Академический Документы

Профессиональный Документы

Культура Документы

TR Design Book

Загружено:

Mohammed JassimОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

TR Design Book

Загружено:

Mohammed JassimАвторское право:

Доступные форматы

C CO ON NS SI ID DE ER RA AT TI IO ON NS S A AB BO OU UT T T TH HE E D DE ES SI IG GN N O OF F A A

T TE EM MP PO OR RA AR RY Y R RE EF FU UG GE E L LO OC CA AT TE ED D I IN N A A O ON N- -S SH HO OR RE E O OR R

O OF FF F- -S SH HO OR RE E C CO OM MP PL LE EX X I IN N T TH HE E O OI IL L & & G GA AS S S SE EC CT TO OR R

Aertecno International

Engineering Company

via Novara 9 - 21047

Saronno (Va)

tel 029621044

tel 029620847

fax 0296702819

info@aertecno.it

www.aertecno.it

Engineering company

ISO9001 certified

Via Novara, 9 -21047 Saronno Italy

www.aertecno.it info@aertecno.it

Tel. +39 029621044 Fax +39 0296702819

Aertecno is a registred

trademark of Aertecno

Ltd.Co. All rights reserved

Document type

REFERENCES

THE DESIGN OF A

TEMPORARY REFUGE

First issue

MAY/2011

Last revision

TR.DOC

Pag. 1 of 8 Rev.0

0) Introduction

This document purpose is to give a guideline for the correct engineering of a Temporary Refuge related to an

oil and gas complex. This kind of installation can be useful both for on-shore and off-shore field.

We can summarize the main points to be focused in this short list:

1) POB to be mustered inside the TR

2) Definition of the normal operations and emergency condition

3) Duration of the emergency condition

4) TR construction design

5) Vital systems inside the TR

6) HVAC System configuration - Breathing air or Oxygen

7) Sequence of operations during emergency condition

8) Type of accommodation of the POB inside the TR

Abbreviations

AHU Air Handling Unit

ATEX ATmosphres EXplosives

BA Breathing Air

CO

2

Carbon dioxide

EDG Emergency Diesel Generator

FERA Fire and Explosion Risk Analysis

F&G Fire and gas

FMECA Failure Mode Effects Criticality Analysis

HC Hydrocarbon Gas

HVAC Heating, Ventilation and Air Conditioning

HS Hydrogen Sulphide

HSE Health, Safety and Environment

HAZID Hazard Identification Study

HAZOP hazard and operability study

Pa Pascal

POB Personnel on Board

SCBA Self Contained Breathing Apparatus

SIL Safety Integrity Level

TLC Telecommunication system

TR Temporary Refuge

Engineering company

ISO9001 certified

Via Novara, 9 -21047 Saronno Italy

www.aertecno.it info@aertecno.it

Tel. +39 029621044 Fax +39 0296702819

Aertecno is a registred

trademark of Aertecno

Ltd.Co. All rights reserved

Document type

REFERENCES

THE DESIGN OF A

TEMPORARY REFUGE

First issue

MAY/2011

Last revision

--

TR .DOC

Pag. 2 of 8 Rev. 0

1) POB to be mustered inside the TR

The first input data necessary for the sizing of a Temporary Refuge Complex is the number of people to be

accommodated inside. This element is fundamental to size the area of the TR and the space of the other

vital rooms. On the base of the People on board (POB) is possible to calculate the correct amount of fresh

air supplied by the HVAC system and the correct air flow of Breathing Air (BA) or oxygen to supplied during

the emergency condition. Can be useful to note some preliminary values:

For each person inside the TR room shall be assured 30-40m/h of fresh air during the normal operation

mode

For each person inside the TR room shall be assured 40 l/min. of BA during emergency

For each person inside the TR room shall assure an area of 1,5-3 m (included services rooms)

2) Definition of the normal operations and emergency condition

The normal operation mode is considered when no alarms are activated during the operation in the complex.

In this situation the Temporary Refuge there are no occupation by the personnel, and there is a preservation

of the temperature and humidity in order to be ready to accommodate all the POB in Emergency. During the

normal operation mode, only the maintenance crew will be in the TR.

