Академический Документы

Профессиональный Документы

Культура Документы

Oil Recovery by Miscible SWAG

Загружено:

Cara BakerОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Oil Recovery by Miscible SWAG

Загружено:

Cara BakerАвторское право:

Доступные форматы

SPE 115710

Oil Recovery by Miscible SWAG Injection

M. Jamshidnezhad/ National Iranian South Oil Co

Copyright 2008, Society of Petroleum Engineers

This paper was prepared for presentation at the 2008 SPE Russian Oil & Gas Technical Conference and Exhibition held in Moscow, Russia, 2830 October 2008.

This paper was selected for presentation by an SPE program committee following review of information contained in an abstract submitted by the author(s). Contents of the paper have not been

reviewed by the Society of Petroleum Engineers and are subject to correction by the author(s). The material does not necessarily reflect any position of the Society of Petroleum Engineers, its

officers, or members. Electronic reproduction, distribution, or storage of any part of this paper without the written consent of the Society of Petroleum Engineers is prohibited. Permission to

reproduce in print is restricted to an abstract of not more than 300 words; illustrations may not be copied. The abstract must contain conspicuous acknowledgment of SPE copyright.

Abstract

Previous studies showed that injection of water and gas as water alternating gas (WAG) process or simultaneous water and gas

(SWAG) process can improve the sweep efficiency. Therefore, oil recovery from depleted reservoirs can be enhanced by

combined injection of water and gas. However, SWAG process compare to WAG process is less known. Investigation of

factors that affect on miscible SWAG injection is the aim of this study. For this purpose, a three-dimensional finite-difference

reservoir simulator is used. Methane (as gas) at minimum miscibility pressure (MMP) is injected into an under-saturated

reservoir which contained typical North Sea oil. Water and gas are injected at fixed rates by two separate horizontal wells. For

more sweep efficiency and increase the distance gas and water travel before segregation, gas is injected at the bottom of

reservoirs. For water, different locations of injection are tested and the effect of water injection location is studied. We also

investigate the effect of water to gas injection rate ratios, well models, and reservoir heterogeneity on sweep efficiency and oil

recovery.

Introduction

Injection of gases (steam, CO2 or hydrocarbon gas) is an important method for increasing recovery in declining oil fields. Gas

improved oil recovery (IOR) can in principle recover nearly all the oil in place, but sweep efficiency of injected gas is poor

(Lake, 1989). Reasons for poor sweep efficiency include reservoir heterogeneity, low density of gas, and low viscosity of the

gas. In relatively homogeneous reservoirs low gas density, leading to gravity override, can severely limit gas sweep and oil

recovery. In most cases gas is injected together with, or alternating with, water, to reduce gas mobility.

In a homogeneous reservoir the flow of fluids is influenced by the density and mobility differences between the injected and

resident fluids. In heterogeneous reservoir permeability differences play a dominant role (Waggoner et al., 1992). The injected

fluid(s) prefer to flow through high-permeability layers, which lead to channeling. The low-permeability layers are bypassed

and not swept by the solvent.

If heterogeneities are not present, gravity governs fluid flow in the reservoir. Solvent in general has a lower density than oil

(and water) and segregates to the top of the reservoir, leaving the bottom part untouched by the solvent.

Previous studies showed that injection of water and gas as water alternating gas (WAG) process or simultaneous water and gas

(SWAG) process can improve the sweep efficiency. Therefore, oil recovery from depleted reservoirs can be enhanced by

combined injection of water and gas (Jamshidnezhad et al. 2008).

The equations of Stone (1982) and Jenkins (1984) predict the distance gas and water travel before they segregate completely

into underride and override zones. The equations describe the steady state that would eventually be attained once all mobile oil

has been removed from the region in which segregation occurs. ). In each zone (mixed, override and underride) saturations and

mobilities are uniform. In rectangular and cylindrical flow, the mixed zone disappears at position Lg and Rg, respectively:

( )

g

m

z w g rt

Q

L

k gW

=

(1)

( )

g

m

z w g rt

Q

R

k g

=

(2)

2 SPE 115710

where Q is total volumetric injection rate of gas and water, kv vertical permeability, w and g densities of water and gas,

respectively, g gravitational acceleration, and rtm the total relative mobility in the mixed zone.

