Академический Документы

Профессиональный Документы

Культура Документы

Petron Plustm Formula 7 Hi-Temp, Etreme-Pressure Multi-Purpose Marine Grease

Загружено:

wellblablablaИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Petron Plustm Formula 7 Hi-Temp, Etreme-Pressure Multi-Purpose Marine Grease

Загружено:

wellblablablaАвторское право:

Доступные форматы

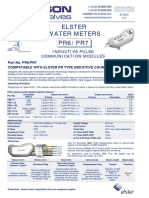

PETRON

PLUSTM

FORMULA 7

HI-TEMP, ETREME-PRESSURE

MULTI-PURPOSE MARINE GREASE

► PART NO.’S: 00510, 00512, 00513, & 00514

TECHNICAL DATA SHEET

Petron Plus Formula 7 High-Temp. Ex-

TM

APPLICATIONS:

treme Pressure Marine Grease is the latest

1. Marine applications.

technological advance in marine grease.

2. Lake or salt water applications.

3. Automotive and industrial applications.

Although Petron PlusTM Formula 7 Marine

4. Construction equipment.

Grease is the premium grease for all marine

5. Where a NLGI 2 grease is required to meet GC/LB

applications, whether lake, or salt water, it

Specifications.

can also be used as an automotive and

industrial grease with excellent shear

stability, load carrying ability, water

resistance, rust resistance and oxidation

resistance.

Petron PlusTM Formula 7 Marine Grease is FEATURES:

free of heavy metals and resists burning and 1. A Calcium Sulfonate Complex.

exceeds NLGI GC/LB (ASTM D-4950). 2. NLGI 2

3. Meets GC/LB (ASTM D-4950) Specifications.

Petron PlusTM Formula 7 Marine Grease will 4. Dropping Point of 550°F+.

provide excellent performance in severe high 5. Timken OK Load of 65 lbs.

temperatures applications, with light or heavy 6. Four Ball EP Weld of 620 kg.

loads, and under wet or dry conditions 7. Excellent water resistance.

Petron PlusTM Formula 7 Marine Grease is

compatibility with a wide variety of seal

materials, such as Nitrile, Viton and

Neoprene.

This product has a 550°+ Dropping point, a BENEFITS:

Timken OK load of 65 lbs. and a weld point 1. Contains no heavy metals.

of 620 kg. 2. Long life grease.

3. Reduced maintenance costs.

4. Exceeds NLGI GC/LB.

Available in 14 ounce tubes, 35 lbs pails, 120

lb keg, & 400 lbs drums.

PETRON PLUSTM INTERNATIONAL, INC.

P.O. BOX 1946 HUTCHINSON, KS 67504 USA, 620/663-8338 Phone, 620/663-8560 Fax,

www.petronplus7.com www.petronomics.com

TYPICAL SPECIFICATIONS:

