Академический Документы

Профессиональный Документы

Культура Документы

M7 ZR PDF

Загружено:

junaid112Исходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

M7 ZR PDF

Загружено:

junaid112Авторское право:

Доступные форматы

Technical Reference Sheet 1403 PK

Status: 02.09

M-7 ZR, Two component epoxy based zinc rich primer

for steel

DESCRIPTION:

M-7 ZR is a two component, solvent borne

zinc rich epoxy primer, providing active

galvanic protection to steel. It is a thick grey

liquid of paint-like consistency, recommended

for use where chloride induced attack on steel

is likely.

Provides positive protection of steel

components against corrosion.

Excellent adhesion to steel.

Short over coating time.

This high performance epoxy compound

fuses zinc to the metal substrate and

protect against corrosion equal to Hot Dip

Galvanizing (meets and exceeds ASTM A780

specification for touch-up and repair of Hot

Dip Galvanize).

.

Standards:

M-7 ZR is formulated to meet the scope of

BS 4652, Type 2

FIELD OF APPLICATION:

As a protective coating to steel

reinforcing bars in concrete.

As a touch-up primer for damaged

galvanized metal.

As a primer for steel substrates prior

to suitable top coating.

M-7 ZR

TECHNICAL DATA

Aspect Thick grey suspension

Density ASTM C 905-79 2400 kg/m

Volume solids % 57 3

Pot life @ at 25C 120 Minute

Tack free time at 25C 25 minute

Recoat time at 25C 6 to 8 hour

Total zinc content in dry

film

>84% by weight

D.F.T. per coat > 50 microns

Application temperature minimum 10C

INDUSTRIAL FLOORING

M-7 ZR, Two component epoxy based zinc rich primer for steel

Directions for use

Surface preparation:

The steel surfaces should be grit blasted or wire

brushed to remove all traces of corrosion. Ensure

no oil, grease or dust is present. Surfaces should

be dry.

Mixing:

Stir each component of M-7 ZR. Add hardener to

Base and mix using a drilling machine fitted with

a mixer.

Application:

Apply M-7 ZR immediately after completion of

preparation to prevent any contamination. Do

not leave blasted or prepared steel uncoated.

Brush the M-7 ZR onto the prepared substrate,

ensuring uniform and full coverage, particularly

on the back face of reinforcement. In case of

doubt on achieving continuous film in one coat

apply second coat immediately after the drying

of the first coat. Please consult PAGEL

representative for advising the numbers of coats

necessary. Repair mortars can be applied as soon

as the M-7 ZR is dry. M-7 ZR is not designed as a

finished coating. Although protection to the steel

will be provided for some time, over coating

should be carried out as soon as possible,

particularly in aggressive environments.

Equipment care:

Tools should be cleaned with CLEANING SOLVENT

NO. 2 immediately after use.

PACKING:

M-7 ZR is a two component system, supplied in 3 liter

combined unit.

COVERGAE:

01 liter pack can cover 8 - 10 m2/coat on smooth

substrates. On rebar approximate coverage shall

be as under:

Diameter of rebar

(in mm)

Coverage

Running meter/liter/coat

8 210-265

12 140-175

16 105-135

25 85-115

32 55-65

Information provided in this leaflet, supplied by our applications consulting service and

contained in other recommendations is based on exhaustive research work and extensive

experience. It is, however, without liability on our part, in particular with regard to third

parties proprietary rights, and does not relieve the user of the responsibility for verifying

that the products and processes are suitable for the intended application. The given testing

dates were found out when having a temperature of 20 C and mean average values and

analysis. Deviations are possible when delivery takes place. Our customer service staff will

be glad to provide assistance at any time. We appreciate the interest you have shown in

our products. This technical data sheet supersedes previously issued information.