Shi and Rossen (1998) show that Eqs. 1 and 2 can be recast in the following way:

( )

1

g

m h

g L z w g

p L

Hk

L N R Lk g

=

(3)

( ) ( )

( )

( )

1

2

g

m h

g z g g L g w g

p R

Hk

R k N R R R g

=

(4)

In Eq. 3, L is the length of the reservoir; N

g

and R

L

are dimensionless gravity number and reservoir aspect ratio, respectively,

|p|

m

the lateral pressure gradient in the mixed zone at the injection face, H reservoir height, and k

h

horizontal permeability. In

Eq. 4, gravity number and reservoir aspect ratio are defined as functions of the segregation length R

g

, the pressure gradient

used in the gravity number, |p|

m

(R

g

), is defined as the horizontal pressure gradient that would be present in the mixed zone at

radial position R

g

in the absence of any gravity segregation.

At later study, Stone (Stone 2004) showed that injecting gas along with water gives higher oil recovery than water flood alone.

He concluded that simultaneous water and immiscible gas floods can reduce water flood residual oil saturations by 50-100 %

in water-wet and intermediate-wet reservoirs, and can provide over 3-fold greater vertical gas sweep than alternate injection.

The studies presented by Stone did not investigate effects of different parameters on SWAG. Investigation of factors that affect

on miscible SWAG injection is the aim of this study. For this purpose, a three-dimensional finite-difference reservoir simulator

is used. Methane (as gas) at minimum miscibility pressure (MMP) is injected into an under-saturated reservoir which

contained typical North Sea oil. Water and gas are injected at fixed rates by two separate horizontal wells. For more sweep

efficiency and increase the distance gas and water travel before segregation, gas is injected at the bottom of reservoirs. For

water, different locations of injection are tested and the effect of water injection location is studied. We also investigate the

effect of water to gas injection rate ratios, well models, and reservoir heterogeneity on sweep efficiency and oil recovery.

Reservoir Model

We built the reservoir model by rectangular Cartesian grids. A summary of reservoir dimensions and physical properties can

be seen in Table 1. Gas (methane) and water are injected by two separate horizontal wells on the left-hand site, and fluids are

produced by a vertical production well located on the right-hand site of the reservoir. The reservoir is initially saturated by

typical North Sea oil (Boersma 1990). PVT properties of oil are summarized in Table 2. Reservoir temperature is 100

o

C and

fluids are injected at 348 bar (minimum miscibility pressure, MMP, Boersma 1990). In all cases, simulations are done in a

randomly generated permeability field, with perturbations of 10%. The values of k

z

and k

h

are randomly selected from a

uniform distribution extending 10% below and 10% above the average permeability values for each direction. Variations of

vertical and horizontal permeability along the wells are plotted in Figure 1. Figure 2 shows relative permeability data.

A three-dimensional compositional finite-difference reservoir simulator, STARS (Computer Modeling Group, Alberta,

Canada), is used to determine the effects of several design parameters on the efficiency of SWAG injection process. STARS

(Steam, Thermal, and Advanced Processes Reservoir Simulator) is CMG's advanced processes simulator for modeling the

flow of three-phase, multi-component fluids, which includes options such as chemical/polymer flooding, thermal applications,

steam injection, horizontal wells, flexible grids and many more.

The injection technique involves the simultaneous injection of water at different locations of the reservoir formation and

injecting gas at the bottom of the formation for 10 years. Figure 3 shows the schematic representation of the proposed SWAG

injection technique.

