Академический Документы

Профессиональный Документы

Культура Документы

193 Gmaw Zug Asme (Andhika Rolando 3g) WPQ

Загружено:

Muhammad Fitransyah Syamsuar PutraОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

193 Gmaw Zug Asme (Andhika Rolando 3g) WPQ

Загружено:

Muhammad Fitransyah Syamsuar PutraАвторское право:

Доступные форматы

IC.

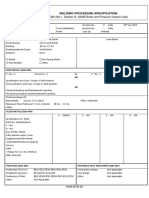

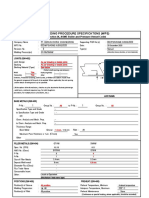

193/GMAW/ZUG/ASME

Welder's Name

Identification of WPS followed Test coupon Production weld

Specification and type/grade or UNS of base metal(s) Thickness

Welding process(es)

Type (ie. Manual, semi-automatic) used

Backing (with/ without)

Plate Pipe (enter diameter if pipe or tube)

Base metal P- Number to P- Number

Filler metal or electrode specification(s) (SFA) (info only)

Filler metal or electrode classification(s) (info only)

Filler metal F-Number(s)

Consumable insert (GTAW or PAW)

Filler Metal Product Form (solid/metal or flux cored/powder) (GTAW or PAW)

Deposit thickness for each process

Process 1 : GMAW 3 layers minimum Yes No

Process 2 : 3 layers minimum Yes No

Position qualified (2G, 6G, 3F, etc.)

Vertical progression (uphill or downhill)

Type of fuel gas (OFW)

Inert gas backing (GTAW, PAW, GMAW)

Transfer mode (spray/globular or pulse to shot circuit-GMAW)

GTAW current type/polarity (AC, DCEP, DCEN)

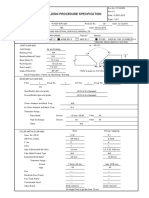

Visual Examination of Completed Weld (QW-302.4)

Transverse face and root bends [QW462.3(a)] Longitudinal bends [QW-462.3(b)] Side bends (QW-462.2)

Pipe bend specimen, corrosion-resistant weld metal overlay [QW-462.5(c)

Plate bend specimen, corrosion-resistant weld metal overlay [QW-462.5(d)

Pipe specimen, macro test for fusion [QW-462.5(b)] Plate specimen, macro test for fusion [QW-462.5(e)]

Type

N/A

Alternative Volumetric Examination Result (QW-191) RT or UT (check one)

Fillet weld - fracture test (QW-181.2)

Fillet weld in plate [QW-462.4(b)] Fillet weld in plate [QW-462.4(b)]

Macro examination (QW-184) Fillet size(in.) Concavity/convexity(in.)

Other tests None

Film or specimens evaluated by Mr. Abdul Djalal Company PT ZUG I.I (28 WQT/VII/ZII/QC-RT/2014)

Mechanical tests conducted by None

Welding supervised by Mr. Fathullah

We certify that the statements in this record are correct and that the test coupons were prepared, welded, and tested in accordance with the

requirements of Section IX of ASME BOILER AND PRESSURE VESSEL CODE.

Date : August 20, 2014

Manufacturer : PT. ZUG INDUSTRY INDONESIA

Prepared by, Reviewed by, KEMENAKERTRANS RI

Result

& Unassigned mtls of Smlr chem. Comp

to these mtls.

- - N/A -

N.A N.A

RESULTS

ACCEPTED

Type Result Type Result

N.A

N/A

ACCEPTED

Welding Engineer

Laboratory test no. None

Photo Welder

Muh. Fitransyah. S.P

Authorized Inspector

N/A Length and percent of defects -

N/A - -

N.A

None None

Short Circuting Short Circuting

None None

3G Plate & Pipe Over 24 in (610 mm) OD = F, V

Uphill Uphill

Pipe 24 in. (610 mm) OD = F

Fillet : Plate & Pipe = F, H, V

N.A N.A

12 mm max. 13.2 mm

ER 70S-6 N.A

F 6 All F6

N.A N.A

SFA 5.18 N.A

GMAW GMAW

MANUAL MANUAL

Without With or Without

Plate Min 2 in. (73 mm) O.D.

