Jawad ZafarОценок пока нет

- Diesel Common Rail Injection Electronic Components ExplainedОт EverandDiesel Common Rail Injection Electronic Components ExplainedРейтинг: 3.5 из 5 звезд3.5/5 (7)

- Overview of BusinessДокумент30 страницOverview of BusinessShrishant PatilОценок пока нет

- My TPPДокумент9 страницMy TPPShrishant PatilОценок пока нет

- Tech-Know-Trans 2K11: Mechanical EngineeringДокумент22 страницыTech-Know-Trans 2K11: Mechanical EngineeringShrishant PatilОценок пока нет

- RECENT TRENDS in AUTOMOBILES (Shrishant Patil & Sagar Bahirje. From A.g.patil Institute of Technology, Solapur.)Документ16 страницRECENT TRENDS in AUTOMOBILES (Shrishant Patil & Sagar Bahirje. From A.g.patil Institute of Technology, Solapur.)Shrishant PatilОценок пока нет

- ROMY2Документ15 страницROMY2Shrishant PatilОценок пока нет

- Six Stroke Engine Coe PandharpurДокумент18 страницSix Stroke Engine Coe PandharpurShrishant PatilОценок пока нет

- Paper Presentation Coe PandharapurДокумент16 страницPaper Presentation Coe PandharapurShrishant PatilОценок пока нет

- Case Study of AutotronicsДокумент12 страницCase Study of AutotronicsShrishant PatilОценок пока нет

- Case Study o FtribologyДокумент16 страницCase Study o FtribologyShrishant PatilОценок пока нет

- Syllabus SheetДокумент11 страницSyllabus SheetShrishant PatilОценок пока нет

- What Is A Dual Fuel SystemДокумент4 страницыWhat Is A Dual Fuel SystemShrishant PatilОценок пока нет

- Petrol Vs Diesel Vs CNG Vs LPGДокумент8 страницPetrol Vs Diesel Vs CNG Vs LPGsohanvg2182Оценок пока нет

- Industrial Tribology (2011)Документ4 страницыIndustrial Tribology (2011)Shrishant PatilОценок пока нет

- Industrial Tribology (Oct 2012)Документ4 страницыIndustrial Tribology (Oct 2012)Shrishant PatilОценок пока нет

- Alternative Fuels in Ic EngineДокумент11 страницAlternative Fuels in Ic EngineShrishant PatilОценок пока нет

- 2.alternative Source of Energy (Fuel Cells)Документ12 страниц2.alternative Source of Energy (Fuel Cells)Shrishant PatilОценок пока нет

- h2 Ic EngineДокумент6 страницh2 Ic EngineAnoob HassanОценок пока нет

- Hydrogen Applications in AutomobilesДокумент12 страницHydrogen Applications in AutomobilesShrishant PatilОценок пока нет

- 10.fuel Cell VehicleДокумент15 страниц10.fuel Cell VehicleShrishant PatilОценок пока нет

- 3.automotive Fuel (Fuel Cell)Документ17 страниц3.automotive Fuel (Fuel Cell)Shrishant PatilОценок пока нет

- ME Mech Automotive Engineering - 26072013Документ55 страницME Mech Automotive Engineering - 26072013Shrishant PatilОценок пока нет

- Introduction To Dual Fuel EngineДокумент2 страницыIntroduction To Dual Fuel EngineShrishant Patil100% (2)

- Digital Twin Spark Ignition EnginesДокумент6 страницDigital Twin Spark Ignition EnginesShrishant PatilОценок пока нет

- Syllabus SheetДокумент11 страницSyllabus SheetShrishant PatilОценок пока нет

- BE Mech Engg.Документ57 страницBE Mech Engg.Vikram ShindeОценок пока нет

- Report Writing SkillsДокумент16 страницReport Writing SkillsShrishant PatilОценок пока нет

- Assembly ZRTVДокумент1 страницаAssembly ZRTVShrishant PatilОценок пока нет

- Projct Status BE MechДокумент2 страницыProjct Status BE MechShrishant PatilОценок пока нет

- Project Title ListДокумент12 страницProject Title ListShrishant PatilОценок пока нет

- Bosch VP44 Info & InstallationДокумент4 страницыBosch VP44 Info & InstallationbenjiОценок пока нет