Factory: PLOT NO.1-A MISC. ZONE, VALUE ADDITION CITY,

SAHIANWALA ROAD, KHURRIANWALA, FAISALABAD, 37630,

PAKISTAN , FON: +92418507212/13, FAX: +92418507214,

WEB: www.pagelpakistan.com , E-mail: info@pagel-pk.com

Вам также может понравиться

- The Iron Puddler My life in the rolling mills and what came of itОт EverandThe Iron Puddler My life in the rolling mills and what came of itОценок пока нет

- Working Procedure For Coating Repair C4Документ7 страницWorking Procedure For Coating Repair C4tuyen nguyenОценок пока нет

- Plug-In Hybrid Electric Vehicles The Ultimate Step-By-Step GuideОт EverandPlug-In Hybrid Electric Vehicles The Ultimate Step-By-Step GuideОценок пока нет

- Harden XДокумент4 страницыHarden Xuocmogiandi_aОценок пока нет

- Company Profile PDFДокумент14 страницCompany Profile PDFసాయి కశ్యప్Оценок пока нет

- Readymix Design Fc'25 Mpa (K-300)Документ3 страницыReadymix Design Fc'25 Mpa (K-300)Iksan Adityo MulyoОценок пока нет

- Sample Submittal Form 2Документ1 страницаSample Submittal Form 2TAHER AMMARОценок пока нет

- Vinyl and Polished Concrete ComparisonДокумент3 страницыVinyl and Polished Concrete ComparisonBilly Twaine FuerteОценок пока нет

- Polished ConcreteДокумент3 страницыPolished ConcreteRhoderick MiqueОценок пока нет

- TerrazzoДокумент7 страницTerrazzojack.simpson.changОценок пока нет

- Methodology For Jemkon DensificationДокумент3 страницыMethodology For Jemkon DensificationMohzin KmОценок пока нет

- Airfield Pavement Rehabilitation PDFДокумент114 страницAirfield Pavement Rehabilitation PDFTim LinОценок пока нет

- TDS Epoxy Zinc Phosphate Primer HB 50 GreyДокумент3 страницыTDS Epoxy Zinc Phosphate Primer HB 50 GreySAlman Khan50% (2)

- Terrazzo and Chequered TileДокумент33 страницыTerrazzo and Chequered Tileshiza shekhОценок пока нет

- Vertex Chemicals Pvt. LTD.: Rate Analysis SheetДокумент6 страницVertex Chemicals Pvt. LTD.: Rate Analysis SheetRana Ahmad Aamir100% (1)

- Exposed Polished Concrete (New Build) Process Information: Stage 1)Документ2 страницыExposed Polished Concrete (New Build) Process Information: Stage 1)Sashi KumarОценок пока нет

- Hot Dip Galvanizing For FastenersДокумент3 страницыHot Dip Galvanizing For FastenersIrwin CastroОценок пока нет

- Disclosure To Promote The Right To InformationДокумент21 страницаDisclosure To Promote The Right To InformationBrijeshОценок пока нет

- Ansi 70Документ2 страницыAnsi 70Omar Reinoso TigreОценок пока нет

- Wispeco Aluminium ProfilesДокумент22 страницыWispeco Aluminium ProfilesPatrick153Оценок пока нет

- Choosing The Right Conformal Coating The Facts & MythsДокумент4 страницыChoosing The Right Conformal Coating The Facts & Mythssdfdfs7253Оценок пока нет

- TT C 490GДокумент36 страницTT C 490Gawesome_600Оценок пока нет

- Composite Material Machining Guide Aerospace PDFДокумент22 страницыComposite Material Machining Guide Aerospace PDFXu WeixingОценок пока нет

- Astm E2491 06Документ13 страницAstm E2491 06phanthanhhungОценок пока нет

- Cored Wire in Steel MakingДокумент11 страницCored Wire in Steel Makingbcnjy02Оценок пока нет

- D1 - 1 2020 - Structural Welding Code-Steel-02Документ1 страницаD1 - 1 2020 - Structural Welding Code-Steel-02Trung NguyenОценок пока нет

- INTERTEK Compression-Flexural Test Report FinalДокумент53 страницыINTERTEK Compression-Flexural Test Report FinalrycproyectistaОценок пока нет

- SSPC QP 3Документ6 страницSSPC QP 3anoopkumarОценок пока нет

- C57.12.28-2005 Pad-Mounted Equipment-Enclosure IntegrityДокумент28 страницC57.12.28-2005 Pad-Mounted Equipment-Enclosure IntegrityPedro Luis YanezОценок пока нет

- Letter of Intent (Loi) : Kindly Contact For More Details. Contact - Syed Ahmed Ali Mobile - 966 560 700 103Документ1 страницаLetter of Intent (Loi) : Kindly Contact For More Details. Contact - Syed Ahmed Ali Mobile - 966 560 700 103Luis HernandezОценок пока нет

- Thermal Conductivity Test-PUДокумент2 страницыThermal Conductivity Test-PUshazeb aliОценок пока нет