During normal operation mode the HVAC system will be arranged to operate with variable ratio of re-

circulated air, up to 50% of the total air supply in order to have the maximum energy saving .

The Emergency condition is activated in case of accident (release of toxic gases from the wells or

hydrocarbons, jet fires and explosions). In this situation it is necessary to muster the workforce into a

Temporary Safe Refuge capable to protect them from toxic gases, fire and blast.

During Emergency Condition the HVAC System will be arranged to operate recirculating the entire quantity

of air. The new breathing air will be supplied by a bottled air system that will ensure the breathing air

necessary to the POB inside the TR and other vital rooms.

3) Duration of the emergency condition

Typically the duration of the emergency condition can be of 2 or 3 hours, but the maximum is determined by

the storage of the energy and breathing air installable inside the TR complex. In the calculation of the

quantity of energy (electric, thermal, cooling) shall be considered the 100% spare. The same value shall be

applied to vital equipments and/or systems, so we will have 1 component 100% running and 1 component

100% stand-by.

Engineering company

ISO9001 certified

Via Novara, 9 -21047 Saronno Italy

www.aertecno.it info@aertecno.it

Tel. +39 029621044 Fax +39 0296702819

Aertecno is a registred

trademark of Aertecno

Ltd.Co. All rights reserved

Document type

REFERENCES

THE DESIGN OF A

TEMPORARY REFUGE

First issue

MAY/2011

Last revision

--

TR .DOC

Pag. 3 of 8 Rev. 0

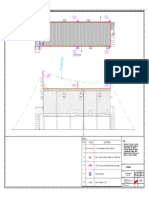

4) TR construction design

The TR complex shall be designed in order to assure:

the gas tightness (in order to prevent ingress of toxic hydrocarbon gas)

the blast resistant from external explosion

the fire protection (shall be provided insulation all along the TR surface, including floors and ceilings,

A60 rated as a minimum and B15 in the internal walls as well).

the IP55 degree of protection

the thermal insulation

minimal hook-up with external services

space and facilities for maintenance and replacement of equipment

safe boarding and evacuation

long design life

operating on a full-time all-year-round basis without service interruptions

The complex construction mode, the typology of structures and partition, the hazardous area classification

and the fire&gas philosophy will be arranged after the FERA analysis. The Fire and Explosion Risk Analysis

(FERA) shall identify the fire and explosion hazards in the operation area and will assess the magnitude of

these hazards. The objective is to provide input to the passive and active fire protection, the blast rating,

buildings and outdoor vital equipment.

Engineering company

ISO9001 certified

Via Novara, 9 -21047 Saronno Italy

www.aertecno.it info@aertecno.it

Tel. +39 029621044 Fax +39 0296702819

Aertecno is a registred

trademark of Aertecno

Ltd.Co. All rights reserved

Document type

REFERENCES

THE DESIGN OF A

TEMPORARY REFUGE

First issue

MAY/2011

Last revision

--

TR .DOC

Pag. 4 of 8 Rev. 0

5) Vital systems inside the TR

Inside the Temporary Refuge complex shall be assure this vital systems:

Electric energy assured by battery storage

TLC-Radio system

Emergency lighting

Drinking water system

HVAC system (to assure an acceptable temperature inside the vital rooms)

Breathing air system

Fire fighting system (Inergen system for the electrical rooms)

Shall be necessary to define the hazardous area classification. Typically all external equipments are ATEX

certified.

All vital systems shall be able to run also under this alarms

Loss of pressurisation.