PETRON PLUSTM

FORMULA 7

HI-TEMP, EXTREME-PRESSURE, MULTI-PURPOSE MARINE GREASE

—————————————————————————————————–——–——————–————

Part No., . . . . . . . . . . 00510, 00512, 00513, & 00514

Thickener, . . . . . . . . . . Calcium Sulfonate Complex

NLGI, Consistency Grade, ASTM D-217, . . . . . . . . 2

Texture, . . . . . . . . . . . Smooth

Dropping Point, °F, ASTM D-2265, . . . . . . . . 550+

PENETRATION

Unworked, ASTM D-217, . . . . . . . . . 270

Worked 60 Strokes, ASTM D-217, . . . . . . . 279

10,000 Strokes change from 60 strokes, . . . . . . . . ±1

100,000 Strokes change from 60 strokes, , . . . . . . . ±2

Flash Point, COC, °F, . . . . . . . . . . 480

Fire Point, °F. ASTM D-92, . . . . . . . . . 520

Wheel Bearing Leakage, % loss, gms, ASTM D-1263, . . . . . . 0.4

Water Washout, @ 175°F, mass %, ASTM D-1264, . . . . . . 1

Fafnir, ASTM D-4170, . . . . . . . . . . 2.50

Oil Separation: Pressure Bleed, mass %, ASTM D-1742, . . . . . . 1.5

Shell Roll Stability, % change, ASTM D-1831, . . . . . . . 5

Timken OK Load, lbs, ASTM D-2509, . . . . . . . . 65

Four Ball EP Weld, kgf, ASTM D-2596, . . . . . . . . 620

Four Ball Load Wear Index, ASTM D-2596, . . . . . . . 100

Four Ball Wear Scar, mm, ASTM D-2266, . . . . . . . 0.39

DI Rust Protection, ASTM D-1743, . . . . . . . . Pass

High Temperature Life, hrs, ASTM D-3527, . . . . . . . 140

OIL VISCOSITY

@ 100°F, SUS, ASTM D-2161, . . . . . . . . . 1090

@ 210°F, SUS, ASTM D-2161, . . . . . . . . . 83

Viscosity Index, ASTM D-2270, . . . . . . . . . 95

Elastomer CR Compatibility, Vol. change, %, ASTM D-4289, . . . . . 12.7

Elastomer CR Compatibility, Hardness, pts, ASTM D-4289, . . . . . -9

Elastomer NBR-L Compatibility, Vol. change, %, ASTM D-4289, . . . . . 5.1

Elastomer NBR-L Compatibility, Hardness, pts, ASTM D-4289, . . . . . -6

Pounds per gallon,, . . . . . . . . . . 8.16

Color, . . . . . . . . . . . . Aqua Green

Distributed By:

June, 2009

Warranty: All products purchased from Petron Plus International, Inc., (PPII) are subject to terms and conditions set out in the contract, order acknowledgment and/or bill of lading. PPII warrants only

that its product will meet those specifications designated as such herein or in other publications. All other information supplied by PPII is considered accurate but is furnished upon the express

condition that the customer shall make its own assessment to determine the product’s suitability for a particular purpose. No warranty is expressed or implied regarding such other information, the

data upon which the same is based, or the results to be obtained from the use thereof; that any product shall be merchantable or fit for any particular purpose, or that the use of such other information or

product will not infringe any patent.

Вам также может понравиться

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsОт EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsРейтинг: 5 из 5 звезд5/5 (1)

- Petron Plustm Formula 7 Hi-Temp, Etreme-Pressure Multi-Purpose Polyurea GreaseДокумент2 страницыPetron Plustm Formula 7 Hi-Temp, Etreme-Pressure Multi-Purpose Polyurea GreasewellblablablaОценок пока нет

- 93 Sinopec Extreme Pressure Lithium Complex GreaseДокумент3 страницы93 Sinopec Extreme Pressure Lithium Complex GreaseAmadeus CocaОценок пока нет

- Petron Plustm Formula 7 Diesel Engine ConditionerДокумент2 страницыPetron Plustm Formula 7 Diesel Engine ConditionerwellblablablaОценок пока нет

- Product Data Sheet: Synthetic Gear OilДокумент2 страницыProduct Data Sheet: Synthetic Gear OilDiegoОценок пока нет

- Decathlon Extreme Synthetic Gear OilДокумент1 страницаDecathlon Extreme Synthetic Gear OilDon HowardОценок пока нет

- Castrol Pyroplex Blue - Data SheetДокумент3 страницыCastrol Pyroplex Blue - Data SheetJeremias UtreraОценок пока нет

- Sinopec Super Grease NLGI 2Документ2 страницыSinopec Super Grease NLGI 2Yoong TanОценок пока нет

- PDSDetail PageДокумент3 страницыPDSDetail PageOSPEN NOAH SITHOLEОценок пока нет

- Petron Plustm Formula 7 The Engine ConditionerДокумент2 страницыPetron Plustm Formula 7 The Engine ConditionerwellblablablaОценок пока нет