Table 1: Grid size and rock properties for different cases

Volume

(L*W*H) m3

No. of grids

( Nx*Ny*Nz)

Total injection

rate (res.m3/d)

Porosity

(fraction)

Horizontal

permeability (md)

Vertical

permeability (md)

(32*40*20) 64*10*43 15000 0.25 1000 210

SPE 115710 3

Table 2: Fluid properties

Fluid Density (kg/m3) Viscosity

(cp)

Water 1000 1

N2 163 0.0144

C12H26 804 0.86

Figure 1. Variations of vertical and horizontal permeability along the wells

Kx

920

940

960

980

1000

1020

1040

1060

1080

1100

0 2 4 6 8 10 12 14 16

Grid block number in J direction

K

x

(

m

D

)

Kz

0

50

100

150

200

250

0 2 4 6 8 10 12 14 16

Grid block number in J direction

K

z

(

m

D

)

Figure 2. Relative permeability data

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1

0 0.2 0.4 0.6 0.8 1

Sw

K

r

Krw

Krow

0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1

Sl

K

r

Krg

Krog

4 SPE 115710

Figure 3. schematic representation of the proposed SWAG injection technique.

Simulation Runs

For better understanding the effect of different parameters, we define a "base case" and then compare other cases with the base

case. The base case represents a homogeneous reservoir initially saturated with oil (at So) and water (at Swc), and then water

is injected at the middle and gas is injected at the bottom through two horizontal wells. For this case, total injection rate of gas

and water is about 7000 sm

3

/day and water fraction of 0.28.

Figures 4 and 5 show the results of 10 years gas and water injection in "base case". As we can see from Figure 4, the

ultimate recovery for simultaneous injection of water and gas in base case is about 75%. Figure 5 shows that segregation

occurs after 7 m traveling in layer 10. Figure 6 reveals nearly uniform movement of fluids before segregation.

Figure 4. Recovery factor in base case model Figure 5. Gas-water segregation in base case, view in IK plane

Base case

0

10

20

30

40

50

60

70

80

0 1000 2000 3000 4000

Time

RF

In the next case, we investigate effect of water injector location on oil recovery and segregation. Figures 7 and 8 show

schematics of two cases: case with water injection at top of reservoir and case with water injection near gas injection well. As

we can see from Figure 9, changing the location of water injector has no effect on oil recovery factor. For these cases

segregation again occurs at 14

th

grid( in i-direction) and movement of fluids before segregation is nearly uniform, Figures

10-13.

Effect of gas flow rate on segregation length is shown in Figures 14 and 15. In this case we doubled gas flow rate from

7000 sm

3

/day to 14000 sm

3

/day. Figure 16 compares oil recovery factor of this case to base case.

Another case is a case with double water injection rate. Results of this case are shown in Figures 17 and 18. Effect of

increasing water injection rate on oil recovery and its comparison to base case is shown in Figure 19.

The last case we study is a heterogenic model. In this case vertical and horizontal permeability are distributed randomly.

Horizontal permeability data are between 1 and 1000 md, vertical permeability data are between 1 and 220 md, Figure 20.

Effect of heterogeneity on oil recovery is shown in Figure 21. From Figure 22, one can see that heterogeneity increases

non-uniformity of gas through the reservoir, however, segregation length is greater than base case, see Figure 23.

SPE 115710 5

Figure 6. Fluids uniform flow before complete segregation Figure 7. Schematic of SWAG, water at nearly top

Figure 8. Schematic of SWAG, water at nearly bottom Figure 9. Effect of water injector location on recovery factor

0

10

20

30

40

50

60

70

80

0 1000 2000 3000 4000

Time (day)

R

F

Base case

Water is injected at top

water is injected near

gas well

Figure 10. Gas-water segregation, case of Figure 11. Gas-water segregation, case of

water at top, view in IK plane water at top, view in IJ plane

6 SPE 115710

Figure 12. Gas-water segregation, case of Figure 13. Gas-water segregation, case of

water at nearly bottom, view in IJ plane water at nearly bottom, view in IK plane

Figure 14. Gas-water segregation, case of Figure 15. Gas-water segregation, case of

doubled gas injection rate, view in IJ plane doubled gas injection rate, view in IK plane

Figure 16. Effect of gas injection rate on recovery factor Figure 17. Gas-water segregation, case of doubled water

injection rate, view in IK plane

0

10

20

30

40

50

60

70

80

0 1000 2000 3000 4000

Time (day)