- 18-ASTM E2174-14bДокумент7 страниц18-ASTM E2174-14bAli Adnaan RazaОценок пока нет

- Corrosion and Corrosion Test Methods of ZincДокумент9 страницCorrosion and Corrosion Test Methods of ZincMrPalm LimОценок пока нет

- Laser WeldingДокумент11 страницLaser WeldingnkalaiОценок пока нет

- Anodizing Presentation CДокумент21 страницаAnodizing Presentation CAnang AstonОценок пока нет

- Lincoln DC1000 PDFДокумент34 страницыLincoln DC1000 PDFÖzgür TuştaşОценок пока нет

- Raised Floor Works-SpecsДокумент5 страницRaised Floor Works-SpecsdenisjayОценок пока нет

- Elcometer 266 DC Portable Holiday DetectorДокумент3 страницыElcometer 266 DC Portable Holiday DetectorkhuramluckОценок пока нет

- DCSP Tig Welding of Aa2219 Aluminum AlloyДокумент14 страницDCSP Tig Welding of Aa2219 Aluminum AlloySgk ManikandanОценок пока нет

- ASTM E505 - 01 (2011) Standard Reference Radiographs For Inspection of Aluminum and Magnesium Die CastingsДокумент3 страницыASTM E505 - 01 (2011) Standard Reference Radiographs For Inspection of Aluminum and Magnesium Die CastingschinwaihoongОценок пока нет

- AEE - Northern Ohio - Stockton Infrared Presentation - SMДокумент257 страницAEE - Northern Ohio - Stockton Infrared Presentation - SMIuli BaicoianuОценок пока нет

- Resistance of Organic Coatings To The Effects of Rapid Deformation (Impact)Документ1 страницаResistance of Organic Coatings To The Effects of Rapid Deformation (Impact)Name100% (1)

- FlooringДокумент6 страницFlooringSTUDY JUNCTIONОценок пока нет

- MIL-STD-645B Dip Brazing of Aluminum AlloysДокумент16 страницMIL-STD-645B Dip Brazing of Aluminum AlloysRichard BennardoОценок пока нет

- Welding FundamentalsДокумент44 страницыWelding FundamentalsJean PierreОценок пока нет

- 521+technical Data Sheet V-6Документ2 страницы521+technical Data Sheet V-6TeenTeen GaMingОценок пока нет

- CSSBI S17-2005 Steel BuildingДокумент8 страницCSSBI S17-2005 Steel BuildingEric NolascoОценок пока нет

- Ias Ac172-0719Документ18 страницIas Ac172-0719이혁재Оценок пока нет

- Specification PVDF High Purity CPДокумент7 страницSpecification PVDF High Purity CPAnand KPОценок пока нет

- Is 14700 4 1 2008Документ20 страницIs 14700 4 1 2008Juan Pablo Villazon RichterОценок пока нет

- Is: 11871-1986Документ24 страницыIs: 11871-1986Sumit LakhotiaОценок пока нет

- PVD HardCoating PDFДокумент20 страницPVD HardCoating PDFsatanjrОценок пока нет

- GB5237.2-2017 英文Документ16 страницGB5237.2-2017 英文TheAnh TranОценок пока нет

- Mil PRF 46010HДокумент17 страницMil PRF 46010HGoogle UserОценок пока нет

- Painting ProcessДокумент4 страницыPainting ProcesslingayasОценок пока нет

- MIL-DTL-53072D With Amendment 1Документ38 страницMIL-DTL-53072D With Amendment 1pmicjenОценок пока нет

- E 329 - 00 - Rtmyos0wmei - PDFДокумент8 страницE 329 - 00 - Rtmyos0wmei - PDFMario ZepedaОценок пока нет

- Phosphating ProcedureДокумент5 страницPhosphating ProcedureJohnОценок пока нет

- Product Information GuideДокумент32 страницыProduct Information GuideSanjay PatelОценок пока нет

- Astm A780Документ4 страницыAstm A780Raúl Venegas Munita100% (5)

- IFB For Construction of Pedestrian Steel Overhead Bridges For Contract No HS PN 15-05-01 02 in Punjab North LahoreДокумент1 страницаIFB For Construction of Pedestrian Steel Overhead Bridges For Contract No HS PN 15-05-01 02 in Punjab North Lahorejunaid112Оценок пока нет