- PetroPlate M5800 EP Grease PDFДокумент1 страницаPetroPlate M5800 EP Grease PDFlukastadeoОценок пока нет

- 220 Synfilm GT PdsДокумент3 страницы220 Synfilm GT PdsSaul CarrilloОценок пока нет

- Valplex EP NLGI 2: Specifications and Approvals ApplicationsДокумент2 страницыValplex EP NLGI 2: Specifications and Approvals Applicationsdiah ayuОценок пока нет

- Gazpromneft Grease L EP: Multipurpose Extreme Pressure Lithium GreaseДокумент2 страницыGazpromneft Grease L EP: Multipurpose Extreme Pressure Lithium GreasenghiaОценок пока нет

- Araldite 2011 Structural Adhesive: Advanced MaterialsДокумент6 страницAraldite 2011 Structural Adhesive: Advanced MaterialsrezaeibehrouzОценок пока нет

- Sinopec Extreme Pressure Lithium GreaseДокумент3 страницыSinopec Extreme Pressure Lithium GreaseYoong TanОценок пока нет

- TDS Adhesion CompoundДокумент6 страницTDS Adhesion CompoundNhien ManОценок пока нет

- Petron Plustm Formula 7Документ2 страницыPetron Plustm Formula 7wellblablablaОценок пока нет

- Sinopec HP-R GreaseДокумент3 страницыSinopec HP-R GreaseYoong TanОценок пока нет

- Product Information: Valvoline Multi-Purpose GreasesДокумент1 страницаProduct Information: Valvoline Multi-Purpose GreasesAmir DaneshОценок пока нет

- Roller Bearing GreaseДокумент2 страницыRoller Bearing GreaseYoong TanОценок пока нет

- Alpha SP Range: DescriptionДокумент3 страницыAlpha SP Range: Descriptionvicky kОценок пока нет

- LM GREASE SpheerolДокумент2 страницыLM GREASE Spheerolmohammed nasserОценок пока нет

- HT Mobilux Ep 2 EngДокумент2 страницыHT Mobilux Ep 2 EngdgslimaОценок пока нет

- Product Data Sheet: Gulfsea Gear Oil SeriesДокумент2 страницыProduct Data Sheet: Gulfsea Gear Oil SeriesObydur RahmanОценок пока нет

- 76 Grasa Megaplex XD3Документ2 страницы76 Grasa Megaplex XD3Gustavo De Haro GonzálezОценок пока нет

- High Temperature-Grease-pds-EngДокумент3 страницыHigh Temperature-Grease-pds-Engdavide comuzziОценок пока нет

- Darina RL GR 2Документ2 страницыDarina RL GR 2nutchai2538Оценок пока нет

- SP Eng NLGI 1,2,3 2012 OctДокумент3 страницыSP Eng NLGI 1,2,3 2012 OctundraazolbayarОценок пока нет

- Alpha SP RangeДокумент2 страницыAlpha SP RangeaskodidcОценок пока нет

- Multi-Purpose Grease: Specifications and Approvals ApplicationsДокумент2 страницыMulti-Purpose Grease: Specifications and Approvals ApplicationsCatherine Fatima Mae LeynoОценок пока нет

- 6040-1440 DS EptechДокумент2 страницы6040-1440 DS Eptechcarlos samilaОценок пока нет

- Bpxe Bezu8tДокумент2 страницыBpxe Bezu8tArthur Sanda LayukОценок пока нет

- Pso Alpha GreaseДокумент1 страницаPso Alpha GreaseMuhammad EhsanОценок пока нет

- 1482408304balmerol Sealguard HT NДокумент2 страницы1482408304balmerol Sealguard HT NHarsha VardhanОценок пока нет

- Technical Data Sheet: Priming LubricantДокумент1 страницаTechnical Data Sheet: Priming LubricantDon HowardОценок пока нет