RF

Gas rate doubled

Base case

SPE 115710 7

Figure 18. Gas-water segregation, case of doubled water Figure 19. Effect of water injection rate on recovery factor

injection rate, view in IJ plane

0

10

20

30

40

50

60

70

80

0 1000 2000 3000 4000

Time (day)

RF

Base case

water is injected at

doubled rate

Figure 20. Horizontal and vertical permeability distribution in heterogeneous case

Figure 21. Effect of heterogeneity on oil recovery factor Figure 22. Gas-water segregation, case of heterogeneous

view in IJ plane

0

10

20

30

40

50

60

70

80

0 1000 2000 3000 4000

Time (day)

RF

Base case

Heteregenous case

8 SPE 115710

Figure 23. Gas-water segregation, case of heterogeneous view in IK plane

Conclusions

Simultaneous water and gas injection into petroleum reservoirs is more efficient than alone gas injection and water injection.

In this study, we investigated effect of several factors on simultaneous water and gas injection. These factors were gas to water

injection rates, location of water injector, and heterogeneity of horizontal and vertical permeabilities. As we can see from

Figure 24, these factors have no strong effect on oil recovery factor. However, they can affect on segregation length and non-

uniformity of gas flow.

Figure 24. Effect of different factors on oil recovery factor

0

10

20

30

40

50

60

70

80

0 500 1000 1500 2000 2500 3000 3500 4000

Time (day)

RF

Gas rate doubled Base case

Heteregenous case Water is injected at top

water is injected near gas well water is injected at doubled rate

References

Jamshidnezhad, M., Chen,C. Kool,P. and Rossen, W.R., Well Stimulation and Gravity Segregation in Gas Improved Oil Recovery, SPE

112375, presented the 2008 SPE International Symposium and Exhibition on Formation Damage Control held in Lafayette, Louisiana,

U.S.A., 1315 February 2008

Jenkins, M. K., 1984: "An Analytical Model for Water/Gas Miscible Displacements," SPE 12632, presented at the 1984 SPE/DOE

Symposium on Enhanced Oil Recovery, Tulsa, OK, April 15-18.

Lake, L.: Enhanced Oil Recovery, Prentice Hall, Englewood Cliffs, NJ (1989).

Shi, J.-X., and Rossen, W.R.: Simulation of Gravity Override in Foam Processes in Porous Media, SPEREE 1, 148-154, 1998.

Stone, H. L.: "A Simultaneous Water and Gas Flood Design with Extraordinary Vertical Gas Sweep," SPE paper 91724, presented at the

2004 SPE International Petroleum Conference in Mexico, 7-9 November, Puebla, Mexico.

Stone, H. L.: "Vertical Conformance in an Alternating Water-Miscible Gas Flood," SPE 11130, presented at the 1982 SPE Annual Tech.

Conf. and Exhibition, New Orleans, LA, Sept. 26-29.

Waggoner, J.R., Castillo, J.L. and Lake, L.W.: Simulation of EOR Processes in Stochastically Generated Permeable Media, SPE 21237,

SPE Formation Evaluation, 173-180, June 1992.

Вам также может понравиться

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Slangman Guide To Street Speak 1 PDFДокумент168 страницThe Slangman Guide To Street Speak 1 PDFwatashivnn100% (1)

- Russian Lateral (BKZ) AnalysisДокумент7 страницRussian Lateral (BKZ) Analysisjacky roseОценок пока нет

- Internal Corrosion Direct Assessment For Multiphase Flow Pipelines103922-MSДокумент9 страницInternal Corrosion Direct Assessment For Multiphase Flow Pipelines103922-MSGucОценок пока нет

- Enhanced Heavy Oil Recovery Using Steam InjectionДокумент5 страницEnhanced Heavy Oil Recovery Using Steam InjectionabdobedirОценок пока нет

- Enhanced Oil Recovery With CO2Capture and SequestrationДокумент20 страницEnhanced Oil Recovery With CO2Capture and SequestrationCara BakerОценок пока нет

- SPE 189134 Economic Optimization of Water and Gas Shut Off Treatment in Oil WellsДокумент16 страницSPE 189134 Economic Optimization of Water and Gas Shut Off Treatment in Oil WellsEdgar GonzalezОценок пока нет