Both duty plant fail to operate

Intake damper open and F&G signal

Internal H2S levels

Internal CO2 levels

Fire detection

This kind of consideration can be performed only after HSE sessions of:

1st step HAZID

2nd step HAZOP

3rd step SIL

4th step FMECA on vital systems

Engineering company

ISO9001 certified

Via Novara, 9 -21047 Saronno Italy

www.aertecno.it info@aertecno.it

Tel. +39 029621044 Fax +39 0296702819

Aertecno is a registred

trademark of Aertecno

Ltd.Co. All rights reserved

Document type

REFERENCES

THE DESIGN OF A

TEMPORARY REFUGE

First issue

MAY/2011

Last revision

--

TR .DOC

Pag. 5 of 8 Rev. 0

6) HVAC System configuration - Breathing air or Oxygen

During the normal operation mode supply and exhaust fans shall be continuously powered by the emergency

power distribution system in order to maintain a positive pressure (typically 50 Pa minimum), to prevent the

possibility of gas or smoke ingress in the vital areas and to maintain air changes for healthy conditions.

shall be provided smoke, toxic gas and flammable gas detectors at the HVAC air intakes. In the event of

smoke or gas being detected outside the fresh air intake, the fire & gas dampers shall shut and the control

logic system shall automatically switch the HVAC system into re-circulating mode utilising only the existing

air volume.

In this condition shall be started the emergency condition mode.

There are two choices to design the breathing air system inside the TR.

The first choice is to use an oxygen storage to mix the recirculating air of the TR, monitoring the O

2

level and

adopting CO

2

scrubbing system in order to maintain air quality for the TR endurance period.

A chemical air filter shall be provided on the supply air and a polishing type filter shall also be provided on

the return air duct.

To keep the correct pressurization the HVAC system shall incorporate a back-up air pressurisation system

(compressed breathing air). This system shall be designed to prevent ingress of toxic hydrocarbon gas within

the TR and the associated airlocks.

The second choice is to use full recirculating HVAC system (only for temperature control) and a

pressurization with breathing air system composed by a suitable breathing air storage (high pressure air

bottles storage). This system shall be connected with an overpressure system and with the differential

pressure transmitters installed in the TR rooms. During emergency condition the T.R. overpressure system

shall be able to exhaust all the breathing air necessary to assure the personnel's respiration and

contemporarily assuring the correct pressure value inside the rooms considering the leakage rate of

structures, partitions, doors, walls and roof, HVAC penetrations measured during commissioning.

The HVAC intakes and outlets ductworks shall be in accordance with the details below.

All HVAC fresh air intakes to be from a non-hazardous area.

All air intake ducts shall be sized to retain gas concentration for a minimum period of 10 seconds.

The fresh air intake shall be composed by:

Smoke and heat detectors

HC (expressed in terms of CH4 equivalent) and Toxic Gas detectors

Ductwork sized to retain gas for a minimum of 10 seconds

2No Fire and gas dampers (i.e. dampers will close in case of detection of heat and/or smoke, for fire

& gas protection against fire, and in case of detection of flammable gases / toxic gases, for toxic gas

protection expressed in terms of CH4, H2S or SO2

Blast resistant damper

Engineering company

ISO9001 certified

Via Novara, 9 -21047 Saronno Italy

www.aertecno.it info@aertecno.it

Tel. +39 029621044 Fax +39 0296702819

Aertecno is a registred

trademark of Aertecno

Ltd.Co. All rights reserved

Document type

REFERENCES

THE DESIGN OF A

TEMPORARY REFUGE

First issue

MAY/2011

Last revision

--

TR .DOC

Pag. 6 of 8 Rev. 0

Dedicated HVAC system (with dedicated AHU and exhaust fan or overpressure system) shall be provided for

those rooms:

Battery room

TR rooms air lock

Technical rooms or other rooms not running during emergency

Toilets

First aid-hospital

Stores

Emergency Electrical rooms

The Breathing Air System shall be composed by:

breathing air compressors package,

breathing air bottles system package,

pressure reduction groups,

breathing air cascade system,

air lock breathing air pressurization and nozzles washing system,

TR breathing air pressurization system,

SCBA refilling package

All the main BA system and vital equipment shall be arranged such that the total complement shall be 2

x100% (1 package 100% running, 1 package 100% spare in stand-by).

Engineering company

ISO9001 certified

Via Novara, 9 -21047 Saronno Italy

www.aertecno.it info@aertecno.it

Tel. +39 029621044 Fax +39 0296702819

Aertecno is a registred

trademark of Aertecno

Ltd.Co. All rights reserved

Document type

REFERENCES

THE DESIGN OF A

TEMPORARY REFUGE

First issue

MAY/2011

Last revision

--

TR .DOC

Pag. 7 of 8 Rev. 0

7) Sequence of operations during emergency condition

Fire and gas detection system send an alarm

All the personnel run to the muster point near the TR Complex

The TR F&G system run the emergency sequence operation, close the F&G dampers and lock the

external doors

The diesel generators stop and the electric power is supplied by batteries

The HVAC system is switched from fresh air mode to full recirculation mode.