- BP Energrease Ls and Ls-Ep: DescriptionДокумент2 страницыBP Energrease Ls and Ls-Ep: DescriptionbenjaminОценок пока нет

- Whitmore Paragon Heavy Duty Gear OilДокумент1 страницаWhitmore Paragon Heavy Duty Gear OilDon HowardОценок пока нет

- Lithium Base With Molybdenum Disulfide GreaseДокумент2 страницыLithium Base With Molybdenum Disulfide GreaseYoong TanОценок пока нет

- Grease FlyerДокумент2 страницыGrease FlyerBình LươngОценок пока нет

- Aceite Royal Purple - Synfilm - 46Документ2 страницыAceite Royal Purple - Synfilm - 46micmarley2012Оценок пока нет

- GL XX Mobil Polyrex EP 2Документ3 страницыGL XX Mobil Polyrex EP 2Sergio PereiraОценок пока нет

- L-CKD Heavy Duty Industrial Gear OilДокумент3 страницыL-CKD Heavy Duty Industrial Gear OilDavidОценок пока нет

- Technical Data Sheet: Synthetic Oil For Trunnion Bearings and Mining MachinesДокумент1 страницаTechnical Data Sheet: Synthetic Oil For Trunnion Bearings and Mining MachinesDon HowardОценок пока нет

- Bentone 2018Документ2 страницыBentone 2018Victor ZhicayОценок пока нет

- High Temperature Grease: DescriptionДокумент2 страницыHigh Temperature Grease: Descriptionvicky kОценок пока нет

- AMSOIL DOMINATOR® Synthetic Racing Grease (GRG)Документ2 страницыAMSOIL DOMINATOR® Synthetic Racing Grease (GRG)amsoildealerОценок пока нет

- 4408 Fully Synthetic Heavy Duty Industrial Gear OilДокумент3 страницы4408 Fully Synthetic Heavy Duty Industrial Gear OilYoong TanОценок пока нет

- Ap HTLC Grease - PDSДокумент1 страницаAp HTLC Grease - PDSSinh LeОценок пока нет

- Heavy Duty LC Mining GreaseДокумент2 страницыHeavy Duty LC Mining GreaseYoong TanОценок пока нет

- Gulf Synthetic Gear Oil - PAGДокумент1 страницаGulf Synthetic Gear Oil - PAGatripathi2009Оценок пока нет

- Product Data Sheet: Molylube Ultra Open Gear LubricantДокумент2 страницыProduct Data Sheet: Molylube Ultra Open Gear LubricantDiegoОценок пока нет

- Electrical Motor Bearing Grease LGHQ 2: DescriptionДокумент2 страницыElectrical Motor Bearing Grease LGHQ 2: DescriptionMARCO ANTONIO ESTAY PEREIRAОценок пока нет

- Ceran FGДокумент2 страницыCeran FGUtkarshОценок пока нет

- Oli Energol GR-XPДокумент2 страницыOli Energol GR-XPakun leptopОценок пока нет

- Spheerol LMMДокумент2 страницыSpheerol LMMSabari SreekumarОценок пока нет

- Product Data Sheet: Biodegradable Multipurpose Extreme Pressure GreaseДокумент2 страницыProduct Data Sheet: Biodegradable Multipurpose Extreme Pressure GreaseHewa PCОценок пока нет

- UntitledДокумент1 страницаUntitledwellblablablaОценок пока нет

- TDS - Brochure - Automotive MoleculesДокумент4 страницыTDS - Brochure - Automotive MoleculeswellblablablaОценок пока нет

- 12123Документ2 страницы12123wellblablablaОценок пока нет

- 12123Документ2 страницы12123wellblablablaОценок пока нет

- TDS - Brochure - Industrial MoleculeДокумент4 страницыTDS - Brochure - Industrial MoleculewellblablablaОценок пока нет

- TDS - Industrial BrochureДокумент5 страницTDS - Industrial BrochurewellblablablaОценок пока нет