P. No.1 to P. No.1 P-No. 1 through P-No.15F, P-No.34,

and P-No.41 through P-No. 49

018/WPS/GMAW R.0

SA 516 Gr.70 12 mm

Testing Conditions and Qualification Limits

Welding Variables (QW-350) Actual Values Range Qualified

Test Description

WELDING PERFORMANCE QUALIFICATIONS (WPQ)

(Section IX, ASME Boiler and Pressure Vessel Code)

Mr. Andhika Rolando Identification no. Z 87

PT. ZUG INDUSTRY INDONESIA

Pergudangan Miami Jl. Rawa Melati Blok A. No.5

Kel. Tegal Alur - Kec. Kalideres Jakarta. Barat 11820

Phone : (62) 21-55952077 Fax : (62) 21-55951873

Email : zug@cbn.net.id

Photo Welder

Вам также может понравиться

- Welder Performance Qualification-Interactive Form QW-484AДокумент1 страницаWelder Performance Qualification-Interactive Form QW-484AJaved Mohammed100% (5)

- Welder Performance Qualification (WPQ)Документ2 страницыWelder Performance Qualification (WPQ)alokbdasОценок пока нет

- WPQ-1083 3G PDFДокумент2 страницыWPQ-1083 3G PDFduendex360100% (1)

- WPQ WeldCanada PDFДокумент1 страницаWPQ WeldCanada PDFAhmad DanielОценок пока нет

- WPQ CS SmawДокумент1 страницаWPQ CS Smawniket0Оценок пока нет

- PQR Form (Welding)Документ2 страницыPQR Form (Welding)jasmineammaОценок пока нет

- Fcaw 16 THKДокумент5 страницFcaw 16 THKparesh2387Оценок пока нет

- 163 Gmaw Zug Asme (Sri Supatmi 3g) WPQДокумент4 страницы163 Gmaw Zug Asme (Sri Supatmi 3g) WPQMuhammad Fitransyah Syamsuar PutraОценок пока нет

- WPS - 024Документ4 страницыWPS - 024MAT-LIONОценок пока нет

- Ilcs-Smaw-D1.3-Deck (G) WPSДокумент3 страницыIlcs-Smaw-D1.3-Deck (G) WPSRoss100% (1)

- ASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationДокумент2 страницыASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationAmit SharmaОценок пока нет

- WPS Format For ASME IX - PQR-AllДокумент3 страницыWPS Format For ASME IX - PQR-AllThe Welding Inspections Community100% (1)

- Format WPQДокумент2 страницыFormat WPQAkash Singh TomarОценок пока нет

- PQR-04 - AWS D1.6D1.6M-2007 Structural Welding Code - Stainless Steel PDFДокумент1 страницаPQR-04 - AWS D1.6D1.6M-2007 Structural Welding Code - Stainless Steel PDFchandraОценок пока нет

- Revised Wps For Gtaw - Xls Dated 25.01.2017Документ2 страницыRevised Wps For Gtaw - Xls Dated 25.01.2017GopinathОценок пока нет

- Welding Procedure Specification (PWPS) Asme Sec Ix, Asme Boiler & Pressure Vessel Code Contract: STP-Ph1Документ2 страницыWelding Procedure Specification (PWPS) Asme Sec Ix, Asme Boiler & Pressure Vessel Code Contract: STP-Ph1Karam Fta Al-andalusОценок пока нет

- PQRДокумент2 страницыPQRHoangОценок пока нет

- WPS-PQR Gmaw LtiДокумент2 страницыWPS-PQR Gmaw Ltibgonzalez198150% (2)

- Wps Gmaw SawДокумент2 страницыWps Gmaw Sawupedro26Оценок пока нет

- PT Kuwera Karya Me: PanduДокумент2 страницыPT Kuwera Karya Me: PanduGalang Pratama PutraОценок пока нет

- Qw-482 Welding Procedure Specification (WPS)Документ4 страницыQw-482 Welding Procedure Specification (WPS)Aldeline SungahidОценок пока нет

- Welding Procedure Specification For GTAW & GMAWДокумент4 страницыWelding Procedure Specification For GTAW & GMAWanh thoОценок пока нет

- SAIC-LT-2007 LeaK Testing-Vacuum BoxДокумент3 страницыSAIC-LT-2007 LeaK Testing-Vacuum BoxKirubhakarPooranamОценок пока нет