Is activated the compressed air pressurization system and the BA system.

The air lock BA washing system is ready to start

The air lock doors are unlocked for the first mustering sequence

A predetermined number of personnel go inside the air lock (the TR doors are still closed)

Start the BA washing sequence inside the air lock (the air lock doors are now closed)

A toxic gas analyzer verify the absence of gas (if the gas is revealed, start an additional washing

sequence)

The TR rooms doors can be opened.

Start another mustering sequence (during the mustering, people outside the TR complex waiting for

their turn are connected with the outdoor BA Cascade system)

People inside the TR rooms take their sit or their numbered position, waiting for the rescue vehicle or

for the end of the alarm.

In case of TR evacuation (at the end of the 2 or 3 hours of emergency capacity of the TR), will start

the disembarking sequence (through the air lock with only 1 washing sequence).

Engineering company

ISO9001 certified

Via Novara, 9 -21047 Saronno Italy

www.aertecno.it info@aertecno.it

Tel. +39 029621044 Fax +39 0296702819

Aertecno is a registred

trademark of Aertecno

Ltd.Co. All rights reserved

Document type

REFERENCES

THE DESIGN OF A

TEMPORARY REFUGE

First issue

MAY/2011

Last revision

--

TR .DOC

Pag. 8 of 8 Rev. 0

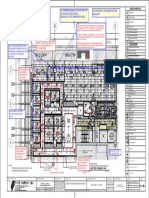

8) Type of accommodations inside the TR

The Temporary Refuge complex shall contain:

Temporary refuge rooms with accommodation facilities

Coffee/tea Room

Radio & Telecommunications Room (with access from the complex safe area)

Electrical Rooms

Battery Rooms

Transformer EDG Room

Airlocks for entrance

Airlock for exit with direct access into escape tunnel

Compressed Breathing Air Cylinder & Water Tank/Pump Room

HVAC room

Inergen Room

Area for external equipments

Control room - Office Area

Workshop and stores

First Aid - hospital

Toilet and washroom facilities

Вам также может понравиться

- Sea Change: Offshore Safety and The Legacy of Piper Alpha: AnalysisДокумент3 страницыSea Change: Offshore Safety and The Legacy of Piper Alpha: Analysiscrackerz83Оценок пока нет

- Summers 2008 Structures Congress Modular Blast Resistant Buildings PaperДокумент7 страницSummers 2008 Structures Congress Modular Blast Resistant Buildings PaperJose Luis Velasco CadavidОценок пока нет

- Feed-Back AMP2-AKOGEP PFP PhilosophyДокумент6 страницFeed-Back AMP2-AKOGEP PFP PhilosophyDubey DeepakОценок пока нет

- AR-A7722-S-40014 Rev. 1Документ5 страницAR-A7722-S-40014 Rev. 1Silvana Del CarpioОценок пока нет

- E House Layout1Документ1 страницаE House Layout1saikatОценок пока нет

- BKO IFC - ArchitecturalДокумент79 страницBKO IFC - ArchitecturalMayar MohamedОценок пока нет

- 1703 C014Документ10 страниц1703 C014Swapnajit KonwarОценок пока нет

- Xvii Paper 40Документ25 страницXvii Paper 40Karina Dewi OktavianiОценок пока нет

- Gexol PDFДокумент36 страницGexol PDFclaudiogut123Оценок пока нет

- LNG UVCE MitigtionДокумент47 страницLNG UVCE MitigtionVăn HoàngОценок пока нет

- 823457063632interactief Shell Moerdijk enДокумент210 страниц823457063632interactief Shell Moerdijk ensushant100% (1)

- HSE Dropped ObjectsДокумент10 страницHSE Dropped Objectsegy pureОценок пока нет