- Petron PlusΤΜ Formula 7Документ2 страницыPetron PlusΤΜ Formula 7wellblablablaОценок пока нет

- TDS - Brochure - Automotive BrochureДокумент2 страницыTDS - Brochure - Automotive BrochurewellblablablaОценок пока нет

- Petron Plustm Formula 7Документ2 страницыPetron Plustm Formula 7wellblablablaОценок пока нет

- Petron Plustm Formula 7Документ2 страницыPetron Plustm Formula 7wellblablablaОценок пока нет

- Petron Plustm Formula 7Документ2 страницыPetron Plustm Formula 7wellblablablaОценок пока нет

- Petron Plustm Formula 7Документ2 страницыPetron Plustm Formula 7wellblablablaОценок пока нет

- Petron Plustm Formula 7 Industrial Super Lube (Aerosol)Документ2 страницыPetron Plustm Formula 7 Industrial Super Lube (Aerosol)wellblablablaОценок пока нет

- Petron Plustm Formula 7Документ2 страницыPetron Plustm Formula 7wellblablablaОценок пока нет

- Petron Plustm Formula 7Документ2 страницыPetron Plustm Formula 7wellblablablaОценок пока нет

- Petron Plustm Formula 7 Hi-Temp, Etreme-Pressure Multipurpose Lithium Complex GreaseДокумент2 страницыPetron Plustm Formula 7 Hi-Temp, Etreme-Pressure Multipurpose Lithium Complex GreasewellblablablaОценок пока нет

- Petron Plustm Formula 7 The Engine ConditionerДокумент2 страницыPetron Plustm Formula 7 The Engine ConditionerwellblablablaОценок пока нет

- Petron Plustm Formula 7 Transmission & Gearbox SupplementДокумент2 страницыPetron Plustm Formula 7 Transmission & Gearbox SupplementwellblablablaОценок пока нет

- T - Petron Plus Ind. Testimonial - Jaguar CarsДокумент1 страницаT - Petron Plus Ind. Testimonial - Jaguar CarswellblablablaОценок пока нет

- TDS - 51053Документ2 страницыTDS - 51053wellblablablaОценок пока нет

- T - Petron Plus P-1 Testimonial - Warren Johnson EntДокумент1 страницаT - Petron Plus P-1 Testimonial - Warren Johnson EntwellblablablaОценок пока нет

- T - Petron Plus Ind. Testimonial - GSA (General Services Administration)Документ1 страницаT - Petron Plus Ind. Testimonial - GSA (General Services Administration)wellblablablaОценок пока нет

- T - Petron Plus Ind. Testimonial - Ford Motor CoДокумент1 страницаT - Petron Plus Ind. Testimonial - Ford Motor CowellblablablaОценок пока нет

- T - Petron Plus Ind. Testimonial - H&K MP5Документ1 страницаT - Petron Plus Ind. Testimonial - H&K MP5wellblablablaОценок пока нет

- T - Petron Plus Ind. Testimonial - GM EgyptДокумент1 страницаT - Petron Plus Ind. Testimonial - GM EgyptwellblablablaОценок пока нет

- T - Petron Plus Ind. Testimonial - China BusДокумент1 страницаT - Petron Plus Ind. Testimonial - China BuswellblablablaОценок пока нет

- T - Petron Plus Customer Logo'sДокумент2 страницыT - Petron Plus Customer Logo'swellblablablaОценок пока нет

- HUM110 Gilgamesh EssayДокумент4 страницыHUM110 Gilgamesh EssaynsmeganОценок пока нет

- 6Документ2 страницы6Min Hsuan HsianОценок пока нет

- Guinea Pig: Domestication: Basic Species InformationДокумент4 страницыGuinea Pig: Domestication: Basic Species InformationBondОценок пока нет

- ResumeДокумент3 страницыResumejohn DaqueОценок пока нет

- Guideline On Smacna Through Penetration Fire StoppingДокумент48 страницGuideline On Smacna Through Penetration Fire Stoppingwguindy70Оценок пока нет