- WPS1Документ10 страницWPS1bhavin178Оценок пока нет

- Wps 316L Gtaw R00Документ3 страницыWps 316L Gtaw R00Richard Periyanayagam100% (3)

- WOPQ Form English1Документ2 страницыWOPQ Form English1oaperuchenaОценок пока нет

- SMAW DuniДокумент4 страницыSMAW DuniMuhammad Fitransyah Syamsuar PutraОценок пока нет

- 004 Gtaw P5aДокумент16 страниц004 Gtaw P5aMuhammad Fitransyah Syamsuar Putra100% (1)

- Welding Procedure Specification (WPS) : FM-87 Issue - 01 Date: Feb, 12,2015 Page 1 of 2Документ2 страницыWelding Procedure Specification (WPS) : FM-87 Issue - 01 Date: Feb, 12,2015 Page 1 of 2tayyabОценок пока нет

- Cajon-001 WPSДокумент2 страницыCajon-001 WPSDanem HalasОценок пока нет

- WPS Format For AWS D1.1 - WPS - SMAWДокумент1 страницаWPS Format For AWS D1.1 - WPS - SMAWThe Welding Inspections CommunityОценок пока нет

- WPS PQR PDFДокумент23 страницыWPS PQR PDFAhmad Daniel100% (1)

- Welding Parameter Record SheetДокумент2 страницыWelding Parameter Record SheetPravin Patil100% (1)

- Wps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxДокумент5 страницWps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxjobert100% (1)

- WPS PQR A36.20Документ5 страницWPS PQR A36.20gchaves504100% (2)

- Alum 6xxx PwpsДокумент1 страницаAlum 6xxx PwpsAbu Zahid100% (1)

- Aws D1.1 - WPS - Smaw-Fcaw PDFДокумент1 страницаAws D1.1 - WPS - Smaw-Fcaw PDFBernathTurnipОценок пока нет

- Aws 001Документ1 страницаAws 001akshay sarfareОценок пока нет

- Wps For Smaw06-001 (Pipe 6g CS)Документ10 страницWps For Smaw06-001 (Pipe 6g CS)walitedisonОценок пока нет

- WPQДокумент1 страницаWPQChava TejaОценок пока нет

- Wps Aws d1.1 NEWДокумент2 страницыWps Aws d1.1 NEWIkhy Tohepaly100% (1)

- Welding Proposed Pwps For Our Jubail WorkДокумент2 страницыWelding Proposed Pwps For Our Jubail WorkAlam MD Sazid100% (1)

- ASME IX-Welder Performance Qualification (WPQ) : Welding and NDT Purposed FormatДокумент1 страницаASME IX-Welder Performance Qualification (WPQ) : Welding and NDT Purposed FormatArshadAliОценок пока нет

- Smaw PQR FinalДокумент3 страницыSmaw PQR Finalsheikmoin100% (1)

- Wps Mma PipeДокумент2 страницыWps Mma PipeDimitris NikouОценок пока нет

- WPQR2Документ3 страницыWPQR2Thanasis KyrgiazoglouОценок пока нет

- Wps Is 2062 GR B Butt-OkДокумент2 страницыWps Is 2062 GR B Butt-OkAnand Kesarkar33% (3)

- Welding Procedure SpecificationДокумент3 страницыWelding Procedure SpecificationAhmed saber100% (2)

- Wps Format Asme Sec - IxДокумент2 страницыWps Format Asme Sec - IxDeepu ChandranОценок пока нет

- Wqt-Visual-Mag - BS 2Документ24 страницыWqt-Visual-Mag - BS 2KyОценок пока нет

- Piping WpsДокумент37 страницPiping WpsZulfokar FahdawiОценок пока нет

- Welder'S Qualification Test Certificate: (As Per Asme Sec Ix)Документ2 страницыWelder'S Qualification Test Certificate: (As Per Asme Sec Ix)vijay100% (1)

- WPSДокумент3 страницыWPSKhurram Burjees100% (1)

- Sample Welder ID As Per ASME Section IXДокумент99 страницSample Welder ID As Per ASME Section IXVivek Jadhav100% (1)