- Vendor Data Book For Helideck Fixed Foam System (ABS Approved)Документ53 страницыVendor Data Book For Helideck Fixed Foam System (ABS Approved)VAN VIET NGOОценок пока нет

- Shop Drawing - 500 GPM at 8 Bar EDJ UL Listed End Suction-For Prasoon-ModelДокумент1 страницаShop Drawing - 500 GPM at 8 Bar EDJ UL Listed End Suction-For Prasoon-ModelSooraj VsОценок пока нет

- GangwaysДокумент1 страницаGangwaysRajadurai SinghОценок пока нет

- PSM 3.2 - Managing Risk (v3)Документ59 страницPSM 3.2 - Managing Risk (v3)Ahmed HamadОценок пока нет

- Hazardous Area MotorsДокумент8 страницHazardous Area MotorsRamanathan AthappaОценок пока нет

- Business Continuity Management in A Dynamic Environment - Lessons From MacondoДокумент8 страницBusiness Continuity Management in A Dynamic Environment - Lessons From MacondoPetroNews100% (1)

- Cedaw Final ReportДокумент140 страницCedaw Final ReportGeorge MaliarisОценок пока нет

- The Importance To Correctly Assess The Flammable Hazards During Design and OperationДокумент25 страницThe Importance To Correctly Assess The Flammable Hazards During Design and OperationMultindo Barra KaryaОценок пока нет

- CCTV PDFДокумент29 страницCCTV PDFIovi DanielОценок пока нет

- NR 15 - Unhealthy Activities and Operations PDFДокумент96 страницNR 15 - Unhealthy Activities and Operations PDFpОценок пока нет

- Piping and Instrumentation Diagram: Fixed Firewater System - Deluge Distribution Upper Deck / Main Deck System 53Документ1 страницаPiping and Instrumentation Diagram: Fixed Firewater System - Deluge Distribution Upper Deck / Main Deck System 53Mohd KhaidirОценок пока нет

- 7J48N-00-15-17-006-1 Emergency Shutdown SystemДокумент49 страниц7J48N-00-15-17-006-1 Emergency Shutdown SystemAhmed FayedОценок пока нет

- Delta Marine Board Mineral WoolДокумент1 страницаDelta Marine Board Mineral WoolMichael HaiseОценок пока нет

- Blast Resistant Equipment CentersДокумент4 страницыBlast Resistant Equipment Centers1mmahoneyОценок пока нет

- General Piping - Process and Utility Field Pressure TestingДокумент20 страницGeneral Piping - Process and Utility Field Pressure TestingJanuar GhifaryОценок пока нет

- Ralf Bruyninckx Case 1 Fire Water NetworkДокумент16 страницRalf Bruyninckx Case 1 Fire Water NetworkBaba JohnehОценок пока нет

- Is Your Temporary Refuge Truly SafeДокумент10 страницIs Your Temporary Refuge Truly Safedutru2003Оценок пока нет

- Geanonimiseerd 6345167 1630584461655 000-JSD-1900-0001 E 13Документ50 страницGeanonimiseerd 6345167 1630584461655 000-JSD-1900-0001 E 13reza abriОценок пока нет

- PEGS-01015-SAF-005 Rev.1-0Документ35 страницPEGS-01015-SAF-005 Rev.1-0Monkey The LuffyОценок пока нет

- Notes: P.T. Badak N.G.L. Bontang L.N.G. PlantДокумент10 страницNotes: P.T. Badak N.G.L. Bontang L.N.G. PlantAdidtya Budhi SaputraОценок пока нет

- Verification of Lifting Appliances For The Oil and Gas IndustryДокумент46 страницVerification of Lifting Appliances For The Oil and Gas IndustryPinco PalloОценок пока нет

- OCP 6-Gas Cutting - Oxy-AcetyleneДокумент1 страницаOCP 6-Gas Cutting - Oxy-AcetyleneFaisal Raza100% (1)

- ASC - LRN - HSE - MGT - LHN - 9110-11 - HEMP-Basics v1.0Документ74 страницыASC - LRN - HSE - MGT - LHN - 9110-11 - HEMP-Basics v1.0modesto66Оценок пока нет