- Manual of Signs, Signals & Road Markings (July, 1989)Документ302 страницыManual of Signs, Signals & Road Markings (July, 1989)junaid112Оценок пока нет

- Principles of Infectious Disease Epidemiology PDFДокумент85 страницPrinciples of Infectious Disease Epidemiology PDFjunaid112100% (1)

- Tender Documents SPPAP Solar Systems Phase II Tender No NRSP-SPPAP II Solar I2019Документ36 страницTender Documents SPPAP Solar Systems Phase II Tender No NRSP-SPPAP II Solar I2019junaid112Оценок пока нет

- Monthly Bulletin of Statistics, December, 20 - 2Документ296 страницMonthly Bulletin of Statistics, December, 20 - 2junaid112Оценок пока нет

- NCHRP RPT 568 PDFДокумент226 страницNCHRP RPT 568 PDFjunaid112Оценок пока нет

- Smiu Volume IIIДокумент83 страницыSmiu Volume IIIjunaid112Оценок пока нет

- Pc-I (Infrastructure-Proforma For Development Projects)Документ12 страницPc-I (Infrastructure-Proforma For Development Projects)Haider IqbalОценок пока нет

- BRIEF ON KARACHI PACKAGE 7 May 2018Документ3 страницыBRIEF ON KARACHI PACKAGE 7 May 2018junaid112Оценок пока нет

- Soc English 2018 MBLДокумент19 страницSoc English 2018 MBLSalman ArshadОценок пока нет

- PCA Rectangular Concrete TanksДокумент16 страницPCA Rectangular Concrete TanksMuhammad Azeem KhanОценок пока нет

- 10 05 18 Tender Re Construction of Nishtar Road PDFДокумент1 страница10 05 18 Tender Re Construction of Nishtar Road PDFjunaid112Оценок пока нет

- STD Procedure For Evaluation of Bids For Procurement of WorksДокумент33 страницыSTD Procedure For Evaluation of Bids For Procurement of Worksjunaid112Оценок пока нет

- Islamiyat (Nur) PDFДокумент2 страницыIslamiyat (Nur) PDFjunaid112Оценок пока нет

- BRT Project PDFДокумент2 страницыBRT Project PDFjunaid112Оценок пока нет

- Pakistan Trailer StandardДокумент12 страницPakistan Trailer StandardASQОценок пока нет

- Introduction To 503Документ11 страницIntroduction To 503junaid112Оценок пока нет

- Civil 3D Tips & TricksДокумент5 страницCivil 3D Tips & Tricksjunaid112Оценок пока нет

- PC IV FormДокумент8 страницPC IV FormAnonymous 1elxjIОценок пока нет

- Some Techniques in GeneticsДокумент10 страницSome Techniques in Geneticsjunaid112Оценок пока нет

- Release Position 2017-18 PDFДокумент353 страницыRelease Position 2017-18 PDFjunaid112Оценок пока нет

- Modified PC 1Документ14 страницModified PC 1Farhat Abbas DurraniОценок пока нет

- Traffic Barriers PDFДокумент27 страницTraffic Barriers PDFjunaid112Оценок пока нет

- Pc-I (Infrastructure-Proforma For Development Projects)Документ12 страницPc-I (Infrastructure-Proforma For Development Projects)Haider IqbalОценок пока нет

- PC Iii (B)Документ2 страницыPC Iii (B)junaid112Оценок пока нет

- Essay WritingДокумент74 страницыEssay Writingtiendn92% (50)

- Revised 2005Документ5 страницRevised 2005Ali AkbarОценок пока нет

- PC-III (A)Документ4 страницыPC-III (A)Iftikhar KamranОценок пока нет

- Road User Cost ManualДокумент114 страницRoad User Cost ManualDina Rachmayati100% (1)

- IELTS Exam Preparation - IELTS Home PDFДокумент2 страницыIELTS Exam Preparation - IELTS Home PDFjunaid112100% (1)

- Cascade, Ratio, and Feedforward ControlДокумент47 страницCascade, Ratio, and Feedforward ControlSteaphnie_Sava_5881Оценок пока нет

- Biochemistry & Molecular Biology Journal - Open Access JournalДокумент2 страницыBiochemistry & Molecular Biology Journal - Open Access JournalManjida RahmanОценок пока нет

- Atomic Spectrum of HydrogenДокумент3 страницыAtomic Spectrum of HydrogenlovemynaturecountryОценок пока нет