- VLG02 NGUYEN QUANG TUAN - 6G Duplex, T 18.26mmДокумент3 страницыVLG02 NGUYEN QUANG TUAN - 6G Duplex, T 18.26mmTuTuy AnОценок пока нет

- 161 Gmaw Zug Asme (Beni Kantona 3g) WPQДокумент2 страницы161 Gmaw Zug Asme (Beni Kantona 3g) WPQMuhammad Fitransyah Syamsuar PutraОценок пока нет

- Qw-484A Suggested Format A For Welder Performance Qualifications (WPQ) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)Документ1 страницаQw-484A Suggested Format A For Welder Performance Qualifications (WPQ) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)Aries MarteОценок пока нет

- QW484AДокумент1 страницаQW484AMohamed Ahmed MaherОценок пока нет

- 188-Gmaw-Zug-Asme (Rivaldy Hendrawan-3g) - WPQДокумент1 страница188-Gmaw-Zug-Asme (Rivaldy Hendrawan-3g) - WPQMuhammad Fitransyah Syamsuar Putra100% (1)

- WPQ TemplateДокумент1 страницаWPQ Templatejoshrathburn1980Оценок пока нет

- Tanda TerimaДокумент2 страницыTanda TerimaMuhammad Fitransyah Syamsuar PutraОценок пока нет

- Manufacturing Data Record IndexДокумент2 страницыManufacturing Data Record IndexMuhammad Fitransyah Syamsuar PutraОценок пока нет

- Employee Hours Worked Last Three YearsДокумент1 страницаEmployee Hours Worked Last Three YearsMuhammad Fitransyah Syamsuar PutraОценок пока нет

- Program K3 2023Документ2 страницыProgram K3 2023Muhammad Fitransyah Syamsuar PutraОценок пока нет

- Laporan PiketДокумент12 страницLaporan PiketMuhammad Fitransyah Syamsuar PutraОценок пока нет

- Transmittal FormДокумент90 страницTransmittal FormMuhammad Fitransyah Syamsuar PutraОценок пока нет

- PT BridonДокумент1 страницаPT BridonMuhammad Fitransyah Syamsuar PutraОценок пока нет

- Lifting Lug Calculation G1-5Документ3 страницыLifting Lug Calculation G1-5Muhammad Fitransyah Syamsuar Putra100% (1)

- PT DjabesmenДокумент1 страницаPT DjabesmenMuhammad Fitransyah Syamsuar PutraОценок пока нет

- PT DjabesmenДокумент1 страницаPT DjabesmenMuhammad Fitransyah Syamsuar PutraОценок пока нет

- PQR PT Bse WPS 07Документ2 страницыPQR PT Bse WPS 07Muhammad Fitransyah Syamsuar PutraОценок пока нет

- Method Statement For Prediction Weld Shrinkage On StructuralДокумент4 страницыMethod Statement For Prediction Weld Shrinkage On StructuralMuhammad Fitransyah Syamsuar PutraОценок пока нет

- Design Intermittent WeldingДокумент5 страницDesign Intermittent WeldingMuhammad Fitransyah Syamsuar PutraОценок пока нет

- Lifting Lug Calculation G1-5Документ3 страницыLifting Lug Calculation G1-5Muhammad Fitransyah Syamsuar Putra100% (1)

- Wps - Asme Ix - Gtaw - Plat SteДокумент6 страницWps - Asme Ix - Gtaw - Plat SteMuhammad Fitransyah Syamsuar PutraОценок пока нет

- Annex C Residual Stress Profiles: Fitnet Mk7Документ62 страницыAnnex C Residual Stress Profiles: Fitnet Mk7Muhammad Fitransyah Syamsuar PutraОценок пока нет

- 7 Inspection and Repair: 3 Api S 2BДокумент1 страница7 Inspection and Repair: 3 Api S 2BMuhammad Fitransyah Syamsuar PutraОценок пока нет

- Wps - Asme Ix - Gtaw - PipaДокумент5 страницWps - Asme Ix - Gtaw - PipaMuhammad Fitransyah Syamsuar PutraОценок пока нет

- AMH Magz Vol 9Документ40 страницAMH Magz Vol 9Muhammad Fitransyah Syamsuar Putra0% (1)

- WPQTДокумент18 страницWPQTMuhammad Fitransyah Syamsuar PutraОценок пока нет

- Decision Tree AlgorithmДокумент22 страницыDecision Tree Algorithmvani_V_prakashОценок пока нет