- SPE-119732 Forecasting PDFДокумент17 страницSPE-119732 Forecasting PDFLuis Alberto Colan Garcia100% (1)

- RTДокумент343 страницыRTCara BakerОценок пока нет

- Recent Technological Advances in The Application of Nano-CatalyticДокумент1 страницаRecent Technological Advances in The Application of Nano-CatalyticCara BakerОценок пока нет

- A Core Ood Investigation of Nano Uid Enhanced Oil Recovery pdf1Документ11 страницA Core Ood Investigation of Nano Uid Enhanced Oil Recovery pdf1delmarciogomes6739Оценок пока нет

- (WWW - Cccnit.org) - How To Write and Publish ISI Papers (Level 1)Документ83 страницы(WWW - Cccnit.org) - How To Write and Publish ISI Papers (Level 1)Cristina PufescuОценок пока нет

- Jamali Thesis 2014Документ96 страницJamali Thesis 2014Cara BakerОценок пока нет

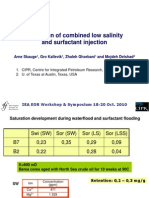

- Simulation of Combined Low Salinity and Surfactant InjectionДокумент30 страницSimulation of Combined Low Salinity and Surfactant InjectionCara BakerОценок пока нет

- Kunnas, Jari - Schlumberger EclipseДокумент51 страницаKunnas, Jari - Schlumberger Eclipsebangtamcva100% (1)

- Numerical Simulation and Optimization of Carbon Dioxide UtilizatiДокумент86 страницNumerical Simulation and Optimization of Carbon Dioxide UtilizatiCara BakerОценок пока нет

- Vocabulary High School Ak PDFДокумент78 страницVocabulary High School Ak PDFCara BakerОценок пока нет

- Simulation of Combined Low Salinity and Surfactant InjectionДокумент30 страницSimulation of Combined Low Salinity and Surfactant InjectionCara BakerОценок пока нет

- Vocabulary High School Ak PDFДокумент78 страницVocabulary High School Ak PDFCara BakerОценок пока нет

- Results of Experimental Researches of Plasma-Pulse Action Technology For Stimulation On The Heavy Oil FieldДокумент4 страницыResults of Experimental Researches of Plasma-Pulse Action Technology For Stimulation On The Heavy Oil FieldCara BakerОценок пока нет

- A New Model of Trapping and Relative Permeability Hysteresis For All Wettability CharacteristicsДокумент12 страницA New Model of Trapping and Relative Permeability Hysteresis For All Wettability CharacteristicsCara BakerОценок пока нет

- Eclipse Tutorial4Документ11 страницEclipse Tutorial4Cara BakerОценок пока нет

- Gibbs Free Energy and Fug A CityДокумент3 страницыGibbs Free Energy and Fug A CityCara BakerОценок пока нет

- Example CH 6Документ8 страницExample CH 6Cara BakerОценок пока нет

- Co2 Emission in IranДокумент4 страницыCo2 Emission in IranCara BakerОценок пока нет

- SPE-23429 A Simple Method of Predicting The Performance of Sucker Rod Pumping SystemДокумент10 страницSPE-23429 A Simple Method of Predicting The Performance of Sucker Rod Pumping SystemOsmund MwangupiliОценок пока нет

- Horizontal Well - Sada JoshiДокумент9 страницHorizontal Well - Sada JoshiAngela Risma100% (1)

- SPE-191656-MS Case Study On Fluorocarbons Interior Coating For Anticorrosion and Wax-Deposition Inhibition in ASP Flooding ProductionДокумент16 страницSPE-191656-MS Case Study On Fluorocarbons Interior Coating For Anticorrosion and Wax-Deposition Inhibition in ASP Flooding ProductionDIKE PutraОценок пока нет

- SPE-174839-MS Engineered Shale Completions Based On Common Drilling DataДокумент15 страницSPE-174839-MS Engineered Shale Completions Based On Common Drilling DataJohanОценок пока нет