- Y. Osamura Et Al.: Rjournal of Molecular Structure Theochem 461 462 1999 399 416 400Документ17 страницY. Osamura Et Al.: Rjournal of Molecular Structure Theochem 461 462 1999 399 416 400IvanAgustínAymerichОценок пока нет

- AlkanolamideДокумент5 страницAlkanolamidebellesuperОценок пока нет

- Enols and EnolatesДокумент1 страницаEnols and EnolatesmeeeBDОценок пока нет

- Practice Calculations 2012Документ58 страницPractice Calculations 2012Lia Romain67% (6)

- Raghavendra Bhat. GPUC High School Section, MegaravalliДокумент8 страницRaghavendra Bhat. GPUC High School Section, Megaravallisyedyaseen39375Оценок пока нет

- Tutorial3 - C3 - CHE 244Документ3 страницыTutorial3 - C3 - CHE 244Sheikh AdibОценок пока нет

- Chemical Engineering CommunicationsДокумент16 страницChemical Engineering CommunicationsMichelle Quilaqueo NovoaОценок пока нет

- TDS - Opulyn 301 - Ingles - H&LДокумент3 страницыTDS - Opulyn 301 - Ingles - H&LRicardo BohorquezОценок пока нет

- Phy Cet Wei 23Документ4 страницыPhy Cet Wei 23endtimes066xОценок пока нет

- GENBIO2 - Lesson - The Central Dogma of Molecular BiologyДокумент2 страницыGENBIO2 - Lesson - The Central Dogma of Molecular BiologyJazmaine SimbulanОценок пока нет

- 0-2313 Weld Lesson PlansДокумент12 страниц0-2313 Weld Lesson PlansMa'den-i Envâr-ı FütuvvetОценок пока нет

- NCNA PatentДокумент36 страницNCNA PatentCharles GrossОценок пока нет

- Bamboo+Alumina CompositeДокумент5 страницBamboo+Alumina CompositeAmmineni Syam PrasadОценок пока нет

- COMEDK Important Topics and Revised SyllabusДокумент49 страницCOMEDK Important Topics and Revised SyllabusVishal VermaОценок пока нет

- Pharmacognosy Lecture # 7+8 (Lipids) (By, Sir Tanveer Khan)Документ40 страницPharmacognosy Lecture # 7+8 (Lipids) (By, Sir Tanveer Khan)Arslan AbdullahОценок пока нет

- A Study of Copper (II) Complexes With Different LigandsДокумент3 страницыA Study of Copper (II) Complexes With Different LigandsZul Nazrie50% (6)

- Dicti of Phy and ElectronicsДокумент1 357 страницDicti of Phy and Electronicsrahul106Оценок пока нет

- Abstract of ASTM A574M 1997Документ7 страницAbstract of ASTM A574M 1997Jesse ChenОценок пока нет

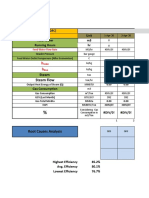

- DDFC Boiler Effeciency AnalysisДокумент21 страницаDDFC Boiler Effeciency AnalysisPublic DemandОценок пока нет

- Theory Lm2500 Principios Basicos de Operacion PDFДокумент25 страницTheory Lm2500 Principios Basicos de Operacion PDFamir8100Оценок пока нет

- Apiezon AP100 Grease MSDSДокумент5 страницApiezon AP100 Grease MSDSData Sheet SolutionsОценок пока нет

- Stockmann 2016Документ12 страницStockmann 2016Barbara SilvaОценок пока нет

- Astm A194Документ13 страницAstm A194AliОценок пока нет

- Sol Gel Synthesis of Nanocrystalline Magnesium Fluoride Its Use in The Preparation of MgF2 Films and MgF2 SiO2 Composites 1996 Chemistry of MaterialsДокумент8 страницSol Gel Synthesis of Nanocrystalline Magnesium Fluoride Its Use in The Preparation of MgF2 Films and MgF2 SiO2 Composites 1996 Chemistry of MaterialskarthikdhadalaОценок пока нет

- Datasheet For Vent ScrubberДокумент5 страницDatasheet For Vent ScrubbercliffrajjoelОценок пока нет

- The Application of CoulombДокумент4 страницыThe Application of CoulombBirgittaОценок пока нет

- Minimum Thermal FlowДокумент4 страницыMinimum Thermal Flowdk4monjureОценок пока нет