- MAIN ENGINE ALARMS AND INTERLOCKS & Engine Monitoring System (CSIM) & PAM)Документ32 страницыMAIN ENGINE ALARMS AND INTERLOCKS & Engine Monitoring System (CSIM) & PAM)Harishbhusan PanigrahiОценок пока нет

- Course Outline: ABE 105 - AB Power EngineeringДокумент2 страницыCourse Outline: ABE 105 - AB Power EngineeringKaren Joy BabidaОценок пока нет

- Assignment BalancingДокумент2 страницыAssignment BalancingImmy SarkarОценок пока нет

- 700 Series TBIДокумент7 страниц700 Series TBIFelipe LichirguОценок пока нет

- IPL, Husqvarna, 541 RB,, BRUSHCUTTERS - CLEARING SAWS PDFДокумент51 страницаIPL, Husqvarna, 541 RB,, BRUSHCUTTERS - CLEARING SAWS PDFJaime AmarizОценок пока нет

- Cylinder Heads & ValvesДокумент95 страницCylinder Heads & ValvesFrank MosesОценок пока нет

- New Holland Eh215 Crawler ExcavatorДокумент653 страницыNew Holland Eh215 Crawler ExcavatorcarlosОценок пока нет

- Man 6L23-30H Wear LimitsДокумент1 страницаMan 6L23-30H Wear LimitsOsman AbaliОценок пока нет

- Diesel Engine 16V 2000 M61: MarineДокумент2 страницыDiesel Engine 16V 2000 M61: MarinemnezamiОценок пока нет

- John Deere 5100R OCДокумент3 страницыJohn Deere 5100R OCYundi GaoОценок пока нет

- Diesel Engines Basic TheoryДокумент3 страницыDiesel Engines Basic TheoryLaxman Singh SankhlaОценок пока нет

- 350Z ECU Resetting ProceduresДокумент2 страницы350Z ECU Resetting Proceduresr3belzОценок пока нет

- 10 - Failure Analysis GuidebookДокумент32 страницы10 - Failure Analysis GuidebookAnurag Dureja50% (2)

- CFD Analysis of Exhaust ManifoldДокумент59 страницCFD Analysis of Exhaust Manifoldkummethasivasankar100% (1)

- Suzuki GSX250F Across Microfiche CompleteДокумент177 страницSuzuki GSX250F Across Microfiche Completestinger30auОценок пока нет

- Datos Tecnicos Motor A Gas: Manufacturer Shengli Oilfield Shengli Power Machinery Group Company LTD (Shengdong Group)Документ3 страницыDatos Tecnicos Motor A Gas: Manufacturer Shengli Oilfield Shengli Power Machinery Group Company LTD (Shengdong Group)David J LopezОценок пока нет

- Saa6d102e 2C Ku S N 21494941 UpДокумент159 страницSaa6d102e 2C Ku S N 21494941 Upниколай тишаковОценок пока нет

- Holding Down BoltsДокумент5 страницHolding Down BoltsRamneek Arora0% (1)

- 2000 m72M013023 - 02EДокумент42 страницы2000 m72M013023 - 02EDimas Saputro100% (1)

- Motor Hidrolik 1Документ47 страницMotor Hidrolik 1endah alamiОценок пока нет

- 2009-07-04 170949 Mazda TimingДокумент8 страниц2009-07-04 170949 Mazda TimingSuksan SananmuangОценок пока нет

- Unit-5) Air CompressorsДокумент40 страницUnit-5) Air CompressorsChinmay LearningОценок пока нет

- Engine Control System (Sep 2015) PDFДокумент23 страницыEngine Control System (Sep 2015) PDFValeriy DomashenkoОценок пока нет

- A.C. Mechanical Fuel PumpДокумент5 страницA.C. Mechanical Fuel PumpKyle LabileОценок пока нет

- DATASHEETДокумент3 страницыDATASHEETToko DownloadОценок пока нет

- TF20G 2000GPM DieselДокумент1 страницаTF20G 2000GPM DieselKarim Tarek100% (1)

- Second Law Analysis If IC EnginesДокумент16 страницSecond Law Analysis If IC Enginesdjermounimohamed100% (1)

- Illustrated Parts List 290400: Model SeriesДокумент28 страницIllustrated Parts List 290400: Model SeriesDeboraОценок пока нет

- S60MC-C MK 7 Project Guide Two-Stroke Engines: Quit Main MenuДокумент14 страницS60MC-C MK 7 Project Guide Two-Stroke Engines: Quit Main MenuАлександр КозыревОценок пока нет