- Nioec SP 47 32 (R1) (Ed2)Документ9 страницNioec SP 47 32 (R1) (Ed2)aminОценок пока нет

- Solberg Ebook 00010 Web PDFДокумент434 страницыSolberg Ebook 00010 Web PDFToretta AdrianОценок пока нет

- DrawingsДокумент19 страницDrawingsbuntysuratОценок пока нет

- Analyser SheltersДокумент1 страницаAnalyser SheltersHARIS AHAMMEDОценок пока нет

- AGT2012-Vessel Blowdown Systems - Assurance Framework For Operate PhaseДокумент17 страницAGT2012-Vessel Blowdown Systems - Assurance Framework For Operate Phasearunperth0% (1)

- Epci Websites (Autorecovered)Документ48 страницEpci Websites (Autorecovered)Shittu Ahmed OlanrewajuОценок пока нет

- Bita GN62 PDFДокумент9 страницBita GN62 PDFAfzaalUmairОценок пока нет

- Kidde Fm-200 Ecs SpecДокумент6 страницKidde Fm-200 Ecs SpecFi NDОценок пока нет

- Buckling Pin Pressure Relief Technology PDFДокумент12 страницBuckling Pin Pressure Relief Technology PDFfkboulosОценок пока нет

- Hazardous Area Classification 1213495418536513 8Документ100 страницHazardous Area Classification 1213495418536513 8lelualluОценок пока нет

- Firepro - Bom With OsmДокумент3 страницыFirepro - Bom With OsmLloydОценок пока нет

- Block 5 Al Shaheen Field Development: GLF-WHP02-EPCI4Документ30 страницBlock 5 Al Shaheen Field Development: GLF-WHP02-EPCI4Hibri HalimОценок пока нет

- GAPS Guidelines: Electrostatic PrecipitatorsДокумент4 страницыGAPS Guidelines: Electrostatic PrecipitatorsAsad KhanОценок пока нет

- Motors For Hazardous Areas en 12 - 2005 Non SparkingДокумент65 страницMotors For Hazardous Areas en 12 - 2005 Non Sparkinglaem269Оценок пока нет

- As 7240.5-2004 Fire Detection and Alarm Systems Point Type Heat Detectors (ISO7240!5!2003 MOD)Документ10 страницAs 7240.5-2004 Fire Detection and Alarm Systems Point Type Heat Detectors (ISO7240!5!2003 MOD)SAI Global - APACОценок пока нет

- Quick Response Area ReductionДокумент5 страницQuick Response Area ReductionNaseer PashaОценок пока нет

- Cable Tray Sizing ProgramДокумент9 страницCable Tray Sizing ProgramMadhuОценок пока нет

- CenpesДокумент20 страницCenpesnskumarmОценок пока нет

- COOP 2021 15 D 3 FF FP 01 - Rev.01Документ16 страницCOOP 2021 15 D 3 FF FP 01 - Rev.01Mohamed ArafaОценок пока нет

- As 2067-1984 Switchgear Assemblies and Ancillary EquipmentДокумент56 страницAs 2067-1984 Switchgear Assemblies and Ancillary EquipmentAnonymous EVFw59Оценок пока нет

- A554 y 730 Se DWG ZF0 300Документ1 страницаA554 y 730 Se DWG ZF0 300hibariОценок пока нет

- Safety Analysis Function Evaluation (S.A.F.E.) Chart: Project Document No. RevisionДокумент19 страницSafety Analysis Function Evaluation (S.A.F.E.) Chart: Project Document No. RevisionCandraОценок пока нет

- Title: FfirkmДокумент15 страницTitle: FfirkmDipti BhanjaОценок пока нет

- HVACДокумент9 страницHVACMailisa FitriaОценок пока нет

- ASHRAE 4clean RoomДокумент451 страницаASHRAE 4clean Roomtanbqtb03100% (1)

- My Daily Adhkaar (Kids)Документ58 страницMy Daily Adhkaar (Kids)Mohammed Jassim100% (2)