- Thesis ProposalДокумент19 страницThesis Proposaldharmi subedi75% (4)

- Data Sheet No. 01.12.01 - PR6 - 7 Inductive Pulse ModuleДокумент1 страницаData Sheet No. 01.12.01 - PR6 - 7 Inductive Pulse ModuleThaynar BarbosaОценок пока нет

- The Emom Manual: 25 Kettlebell Conditioning WorkoutsДокумент14 страницThe Emom Manual: 25 Kettlebell Conditioning WorkoutsguilleОценок пока нет

- Mil STD 792fДокумент13 страницMil STD 792fdoradoanОценок пока нет

- Employee Final SettlementДокумент1 страницаEmployee Final SettlementZeeshan Mirza0% (1)

- 7-Multiple RegressionДокумент17 страниц7-Multiple Regressionحاتم سلطانОценок пока нет

- 204-04B - Tire Pressure Monitoring System (TPMS)Документ23 страницы204-04B - Tire Pressure Monitoring System (TPMS)Sofia AltuzarraОценок пока нет

- Eric Koech CV - Docx..bakДокумент7 страницEric Koech CV - Docx..bakPeter Osundwa KitekiОценок пока нет

- NRF Nano EthicsДокумент18 страницNRF Nano Ethicsfelipe de jesus juarez torresОценок пока нет

- Royal British College IncДокумент5 страницRoyal British College IncLester MojadoОценок пока нет

- BQ - Electrical Calibration Relay Bld803, NPBДокумент2 страницыBQ - Electrical Calibration Relay Bld803, NPBKazuya KasumiОценок пока нет

- Fill The Gaps With The Correct WordsДокумент2 страницыFill The Gaps With The Correct WordsAlayza ChangОценок пока нет

- Cadorna, Chesca L. - NCPДокумент2 страницыCadorna, Chesca L. - NCPCadorna Chesca LoboОценок пока нет

- How To Do Banana Milk - Google Search PDFДокумент1 страницаHow To Do Banana Milk - Google Search PDFyeetyourassouttamawayОценок пока нет

- Sop For Enlistment of Engineering ConsultantsДокумент1 страницаSop For Enlistment of Engineering Consultantssatheb319429Оценок пока нет

- List of 100 New English Words and MeaningsДокумент5 страницList of 100 New English Words and MeaningsNenad AngelovskiОценок пока нет

- Study Notes On Isomers and Alkyl HalidesДокумент3 страницыStudy Notes On Isomers and Alkyl HalidesChristian Josef AvelinoОценок пока нет

- Alugbati Plant Pigment Extraction As Natural Watercolor SourceДокумент6 страницAlugbati Plant Pigment Extraction As Natural Watercolor SourceMike Arvin Serrano100% (1)

- Making Creams With Olive M 1000Документ28 страницMaking Creams With Olive M 1000Nicoleta Chiric0% (1)

- 001 RuminatingpacketДокумент12 страниц001 Ruminatingpacketكسلان اكتب اسميОценок пока нет

- Goals in LifeДокумент4 страницыGoals in LifeNessa Layos MorilloОценок пока нет

- REV Description Appr'D CHK'D Prep'D: Tolerances (Unless Otherwise Stated) - (In)Документ2 страницыREV Description Appr'D CHK'D Prep'D: Tolerances (Unless Otherwise Stated) - (In)Bacano CapoeiraОценок пока нет

- Revision Ror The First TermДокумент29 страницRevision Ror The First TermNguyễn MinhОценок пока нет

- Maxillofacial Notes DR - Mahmoud RamadanДокумент83 страницыMaxillofacial Notes DR - Mahmoud Ramadanaziz200775% (4)

- IsoTherming® Hydroprocessing TechnologyДокумент4 страницыIsoTherming® Hydroprocessing Technologyromi moriОценок пока нет