- Historical Roots of The "Whitening" of BrazilДокумент23 страницыHistorical Roots of The "Whitening" of BrazilFernandoMascarenhasОценок пока нет

- Program Need Analysis Questionnaire For DKA ProgramДокумент6 страницProgram Need Analysis Questionnaire For DKA ProgramAzman Bin TalibОценок пока нет

- Résumé Emily Martin FullДокумент3 страницыRésumé Emily Martin FullEmily MartinОценок пока нет

- Grade 6 q2 Mathematics LasДокумент151 страницаGrade 6 q2 Mathematics LasERIC VALLE80% (5)

- English ID Student S Book 1 - 015Документ1 страницаEnglish ID Student S Book 1 - 015Williams RoldanОценок пока нет

- AM-FM Reception TipsДокумент3 страницыAM-FM Reception TipsKrishna Ghimire100% (1)

- CH 2 PDFДокумент85 страницCH 2 PDFSajidОценок пока нет

- Boq Cme: 1 Pole Foundation Soil WorkДокумент1 страницаBoq Cme: 1 Pole Foundation Soil WorkyuwonoОценок пока нет

- Jack Arch RetrofitДокумент13 страницJack Arch RetrofitDebendra Dev KhanalОценок пока нет

- Office Administration: School-Based AssessmentДокумент17 страницOffice Administration: School-Based AssessmentFelix LawrenceОценок пока нет

- Projected Costs of Generating Electricity (EGC) 2005Документ233 страницыProjected Costs of Generating Electricity (EGC) 2005susantojdОценок пока нет

- GT-3000 PrintДокумент3 страницыGT-3000 Printmanual imbОценок пока нет

- MIDTERM Exam - Programming 2 - 2SEM 2020Документ3 страницыMIDTERM Exam - Programming 2 - 2SEM 2020Bab bidiОценок пока нет

- Debate Lesson PlanДокумент3 страницыDebate Lesson Planapi-280689729Оценок пока нет

- Muhammad Firdaus - A Review of Personal Data Protection Law in IndonesiaДокумент7 страницMuhammad Firdaus - A Review of Personal Data Protection Law in IndonesiaJordan Amadeus SoetowidjojoОценок пока нет

- L Rexx PDFДокумент9 страницL Rexx PDFborisg3Оценок пока нет

- Terasaki FDP 2013Документ40 страницTerasaki FDP 2013MannyBaldonadoDeJesus100% (1)

- Feb-May SBI StatementДокумент2 страницыFeb-May SBI StatementAshutosh PandeyОценок пока нет

- Change LogДокумент145 страницChange LogelhohitoОценок пока нет

- Re BuyerДокумент20 страницRe BuyerElias OjuokОценок пока нет

- ShopDrawings - Part 1Документ51 страницаShopDrawings - Part 1YapОценок пока нет

- 103-Article Text-514-1-10-20190329Документ11 страниц103-Article Text-514-1-10-20190329Elok KurniaОценок пока нет

- Dark Energy Survey DES CollaborationДокумент38 страницDark Energy Survey DES CollaborationgeorgcantorОценок пока нет

- Tournament Rules and MechanicsДокумент2 страницыTournament Rules and MechanicsMarkAllenPascualОценок пока нет

- Registration Form - Synergies in Communication - 6th Edition - 2017-Drobot AnaДокумент3 страницыRegistration Form - Synergies in Communication - 6th Edition - 2017-Drobot AnaAna IrinaОценок пока нет

- Tripura 04092012Документ48 страницTripura 04092012ARTHARSHI GARGОценок пока нет

- Michael Ungar - Working With Children and Youth With Complex Needs - 20 Skills To Build Resilience-Routledge (2014)Документ222 страницыMichael Ungar - Working With Children and Youth With Complex Needs - 20 Skills To Build Resilience-Routledge (2014)Sølve StoknesОценок пока нет

- 27 Points of Difference Between Personnel Management & HRDДокумент2 страницы27 Points of Difference Between Personnel Management & HRDMurtaza Ejaz33% (3)

- Modicon PLC CPUS Technical Details.Документ218 страницModicon PLC CPUS Technical Details.TrbvmОценок пока нет