- SPE/IADC-184660-MS CFD Modelling of Observed Cuttings Transport in Oil-Based and Water-Based Drilling FluidsДокумент12 страницSPE/IADC-184660-MS CFD Modelling of Observed Cuttings Transport in Oil-Based and Water-Based Drilling FluidsKelly Jhoanna JimenezОценок пока нет

- 95010-MS Water ShutoffДокумент12 страниц95010-MS Water Shutoffhade wantoОценок пока нет

- Coats 1989Документ37 страницCoats 1989husseinhshОценок пока нет

- SPE 88554 Forecast of Natural Gas Development: From The Point of Reserve-Production RatioДокумент5 страницSPE 88554 Forecast of Natural Gas Development: From The Point of Reserve-Production RatioGabriel SОценок пока нет

- Karurkar 2015Документ12 страницKarurkar 2015HSEQ AZUL ENERGYОценок пока нет

- Paper Sobre Gravel Pack - SPE-107297-MSДокумент19 страницPaper Sobre Gravel Pack - SPE-107297-MSDugas DeivyОценок пока нет

- SPE 62796 Wellbore Stability PredictionДокумент8 страницSPE 62796 Wellbore Stability PredictionBruceОценок пока нет

- SPE-196131-D Measurements While DrillingДокумент10 страницSPE-196131-D Measurements While DrillingCamila PalaciosОценок пока нет

- 12 Project Management in Times of CrisisДокумент12 страниц12 Project Management in Times of CrisisNofril ZendriadiОценок пока нет

- Horizontal Wells LoggingДокумент18 страницHorizontal Wells LoggingShubham PrakashОценок пока нет

- Clayton, R., Chen, S., & Lefort, G. (2005) - New Bit Design, Cutter Technology Extend PDC Applications To Hard Rock Drilling PDFДокумент9 страницClayton, R., Chen, S., & Lefort, G. (2005) - New Bit Design, Cutter Technology Extend PDC Applications To Hard Rock Drilling PDFadeelsnОценок пока нет

- SPE 106855 Phase Envelopes From Black-Oil Models: DefinitionsДокумент9 страницSPE 106855 Phase Envelopes From Black-Oil Models: DefinitionsEstefany Marcela DiazОценок пока нет

- Spe 10067 MS PDFДокумент21 страницаSpe 10067 MS PDFManuel ChОценок пока нет

- Spe 64647 Experimental Study On Friction Pressure Drop For Nonnewtonian Drilling Fluids in Pipe and Annular FlowДокумент11 страницSpe 64647 Experimental Study On Friction Pressure Drop For Nonnewtonian Drilling Fluids in Pipe and Annular Flowmauro87065458Оценок пока нет

- Progressing Cavity (PC) Pump Design Optimization For Abrasive ApplicationsДокумент6 страницProgressing Cavity (PC) Pump Design Optimization For Abrasive ApplicationsRizwan FaridОценок пока нет

- Estimationof Minimumand Maximum Horizontal Stressesfrom Well Loga Case Studyin Rumaila Oil Field IraqДокумент14 страницEstimationof Minimumand Maximum Horizontal Stressesfrom Well Loga Case Studyin Rumaila Oil Field IraqBeatriz Velásquez LeónОценок пока нет

- SPE 20720 ChengДокумент8 страницSPE 20720 ChengRaul GalvisОценок пока нет

- Workshop: Application of Fit-for-Purpose Smart Technology To Improve Mature Assets WorkshopДокумент5 страницWorkshop: Application of Fit-for-Purpose Smart Technology To Improve Mature Assets WorkshopCostas AggelidisОценок пока нет

- Radial Drilling in ArgentinaДокумент11 страницRadial Drilling in ArgentinaFerhat GüneşОценок пока нет

- Ahmed Sabry Resume - DataДокумент2 страницыAhmed Sabry Resume - DataAhmed SabryОценок пока нет

- All Petroleum Events For The Year 2017Документ9 страницAll Petroleum Events For The Year 2017FerasaОценок пока нет

- Rdcucing NPT - Lean Manufacturing AproachДокумент9 страницRdcucing NPT - Lean Manufacturing AproachFerney BohorquezОценок пока нет