- MCTДокумент4 страницыMCTmoosuhaibОценок пока нет

- NOFIRNO Pipe Catalog Marine March 2010 PDFДокумент36 страницNOFIRNO Pipe Catalog Marine March 2010 PDFMohammed JassimОценок пока нет

- Blue Guide 2016 EngДокумент145 страницBlue Guide 2016 Engmax_ingОценок пока нет

- Fire and Gas Safety Systems For Oil and Gas Applications: Gulf Fire Gulf FireДокумент2 страницыFire and Gas Safety Systems For Oil and Gas Applications: Gulf Fire Gulf FireMohammed Jassim100% (1)

- Suction PumpДокумент33 страницыSuction PumpMohammed JassimОценок пока нет

- PMP Exam Content OutlineДокумент19 страницPMP Exam Content OutlineBoneyPhilipОценок пока нет

- Testing Regime For Offshore TR-HVAC Fire Dampers & TR Pressurisation RquirementsДокумент6 страницTesting Regime For Offshore TR-HVAC Fire Dampers & TR Pressurisation Rquirementsmartin_stone_1Оценок пока нет

- Produktdatenblatt Tefrotex 500Документ1 страницаProduktdatenblatt Tefrotex 500Mohammed JassimОценок пока нет

- Tank Fabrication SpecsДокумент21 страницаTank Fabrication Specsjlcheefei9258100% (1)

- Tank Vessel HandbookДокумент76 страницTank Vessel HandbooklsgmzОценок пока нет

- Construction Estimating Using Excel 2nd Edition .PDДокумент53 страницыConstruction Estimating Using Excel 2nd Edition .PDMohammed Jassim100% (1)

- Produktdatenblatt Tefrotex 700Документ1 страницаProduktdatenblatt Tefrotex 700Mohammed JassimОценок пока нет

- 7f154160665ca8f29db6fb0a592a4b11Документ114 страниц7f154160665ca8f29db6fb0a592a4b11Mohammed JassimОценок пока нет

- Corrosion Rate CalculationДокумент4 страницыCorrosion Rate CalculationMohammed JassimОценок пока нет

- Project Management Professional HandbookДокумент41 страницаProject Management Professional HandbookbeneaththesoundОценок пока нет

- ABS Rules For Cable SizingДокумент2 страницыABS Rules For Cable SizingMohammed JassimОценок пока нет

- Laboratory Ventilation and Fume Hood DesignДокумент51 страницаLaboratory Ventilation and Fume Hood DesignashifОценок пока нет

- TR Design BookДокумент9 страницTR Design BookMohammed JassimОценок пока нет

- Zone and ATEX PDFДокумент17 страницZone and ATEX PDFMohammed JassimОценок пока нет

- Restaurants - Guide - Improve Indoor Air QualityДокумент4 страницыRestaurants - Guide - Improve Indoor Air QualityCks RamanОценок пока нет

- Durastic Product SelectorДокумент1 страницаDurastic Product SelectorMohammed JassimОценок пока нет

- Directions To Unknown Road 4.5 KM - About 5 MinsДокумент3 страницыDirections To Unknown Road 4.5 KM - About 5 MinsMohammed JassimОценок пока нет

- HVAC noise722201320446PM1 PDFДокумент90 страницHVAC noise722201320446PM1 PDFMohammed Jassim100% (2)

- Duro DyneДокумент2 страницыDuro DyneMohammed JassimОценок пока нет

- Cat 3516B-2250 enДокумент1 страницаCat 3516B-2250 enMohammed JassimОценок пока нет

- 3516B+2500+kVA+Standby+HD+HV+LowEmiss EMCP4Документ6 страниц3516B+2500+kVA+Standby+HD+HV+LowEmiss EMCP4Mohammed JassimОценок пока нет

- Heat Load Calculation Manual PDFДокумент223 страницыHeat Load Calculation Manual PDFMohammed Jassim100% (2)

- Total Spells For Fate CoreДокумент4 страницыTotal Spells For Fate CoreJosh SalyersОценок пока нет

- Job Safety Analysis Risk Assess Restricted Spaces v1 290311Документ9 страницJob Safety Analysis Risk Assess Restricted Spaces v1 290311Anto MaryadiОценок пока нет

- PT Lestari Banten Energi: Ship and Port Safety & Security ChecklistДокумент2 страницыPT Lestari Banten Energi: Ship and Port Safety & Security ChecklistmandortajirОценок пока нет

- SAFETYWARE Catalogs BodyProtection InteretsingДокумент19 страницSAFETYWARE Catalogs BodyProtection InteretsingsaniawaqarОценок пока нет

- Ventura County Grand Jury Report: Firefighting Air Assets: The Camarillo Springs FireДокумент16 страницVentura County Grand Jury Report: Firefighting Air Assets: The Camarillo Springs FireTheFillmoreGazetteОценок пока нет

- Soal Bahasa Inggris Dan Kunci Jawaban Kelas XIДокумент9 страницSoal Bahasa Inggris Dan Kunci Jawaban Kelas XIAab AL-WahhaabОценок пока нет

- Presentasi Kelompok 3 Bahasa Inggris News Item TextДокумент12 страницPresentasi Kelompok 3 Bahasa Inggris News Item TextAS ART70% (10)

- Revise This MemoДокумент2 страницыRevise This MemoAlvin RymashОценок пока нет

- MIG Welding Training NotesДокумент11 страницMIG Welding Training NotesJrich19Оценок пока нет

- Inbound 1893109920938229305Документ15 страницInbound 1893109920938229305DESIREE BUENAAGUAОценок пока нет

- Moon Druid Spell ListДокумент1 страницаMoon Druid Spell Listscreechingbint4118Оценок пока нет

- MauiДокумент11 страницMauiErrepe0% (1)

- Balaraman Ashvin EES Media Report Depth Study 2020 2 PresentationДокумент12 страницBalaraman Ashvin EES Media Report Depth Study 2020 2 Presentationashvinbalaraman0Оценок пока нет

- CFPA E Guideline No 26 2010 FДокумент30 страницCFPA E Guideline No 26 2010 Fdvs99Оценок пока нет

- Divine Word College of Calapan: Criminology DepartmentДокумент12 страницDivine Word College of Calapan: Criminology DepartmentJovie Masongsong100% (1)

- C02 Fire Suppression System For Marine ApplicationsДокумент4 страницыC02 Fire Suppression System For Marine Applicationschris_ohaboОценок пока нет

- Question Bank-Ee 1006 - Electric Safety and QualityДокумент4 страницыQuestion Bank-Ee 1006 - Electric Safety and Qualitykarthikeyan50% (2)

- Tremendous Trifles: The Perfect GameДокумент2 страницыTremendous Trifles: The Perfect GameGeorge BalanОценок пока нет

- Norse Mythology 2Документ17 страницNorse Mythology 2AtraОценок пока нет

- Eurasian Dream JudgementДокумент11 страницEurasian Dream JudgementRaghu100% (2)

- Nullifire BrochureДокумент4 страницыNullifire BrochureScott O'ReillyОценок пока нет

- CSIRO ActivFire® Certification Is Costing LivesДокумент19 страницCSIRO ActivFire® Certification Is Costing LivesThe World Fire Safety FoundationОценок пока нет

- The Lesson of The Titanic, Article, 1912Документ6 страницThe Lesson of The Titanic, Article, 1912TitanicwareОценок пока нет

- 02 Fire Alarm Systems (Where Required) - HotelДокумент42 страницы02 Fire Alarm Systems (Where Required) - HotelMAKANОценок пока нет

- Disaster PreparednessДокумент43 страницыDisaster PreparednessskyeОценок пока нет

- Nature of Shipboard HazardsДокумент8 страницNature of Shipboard HazardshutsonianpОценок пока нет

- Doe STD 1066Документ84 страницыDoe STD 1066avanish.vОценок пока нет

- Fire Quiz QuestionsДокумент22 страницыFire Quiz Questionssauravsinhaa50% (2)

- Mezzanine Level - Reflected Ceiling PlanДокумент1 страницаMezzanine Level - Reflected Ceiling PlanGally LagrataОценок пока нет

- Above Ground Storage TankДокумент6 страницAbove Ground Storage TankBasil OguakaОценок пока нет